Beruflich Dokumente

Kultur Dokumente

BS 3958-1 PDF

Hochgeladen von

Anitha MjOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BS 3958-1 PDF

Hochgeladen von

Anitha MjCopyright:

Verfügbare Formate

BS 3958-1:

1982

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BRITISH STANDARD

CONFIRMED

DECEMBER 2007

Specification for

Thermal insulation

materials

Part 1: Magnesia preformed insulation

UDC 662.998:666.96:661.846.22

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BS 3958-1:1982

Cooperating organizations

The Refrigeration, Heating and Air Conditioning Standards Committee, under

whose direction this British Standard was prepared, consists of

representatives from the following:

Association of Manufacturers of Domestic

Electrical Appliances

Association of Consulting Engineers

Boiler and Radiator Manufacturers

Association Limited

British Combustion Equipment

Manufacturers Association

British Gas Corporation*

British Refrigeration and Air Conditioning

Association*

Building Services Research and Information

Association

Chartered Institution of Building Services*

Department of Energy (Energy Technology)

Department of Health and Social Security*

Department of the Environment (PSA)

Electricity Supply Industry in England and

Wales*

Heating and Ventilating Contractors

Association

Hevac Association

Institute of Energy

Institute of Refrigeration*

Institution of Gas Engineers*

Lloyds Register of Shipping

Manufacturers Association of Radiators and

Convectors Limited

Ministry of Defence

National Coal Board

Society of British Gas Industries

Water-tube Boilermakers Association*

The organizations marked with an asterisk in the above list, together with the

following, were directly represented on the Technical Committee entrusted

with the preparation of this British Standard:

This British Standard, having

been prepared under the

direction of the Refrigeration,

Heating and Air Conditioning

Standards Committee, was

published under the authority

of the Board of BSI and comes

into effect on

31 August 1982

BSI 03-1999

First published December 1965

First revision February 1970

Second revision August 1982

The following BSI references

relate to the work on this

standard:

Committee reference RHE/9

Draft for comment 80/76973 DC

ISBN 0 580 12597 1

Albury Laboratories Limited

Asbestos Cement Manufacturers

Association Limited

British Ceramic Research Association

British Rubber Manufacturers Association

Combustion Engineering Association

Cranfield Institute of Technology

Department of Industry (National Physical

Laboratory)

Department of the Environment (Building

Research Establishment)

Department of the Environment (Housing

and Construction)

Energy Industries Council

Engineering Equipment Users Association

EPS Association

Eurisol (UK) Association of Manufacturers of

Mineral Fibre Insulation

Fibre Building Board Development

Organization Limited

Gypsum Products Development Association

Institution of Mechanical Engineers

Process Plant Association

Royal Institute of British Architects

Structural Insulation Association

Thermal Insulation Manufacturers and

Suppliers Association (TIMSA)

Thermal Insulations Contractors

Association

Yarsley Testing Laboratories Limited

Coopted member

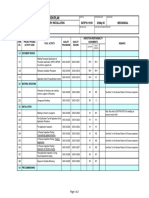

Amendments issued since publication

Amd. No.

Date of issue

Comments

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BS 3958-1:1982

Contents

Cooperating organizations

Foreword

1 Scope

2 References

3 Definitions

4 Sampling and testing

5 Composition

6 Moisture content

7 Physical requirements

8 Chemical requirements

9 Identification of asbestos-free material

10 Standard shapes and sizes

11 Dimensional tolerances

12 Marking

Appendix A Methods of test for alkalinity and composition

Table 1 Thermal conductivity values

Publications referred to

BSI 03-1999

Page

Inside front cover

ii

1

1

1

1

1

1

1

1

2

2

2

2

3

1

Inside back cover

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BS 3958-1:1982

Foreword

This revision of this Part of this British Standard is one of a series published

under the direction of the Refrigeration, Heating and Air Conditioning Standards

Committee to specify requirements for a particular range of insulating materials.

It supersedes the 1970 edition which is withdrawn.

Other Parts of this standard are:

Part 2: Calcium silicate preformed insulation;

Part 3: Metal mesh faced mineral wool mats and mattresses;

Part 41): Bonded preformed man-made mineral fibre pipe sections;

Part 5: Bonded mineral wool slabs (for use at temperatures above 50 C);

Part 6: Finishing materials; hard setting composition, self-setting cement

and gypsum plaster.

A British Standard does not purport to include all the necessary provisions of a

contract. Users of British Standards are responsible for their correct application.

Compliance with a British Standard does not of itself confer immunity

from legal obligations.

Summary of pages

This document comprises a front cover, an inside front cover, pages i and ii,

pages 1 to 4, an inside back cover and a back cover.

This standard has been updated (see copyright date) and may have had

amendments incorporated. This will be indicated in the amendment table on

the inside front cover.

1) In

ii

course of revision.

BSI 03-1999

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BS 3958-1:1982

1 Scope

This Part of this British Standard specifies

composition, moisture content, physical and

chemical requirements for magnesia preformed

insulation slabs, lags and pipe sections, generally

for use up to about 315 C.

NOTE BS 874 requires the test report to state which method of

test was employed, the bulk density of the material, the hot face

temperature and cold face temperature (generally within the

range 15 C to 30 C), the conditioning procedure and the

moisture content before and after the test.

Sampling and testing shall be in accordance with

the appropriate clause in BS 2972 unless otherwise

stated in this standard. For thermal conductivity

determinations a flat slab shall be used for the tests.

7.3 Bulk density. The bulk density of the dry

material shall lie within the range 175 kg/m3

to 225 kg/m3.

7.4 Flexural strength. The flexural strength shall

be not less than 250 kN/m2.

7.5 Compressive strength. The reduction in

thickness shall not exceed 5 % under a compressive

load of 350 kN/m2.

7.6 Heat stability. When tested in accordance with

BS 2972 under conditions of soaking heat at

increasing temperatures the material shall be

deemed suitable for normal use at operating

temperatures at which the following requirements

are met:

a) linear shrinkage 2 % maximum;

b) reduction in thickness not exceeding 5 % under

a compressive load of 200 kN/m2.

5 Composition

8 Chemical requirements

2 References

The titles of the standards publications referred to

in this standard are listed on the inside back cover.

3 Definitions

For the purposes of this Part of this

British Standard, the definitions given in BS 874,

BS 2972, BS 3533, BS 5422 and BS 5970 apply.

4 Sampling and testing

The material shall consist of a mixture of not less

than 85 % by mass of light basic magnesium

carbonate with well-opened reinforcing fibres

evenly distributed (see 8.2, note 2).

6 Moisture content

When tested in accordance with 40.1 of

BS 2972:1975 the moisture content of the material

as received shall not exceed 5 % by mass.

7 Physical requirements

7.1 General. In the application of the physical

requirements of 7.3 to 7.6, 95 % confidence limits

shall apply.

7.2 Thermal conductivity. When tested in

accordance with the appropriate method of test for

thermal conductivity given in BS 874, the thermal

conductivity shall not exceed the values given in

Table 1.

Table 1 Thermal conductivity values

Mean temperature

Thermal conductivity

W/(m K)

50

0.059

100

0.064

150

0.070

180

0.074

BSI 03-1999

8.1 Alkalinity. When tested by the method

described in Appendix A the pH value recorded shall

be between 9.5 and 11.0.

8.2 Corrosive attack. The material shall not

include significant quantities of substances that will

promote corrosive attack on the surfaces with which

it is to be in contact. Where necessary, trace

quantities of water-soluble chlorides shall be

estimated in accordance with section 22 of

BS 2972:1975.

NOTE 1 Water-soluble chlorides are normally present in trace

quantities in magnesia preformed insulation as in most thermal

insulating materials. In the presence of moisture and oxygen,

and under certain adverse metallurgical conditions, chloride ions

are capable of initiating stress corrosion cracking in susceptible

metal alloys such as austenitic stainless steels.

It is not practicable to indicate a safe upper limit for chloride

content since water can leach out soluble chlorides from

substantial volumes of insulating materials and allow them to be

concentrated at the metal-insulation interface. In addition, water

from outside sources such as the process itself or wind-driven

spray can substantially increase the chloride content of the

insulation.

In conditions potentially conducive to stress corrosion cracking,

appropriate safeguards should be adopted (see BS 5970).

NOTE 2 Some organic matter may be present either in fibrous

form or as a bonding agent. It is suggested that the composition

of the product be checked with the manufacturer for use in

process conditions where organics may present a hazard,

e.g. processes involving powerful oxidizing agents, or thermal

insulation on pipework and plant in a flammable atmosphere.

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BS 3958-1:1982

9 Identification of asbestos-free

material

9.1 In order to identify those materials that are not

subject to control by Government regulations,

(see note), asbestos-free magnesia preformed

insulation, manufactured in accordance with Part 1

of this standard, shall be distinctively coloured

pink/red. The colouring matter shall remain

sufficiently stable and permanent under service

conditions to permit the ready identification of the

outer surface of the insulation.

NOTE Government regulations2) concerning

asbestos-containing insulation require that special precautions

be observed in order to safeguard the health of individuals who

are handling these materials or who are working in the vicinity.

9.2 Materials which contain asbestos fibre shall not

be other than self-coloured.

10 Standard shapes and sizes

10.1 Preformed magnesia shall be supplied in the

form of flat slabs, bevelled lags, pipe sections or

radiused and bevelled lags complying with the

following.

NOTE Not all suppliers provide the full range of standard

shapes and sizes listed in a) to d). Conversely other shapes and

sizes may be available. Suppliers literature should be consulted

for details of the range offered.

a) Flat slabs

Length: 914 mm

Width: 150 mm to 305 mm

Thickness: 25 mm to 100 mm.

b) Pipe sections

Length: 914 mm

Diameter: to fit standard pipes of external

diameter up to 329 mm

Wall thickness: 25 mm to 75 mm.

c) Bevelled lags

Length: 914 mm

Major width: 75 mm to 150 mm

Thickness: 25 mm to 100 mm.

d) Radiused and bevelled lags

Length: 914 mm

Width of outer curved surface:

approximately 140 mm to 170 mm depending on

radius of curvature, thickness and number of

lags to fit circumference.

10.2 Flat slabs shall be free from warp. Mating faces

shall be plane and edges shall be square to the

surfaces and to one another.

10.3 Pipe sections and lags shall be concentric and

free from warp. Mating faces shall be plane and

ends shall correspond with a plane at right angles to

the long axis.

10.4 Bevelled edges of radiused and bevelled lags

shall correspond with the radii of the curved surface

to be insulated.

11 Dimensional tolerances

The insulation shapes shall be in accordance with

the dimensions stated by the manufacturer (or

supplier, as appropriate), subject to the following

tolerances.

a) Slabs and lags

Length and width: 3 mm

Thickness: 1.5 mm, + 3 mm.

b) Pipe sections

Length: 3 mm

Inside diameter: 0, + 5 mm

Thickness (average): 1.5 mm, + 3 mm

Uniformity: the local thickness at any point shall

not vary from the average thickness by more

than 3 mm.

12 Marking

Each package shall be indelibly marked with the

following:

a) the manufacturers name, mark or symbol;

b) the manufacturers type designation and

maximum service temperature limit: if the

material contains asbestos, this shall be clearly

indicated;

c) the nominal dimensions;

d) the number of this British Standard,

i.e. BS 3958/13).

2) Statutory Instruments 1969, No. 690, Factories, The Asbestos

3) Marking BS 3958/1 on or in relation to a product is a claim by

Regulations 1969.

the manufacturer that the product has been manufactured in

accordance with the requirements of the standard. The accuracy of such a claim is therefore solely the manufacturers

responsibility. Enquiries as to the availability of third party certification to support such claims should be addressed to the

Director, Quality Assurance Division, British Standards Institution, Maylands Avenue, Hemel Hempstead, Herts HP2 4SQ in

the case of certification marks administered by BSI or to the appropriate authority for other certification marks.

BSI 03-1999

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BS 3958-1:1982

Appendix A Methods of test for

alkalinity and composition

A.1 Preparation of sample. From the bulk

sample, taken in accordance with BS 2972, cut five

pieces, each of approximate mass 7 g, from separate

units. Crush these pieces and mix thoroughly.

A.2 Determination of pH. Weigh 2 g of the

crushed sample and shake well for 10 min

with 100 mL of distilled water at room temperature.

Leave to settle for 5 min and measure the pH of the

mixture, using a standard pH meter

(see BS 1647 and BS 3145) and decanting the

solution if necessary. Repeat the test on a

further 2 g of the sample and report the mean pH

value.

A.3 Check on composition

A.3.1 General. If it is considered desirable to

determine fibre or magnesia contents, the following

methods are suitable.

4)

A.3.2 Fibre content. Dry and weigh up to 30 g of the

remainder of the crushed sample, transfer to a

beaker, add 200 mL of distilled water and 30 mL of

glacial acetic acid. Boil gently for 10 min, filter by

suction through a Buchner funnel and wash with

distilled water. Dry the residue to constant mass

at 105 C to 110 C.

Mass of fibre in sample (in %)

mass of residue

= ------------------------------------------- 100.

mass of sample

A.3.3 Magnesium oxide content. Transfer the

filtrate and washings from A.3.2 to a calibrated 2 L

flask and dilute to the mark. Mix well and withdraw

suitable aliquots for the determination of magnesia

by titration with diaminoethane-tetra-acetic acid

(EDTA)4). Calculate as a percentage by mass of the

weighed sample.

A method for the determination of magnesia, using EDTA, is given in BS 1902-2A.

BSI 03-1999

blank

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BS 3958-1:1982

Publications referred to

BS 874, Methods for determining thermal insulating properties, with definitions of thermal insulating

terms.

BS 1647, pH scale.

BS 1902, Methods of testing refractory materials.

BS 1902-2A, Chemical analysis of high silica and aluminosilicate materials.

BS 2972, Methods of test for inorganic thermal insulating materials.

BS 3145, Specification for laboratory pH meters.

BS 3533, Glossary of terms relating to thermal insulation.

BS 5422, Specification for the use of thermal insulating materials.

BS 5970, Code of practice for thermal insulation of pipework and equipment.

BS 3958, Specification for thermal insulation materials5).

BS 3958-2, Calcium silicate preformed insulation.

BS 3958-3, Metal mesh faced mineral wool mats and mattresses.

BS 3958-4, Bonded preformed man-made mineral fibre pipe sections6).

BS 3958-5, Bonded mineral wool slabs (for use at temperatures above 50 C).

BS 3958-6, Finishing materials; hard setting composition, self-setting cement and gypsum plaster.

5) Referred

6) In

to in the foreword only.

course of revision

BSI 03-1999

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BSI

389 Chiswick High Road

London

W4 4AL

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BSI British Standards Institution

BSI is the independent national body responsible for preparing British Standards. It

presents the UK view on standards in Europe and at the international level. It is

incorporated by Royal Charter.

Revisions

British Standards are updated by amendment or revision. Users of British Standards

should make sure that they possess the latest amendments or editions.

It is the constant aim of BSI to improve the quality of our products and services. We

would be grateful if anyone finding an inaccuracy or ambiguity while using this

British Standard would inform the Secretary of the technical committee responsible,

the identity of which can be found on the inside front cover. Tel: 020 8996 9000.

Fax: 020 8996 7400.

BSI offers members an individual updating service called PLUS which ensures that

subscribers automatically receive the latest editions of standards.

Buying standards

Orders for all BSI, international and foreign standards publications should be

addressed to Customer Services. Tel: 020 8996 9001. Fax: 020 8996 7001.

In response to orders for international standards, it is BSI policy to supply the BSI

implementation of those that have been published as British Standards, unless

otherwise requested.

Information on standards

BSI provides a wide range of information on national, European and international

standards through its Library and its Technical Help to Exporters Service. Various

BSI electronic information services are also available which give details on all its

products and services. Contact the Information Centre. Tel: 020 8996 7111.

Fax: 020 8996 7048.

Subscribing members of BSI are kept up to date with standards developments and

receive substantial discounts on the purchase price of standards. For details of

these and other benefits contact Membership Administration. Tel: 020 8996 7002.

Fax: 020 8996 7001.

Copyright

Copyright subsists in all BSI publications. BSI also holds the copyright, in the UK, of

the publications of the international standardization bodies. Except as permitted

under the Copyright, Designs and Patents Act 1988 no extract may be reproduced,

stored in a retrieval system or transmitted in any form or by any means electronic,

photocopying, recording or otherwise without prior written permission from BSI.

This does not preclude the free use, in the course of implementing the standard, of

necessary details such as symbols, and size, type or grade designations. If these

details are to be used for any other purpose than implementation then the prior

written permission of BSI must be obtained.

If permission is granted, the terms may include royalty payments or a licensing

agreement. Details and advice can be obtained from the Copyright Manager.

Tel: 020 8996 7070.

Das könnte Ihnen auch gefallen

- BS 85500 2015 PDFDokument38 SeitenBS 85500 2015 PDFmastergeo35Noch keine Bewertungen

- Pas 00024-2012Dokument92 SeitenPas 00024-2012Emre ÖzaydınNoch keine Bewertungen

- BS PDFDokument61 SeitenBS PDFprobirNoch keine Bewertungen

- BS 750Dokument30 SeitenBS 750Jabnon Nonjab100% (1)

- Product Sheet - Parsys Cloud - Parsys TelemedicineDokument10 SeitenProduct Sheet - Parsys Cloud - Parsys TelemedicineChristian Lezama Cuellar100% (1)

- Astm C656Dokument3 SeitenAstm C656alokjha_03Noch keine Bewertungen

- Astm C 1290 - Fibrous Glass Balnket For DuctsDokument4 SeitenAstm C 1290 - Fibrous Glass Balnket For DuctsleandroschroederNoch keine Bewertungen

- BS en Iso 1182 2010Dokument42 SeitenBS en Iso 1182 2010Yeung davidNoch keine Bewertungen

- BS 6375-1-2015 - (2015-05-18 - 09-55-44 PM)Dokument26 SeitenBS 6375-1-2015 - (2015-05-18 - 09-55-44 PM)MarcinNoch keine Bewertungen

- Chartek 7 8+1709 Application Manual Rev0 010507Dokument200 SeitenChartek 7 8+1709 Application Manual Rev0 010507Florin Balan100% (5)

- Astm C1029Dokument4 SeitenAstm C1029Nacer Kisy100% (2)

- Qatar National Construction Standards 2010 - Table of ContentsDokument8 SeitenQatar National Construction Standards 2010 - Table of Contentsarifsarwo100% (1)

- Karumel Ex4412: KCC CorporationDokument4 SeitenKarumel Ex4412: KCC CorporationABAID ULLAHNoch keine Bewertungen

- BS 3958-2 1982 (E)Dokument8 SeitenBS 3958-2 1982 (E)Danny BiermansNoch keine Bewertungen

- BS 6464 1984 Reinforced Plastics Pipes Fittings and Joints For Process Plants PDFDokument60 SeitenBS 6464 1984 Reinforced Plastics Pipes Fittings and Joints For Process Plants PDFDavid FonsecaNoch keine Bewertungen

- BS 5422 PDFDokument82 SeitenBS 5422 PDFAnitha Mj75% (4)

- Pressure - Temperature Ratings of Plain End Seamless Chromium - Molybdenum Alloy Steel Pipe To ASTM A335 Grade P11 (1 % Chromium - % Molybdenum)Dokument2 SeitenPressure - Temperature Ratings of Plain End Seamless Chromium - Molybdenum Alloy Steel Pipe To ASTM A335 Grade P11 (1 % Chromium - % Molybdenum)Anitha MjNoch keine Bewertungen

- Dabacon Error Codes in PDMSDokument7 SeitenDabacon Error Codes in PDMSAnitha MjNoch keine Bewertungen

- Ainsworth, The One-Year-Old Task of The Strange SituationDokument20 SeitenAinsworth, The One-Year-Old Task of The Strange SituationliliaNoch keine Bewertungen

- BS 3958-4 PDFDokument10 SeitenBS 3958-4 PDFAnitha MjNoch keine Bewertungen

- BS 3958-2 PDFDokument10 SeitenBS 3958-2 PDFAnitha MjNoch keine Bewertungen

- BS 3958 4 PDFDokument10 SeitenBS 3958 4 PDFramy abazaNoch keine Bewertungen

- Monokote Mk6 - Hy TdsDokument2 SeitenMonokote Mk6 - Hy TdsEngTamerNoch keine Bewertungen

- SCE FireProtectionEngineeringInstructionManualDokument33 SeitenSCE FireProtectionEngineeringInstructionManualstmNoch keine Bewertungen

- Mandolite 550 DSDokument4 SeitenMandolite 550 DSnrd9771Noch keine Bewertungen

- Passive Fire Protection Getting It Right Wilf Butcher PDFDokument44 SeitenPassive Fire Protection Getting It Right Wilf Butcher PDFSonny Ramos100% (1)

- BS 476-7-1971 - Fire Tests On Building Materials & Structures - Part 7 - Surface Spread of Flame Tests For MaterialsDokument18 SeitenBS 476-7-1971 - Fire Tests On Building Materials & Structures - Part 7 - Surface Spread of Flame Tests For MaterialsBiplabNoch keine Bewertungen

- Ul 1709 (2022)Dokument34 SeitenUl 1709 (2022)gaso99100% (1)

- ACP Standards Saudi ArabiaDokument29 SeitenACP Standards Saudi ArabiaRoland James Arimado50% (2)

- BYBU - XR701 Fire Resistance Ratings - ANSI/UL 1709Dokument2 SeitenBYBU - XR701 Fire Resistance Ratings - ANSI/UL 1709FPA InspectorNoch keine Bewertungen

- LPS 1048 Requirements For The Approval of Sprinkler System Contractors in The UK and IrelandDokument29 SeitenLPS 1048 Requirements For The Approval of Sprinkler System Contractors in The UK and IrelandMohammad NaghizadehNoch keine Bewertungen

- BS 476-11 1982 - Fire Test On Building Materials and Structures (Part 11-Method For Assessing The Heat Emission From Building Materials) PDFDokument23 SeitenBS 476-11 1982 - Fire Test On Building Materials and Structures (Part 11-Method For Assessing The Heat Emission From Building Materials) PDFMegat AlexanderNoch keine Bewertungen

- BS en 13598 1 2020Dokument36 SeitenBS en 13598 1 2020Mohammad SheaitoNoch keine Bewertungen

- Hot Dip Galvanized (ISO 9223)Dokument2 SeitenHot Dip Galvanized (ISO 9223)Miguel QueirosNoch keine Bewertungen

- ASTM C168-97 Standard Terminology Relating To Thermal InsulationDokument6 SeitenASTM C168-97 Standard Terminology Relating To Thermal Insulationdodi ikhsan100% (1)

- BS 476 31.1 PDFDokument14 SeitenBS 476 31.1 PDFAlexander AlexanderNoch keine Bewertungen

- ASPE05 - An Industry Guide To Design For Installation of Fire & Smoke Resisting Dampers (Grey Book)Dokument27 SeitenASPE05 - An Industry Guide To Design For Installation of Fire & Smoke Resisting Dampers (Grey Book)Basil OguakaNoch keine Bewertungen

- 7.3 Calculation of PFP ThicknessDokument10 Seiten7.3 Calculation of PFP ThicknessFrancisco Javier Martinez Burgo100% (3)

- Steel Fire Doors 20071204142930 I.french PDFDokument12 SeitenSteel Fire Doors 20071204142930 I.french PDFZoltán BoérNoch keine Bewertungen

- BS 476-23-1987Dokument24 SeitenBS 476-23-1987Hadi Iz'aanNoch keine Bewertungen

- BYBU - XR711 - Fire-Resistance Ratings - ANSI - UL 1709 - UL Product Iq AVI 2020 PDFDokument3 SeitenBYBU - XR711 - Fire-Resistance Ratings - ANSI - UL 1709 - UL Product Iq AVI 2020 PDFCIAKNoch keine Bewertungen

- Colour Standards SansDokument8 SeitenColour Standards Sanskeagan_xtcNoch keine Bewertungen

- 1 SATIP-N-110-01 Castable Refractory InstallationDokument2 Seiten1 SATIP-N-110-01 Castable Refractory Installationsonalisabir100% (1)

- BS 476-23 1987Dokument25 SeitenBS 476-23 1987deepakc598Noch keine Bewertungen

- BS en 10088-4-2009Dokument48 SeitenBS en 10088-4-2009khanhNoch keine Bewertungen

- Cemtec A1 Black PUDokument2 SeitenCemtec A1 Black PUPageduesca RouelNoch keine Bewertungen

- Promat PFPH Chapter 1 Introduction PDFDokument16 SeitenPromat PFPH Chapter 1 Introduction PDFHeba S. Al-saudiNoch keine Bewertungen

- Methods of Fire Protection of Steel StructuresDokument10 SeitenMethods of Fire Protection of Steel StructuresArbaz AhmedNoch keine Bewertungen

- IEC 60332-3-22 Test On Electrical Cables Under Fire ConditionDokument30 SeitenIEC 60332-3-22 Test On Electrical Cables Under Fire ConditionNguyễn Nhật ÁnhNoch keine Bewertungen

- HILTI Firestop and Fire Protection SystemsDokument9 SeitenHILTI Firestop and Fire Protection Systemsfrikkie@100% (1)

- BS 476-4 (1970) - Fire Tests On Building Materials and Structures PDFDokument12 SeitenBS 476-4 (1970) - Fire Tests On Building Materials and Structures PDFdoubleNoch keine Bewertungen

- UL1709 ScopeDokument2 SeitenUL1709 ScopeSaravanan PanduranganNoch keine Bewertungen

- Chartek 1709 SDSDokument2 SeitenChartek 1709 SDSJOHN100% (1)

- NFCA2016InspectionTrainingProgramLinktowebsite032116WM PDFDokument184 SeitenNFCA2016InspectionTrainingProgramLinktowebsite032116WM PDFZaid Raslan AyoubNoch keine Bewertungen

- 11654Dokument8 Seiten11654Wildo-aprizaNoch keine Bewertungen

- BS en 12502-3Dokument18 SeitenBS en 12502-3laboratorium logamNoch keine Bewertungen

- Chilled Water Ceiling Cassette Fan Coil UnitDokument6 SeitenChilled Water Ceiling Cassette Fan Coil UnitZhen Sin0% (1)

- BS 443Dokument15 SeitenBS 443bdiitNoch keine Bewertungen

- BS 1521Dokument11 SeitenBS 1521Shameel PtNoch keine Bewertungen

- BS 6622-2007Dokument60 SeitenBS 6622-2007oadipphone7031100% (7)

- BS1747-1 :1969Dokument14 SeitenBS1747-1 :1969Jessica FarrugiaNoch keine Bewertungen

- Data Sheet - Product Selection and Specification - Ducting Equip and Acoustical InsulationDokument13 SeitenData Sheet - Product Selection and Specification - Ducting Equip and Acoustical InsulationDaniella FergussonNoch keine Bewertungen

- BS 5835-1-1980 PDFDokument21 SeitenBS 5835-1-1980 PDFMohammad Twaha JaumbocusNoch keine Bewertungen

- Is 13411Dokument44 SeitenIs 13411Aditya PratapNoch keine Bewertungen

- National Standard's China - Wrougth Aluminium Alloy ExtrudedDokument18 SeitenNational Standard's China - Wrougth Aluminium Alloy ExtrudedMauricio RiquelmeNoch keine Bewertungen

- 1040-3040 M SchemeDokument47 Seiten1040-3040 M SchemeAnitha MjNoch keine Bewertungen

- BS 3533 PDFDokument22 SeitenBS 3533 PDFKarunakaran Nallasingam100% (2)

- BS 874-3.2 PDFDokument18 SeitenBS 874-3.2 PDFAnitha Mj100% (1)

- Considerations in The Design of Smoke Management Systems For AtriumsDokument6 SeitenConsiderations in The Design of Smoke Management Systems For AtriumsAnitha MjNoch keine Bewertungen

- The Explosives Rules, 1983 PDFDokument130 SeitenThe Explosives Rules, 1983 PDFAnitha MjNoch keine Bewertungen

- TECHNICAL SPECIFICATION Tankage PDFDokument75 SeitenTECHNICAL SPECIFICATION Tankage PDFAnitha MjNoch keine Bewertungen

- Petroleum Acts PDFDokument81 SeitenPetroleum Acts PDFAnitha MjNoch keine Bewertungen

- Equivalent Papers K To L SchemeDokument1 SeiteEquivalent Papers K To L SchemeAnitha Mj0% (1)

- Wada Defending Cannabis BanDokument18 SeitenWada Defending Cannabis Banada UnknownNoch keine Bewertungen

- Ecg Quick Guide PDFDokument7 SeitenEcg Quick Guide PDFansarijavedNoch keine Bewertungen

- Data Sheet FC SIDokument2 SeitenData Sheet FC SIAndrea AtzeniNoch keine Bewertungen

- Ransport and Installation Instructions CTX 510 EcoDokument32 SeitenRansport and Installation Instructions CTX 510 EcoMiliano FilhoNoch keine Bewertungen

- Multilevel Full Mock Test 5: Telegramdagi KanalDokument20 SeitenMultilevel Full Mock Test 5: Telegramdagi KanalShaxzod AxmadjonovNoch keine Bewertungen

- Power of AttorneyDokument10 SeitenPower of AttorneyRocketLawyer82% (17)

- Chan v. ChanDokument2 SeitenChan v. ChanjdpajarilloNoch keine Bewertungen

- FNCP Improper Waste DisposalDokument2 SeitenFNCP Improper Waste DisposalKathleen Daban RagudoNoch keine Bewertungen

- Poster For Optimisation of The Conversion of Waste Cooking Oil Into BiodieselDokument1 SeitePoster For Optimisation of The Conversion of Waste Cooking Oil Into BiodieselcxmzswNoch keine Bewertungen

- What Is Emergency ManagementDokument8 SeitenWhat Is Emergency ManagementHilina hailuNoch keine Bewertungen

- Tomography: Tomography Is Imaging by Sections or Sectioning Through The Use of AnyDokument6 SeitenTomography: Tomography Is Imaging by Sections or Sectioning Through The Use of AnyJames FranklinNoch keine Bewertungen

- Afforestation Powerpoint For NandniDokument9 SeitenAfforestation Powerpoint For NandniFagun Sahni100% (1)

- FRM Valuation & Risk Models Dowd, Chapter 2: - Hosted by David Harper Cfa, FRM, Cipm - Published April 22, 2012Dokument19 SeitenFRM Valuation & Risk Models Dowd, Chapter 2: - Hosted by David Harper Cfa, FRM, Cipm - Published April 22, 2012BeastNoch keine Bewertungen

- DELIGHT Official e BookDokument418 SeitenDELIGHT Official e BookIsis Jade100% (3)

- Erich FrommDokument2 SeitenErich FrommTina NavarroNoch keine Bewertungen

- Editorship, Dr. S.A. OstroumovDokument4 SeitenEditorship, Dr. S.A. OstroumovSergei OstroumovNoch keine Bewertungen

- 1 BSC Iriigation Engineering 2018 19 Std1Dokument70 Seiten1 BSC Iriigation Engineering 2018 19 Std1Kwasi BempongNoch keine Bewertungen

- Technology For Teaching and Learning 2 OBE SyllabusDokument9 SeitenTechnology For Teaching and Learning 2 OBE Syllabusjesreel canalNoch keine Bewertungen

- Quality Assurance Kamera GammaDokument43 SeitenQuality Assurance Kamera GammawiendaintanNoch keine Bewertungen

- TDS Shell Spirax s6 Gxme 75w-80Dokument2 SeitenTDS Shell Spirax s6 Gxme 75w-80rstec pyNoch keine Bewertungen

- 13 Lombe Mumba Ramson 2017 Knowledge Attitude and Practice of Breast Self Examination For Early Detectoin of Breast Cancer Among Women in Roan Constituency in Luanshya Copperbelt Province ZambiaDokument9 Seiten13 Lombe Mumba Ramson 2017 Knowledge Attitude and Practice of Breast Self Examination For Early Detectoin of Breast Cancer Among Women in Roan Constituency in Luanshya Copperbelt Province ZambiaArick Frendi AndriyanNoch keine Bewertungen

- Hippocrates OathDokument6 SeitenHippocrates OathSundary FlhorenzaNoch keine Bewertungen

- Updated2021.KEBOS GR11-2KVA 1800W Online Rack Mount UPS DatasheetDokument2 SeitenUpdated2021.KEBOS GR11-2KVA 1800W Online Rack Mount UPS DatasheetRicardo HolleroNoch keine Bewertungen

- Rediscovering Alginate Wound DressingsDokument4 SeitenRediscovering Alginate Wound DressingstanveerhusseinNoch keine Bewertungen

- Fittings: Fitting Buying GuideDokument2 SeitenFittings: Fitting Buying GuideAaron FonsecaNoch keine Bewertungen

- Grundfos Data Booklet MMSrewindablesubmersiblemotorsandaccessoriesDokument52 SeitenGrundfos Data Booklet MMSrewindablesubmersiblemotorsandaccessoriesRashida MajeedNoch keine Bewertungen

- ResearchDokument13 SeitenResearchCHOYSON RIVERALNoch keine Bewertungen

- A I R P O R T S Construction Program Management 56Dokument56 SeitenA I R P O R T S Construction Program Management 56Carl WilliamsNoch keine Bewertungen