Beruflich Dokumente

Kultur Dokumente

Voids Beneath Slabs On Ground

Hochgeladen von

Professor Dr. Nabeel Al-Bayati-Consultant EngineerOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Voids Beneath Slabs On Ground

Hochgeladen von

Professor Dr. Nabeel Al-Bayati-Consultant EngineerCopyright:

Verfügbare Formate

Voids Beneath

Slabs-on-Ground

Using the impulse-response test to verify adequate slab support

By Hal Amick, Blong Xiong, Ning Tang, and Michael Gendreau

A concrete slab-on-ground is one of the most popular

of all floor types for many applications, especially

research facilities, where they usually provide the highest

beneath the slab, w is the local displacement downward,

and l is the characteristic length. D is the plate rigidity,

defined by

quality with respect to floor vibration. They are stiff and

uniformly supported, so they don’t exhibit the resonance (2)

characteristics of a suspended slab. As a result, they are ν

much less responsive to footfall. where t is the slab thickness, and E and ν are Young’s

Occasionally, the value of a slab-on-ground is degraded modulus of elasticity and Poisson’s ratio for the concrete,

because the slab separates from the subgrade, leaving a respectively. The term l in Eq. (1) is defined as

void. If this void has a large plan area, the floor will behave

more like a suspended floor, exhibiting resonance and (3)

becoming more responsive to footfall and mechanical

excitation. In a laboratory space, this could render the These relationships may be arranged to define a point

floor unfit for the lab equipment in the area. Separation stiffness ks in terms of the slab thickness and elastic

from the soil can also weaken the floor and lead to cracking. properties of the concrete along with the subgrade

It’s often desirable to detect a void or determine its modulus written as

horizontal extent, as well as verify that corrective

measures have been successful. The results of one such (4)

remedial study, with measurements before and after ν

remediation by grout injection, are presented in this article. The subscript s on the stiffness indicates that it’s a

static stiffness. As with a single degree of freedom

Dynamic Characteristics of a system, the point resistance of a slab-on-ground varies

Slab-on-Ground with the frequency of the applied load, defining the

A slab-on-ground may be considered a plate on an notion of dynamic stiffness, or stiffness that varies with

elastic foundation, assuming that the soil is elastic. When frequency. Generally, dynamic stiffness is identical to

a vertical point load is applied to the center of a slab, it static stiffness at frequencies significantly below the

will deform downward in a dish shape with the maximum fundamental resonance frequency of the slab-foundation

deflection occurring beneath the load. The local reaction system.

pressure of the soil against the underside of the slab will We’ve observed that a slab that is in solid, uniform

be a function of the deflection in that vicinity. It has been contact with the subgrade does not usually exhibit

shown1 that the reaction pressure p of an elastic foundation resonance at frequencies less than about 80 Hz, and that

beneath a plate may be given as the stiffness is relatively constant up to this frequency.

A void of significant horizontal dimension, however, will

(1) result in resonance at a frequency less than about 80 Hz

that is observable using certain types of dynamic

where S is the modulus of subgrade reaction of the soil measurement techniques.

Concrete international / july 2009 29

Fig. 3: The dynamic stiffness spectrum for the measurements

shown in Fig. 2 is the inverse of the receptance spectrum. The

dashed line is the static stiffness of the slab-foundation

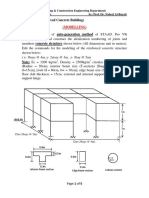

Fig. 1: During an impulse-response test, the computer measures system. The resonance at 80 Hz now appears as a dip

the signals produced by a load cell in the hammer and a motion (1 N/m = 0.00571 lb/in.)

sensor

each divided by the excitation force spectrum, in which

case the resulting normalized spectra are known as

receptance (or compliance), mobility, or accelerance,

respectively. The inverse of receptance is dynamic

stiffness. For greater detail on the representation of

impulse-response data, see Reference 2.

The impulse response of a point on a structure is

straightforward to measure with an impact force source,

a vibration sensor, and a two-channel spectrum analyzer.2

As shown in Fig. 1, a hammer equipped with a force

sensor may be used to apply an impact force and measure

the force created. An accelerometer, a sensor that

measures acceleration, may be used to measure the

Fig. 2: A typical slab-on-ground receptance spectrum with a peak dynamic response to the impact, and the signal may be

at 80 Hz that indicates a resonance frequency (1 m/N = 175 in./lb) double-integrated electronically to create a displacement

signal. The spectrum analyzer can sample the force and

response signals simultaneously and produce a receptance

In the sections that follow, we’ll illustrate the dynamic spectrum, such as the one shown in Fig. 2. The receptance

characteristics of both a well-supported slab and a slab spectrum shows the receptance as a function of frequency.

over a void and discuss how that void was remediated. The dynamic stiffness spectrum, shown in Fig. 3, is the

Follow-up measurements demonstrate that the remediation inverse of the receptance spectrum. The static stiffness ks

was successful, eliminating resonance and producing at the point of load application is the asymptotic value of

behavior similar to the well-supported portion of the slab. dynamic stiffness at low frequencies. This is shown as the

dashed line in Fig. 3.

Measuring in-place slab properties The presence of a void of significant size is best

The impulse-response test2,3 permits measurement of identified by a deviation of the spectrum from “normal”

frequency-dependent response to an impact load. Test for a given slab, which can be defined based on the

results are presented in a manner representing the statistical range of the dynamic properties. Equation (4)

dynamic response (motion amplitude per unit force) or shows that the point stiffness depends on the slab

the dynamic resistance (force amplitude required to thickness, the elastic properties of the concrete, and the

cause a unit amplitude of motion). subgrade modulus, all of which may vary over a large

Response to the impact load may be represented in area. To account for this expected variation of dynamic

terms of displacement, velocity, or acceleration spectra, response for good support conditions, receptance may

30 july 2009 / Concrete international

Fig. 4: Receptance spectra measured at 22 locations on a 150 mm Fig. 5: The log mean receptance for the 22 locations shown in

(6 in.) thick slab-on-ground (1 m/N = 175 in./lb) Fig. 4 and log mean ± 1 log standard deviation or one-sigma

limits (1 m/N = 175 in./lb)

be measured at a large number of locations, as shown in

Fig. 4, which represents measurements at 22 locations.

There are some peaks that represent resonances, but

they all lie at frequencies above 70 Hz. The shapes of the

spectra below that frequency are virtually identical. The

variation in response is summarized in Fig. 5 in terms of

the logarithmic mean (heavy curve) and the logarithmic

mean ± 1 standard deviation of the logarithmic spectra

(light curves). The logarithmic mean at a given frequency

is the mean of the logarithms of the value at that frequency

for all of the individual spectra. The standard deviation of

the logarithmic spectra is obtained in a similar manner.

Fig. 6: Receptance spectra measured at three locations over a

The range represented by the light curves in Fig. 5 will be void, compared with the log mean and one-sigma limits of a

called the “one-sigma limit.” The average coefficient of normally supported slab (1 m/N = 175 in./lb)

variation of the data at frequencies less than 70 Hz is 52%.

Though there are exceptions, the spectrum of log

mean receptance exhibits a characteristic we find typical with the curves representing normal behavior:

of slabs-on-ground: it may be approximated by two ■■ The receptance spectra over the voids exhibit a peak

straight lines—one horizontal and the other sloping. In at the same frequency, representing the fundamental

this case, they intersect at about 80 Hz. resonance frequency of the unsupported slab. In this

case, the frequency is about 30 Hz;

slabs with underlying voids ■■ The portion to the left of the resonance frequency,

Several locations on the slab were suspected of curling representing the inverse of static stiffness, is significantly

at the edges, causing the slab to lift off the subgrade. The higher than the one-sigma limits of receptance for this

spectra in these areas were not included in the set slab. In this case, the receptance at Point 1 is about

shown in Fig. 4 representing “normal” behavior. Several eight times the average for the supported slab; and

measurements from one of the curled areas are shown in ■■ The slope of the segment to the right of the resonance

Fig. 6 and are compared with the one-sigma limits of the peak differs noticeably from the slope of the log mean

data measured at locations with normal bearing. Point 1 receptance for the data measured at locations with

was near the softest location of the slab, in this case, near normal bearing.

a corner. Point 3 was much closer to where the slab It may be adequate to simply confirm the presence or

contacted the soil. Several characteristics of the curves absence of voids. In the event, however, that it’s necessary

for Points 1 to 3 may be observed by comparing them to document the lateral extent of a void, the receptance

Concrete international / july 2009 31

spectra can be obtained on a grid pattern. A low-frequency

resonance will be present at all locations over the void,

and it will disappear when the slab comes in contact with

the subgrade. It’s impossible to determine the height of

the void from these measurements. This requires coring

and direct measurement.

void Repair

A void below a slab may be filled using grout injection,

although significant care is required. If the grout is

over-pressurized, the slab can lift, causing voids at other

locations. When properly implemented, however, the slab

is once again brought into solid contact with the subgrade.

The void at the test location represented in Fig. 6 Fig. 7: Test setup at repaired area. Arrows indicate the plugged

was repaired using grout injection by an experienced injection sites

geotechnical contractor. A collection of 50 mm (2 in.)

diameter holes were drilled through the slab at

21 locations along the curled edge. The holes were

spaced about 600 mm (24 in.) apart along a line about

600 mm (24 in.) from the edge. At every other hole,

another hole was drilled about 300 mm (12 in.) from the

edge. The void space at each hole was measured, and the

height ranged from 3 to 25 mm (1/8 to 1 in.).

About 0.1 m3 (0.13 yd3) of fly ash and portland cement

grout was pumped into the void via the cored holes. The

grout was tested on site to have a 14-second efflux time

flowing through a standard flow cone in accordance with

ASTM C939.4 When the pressurized grout traveled to

adjacent holes and returned up toward the surface, those

holes were plugged. This allowed the grout to migrate to

other holes. All holes were patched with a nonshrink, Fig. 8: Measured receptance spectra at the softest location

before and after grout injection compared with the log mean

high-strength grout recommended by the contractor. and one-sigma limits for response of a normally supported slab

(1 m/N = 175 in./lb)

Behavior with a repaired void

After the grout cured, impulse-response tests were

performed once again to verify the remediation. The Point 1 in Fig. 6, along with the log mean and one-sigma

locations that had the abnormal receptance spectra were limits. The repair led to a measured ambient velocity

tested again. Figure 7 shows the test setup at the area spectrum that was within the one-sigma limits for a

associated with the data in Fig. 6. Figure 8 shows the normally supported slab. The sharp peaks represent the

receptance spectra before and after the repair at the vibrations from rotating mechanical equipment, and their

location identified as Point 1 in Fig. 6. The repair led to a amplitudes are not problematic.

measured receptance that was within the one-sigma Measurements were also made using footfall excitation,

limits for a normally supported slab. In addition, tests as this was more likely than ambient conditions to excite

were performed at locations beyond the perimeter of the floor resonance, if it occurred. Figure 10 shows the

void to ensure there had been no lifting due to excessive velocity spectrum at the same location, along with the

grout pressure. None was indicated. log mean and one-sigma limits for footfall at all of the

After the slab remediation, the construction was measured locations. There are no resonance peaks

completed. As part of the building commissioning evident in the data, and the measured footfall velocity

process, a vibration survey was carried out in the spectrum was within the one-sigma limits for a normally

laboratory wing of the building. As is customary, the supported slab.

vibration data in the operating facility were characterized

statistically using the log mean and one-sigma limits of References

the survey data.5 Figure 9 shows the post-construction 1. Timoshenko, S., and Woinowsky-Krieger, S., Theory of Plates

ambient velocity spectrum at the location identified as and Shells, second edition, McGraw-Hill, New York, 1959, pp. 265-269.

32 july 2009 / Concrete international

Hal Amick is Vice President and a Principal

of Colin Gordon & Associates, a California-

based vibration engineering consultancy,

where he is responsible for the firm’s

structural dynamics and ground vibration

work. He received his BS from the University

of Wyoming and his MS, MEng, and PhD

from the University of California, Berkeley.

His consulting focus is on facilities for

nanoscale research. He and Michael Gendreau have provided

Fig. 9: Ambient velocity spectrum (heavy line) at the softest vibration control design for over two dozen nanotechnology

location after grout injection measured with the facility in research facilities worldwide.

operation. The log mean (light, solid line) and one-sigma limits

(light, dashed lines) for ambient vibration of a normally supported

slab are shown for comparison (1 μin./second = 25.4 nm/second) Blong Xiong is a Consultant with Colin

Gordon & Associates where his work

includes vibration and noise measurement

of structures and building sites, environ-

mental noise modeling, and finite element

analysis of building structures. He received

his BS from Kettering University, Flint, MI,

and his MS from Chalmers University of

Technology, Göteborg, Sweden. Prior to

joining Colin Gordon & Associates in 2006, he worked on vehicle

noise and vibration control for the automotive industry.

Ning Tang is a Consultant with Colin Gordon

& Associates where his work involves the

areas of structural dynamics and finite

element analyses, dynamic soil-structure

Fig. 10: Footfall velocity spectrum (heavy line) at the softest interaction and vibration measurements

location after grout injection. The log mean (light, solid line) and and analyses. He received a BS and MS in

one-sigma limits (light, dashed lines) for ambient vibration of a

normally supported slab are shown for comparison (1 μin./ aerospace engineering from Northwestern

second = 25.4 nm/second) Polytechnical University, Xi’an, China, and a

PhD in mechanical engineering from the

University of Wisconsin-Madison. Prior to joining the company

2. McConnell, K.G., Vibration Testing: Theory and Practice, Wiley, in 2006, he was involved with the development and testing of

New York, 1995, 606 pp. microelectronic and mass storage components.

3. ACI Committee 228, “Nondestructive Test Methods for

Evaluation of Concrete in Structures (ACI 228.2R-98) (Reapproved Michael Gendreau is President and

2004),” American Concrete Institute, Farmington Hills, MI, 1998, 62 pp. Principal of Colin Gordon & Associates.

4. ASTM C939-02, “Standard Test Method for Flow of Grout for He received a BA in physics from the

Preplaced-Aggregate Concrete (Flow Cone Method),” ASTM University of California at Santa Cruz. He

International, West Conshohocken, PA, 2002, 3 pp. specializes in facility interior vibration and

5. Amick, H., and Gendreau, M., “Considerations Regarding the noise control; structural dynamic testing;

Appropriate Timing for Advanced Technology Facility Vibration machinery vibration isolation; site studies,

Surveys,” Semiconductor Fabtech, No. 25, Cleanroom Section, Mar. including the measurement of environmental

2005, pp. 1-4. vibration and noise, interpretation of local

noise regulations, and building noise and vibration design

Selected for reader interest by the editors after independent expert criteria; and preparation of environmental impact and design

evaluation and recommendation. feasibility reports.

Concrete international / july 2009 33

Das könnte Ihnen auch gefallen

- Steel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiDokument6 SeitenSteel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- Astm C-42Dokument6 SeitenAstm C-42Víctor M Fernández JiménezNoch keine Bewertungen

- Steel Frame Structure Analysis and Design by Staad-Pro (Example - 4) by Prof. Dr. Nabeel Al-BayatiDokument3 SeitenSteel Frame Structure Analysis and Design by Staad-Pro (Example - 4) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (2)

- Reinforced Concrete Building, Modelling, Analysis and Design by Staad-Pro (Example 3) by Prof. Dr. Nabeel Al-BayatiDokument5 SeitenReinforced Concrete Building, Modelling, Analysis and Design by Staad-Pro (Example 3) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer50% (2)

- Shear Design Summary for Reinforced Concrete BeamsDokument8 SeitenShear Design Summary for Reinforced Concrete BeamsShashikant Gaur0% (1)

- Strength and Behavior in Shear of Reinforced Concrete Deep Beams Under Dynamic Loading Conditions PDFDokument15 SeitenStrength and Behavior in Shear of Reinforced Concrete Deep Beams Under Dynamic Loading Conditions PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNoch keine Bewertungen

- New Approach Prediction of Compression Strength of Normal and Porcelanite Aggregate Lightweight Concrete by Non-Destructive TestDokument8 SeitenNew Approach Prediction of Compression Strength of Normal and Porcelanite Aggregate Lightweight Concrete by Non-Destructive TestProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNoch keine Bewertungen

- Reinforced Concrete Building Modeling by Staad-Pro (Example-1) by Prof. Dr. Nabeel Al-BayatiDokument6 SeitenReinforced Concrete Building Modeling by Staad-Pro (Example-1) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- Structural Concrete Details by AutoCAD-Example 2-Prof. Dr. Nabeel Al-Bayati PDFDokument7 SeitenStructural Concrete Details by AutoCAD-Example 2-Prof. Dr. Nabeel Al-Bayati PDFProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- Repair of Reinforced Concrete Deep Beams Using Post-Tensioned CFRP Rods PDFDokument39 SeitenRepair of Reinforced Concrete Deep Beams Using Post-Tensioned CFRP Rods PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNoch keine Bewertungen

- New Approach Prediction of Compression Strength of Normal and Porcelanite Aggregate Lightweight Concrete by Non-Destructive TestDokument8 SeitenNew Approach Prediction of Compression Strength of Normal and Porcelanite Aggregate Lightweight Concrete by Non-Destructive TestProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNoch keine Bewertungen

- APSEC 2006 Proceedings on Design of RC BeamsDokument17 SeitenAPSEC 2006 Proceedings on Design of RC BeamsvinthfNoch keine Bewertungen

- Experimental Behavior of Composite Deep Beams, AUB Conference, 2015 PDFDokument8 SeitenExperimental Behavior of Composite Deep Beams, AUB Conference, 2015 PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNoch keine Bewertungen

- Experimental Behavior of Composite Deep Beams, AUB Conference, 2015 PDFDokument8 SeitenExperimental Behavior of Composite Deep Beams, AUB Conference, 2015 PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNoch keine Bewertungen

- Shear StrengtheningDokument8 SeitenShear StrengtheningMohamed MoatazNoch keine Bewertungen

- Bending Stiffness and Neutral Axis Depth Variation of High Strength Concrete Beams in Seismic Hazardous Areas Experimental InvestigationDokument13 SeitenBending Stiffness and Neutral Axis Depth Variation of High Strength Concrete Beams in Seismic Hazardous Areas Experimental InvestigationArjun MulluNoch keine Bewertungen

- EIA Practice in India and Its EvaluationDokument19 SeitenEIA Practice in India and Its EvaluationDharmesh100% (1)

- Strength Assessment of Concrete Structures PDFDokument58 SeitenStrength Assessment of Concrete Structures PDFProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- Oil StorFage Tank Foundations BobergDokument3 SeitenOil StorFage Tank Foundations BobergNabil Al-KhirdajiNoch keine Bewertungen

- A Design For Circular Concrete Tank Pca Design MethodDokument15 SeitenA Design For Circular Concrete Tank Pca Design MethodajebNoch keine Bewertungen

- StaircaseDokument14 SeitenStaircaserameshbabu_1979Noch keine Bewertungen

- Computer Application in Water Works EngineeringDokument12 SeitenComputer Application in Water Works EngineeringProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNoch keine Bewertungen

- Ansi - Eia 748 BDokument34 SeitenAnsi - Eia 748 BProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNoch keine Bewertungen

- Aci Structural Journal Mar.-Apr. 2015 v. 112 No. 02Dokument146 SeitenAci Structural Journal Mar.-Apr. 2015 v. 112 No. 02Professor Dr. Nabeel Al-Bayati-Consultant Engineer100% (5)

- MS Project 2002 Getting Started PDFDokument20 SeitenMS Project 2002 Getting Started PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNoch keine Bewertungen

- Aci Structural Journal Jan.-Feb. 2015 v. 112 No. 01Dokument122 SeitenAci Structural Journal Jan.-Feb. 2015 v. 112 No. 01Professor Dr. Nabeel Al-Bayati-Consultant Engineer100% (3)

- IBM SPSS Statistics PDFDokument8 SeitenIBM SPSS Statistics PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNoch keine Bewertungen

- IBM SPSS Statistics PDFDokument8 SeitenIBM SPSS Statistics PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNoch keine Bewertungen

- Beam Design Formulas With Shear and MomentDokument20 SeitenBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- Bulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForDokument4 SeitenBulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForIbeth S OTNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- I&C Engineer or Automation EngineerDokument3 SeitenI&C Engineer or Automation Engineerapi-79304330Noch keine Bewertungen

- SiargaoDokument11 SeitenSiargaomalouNoch keine Bewertungen

- ATP Draw TutorialDokument55 SeitenATP Draw TutorialMuhammad Majid Altaf100% (3)

- NMIMS MBA Midterm Decision Analysis and Modeling ExamDokument2 SeitenNMIMS MBA Midterm Decision Analysis and Modeling ExamSachi SurbhiNoch keine Bewertungen

- RBI and Maintenance For RCC Structure SeminarDokument4 SeitenRBI and Maintenance For RCC Structure SeminarcoxshulerNoch keine Bewertungen

- The God Complex How It Makes The Most Effective LeadersDokument4 SeitenThe God Complex How It Makes The Most Effective Leadersapi-409867539Noch keine Bewertungen

- Royal DSMDokument16 SeitenRoyal DSMSree100% (2)

- NX569J User ManualDokument61 SeitenNX569J User ManualHenry Orozco EscobarNoch keine Bewertungen

- Lasers OpDokument6 SeitenLasers OpAndrian PrimadyaNoch keine Bewertungen

- DPCA OHE Notice of Appeal 4-11-2018 FinalDokument22 SeitenDPCA OHE Notice of Appeal 4-11-2018 Finalbranax2000Noch keine Bewertungen

- Circle Midpoint Algorithm - Modified As Cartesian CoordinatesDokument10 SeitenCircle Midpoint Algorithm - Modified As Cartesian Coordinateskamar100% (1)

- Pengenalan Icd-10 Struktur & IsiDokument16 SeitenPengenalan Icd-10 Struktur & IsirsudpwslampungNoch keine Bewertungen

- Growing Up Psychic by Chip Coffey - ExcerptDokument48 SeitenGrowing Up Psychic by Chip Coffey - ExcerptCrown Publishing Group100% (1)

- L16 CRE II Heterogeneous Catalysis: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiDokument25 SeitenL16 CRE II Heterogeneous Catalysis: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiMehul VarshneyNoch keine Bewertungen

- McCann MIA CredentialsDokument20 SeitenMcCann MIA CredentialsgbertainaNoch keine Bewertungen

- Relay Testing Management SoftwareDokument10 SeitenRelay Testing Management Softwarechichid2008Noch keine Bewertungen

- Upsized To 12 Gallon Still On A 36"x56" Sheet: Pint O Shine's 6 Gallon Pot Still Design and TemplateDokument50 SeitenUpsized To 12 Gallon Still On A 36"x56" Sheet: Pint O Shine's 6 Gallon Pot Still Design and TemplateyamyrulesNoch keine Bewertungen

- D5435 PDFDokument6 SeitenD5435 PDFZamir Danilo Morera ForeroNoch keine Bewertungen

- Recording and reporting in hospitals and nursing collegesDokument48 SeitenRecording and reporting in hospitals and nursing collegesRaja100% (2)

- Finance Process Optimization - Mapping The Journey To High PerformanceDokument3 SeitenFinance Process Optimization - Mapping The Journey To High PerformanceStephen G. LynchNoch keine Bewertungen

- Group 7 Scope StatementDokument17 SeitenGroup 7 Scope Statementapi-335995226100% (4)

- Lenovo IdeaPad U350 UserGuide V1.0Dokument138 SeitenLenovo IdeaPad U350 UserGuide V1.0Marc BengtssonNoch keine Bewertungen

- Rolfsen Knot Table Guide Crossings 1-10Dokument4 SeitenRolfsen Knot Table Guide Crossings 1-10Pangloss LeibnizNoch keine Bewertungen

- Co2 d30 Laser MarkerDokument8 SeitenCo2 d30 Laser MarkerIksan MustofaNoch keine Bewertungen

- Windows Server 2016 Editions ComparisonDokument4 SeitenWindows Server 2016 Editions ComparisonmasterredhardNoch keine Bewertungen

- Materi Green SCMDokument38 SeitenMateri Green SCManandaailanthusNoch keine Bewertungen

- Signal Processing Problems Chapter 12Dokument20 SeitenSignal Processing Problems Chapter 12CNoch keine Bewertungen

- Failure Reporting, Analysis, and Corrective Action SystemDokument46 SeitenFailure Reporting, Analysis, and Corrective Action Systemjwpaprk1Noch keine Bewertungen

- Phase Domain Modelling of Frequency Dependent Transmission Lines by Means of An Arma ModelDokument11 SeitenPhase Domain Modelling of Frequency Dependent Transmission Lines by Means of An Arma ModelMadhusudhan SrinivasanNoch keine Bewertungen

- Carnot CycleDokument3 SeitenCarnot CyclealexontingNoch keine Bewertungen