Beruflich Dokumente

Kultur Dokumente

ASM 4130 Steel Data Sheet

Hochgeladen von

Pendekar Pemetik Bunga DesaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ASM 4130 Steel Data Sheet

Hochgeladen von

Pendekar Pemetik Bunga DesaCopyright:

Verfügbare Formate

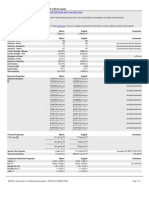

ASM Material Data Sheet

1 of 2

http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=m4130r

AISI 4130 Steel, normalized at 870C (1600F)

Subcategory: AISI 4000 Series Steel; Ferrous Metal; Low Alloy Steel; Medium Carbon Steel; Metal

Key Words: alloy steels, UNS G41300, AMS 6350, AMS 6356, AMS 6360, AMS 6361, AMS 6372, AMS

6370, AMS 6371, AMS 6373, ASTM A322, ASTM A331, ASTM A505, ASTM A513, ASTM A519, ASTM

A646, JIS SCM 2, JIS SCCrM 1, SS14 2225 (Sweden), B.S. CDS 110 (UK), medium carbon steels,

chromium-molybdenum, chrome-moly, MIL SPEC MIL-S-16974, SAE J404, SAE J412, SAE J770, DIN

1.7218, AFNOR 25 CD 4 (France), MIL-S-6758 (flat and round bar), MIS-S-18729 ANN and NORM (sheet

and plate), QQS-624 (round bar)

Component

C

Wt. %

0.28 - 0.33

Cr

0.8 - 1.1

Fe

97.3 - 98.22

Mn

0.4 - 0.6

Mo

0.15 - 0.25

Max 0.035

Max 0.04

Si

0.15 - 0.35

Physical Properties

Metric

English

7.85 g/cc

0.284 lb/in

Hardness, Brinell

197

197

Hardness, Knoop

219

219

Converted from Brinell hardness.

Hardness, Rockwell B

92

92

Converted from Brinell hardness.

Hardness, Rockwell C

13

13

Converted from Brinell hardness.

Value below normal HRC range, for

comparison purposes only.

207

207

Converted from Brinell hardness.

Tensile Strength, Ultimate

670 MPa

97200 psi

Tensile Strength, Yield

435 MPa

63100 psi

25.5 %

25.5 %

60 %

60 %

Modulus of Elasticity

205 GPa

29700 ksi

Typical for steel

Bulk Modulus

140 GPa

20300 ksi

Typical for steel

0.29

0.29

Calculated

Density

Comments

Mechanical Properties

Hardness, Vickers

Elongation at Break

Reduction of Area

Poisson's Ratio

in 50 mm

02/07/2014 9:38

ASM Material Data Sheet

2 of 2

Izod Impact

http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=m4130r

87 J

64.2 ft-lb

70 %

70 %

annealed and cold drawn. Based on

100% machinability for AISI 1212

steel.

80 GPa

11600 ksi

Typical for steel

Electrical Resistivity

2.23e-005 ohm-cm 2.23e-005 ohm-cm

specimen hardened and tempered;

20C (68F)

Electrical Resistivity at Elevated Temperature

0.0001103 ohm-cm 0.0001103 ohm-cm

specimen hardened and tempered;

800C (1470F)

Electrical Resistivity at Elevated Temperature

0.0001171 ohm-cm 0.0001171 ohm-cm

specimen hardened and tempered;

1000C (1830F)

Electrical Resistivity at Elevated Temperature

0.0001222 ohm-cm 0.0001222 ohm-cm

specimen hardened and tempered;

1200C (2192F)

Electrical Resistivity at Elevated Temperature

2.71e-005 ohm-cm 2.71e-005 ohm-cm

specimen hardened and tempered;

100C (212F)

Electrical Resistivity at Elevated Temperature

3.42e-005 ohm-cm 3.42e-005 ohm-cm

specimen hardened and tempered;

200C (390F)

Electrical Resistivity at Elevated Temperature

5.29e-005 ohm-cm 5.29e-005 ohm-cm

specimen hardened and tempered;

400C (750F)

Electrical Resistivity at Elevated Temperature

7.86e-005 ohm-cm 7.86e-005 ohm-cm

specimen hardened and tempered;

600C (1110F)

Machinability

Shear Modulus

Electrical Properties

Thermal Properties

Specific Heat Capacity

0.477 J/g-C

0.114 BTU/lb-F

50-100C

Specific Heat Capacity at Elevated Temperature

0.523 J/g-C

0.125 BTU/lb-F

150-200C

Specific Heat Capacity at Elevated Temperature

0.837 J/g-C

0.2 BTU/lb-F

750-800C

Thermal Conductivity

42.7 W/m-K 296 BTU-in/hr-ft-F

100C

Thermal Conductivity at Elevated Temperature

30.1 W/m-K 209 BTU-in/hr-ft-F

1200C

Thermal Conductivity at Elevated Temperature

40.7 W/m-K 282 BTU-in/hr-ft-F

300C

References for this datasheet.

Some of the values displayed above may have been converted from their original units and/or rounded in order to display the information in a consistant format. Users

requiring more precise data for scientific or engineering calculations can click on the property value to see the original value as well as raw conversions to equivalent units. We

advise that you only use the original value or one of its raw conversions in your calculations to minimize rounding error. We also ask that you refer to MatWeb's disclaimer and

terms of use regarding this information. MatWeb data and tools provided by MatWeb, LLC.

02/07/2014 9:38

Das könnte Ihnen auch gefallen

- Applied Welding Engineering: Processes, Codes, and StandardsVon EverandApplied Welding Engineering: Processes, Codes, and StandardsNoch keine Bewertungen

- Ams 4928Dokument8 SeitenAms 4928REKHA100% (3)

- AISI 1020 Steel, Cold RolledDokument2 SeitenAISI 1020 Steel, Cold RolledAnonymous ZMwWk2v50% (2)

- The Leading Edge by Goro Tamai - Table of ContentsDokument1 SeiteThe Leading Edge by Goro Tamai - Table of ContentsBentley PublishersNoch keine Bewertungen

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesVon EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNoch keine Bewertungen

- The Design of Vertical Pressure Vessels Subjected To Applied ForcesDokument3 SeitenThe Design of Vertical Pressure Vessels Subjected To Applied ForcesMANOJ M100% (1)

- Nippon Steel Data S001enDokument14 SeitenNippon Steel Data S001enpower group100% (1)

- Finite Element Simulation and Experimental Study On Mechanical Behavior of 3D Woven Glass Ber Composite Sandwich PanelsDokument9 SeitenFinite Element Simulation and Experimental Study On Mechanical Behavior of 3D Woven Glass Ber Composite Sandwich PanelsHoria PetrescuNoch keine Bewertungen

- Machine Design: Stress Concentration FactorsDokument30 SeitenMachine Design: Stress Concentration FactorsM.HNoch keine Bewertungen

- Materials Data for Cyclic Loading: Low-Alloy SteelsVon EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsBewertung: 5 von 5 Sternen5/5 (2)

- 17-7 PH Data BulletinDokument16 Seiten17-7 PH Data Bulletinmeckup123Noch keine Bewertungen

- Design of Reinforced Concrete D Regions Using Strut and Tie Models and Nonlinear Finite Element Modelling - Research Groups - Imperial College LondonDokument4 SeitenDesign of Reinforced Concrete D Regions Using Strut and Tie Models and Nonlinear Finite Element Modelling - Research Groups - Imperial College LondonDEYBI ALEJANDRO CHINCHAY POMANoch keine Bewertungen

- Aisi 1045Dokument1 SeiteAisi 1045edraelmx100% (1)

- Versafles Liner HangerDokument8 SeitenVersafles Liner HangerEdison MontanezNoch keine Bewertungen

- Theoretical DeliverabilityDokument197 SeitenTheoretical Deliverabilitymath62210Noch keine Bewertungen

- Metrode ER110S-G FillerDokument6 SeitenMetrode ER110S-G FillerBernie SimcsNoch keine Bewertungen

- ASTM Conductor Spec SheetsDokument27 SeitenASTM Conductor Spec Sheetsjavad4531Noch keine Bewertungen

- Aisi 1008 PDFDokument2 SeitenAisi 1008 PDFIbsonhNoch keine Bewertungen

- Material Inconel 600Dokument16 SeitenMaterial Inconel 600arvindgupta_2005100% (1)

- InvarDokument5 SeitenInvardusan.papez9216Noch keine Bewertungen

- AISI 4130 Steel 870C NormalisedDokument3 SeitenAISI 4130 Steel 870C NormalisedjimNoch keine Bewertungen

- AISI 4130: Incoloy Alloys, Fast QuoteDokument5 SeitenAISI 4130: Incoloy Alloys, Fast QuoteSantanu SahaNoch keine Bewertungen

- MaterialData 6877Dokument2 SeitenMaterialData 6877Maxi PianelliNoch keine Bewertungen

- Stainless AISI 3XXDokument3 SeitenStainless AISI 3XXThitaphol HuyananNoch keine Bewertungen

- AISI Type 403 Stainless Steel Properties and ApplicationsDokument7 SeitenAISI Type 403 Stainless Steel Properties and ApplicationsMiguelPacheecoAgamezNoch keine Bewertungen

- LSS A286Dokument2 SeitenLSS A286anhntran4850Noch keine Bewertungen

- Nichrome Alloys For HeatingDokument10 SeitenNichrome Alloys For HeatingRajaram GanesanNoch keine Bewertungen

- ASM Material Data SheetDokument3 SeitenASM Material Data SheetAscanio BarbosaNoch keine Bewertungen

- Low HydrogenDokument3 SeitenLow Hydrogenseeralan balakrishnanNoch keine Bewertungen

- S7 Tool Steel: What Is ?Dokument3 SeitenS7 Tool Steel: What Is ?Sama UmateNoch keine Bewertungen

- 9ni Cryogenic Materials PDFDokument5 Seiten9ni Cryogenic Materials PDFyogie4061100% (1)

- 6061 Vs 6063Dokument9 Seiten6061 Vs 6063SrRonNoch keine Bewertungen

- 17.4 PH Material SpecificationDokument2 Seiten17.4 PH Material SpecificationDevendra BangarNoch keine Bewertungen

- Properties of Ss410Dokument5 SeitenProperties of Ss410gregkilatonNoch keine Bewertungen

- Data Sheet Aluminium 6061 t6 Group (H)Dokument7 SeitenData Sheet Aluminium 6061 t6 Group (H)احمد نعيمNoch keine Bewertungen

- Conductor SizesDokument4 SeitenConductor SizescoolbuggerNoch keine Bewertungen

- MaterialData - Aço 1045Dokument2 SeitenMaterialData - Aço 1045Victhor AraujoNoch keine Bewertungen

- Properties s45cDokument3 SeitenProperties s45ctomas duranNoch keine Bewertungen

- Stainless Steel 304 Material Property Data SheetDokument2 SeitenStainless Steel 304 Material Property Data SheetRahul SrivastavaNoch keine Bewertungen

- SAF Welding Cutting GuideDokument165 SeitenSAF Welding Cutting GuideSelvem0% (1)

- Series 800 1000 TubularDokument6 SeitenSeries 800 1000 TubularRatnesh GaurNoch keine Bewertungen

- Stainless Steel 410Dokument2 SeitenStainless Steel 410Suriyachai NiamsornNoch keine Bewertungen

- AISI 1008 Steel: UNS G10080Dokument2 SeitenAISI 1008 Steel: UNS G10080omneyaaNoch keine Bewertungen

- Matmatch trusted by 2M engineersDokument6 SeitenMatmatch trusted by 2M engineersbksinghsNoch keine Bewertungen

- Ams 4965 HDokument11 SeitenAms 4965 HOTK Micro-FixNoch keine Bewertungen

- Cosmos Alminium-Technical SpecificationsDokument2 SeitenCosmos Alminium-Technical SpecificationsmindsopenNoch keine Bewertungen

- Acsr SpecsDokument1 SeiteAcsr SpecsPanda NoirNoch keine Bewertungen

- AISI 1045 SteelDokument3 SeitenAISI 1045 Steelsenthil4youNoch keine Bewertungen

- 2205 InfoDokument6 Seiten2205 InfoMave75Noch keine Bewertungen

- 6A05 THRU 6A10: Axial Silastic Guard Junction Standard RectifierDokument2 Seiten6A05 THRU 6A10: Axial Silastic Guard Junction Standard RectifiercuickNoch keine Bewertungen

- 1564 Fox Ev 85 ElettrodoDokument1 Seite1564 Fox Ev 85 ElettrodoAminNoch keine Bewertungen

- 275 287Dokument14 Seiten275 287Anonymous I7dJ0lmdNoch keine Bewertungen

- Aluminum 6061Dokument3 SeitenAluminum 6061Ali FahemNoch keine Bewertungen

- Rectifier Diodes SKN 100 SKR 100 SKN 130 SKR 130 SKN 240 SKR 240Dokument5 SeitenRectifier Diodes SKN 100 SKR 100 SKN 130 SKR 130 SKN 240 SKR 240Hubert Maraza JaliriNoch keine Bewertungen

- Acsr Cond Alumnio Nucleo AceroDokument3 SeitenAcsr Cond Alumnio Nucleo AceroEglee PeckNoch keine Bewertungen

- A743A743MDokument7 SeitenA743A743MAnonymous ggwJDMh8Noch keine Bewertungen

- SAE - AMS 5759lv003Dokument6 SeitenSAE - AMS 5759lv003Nilesh PatilNoch keine Bewertungen

- 1.3343 HS6-5-2CDokument3 Seiten1.3343 HS6-5-2CmustafabodurNoch keine Bewertungen

- Engineering Material PropertiesDokument8 SeitenEngineering Material PropertiesJoe147Noch keine Bewertungen

- AISI1040Dokument2 SeitenAISI1040Anonymous qRbPsLpuNNoch keine Bewertungen

- Material Monel K-500Dokument2 SeitenMaterial Monel K-500MachineryengNoch keine Bewertungen

- Sulfur Recovery Unit: Specialty Wavelength Industrial Infrared ThermometersDokument2 SeitenSulfur Recovery Unit: Specialty Wavelength Industrial Infrared ThermometersAndrew Kevin ThilaksNoch keine Bewertungen

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsVon EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsNoch keine Bewertungen

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusVon EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusNoch keine Bewertungen

- English - McCarter, Sam - IELTS - Academic Writing PDFDokument172 SeitenEnglish - McCarter, Sam - IELTS - Academic Writing PDFVishal100% (11)

- Lion Air eTicket Itinerary ReceiptDokument2 SeitenLion Air eTicket Itinerary ReceiptAgis AlonsoNoch keine Bewertungen

- Day 2Dokument207 SeitenDay 2Pendekar Pemetik Bunga DesaNoch keine Bewertungen

- ASME Section VIII Div 1 Pressure Vessel Design GuideDokument103 SeitenASME Section VIII Div 1 Pressure Vessel Design GuideJaeup YouNoch keine Bewertungen

- Numerical and Experimental Thermal Analysis of A Tunnel Kiln Used in Ceramic ProductionDokument8 SeitenNumerical and Experimental Thermal Analysis of A Tunnel Kiln Used in Ceramic ProductionmahdilabedNoch keine Bewertungen

- Heat 4e Chap04 LectureDokument39 SeitenHeat 4e Chap04 Lectureehdfhdhdfhdh100% (1)

- Basics of Reinforced Concrete Design: OutlineDokument10 SeitenBasics of Reinforced Concrete Design: OutlineariNoch keine Bewertungen

- kns23 Autumn Paper Ysbang - Check - Valve r1Dokument5 Seitenkns23 Autumn Paper Ysbang - Check - Valve r1YOUNGSEOK BANGNoch keine Bewertungen

- HT2Dokument178 SeitenHT2dhruvNoch keine Bewertungen

- 7A Phase TransformationsDokument15 Seiten7A Phase TransformationsAhmed AliNoch keine Bewertungen

- Gas Processors Suppliers Association GPSA Eng (Bookos - Org) - 701-821!1!60!1!20Dokument20 SeitenGas Processors Suppliers Association GPSA Eng (Bookos - Org) - 701-821!1!60!1!20Karen Vl100% (1)

- 3 - Absolute, Effective and Relative PermeabilitiesDokument34 Seiten3 - Absolute, Effective and Relative PermeabilitiesAhmad MammadovNoch keine Bewertungen

- Ramjet Rocket Missile DesignDokument34 SeitenRamjet Rocket Missile DesignCliff ThriveNoch keine Bewertungen

- Nano Refrigerants OverviewDokument26 SeitenNano Refrigerants Overviewchitta sandeep dattuNoch keine Bewertungen

- Che 222 QST & Ans-1Dokument32 SeitenChe 222 QST & Ans-1Tega MorrisonNoch keine Bewertungen

- Flow Measurement Lab EquipmentDokument2 SeitenFlow Measurement Lab EquipmentAli HadiNoch keine Bewertungen

- A i r e- M a x A s ia P t e L t d VAV Flow Calibration and Recommended AirflowDokument1 SeiteA i r e- M a x A s ia P t e L t d VAV Flow Calibration and Recommended AirflowKingsley LimNoch keine Bewertungen

- ThermoCond 19 enDokument4 SeitenThermoCond 19 enAnonymous 7z6OzoNoch keine Bewertungen

- THD3602 Major Test 1 2023Dokument3 SeitenTHD3602 Major Test 1 2023LeighNoch keine Bewertungen

- Performance-Based Seismic Design of Reinforced Concrete Frame Buildings: A Direct Displacement-Based ApproachDokument12 SeitenPerformance-Based Seismic Design of Reinforced Concrete Frame Buildings: A Direct Displacement-Based ApproachSanjeev SahNoch keine Bewertungen

- 1 - Introduction To Steel Design PDFDokument9 Seiten1 - Introduction To Steel Design PDFNadine PascualNoch keine Bewertungen

- Phase Rule Sulphur System: Upma Shrivastava Asstt. Prof. Govt. V.Y.T.PG - Auto.College Durg ChhattisgarhDokument13 SeitenPhase Rule Sulphur System: Upma Shrivastava Asstt. Prof. Govt. V.Y.T.PG - Auto.College Durg ChhattisgarhramukakaNoch keine Bewertungen

- From Boltzmann to Navier-StokesDokument7 SeitenFrom Boltzmann to Navier-StokesDago EspañaNoch keine Bewertungen

- This Study Resource Was: Problem #1 A Sharp-Edge Orifice, 50 MMDokument6 SeitenThis Study Resource Was: Problem #1 A Sharp-Edge Orifice, 50 MMJemuel FloresNoch keine Bewertungen

- Open Channel Prob SolDokument42 SeitenOpen Channel Prob SolLee CastroNoch keine Bewertungen

- Module 2 - Properties of MixingDokument20 SeitenModule 2 - Properties of MixingJohn Emmanuel Abel RamosNoch keine Bewertungen

- Drag Coefficient PDFDokument9 SeitenDrag Coefficient PDFphutd09Noch keine Bewertungen

- Lesson 4 - Heat TransferDokument16 SeitenLesson 4 - Heat TransferJoanna Ruth SeproNoch keine Bewertungen