Beruflich Dokumente

Kultur Dokumente

12 ER SR Palko Marcincin PDF

Hochgeladen von

Šime GlavanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

12 ER SR Palko Marcincin PDF

Hochgeladen von

Šime GlavanCopyright:

Verfügbare Formate

Eng. Rev.

29-1 (2009) 89-93

89

________________________________________________________________________________________________________________________________________________________________

UDC 007.52:004.896:658.51-52

NEKI ASPEKTI U RAZVOJU ROBOTA

SOME ASPECTS IN THE DEVELOPMENT OF ROBOTS

Anton PALKO - Jozef NOVK MARCININ

Saetak: Analiza nedavnih razvoja, kao i najnovijih trendova razvoja automatizacije proizvodnje i ne-proizvodnih

procesa dokazuje da je robotizacija tih procesa u opem konceptu njihove automatizacije i dalje u jedinstvenom i

nezamjenjivom poloaju. Ovi trendovi postavljaju vie zahtjeve o sloenosti inovaciji svih naina unosa automatiziranih

proizvodnih i uslunih sustava. Najnoviji trendovi stvaraju nove potrebe za razvoj i izgradnju novih kategorija i

generacija robota, kao i novi pristup primjene robota.

Kljune rijei:

nedavni trendovi

automatizacija proizvodnje

neproizvodni procesi

industrijski roboti, usluni roboti, osobni roboti

Summary: The analysis of recent developments as well as recent trends of development in the automation of production

and non-production processes proves that the robotization of those processes retains, in the general concept of their

automation, its unique and irreplaceable position. These trends place higher demands on the complexity of innovation

in the introduction of automated production and service systems. Recent trends create new needs in the development

and construction of new categories and generations of robots as well as a new approach to the application of robots.

Keywords:

recent trends

automation of production

non-production processes

industrial robots, service robots, personal robots

1. INTRODUCTION

The analysis of recent developments as well as recent

trends of development in production automation and nonproduction processes proves that robotization of those

processes retains, in the general concept of their

automation, its unique and irreplaceable position. The

advance of robots can be documented by data about their

production and application, see Figure 1, which the IFR

(International Federation of Robotics) presents.

The areas in which robotic systems are implemented have

been spreading dynamically, in addition to the classical

applications of industrial/production fields and

technologies, mainly in the areas and technologies with

non-industrial/non-engineering applications, and in new

areas of services [1, 7].

These trends place higher demands on the complexity of

innovation of all means entering automated production

and service systems. Recent trends have created new

needs in the development and construction of new

categories and generations of robots as well as new

approaches to the application of robots based on higher

sophistication of automated/robotic systems conditioned

by highly distinct implementation of non-traditional

mechanical principles

Figure 1. Robots production and application

90

A. Palko, J. Novk Marcinin: Neki aspekti u razvoju

________________________________________________________________________________________________________________________________________________________________

of control/computer technology, information technology

and artificial intelligence [11, 12].

2. VIEW OF CURRENT STATE OF THE ART

AND ITS CHARACTERISTICS

The current state of the art in robotics and its trends in

development can be characterised and described by:

Development of knowledge and creativity in the area

of robotics on the basis of interest and stimulation of

practical application has been categorized in the

following manner: robotics (a field covering the

theoretical interdisciplinary basis of robotization);

robotic technique (theory of structure and design of

robotic technological devices and indirectly also their

complete basis); robotic technology (the application

of robots, indirectly also the development of new

technology applications); and robotic operation

(operating robotic systems throughout their lifecycle).

Development of applications and production of robots

has,

generally

speaking,

characteristics

of

permanently dynamic growth. Application of robots

in classical industrial/production areas maintains its

own pace of growth.

Development in the application of robots documents

general dynamic advance of robots in new nontraditional areas (all areas of human activities

including non-production and service activities).

From what has been shown above, it is possible to claim

that under real conditions in practical application the

development of robotics will be marked mainly by the

following features:

In classical robot applications, the recent pace

will be kept; dispersion in quantity will be a reflection

of recently demanded efficiency of production in

object areas (automobile industry, food processing

industry, chemical industry and so on).

It will substantiate the automation of production/nonproduction processes on the principles of BMC

(Bionic Manufacturing Systems), IMS (Intelligent

Manufacturing Systems), CIM (Computer Integrated

Manufacturing), CHIM (Computer Human Integrated

Manufacturing),

ICIM

(Intelligent

Computer

Integrated

Manufacturing),

AI-Agents-HolonsFractals will be more intensive, however, with a new

systematic approach to their description and

application.

The concept of robots, as machines and devices, will

be influenced by the advance of new generations of

components for their construction (mechatronic

approach, biomechanical principles, integrated

intelligent components and parts). The new concept of

robots will be based on a modular self-reconfigurable

system, with a high level of flexibility [8].

Emerging new categories of robots which will be

designated mainly for the areas of non-traditional

applications and new areas of usage (service robots,

personal robots), while the development of service

robots and their applications has recently been

compared to the importance of the automobile

industry (the number of applications and different

solutions/designs will be considerably higher than

with automobiles).

3. VIEW OF RECENT DEVELOPMENT OF

RELEVANT AREAS

Analysis of current developments in robotics, mainly the

analysis of trends and the realization of the development

of details in their technical interpretation lead to the view

and opinion of a specific profile of development in

relevant areas, mainly in the following areas:

In the area of approaches to robot design: the concept

of industrial robots is stabilized, the development of

robot families is being solved in comparable types

and sizes (innovation of completing bases is used),

new concepts of serial structures are being solved

(meant primarily for new applications of robots) and

parallel structures; the concept of service robots,

which evolves from confrontation with application

requirements,

non-structured

working/operating

environment and the technologies of realized tasks;

One of the current theoretical and engineering roles of

robotics is the innovation of approaches to robot and

robotic systems constructions for industrial

applications invoked by the need to extend their

functional possibilities not only by extending the

scope of the kinematical structure of their action

mechanism but also by controlling the change of its

function. A theory of mechanisms with selfreconfigurable (variable) structure has begun to be

elaborated as a realistic direction toward a solution.

This direction gives new quality to a robot that is

based on the controlled reconfigurability of its

kinematical and functional structure.

Reconfigurability is a new direction in the

construction of robotic technology, which began to be

intensively pursued in the construction of industrial as

well as services robots. Whereas the area of service

robots is on a relatively high level and the first

applications have been tested in practice, in industrial

robotics this direction represents only an initial phase

in research efforts.

In the area of mechanics: to use the possibility of

designing the kinematic structure of robots and their

modifications for pre-determined tasks; to use a wide

spectrum of possible applications of parallel

mechanisms and the suitable features of parallel

kinematic structures; the use of principles of modular

concepts in the robot design or in the design of its

autonomous modular units; the use of features and

possibilities of new materials for designing new

mechanical parts (composite materials, materials with

a hybrid structure, etc);

In the area of driving technique: design driving

aggregates as intelligent servosystems working as

Eng. Rev. 29-1 (2009) 89-93

91

________________________________________________________________________________________________________________________________________________________________

online expert systems in realtime assembled in the

structure of the hierarchically structured and control

system; design driving aggregates to use motors

running on liquids with a maximum possible rate of

functional integration;

In the area of sensorics: to use sensoric systems for

specified sensoric functions, in relation to operation

and level of given intelligence so that the behaviour

of a robot would be either a feasible algorithm or a

group of algorithms operating the whole robotic

complex; to use principles of the physical phenomena

of an animate and inanimate nature to design

intelligent sensor systems with the ability and features

of artificial sight, hearing, sensing, maintaining and

operating of position, etc.; design of the application of

intelligent technical sensor systems with fewer

technical sensors, fewer concentrators, to solve

collection and processing of information in a system

based on the serial principle;

In the area of control: to use methods of massive

control so that feedback operation solving the

monitoring of the given trajectory of state would be

resolved; to use methods of adaptive control in

connection with intelligent components of robot

mechanics or in connection with information from the

working and technological environment of the

application; design control program for navigation of

service robots addressing the need for parallel

processing of tasks in classes: recording and

evaluating of data from inner and outer sensors; to set

the structure of the control of the intelligent robotic

system as a multilevel system;

In the area of application of technologies of artificial

intelligence: to implement methods and techniques of

artificial intelligence for the needs of simulation of

robot activities, for the needs of robot navigation in

space, and for the needs of robot control;

In the area of running: to the implement new methods

and means of modelling and simulation in design,

operation and securing robotic systems operation; to

use methods defining and describing robotic system

operation through the operator of functional relations

as an operation of a complex multi-element technical

system; to use methods of describing operating

conditions of n-random quantities enabling the

determination of a scholastic model for operating

conditions; to construct models for diagnostics of a

technical nature; to design models of robot

maintenance on the basis of modern approaches.

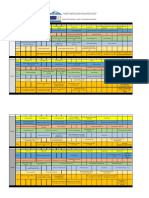

can be arranged according to the current classification of

this technique, Table 1.

Table 1. Classification of robots technique

Robots Technique

Industrial Robots

Service Robots

Figure 2. Example of industrial robot application

Industrial robots (IR) IR is conceptually designed from

a mechanical system (manipulator mechanics/robot

mechanics, positioning, orientation in working zone) and

control system (control, programming) [4]; the task

following its application is technically solved by working

head (manipulation, technological), Figure 2.

Service robots (SR) The decisive and constructionally

most important feature of SR is the locomotion parts

(wheeled, walking, floating, special), which secure their

mobility, Figure 3. The superstructure of locomotion

parts is always solved according to the type of task,

which is supposed to be performed by SR and at the same

time the whole SR is designed in concept and detail

according to the kind and character of the environment in

which it operates [6, 10].

4. PRESENTATION OF RECENT STATE OF

THE ART OF TECHNOLOGY

The Recent state of the art of robotic technology can be

documented by a presentation of selected types of robots

[2] and the designation of their possible applications that

Personal Robots

Figure 3. Mobile service robot

92

A. Palko, J. Novk Marcinin: Neki aspekti u razvoju

________________________________________________________________________________________________________________________________________________________________

Personal robots (PR) uniform and generally approved

definition has not been accepted although there is an

interpretation that is in the process of formulation that it

is a freely programmable device [5, 9], which partially or

fully automatically performs service operations, Figure 4.

5. CONCLUSION

The view of the trends for further development of

robotics and relevant areas presented in the paper indicate

only a part of these relations to the selected technical

problems that are associated with them. Working out and

solving the given technical problems will affect different

specialized fields and areas, new areas of tasks for

specialists from different fields will emerge and they will

require creative dynamic work.

AKNOWLEDGMENTS

The Slovak Ministry of Education has supported this

work, contract KEGA No. 3/5172/07, and by contract of

applied

research

No.

AV4/0003/07.

Figure 4. Personal robot for home application

REFERENCES

[1] Heiligensetzer, P.: Safeguarded Human Robot

Interaction in Production. In: Proceedings ISR 2002,

IFR Stockholm, Stockholm, 2002.

[2] IFR : Proceeding : Statistical and Type of Robotics.

[3] Juriica, L., Vtko,A.: Mechatronics and robotics.

AT&P Journal, Vol. 4, No. 11, 1998.

[4] Klueger, P.: New Communication Concepts for

Industrial Robots. In: Proceedings ISR 2002, IFR

Stockholm, Stockholm, 2002.

[5] Kopacek, P.: Intelligent Manufacturing: Present State

and Future Trends. Journal of Robotic Systems, No.

26, 1999.

[6] Marcinin, J. N.: Mobile Robots Classification. In:

Proceedings of International Congress Machine

Tools, Automation and Robotics in Mechanical

Engineering MATAR 2000, Praha, 2000, pp. 89-93.

[7] Milic, M.: Visionary Production Systems and

Industrial IT. In: Proceedings ISR 2002, IFR

Stockholm, Stockholm, 2002.

[8] Palko, A.: Modular reconfigurable industrial robots.

In: The International Conference of the Carpathian

Euro-Region Specialists in Industrial Systems, Baia

Mare, Romania 2008.

[9] Skaupa, J., Krnk, L., Mostn, V.: Robot Assistant

new component of service robotics.

Acta

Mechnica Slovaca, Vol. 7, No. 3, Koice 2003, pp.

121-128.

[10] Smrek, J., Palko, A., Juriin, J.: Problems of

service robots, study of principles and methods their

application. Mechanical Engineering, Vol. 3, No. 4,

ilina, 1999, pp. 72-74.

[11] Smrek, J., Hajduk, M., op, V.: Recent

Development of Robotics and the Needs for

Development of Relevant Areas. In: Proceedings of

2nd Slovakia Hungarian Joint Symposium on

Applied Machine Intelligence SAMI 2004, TU

Koice, 2004, pp. 209-218, ISBN 963-7154-23-X.

[12] Talcko, J., Pokorn, K.: Development state of

automation in production. In: Proceeding 1st

International Conference New Trends in the

Operation of Production Technology, TU FVT

Preov, 1998, pp. 121-125.

Eng. Rev. 29-1 (2009) 89-93

93

________________________________________________________________________________________________________________________________________________________________

Primljeno / Recived: 27.2.2009.

.

Pregledni lanak

Authors address:

Assoc. Prof. Ing. Anton Palko, PhD.

Prof. Ing. Jozef Novak-Marcinin, PhD.

Technical University of Koice

Faculty of Manufacturing Technologies

with a seat in Preov, Bayerova

1, 08001 Preov, SLOVAKIA

Prihvaeno / Accepted: 18.4.2009.

Subject review

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Paper 1 Searchable Symmetric Encryption With Forward Search PrivacyDokument15 SeitenPaper 1 Searchable Symmetric Encryption With Forward Search PrivacyPromise LoNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- List Lay Cable For ControlDokument5 SeitenList Lay Cable For ControlBayu SeptiadiNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Optima User GuideDokument158 SeitenOptima User GuideVikasNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Cisco SD-WAN Policy Architecture - Dana Yanch PDFDokument1 SeiteCisco SD-WAN Policy Architecture - Dana Yanch PDFEmilio PazNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Kiln Shell Laser ManualDokument19 SeitenKiln Shell Laser Manualบิ๊ก บิ๊กNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- 7.2.5 APQP Phase 2 Checklist Dec 2013Dokument21 Seiten7.2.5 APQP Phase 2 Checklist Dec 2013Mani Rathinam RajamaniNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- LIFI PresentationDokument15 SeitenLIFI PresentationAditya SinghNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- 5-HK5 Miniature Solenoid ValvesDokument6 Seiten5-HK5 Miniature Solenoid ValvessakscribNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- De Lorenzo - Smart Grid EngDokument29 SeitenDe Lorenzo - Smart Grid EngwrdlifeNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Chillers Sequence of OperationDokument23 SeitenChillers Sequence of OperationAshraf TurkyNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Service Charges Wef 01-Oct-2023Dokument11 SeitenService Charges Wef 01-Oct-2023Loona KKNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Ansible For Real-Life Automation - Gineesh MadapparambathDokument893 SeitenAnsible For Real-Life Automation - Gineesh Madapparambathvijayendra0% (1)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- VeriFast LVDT FAQDokument2 SeitenVeriFast LVDT FAQGerardoNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Time Table Spring 2022-2023 V2Dokument3 SeitenTime Table Spring 2022-2023 V2moad alsaityNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Flexible Manufacturing System.Dokument11 SeitenFlexible Manufacturing System.Yaswanth saiNoch keine Bewertungen

- E-Waste An Overview On Generation, Collection, Legislation and Recycling Practices Denise PDFDokument11 SeitenE-Waste An Overview On Generation, Collection, Legislation and Recycling Practices Denise PDFThamirisAgmNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 8 Latest Kitchen Chimney Brands in India 2020Dokument4 Seiten8 Latest Kitchen Chimney Brands in India 2020Sulagna ChowdhuryNoch keine Bewertungen

- B&R Automation Studio Target For SimulinkDokument76 SeitenB&R Automation Studio Target For SimulinkAdrian MeleroNoch keine Bewertungen

- DARCY CV - UpdatedDokument3 SeitenDARCY CV - UpdatedRodel CandelarioNoch keine Bewertungen

- ISO 39001 - Peter HartzellDokument33 SeitenISO 39001 - Peter HartzellJosefinaGarcía100% (2)

- Key Responsibility AreasDokument6 SeitenKey Responsibility AreasSubodh YadavNoch keine Bewertungen

- As 2159 2009 Piling Design and InstallationDokument9 SeitenAs 2159 2009 Piling Design and InstallationKinson LowNoch keine Bewertungen

- Riso Page CalculatorDokument19 SeitenRiso Page CalculatorNana Kwabena Ampem DarkoNoch keine Bewertungen

- Pe 001Dokument216 SeitenPe 001erivan bernardoNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Conveyor Safety Switches 2 5Dokument16 SeitenConveyor Safety Switches 2 5yatinthoratscrbNoch keine Bewertungen

- MOTOROLA Walkie Talkie Consumer Radio TLKR T80Dokument2 SeitenMOTOROLA Walkie Talkie Consumer Radio TLKR T80Sbnjkt aNoch keine Bewertungen

- Demantra SOP EBS Integration Process v1.0Dokument20 SeitenDemantra SOP EBS Integration Process v1.0kmurali321100% (1)

- CyberOps Skills Assessment - Student TRNG - ExamDokument4 SeitenCyberOps Skills Assessment - Student TRNG - ExamIsabella Leon67% (3)

- DTN NS3Dokument4 SeitenDTN NS3Mirza RizkyNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Manual de Reparacion MCR Serie 32-33Dokument34 SeitenManual de Reparacion MCR Serie 32-33Fernando Tapia Gibson100% (2)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)