Beruflich Dokumente

Kultur Dokumente

SP Hero Meter

Hochgeladen von

J Mar De VeraOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SP Hero Meter

Hochgeladen von

J Mar De VeraCopyright:

Verfügbare Formate

1 of 4

http://www.johnstelescopes.com/HTML/Spherometer.htm

Spherometers

A Spherometer is used to measure the radius of curvature on a surface.

When grinding a telescope mirror, this information can tell you the

focal length of the mirror, and can show you any zones that exist on the

mirror during the grinding process. These zones can then be ground

out in a few minutes.

If you wait untill the mirror has been polished out, you may end up

with a figure like the one shown at left. This 12.5" mirror has 21 waves

of error from the center of the mirror to the edge. This error would

have shown .0015 to .0020" or more variation on a 3" diameter

spherometer. On this particular mirror, after 50 - 60 hours of polishing,

Ronchi image of a 12.5" mirror the error was reduced to 7 waves of error. Then by going back to 220

with over 21 waves of Turned grit, this mirror was finished and properly parabolized to within 1/4

down edge spanning the outer 4.5" wave accuracy in only 10 hours.

of the mirror. This error could

have been avoided following the Note: This error was created by an extra long "W" stroke during

steps on this page.

roughing out with 60 grit silicon carbide. When testing with a foucalt

tester, the tester had to be moved almost four inches to find the neutral

In this condition, a mirror cannot zone between center and edge.

be used for astronomical

observations.

This is the base to one of my spherometers. I prefer to use a three

legged base that is less than half the diameter of the mirror. This

allows the testing of zones across the mirror in addition to measuring

the radius of curvature.

To build a simple but accurate spherometer base ...

Base of my 3" spherometer. Notice

the circular grooves made with a

circle cutter, the three feet, the pin

of the indicator in the center, and

the thumb set screw to keep the

indicator from sliding out of the

hole slowly during use.

This base has holes drilled at 1",

2", and 3" diameter. In use, I have

found that the 3" circle is the only

size I ever use. These other sizes

turned out to be a learning

experience, but ended up being a

1. Find or cut out a circle of wood, plastic, or metal.

2. Mark the exact center of the base.

3. Using a circle cutter, cut a shallow groove at the desired radius.

You do not need three sizes like this base.

4. Make three marks around this circle evenly spaced. The straight

line distance between each point will be the same when all three

points are accurately space. Use a protractor, calipers, ruler, or

two marks on the edge of a piece of paper to compare the spacing

between the three marks.

5. Drill and tap three holes centered on the circular groove for a #6

socket cap screw, or an appropriate size for your feet.

6. For the three feet, I have used #6 socket head cap screws. In the

hex head recess, epoxy small spherical ball bearings. Once set,

the ball bearings make great feet for the spherometer.

7. In the exact center, drill a 3/8" hole. You may need to measure

the stem of your dial indicator to verify it's size. With my two

Mitutoyo indicators, they fit perfectly in a 3/8" hole.

8. If the stem has a little play in the hole, drill and tap a hole going

11/4/2005 11:17 AM

2 of 4

http://www.johnstelescopes.com/HTML/Spherometer.htm

waste of time to create. The base

of my other spherometer only has a

3" circle.

through the edge of the disk to put a thumb screw that can be

used to snug against the stem of the dial indicator.

This is my most accurate spherometer. The dial indicator is made by

Mitutoyo, has 1.0 mm of travel with a resolution of only 1um, or

1/1000 mm. This indicator can only be used after fine grinding with

220 or 320 grit, otherwise, the texture on the glass can cause a

deflection of the needle in excess of 1/4 rotation.

To use a dial indicator ...

This Spherometer uses a dial

indicator. Having a needle on the

face makes it easy to see slight

surface variations while sliding the

indicator across the surface of the

mirror.

1. Set the indicator on the center of the mirror and notice the

position of the needle. The actual measurement is not important.

What is important is to notice the movement of the needle across

the surface of the mirror.

2. Slide the indicator slowly towards the edge of the mirror.

3. NOTE: This indicator turns counter clockwise when the

indicator is lifted off the surface of the mirror, so if your

indicator turns the opposite direction when lifted, the following

information needs to be reversed as well.

4. If the needle rotates counter clock wise, then the edge of the

mirror is turned up.

5. If the needle rotates clockwise, then the surface of the mirror is

turned down.

6. If the needle does not move at all, then the mirror is spherical.

7. If there are inconsistent zones in the mirror, then the needle will

move up and down as the spherometer is slid across the glass.

To determine if the zone is a depression, or a hill, watch the

needle.

8. If the needle turns CCW then CW, the zone is a depression.

9. If the needle turns CW then CCW, the zone is a hill.

10. Repeat these steps across the mirror in several places.

11. To test if the mirror is astigmatic (Potato Chip shaped), slide the

spherometer around the mirror in a circle. If the indicator moves

considerably, then the mirror needs to be ground more to remove

the astigmatism.

12. Our goal when grinding our 8" mirrors is to have the surface

within 3um at the end of 220 grit, 2um at the end of 320 grit, and

1um by the end of 25 and 12 micron. Each small tick mark on

the indicator is 1um, the large printed numbers are actually

10um. If needed, continue grinding untill the surface is within

these tolerances. This will eliminate any bad zones in the mirror

before you start polishing and save many hours of work later.

This is the most convenient indicator I use since the indicator can show

a direct digital reading of the surface deviation. The number on the

indicator is looked up on a chart to give a measurement of the focal

length within 1/4" or so depending on the focal length. This indicator

was a gift from a machinist friend who I helped build a 12" F8

dobsonian telescope for. (Thank-You Rick).

11/4/2005 11:17 AM

3 of 4

http://www.johnstelescopes.com/HTML/Spherometer.htm

To use this indicator ...

1. Make certain the indicator is measuring inches not mm. Press

the in / mm button to switch to inches if needed.

2. Zero the indicator (See the next section below)

3. Place the indicator on the center of the mirror.

4. Look up the reading on the printed chart to determine your focal

length and / or radius of curvature on the glass.

This spherometer uses a digital dial

5. Using the method listed above, test the surface of the mirror.

indicator donated by a friend to

6. If the numbers get larger, the edge is turned up, or the indicator

help me teach others how to build

has gone over a depression.

telescopes. Thanks to this

7. If the numbers get smaller, the edge is turned down, or the

donation, my total cost to build this

indicator has gone over a hill.

indicator was less than $5.

8. Our goal when grinding our 8" mirrors is to have the surface

within .0005" at the end of 80 grit. If needed, continue grinding

with 80 grit untill the surface is within .0005". By using a 1/4 to

1/3 center over center stroke, errors on the mirror can be

corrected in a few minutes saving many hours of work later.

To accurately use a spherometer, it needs to be zeroed. My dial

indicator only needs to be zeroed if it will be used to measure radius of

curvature. However since I use this indicator to only show surface

accuracy across the mirror, not curvature, zeroing is not critical. The

digital indicator must be zeroed before testing the mirror. This way,

the number on the display can be looked up directly from the chart.

From experience, this indicator measures the radius of curvature

extremely accurate. The radius of curvature on the example 8" F4.0

mirror was within 1/64" of the calculated value using the spherometer.

The mirror I use to zero the indicators is a surplus military mirror that

is flat to somewhere around 1/20 wave.

To calculate the radius of curvature, several spreadsheets are available

on the internet. The formula is R = (D^2 + 4*S^2)/8*S where R is the

radius of curvature (twice the focal length), D is the diameter where the

feet are mounted at, and S is the sagitta or the measurement on the dial

indicator. For a more detailed explanation see the Spherometer section

on AtroTel.

To zero the spherometers ...

Using a military surplus mirror to

zero both of my spherometers.

1. Place the spherometer on the surface of the mirror.

2. With the digital indicator, turn it on if needed, then press the zero

button.

3. With the dial indicator, loosen the thumb screw. Carefully slide

the indicator untill the small needle is pointing close to the 1.0

mark. Loosen the set screw and rotate the black ring untill the

number "0" is directly under the needle. You may have to do this

several times since your hand pressure is enough to cause the

needle to move.

4. Once zeroed, test the surface on the mirror.

11/4/2005 11:17 AM

4 of 4

http://www.johnstelescopes.com/HTML/Spherometer.htm

5. Once the test is completed, turn off the digital indicator to save

battery life.

11/4/2005 11:17 AM

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Ford Ranger Electical PDFDokument81 SeitenFord Ranger Electical PDFNapiNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Basic Surveying ManualDokument162 SeitenBasic Surveying ManualEric M Schlogel Jr100% (29)

- Drilling Rig Inspection ChecklistDokument29 SeitenDrilling Rig Inspection ChecklistOmaira Sánchez OrtizNoch keine Bewertungen

- Dwyer A Young Franklin Actuators Frm6UG09Dokument22 SeitenDwyer A Young Franklin Actuators Frm6UG09JavierNoch keine Bewertungen

- Service Manual BB 3002 11 05Dokument551 SeitenService Manual BB 3002 11 05Johan95% (20)

- Mae 1Dokument1 SeiteMae 1J Mar De VeraNoch keine Bewertungen

- Universal Declaration of Human RightsDokument5 SeitenUniversal Declaration of Human RightsJ Mar De VeraNoch keine Bewertungen

- SBDL AttiaDokument2 SeitenSBDL AttiaJ Mar De VeraNoch keine Bewertungen

- 4 E1812 E7 D 01Dokument8 Seiten4 E1812 E7 D 01dianerlinNoch keine Bewertungen

- Writing Introductory, Transitional, and Concluding ParagraphsDokument2 SeitenWriting Introductory, Transitional, and Concluding ParagraphsJ Mar De VeraNoch keine Bewertungen

- Dateien 326Dokument22 SeitenDateien 326J Mar De VeraNoch keine Bewertungen

- 13.48 SBCI-BCCSummaryDokument62 Seiten13.48 SBCI-BCCSummaryMexicoGBCNoch keine Bewertungen

- Fold Res HistoryDokument1 SeiteFold Res HistoryJ Mar De VeraNoch keine Bewertungen

- Edg 65 AhDokument11 SeitenEdg 65 AhJ Mar De VeraNoch keine Bewertungen

- SM 5Dokument43 SeitenSM 5J Mar De VeraNoch keine Bewertungen

- 4933 Viswanathan Chapter 1Dokument96 Seiten4933 Viswanathan Chapter 1J Mar De VeraNoch keine Bewertungen

- ReadmeaaaaaaaaaaaaDokument9 SeitenReadmeaaaaaaaaaaaaChristian Marcos AvalosNoch keine Bewertungen

- ZW 74 Thesis PDFDokument243 SeitenZW 74 Thesis PDFJ Mar De VeraNoch keine Bewertungen

- PDF 1Dokument7 SeitenPDF 1J Mar De VeraNoch keine Bewertungen

- Worth A Second LookDokument533 SeitenWorth A Second LookJ Mar De VeraNoch keine Bewertungen

- Vernier MicrometerDokument3 SeitenVernier MicrometerBaltazar MarcosNoch keine Bewertungen

- Architectural PlansDokument20 SeitenArchitectural PlansJ Mar De VeraNoch keine Bewertungen

- SpecificationsDokument116 SeitenSpecificationsJ Mar De VeraNoch keine Bewertungen

- Taproot Theatre Expansion: Recommenda On Review - Updated PacketDokument22 SeitenTaproot Theatre Expansion: Recommenda On Review - Updated PacketJ Mar De VeraNoch keine Bewertungen

- De Vera, Jaymar B. Ar 321/321D Architectural Design 6Dokument2 SeitenDe Vera, Jaymar B. Ar 321/321D Architectural Design 6J Mar De VeraNoch keine Bewertungen

- 309 S Green - SpecDokument43 Seiten309 S Green - SpecJ Mar De VeraNoch keine Bewertungen

- History 4Dokument300 SeitenHistory 4J Mar De VeraNoch keine Bewertungen

- Plant Classification Description: Pachystachys Lutea NeesDokument5 SeitenPlant Classification Description: Pachystachys Lutea NeesJ Mar De Vera0% (1)

- Your Place or Mine (COMPLETED)Dokument825 SeitenYour Place or Mine (COMPLETED)J Mar De Vera100% (6)

- 10 Signatures To Bargain With GOD PDFDokument23 Seiten10 Signatures To Bargain With GOD PDFNami L.Noch keine Bewertungen

- History 4Dokument300 SeitenHistory 4J Mar De VeraNoch keine Bewertungen

- Urban Panning ArchitectureDokument8 SeitenUrban Panning ArchitectureJ Mar De VeraNoch keine Bewertungen

- KHC Sample Home SpecsDokument28 SeitenKHC Sample Home SpecsAl-Fahme SajiranNoch keine Bewertungen

- PHD-4 Capillary Leak: Model 969-3540Dokument4 SeitenPHD-4 Capillary Leak: Model 969-3540Sándor Tamás ForczekNoch keine Bewertungen

- 122 Sporlan Replacement PartsDokument85 Seiten122 Sporlan Replacement PartsEduardo SouzaNoch keine Bewertungen

- Proximity Switch Testing Proceedure - MaycoDokument3 SeitenProximity Switch Testing Proceedure - MaycoBradley BergNoch keine Bewertungen

- 2006 Honda Civic Rear Brake (Bearing) : Ref Req Your No. Qty. Price Part No. Part Description QtyDokument3 Seiten2006 Honda Civic Rear Brake (Bearing) : Ref Req Your No. Qty. Price Part No. Part Description QtyBrumeNoch keine Bewertungen

- Unit No-01: Ashok Institute of Engineering & Technology, PolytechnicDokument4 SeitenUnit No-01: Ashok Institute of Engineering & Technology, PolytechnicPrathmesh BadheNoch keine Bewertungen

- Led RedDokument12 SeitenLed RedJaz MinNoch keine Bewertungen

- BBU 6201 MaintenanceDokument19 SeitenBBU 6201 MaintenancemarhoumeNoch keine Bewertungen

- Dgs Approved Fire FightingDokument4 SeitenDgs Approved Fire FightingDBSNoch keine Bewertungen

- Welcome To TagDokument72 SeitenWelcome To Tagjohny-joko-4023Noch keine Bewertungen

- IsoAir Pro-E A4Dokument2 SeitenIsoAir Pro-E A4MuhamadFaisalAliNoch keine Bewertungen

- Manual As ClontexDokument4 SeitenManual As ClontexFrancisco MartinezNoch keine Bewertungen

- Safeguarding Cutting and Turning MachinesDokument84 SeitenSafeguarding Cutting and Turning MachinesBianco SantanaNoch keine Bewertungen

- ICARO InstallDokument7 SeitenICARO InstallAdrian MandoleseNoch keine Bewertungen

- Paneles de Distribucion GeDokument89 SeitenPaneles de Distribucion GeLuis D UrciaNoch keine Bewertungen

- DASSTECH Photovoltaic Grid-Connected Inverter/ Junction Box: Operation and Installation ManualDokument29 SeitenDASSTECH Photovoltaic Grid-Connected Inverter/ Junction Box: Operation and Installation ManualManimaran MaranNoch keine Bewertungen

- Buick CatalogueDokument4 SeitenBuick CatalogueBobo VevinaNoch keine Bewertungen

- Parry New Price List - 2021Dokument188 SeitenParry New Price List - 2021Karthigai Selvan100% (1)

- Selection guide for coiled tubing and casing cuttersDokument5 SeitenSelection guide for coiled tubing and casing cuttersSusin LimNoch keine Bewertungen

- IT182 CSC 186 Groupings Report AssignmentDokument1 SeiteIT182 CSC 186 Groupings Report AssignmentSTFUjay1234Noch keine Bewertungen

- AKON Panel CatalogeDokument3 SeitenAKON Panel CatalogeNiravBhalodiyaNoch keine Bewertungen

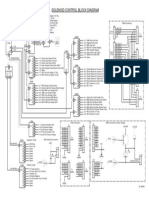

- Solenoid Control Block DiagramDokument1 SeiteSolenoid Control Block DiagramEarliNoch keine Bewertungen

- Gear Box of Feeding Screw Simplex H2NDokument8 SeitenGear Box of Feeding Screw Simplex H2NDulichandNoch keine Bewertungen

- Technical Note - Load Cell Troubleshooting - v1 - February 2016Dokument4 SeitenTechnical Note - Load Cell Troubleshooting - v1 - February 2016Mario MorenoNoch keine Bewertungen

- Solenoid Valve MFH-5-1/4: Data SheetDokument2 SeitenSolenoid Valve MFH-5-1/4: Data Sheetpinjala sivasaiNoch keine Bewertungen

- RAS-08PH1 RAC-08PH1 RAS-10PH1 RAC-10PH1 RAS-14PH1 RAC-14PH1 service manualDokument114 SeitenRAS-08PH1 RAC-08PH1 RAS-10PH1 RAC-10PH1 RAS-14PH1 RAC-14PH1 service manualnmo1122Noch keine Bewertungen

- Tool Makers MicroscopeDokument2 SeitenTool Makers Microscopesukriti dhauni100% (1)