Beruflich Dokumente

Kultur Dokumente

AbattoirsPlantConstructEquipOperation PDF

Hochgeladen von

Anonymous 49VJOeViAOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AbattoirsPlantConstructEquipOperation PDF

Hochgeladen von

Anonymous 49VJOeViACopyright:

Verfügbare Formate

Plant Construction, Equipment and Operation Guidelines

Abattoirs

Plant Construction,

Equipment and

Operation Guidelines

To Qualify for Licensing under the British Columbia

Meat Inspection Regulation

Prepared by:

Food Protection

BC Centre for Disease Control

In Collaboration with:

BC Ministry of Health and the Five Regional

Health Authorities: Vancouver Coastal,

Fraser, Interior, Northern and Vancouver

Island

August 2012

Plant Construction, Equipment and Operation Guidelines

Table of Contents

A.

INSPECTED MEAT AND MEAT PRODUCTS IN BRITISH COLUMBIA .................................................................. 1

B.

GENERAL PRINCIPLES UTILIZED IN THE DEVELOPMENT OF GUIDELINES......................................................... 1

C.

PLANNING AND LOCATING MEAT PLANTS ..................................................................................................... 2

SITE AND LOCATION ........................................................................................................................................................2

APPLICATION FOR APPROVAL ............................................................................................................................................2

APPLICATION DETAIL.......................................................................................................................................................3

D.

GENERAL PLANT CONSTRUCTION STANDARDS .............................................................................................. 4

FLOORS ........................................................................................................................................................................4

DRAINS ........................................................................................................................................................................4

WALLS AND CEILINGS......................................................................................................................................................4

DOORWAYS AND DOORS .................................................................................................................................................5

STAIRS .........................................................................................................................................................................5

LIGHTING ......................................................................................................................................................................6

VENTILATION .................................................................................................................................................................6

WATER SUPPLY..............................................................................................................................................................6

HAND WASHING FACILITIES, SANITIZERS AND HOSE CONNECTIONS..........................................................................................7

REFRIGERATION .............................................................................................................................................................7

WASTE DISPOSAL ...........................................................................................................................................................8

A) Sewage Systems ...........................................................................................................................................8

B) Condemned and Inedible Products ...............................................................................................................8

C) Hide Storage .................................................................................................................................................8

D) Catch Basin ...................................................................................................................................................8

RODENT AND INSECT CONTROL .........................................................................................................................................8

SURROUNDINGS .............................................................................................................................................................8

E.

EQUIPMENT STANDARDS .............................................................................................................................. 9

EQUIPMENT CONSTRUCTION & DESIGN ..............................................................................................................................9

SECTIONS, ROOMS, AND PENS ..........................................................................................................................................9

SPECIAL REQUIREMENTS FOR POULTRY SLAUGHTERING AND PROCESSING ...............................................................................10

F.

SANITATION ................................................................................................................................................ 10

G.

INSPECTION PROCEDURES AND STANDARDS .............................................................................................. 11

H.

TYPICAL LAYOUT: RED MEAT ABATTOIR ...................................................................................................... 12

I.

TYPICAL LAYOUT: POULTRY ABATTOIR ........................................................................................................ 13

-i-

Plant Construction, Equipment and Operation Guidelines

A.

Inspected Meat and Meat Products in British Columbia

A subject of interest to consumers is the assurance that all meat and meat products are properly

inspected for safety and wholesomeness.

There are two types of meat inspection service. One is in registered abattoirs that qualify for federal

inspection and the second is those that qualify under the provincial inspection system. Before abattoirs

can qualify for either inspection service, specific standards of construction must be met through

approval of detailed blueprints and plans. In British Columbia, the BC Centre for Disease Control

currently contracts with the Canadian Food Inspection Agency to provide inspection of abattoirs under

provincial inspection. This booklet identifies the procedures and guidelines to qualify an establishment

for the provincial program.

There are three matters associated with meat inspection that must be clearly understood:

1. Meats inspected under the provincial program are not eligible for export, nor are they allowed to

enter plants under Federal inspection.

2. It is important that the inspection of meat for wholesomeness not be confused with the grading of

meat. Grade terms such as "Canada A1" on beef, are used as indications of quality and are

dependent upon the conformation and finish of the carcass.

3. There are many slaughterhouses licensed under the Livestock Identification Act. These

slaughterhouses are licensed in order that the operators can be forced to keep records of cattle

purchases for use by law enforcement agencies in cases of rustling. This license is not associated

with inspection of carcasses in relation to food safety.

B.

General Principles Utilized in the Development of Guidelines

The principles applied to the development of guidelines for meat slaughter and primary processing

plants have included:

1. The role of government, either Federal or Provincial, should be to monitor food operations and

products to determine and to ensure food products are produced, processed, transported, stored

and offered for sale under acceptable sanitary conditions, and food products must be safe for

human consumption.

The role of industry includes complete responsibility for production, processing, transportation and

sale of food products under acceptable sanitary conditions and ensuring safety for human

consumption.

2. The guidelines should be related to health and safety requirements acceptable in Canada and not

related to additional demands placed on operations by importing countries. This is considered to be

the main difference between Provincial Standards, and Canada Export Standards.

3. The guidelines should be clearly defined for the benefit of both the industry and the consuming

public, and it is the responsibility of the regulatory agency to justify and support prescribed

standards in a meaningful way.

4. At the outset of any program that relates to application of standards, it is reasonable that the

standards should be applied, in total, to all new plants. With respect to existing plants, it is possible

to apply negotiated time frames for standards other than those directly related to consumer health

and safety.

-1-

Plant Construction, Equipment and Operation Guidelines

5. It is essential that the standards/legislation for the humane treatment of food animals be applied to

all meat slaughter plants. There may be certain adjustments required on methods of application,

but the intent and principles must remain intact.

6. The main emphasis should be placed on the purpose and intent of the legislation and standards.

There should be sufficient flexibility in application of guidelines to enable incorporation of newer

methods and techniques, and to accommodate proposals for change where the purpose and intent

can be maintained.

7. There should be a process established whereby industry in particular, and the consuming public in

general, is permitted a continuing review of the standards prescribed and efforts made to

accommodate any valid proposals for change.

8. There are provincial and municipal requirements with respect to meat slaughter plants, which are

not specifically related to the development of these guidelines. It is assumed that, in additional to

these guidelines, the general laws of the land apply.

C.

Planning and Locating Meat Plants

Site and Location

Prior to site selection, plan development, and plant construction, it is essential that all regulatory

requirements of Municipal, Provincial and Federal governments are known. In many instances the initial

action will be assuring that land use and zoning requirements, as well as building codes are recognized.

It is important that land use conflicts or potential conflicts be recognized and addressed at the outset.

Also of importance is early consideration to proposed means of water supply and waste disposal

systems. This is of particular importance where municipal water and waste disposal systems are not

available.

In addition to the requirements that relate to zoning and land use, including approval of the Health

Authority, plants should be located at a site which is free from conditions that might interfere with the

sanitary operation of the plant; (e.g., set reasonably apart from barnyards, stables, dead meat

operations other than approved rendering operations, waste disposal facilities and offensive trades).

Note: Since there are specific technical considerations with respect to site selection, design,

construction, equipment, and operation of slaughter plants, it is recommended that operators

proposing new plants or major revisions to existing plants retain the services of consultants

knowledgeable in the packinghouse industry.

Application for Approval

Application for approval for a provincially licensed slaughter plant should be made through:

Meat Inspection Specialist, Environmental Health Services, BC Centre for Disease Control, 655 12th Ave

W, Vancouver BC V5Z 4R4, 604.707.2453. The application form can be viewed and printed from our

Slaughterhouses webpage.

-2-

Plant Construction, Equipment and Operation Guidelines

Application Detail

A plan, covering the following details, must be submitted with the formal application:

(a) A plot plan showing the boundaries of the plant property; location of the plant in respect to other

buildings or structures; streets; driveways and parking sites including drainage systems and

surfacing materials (e.g., gravel, pavement, etc.); railway lines; sewer lines; gas and water mains;

and power lines. The scale and the north point should be shown;

(b) A floor plan of each level of the plant, showing the purpose for which each room is to be used,

location of walls, partitions, windows, doors, posts, conveyor rails and all equipment (including

draw-off fans, refrigeration units, hose bibs, sanitizers, and hand-wash stations);

(c) A floor plan showing location and size of floor drains, location and size of direct drains for pieces of

equipment using large amounts of water; curbing, gutters and slope of floor towards drains, and the

hot and cold water outlets;

(d) The exterior elevations of the building, showing doors, windows, and platforms;

(e) A cross section of the plant showing ceiling and rail heights;

(f) A roof plan showing skylights, vents, drainage and other pertinent information;

(g) A schedule of room "finishes" must be on or attached to the plans, including a schedule of door

sizes, construction and type of door frame; lighting intensity for each room;

(h) An equipment layout with accompanying "flow charts" of operations. The design and construction

of the equipment must be shown and, where necessary, cross-sections provided to show method of

construction and operation; and

(i) Where the plans refer to significant alterations or changes within an existing plant, the existing

layout and construction should be attached to explain the nature, extent, and effect of proposed

changes.

Note: The plans, as submitted, must also include the following information:

(a) The sewage disposal system to be used (e.g. municipal or private), and preferably,

documentation of approval from the approving agency.

(b) The ventilation system proposed for the plant.

(c) The procedures for humane slaughter.

(d) The procedures for blood collection or disposal.

(e) Complete details of the water supply. The source and water treatment, where necessary,

must be described. Professionally engineered water systems may be required depending on

source and type of meat products being produced. Documentation from the local Health

Authority verifying it has no objection to the plants potable water supply.

(f) The method of handling and disposal of inedible and condemned products is to be

identified.

(g) The ambient temperature of reduced temperature rooms.

-3-

Plant Construction, Equipment and Operation Guidelines

D.

General Plant Construction Standards

Materials used to construct the plant should be strong, durable, and promote maintenance inside and

out. Masonry and steel construction have proven to be the most acceptable.

Floor, wall, and ceiling material, as well as coatings and joint sealant must be of an approved type.

Generally, they must form a durable, smooth, impervious surface, which is readily cleanable.

A list of approved finishing materials can be found in Chapter 3 of the Meat Hygiene Manual, Canadian

Food Inspection Agency, or demonstrated equivalent.

Floors

All workroom floors must be coved and constructed of hard impervious material such as, dense acid

resisting, non-dusting, and waterproof concrete, and graded 1-2cm/m to the drains.

Freezer floors must be provided with adequate insulation to prevent frost penetration into the

underlying soil.

Since plant construction generally determines the plants capability to meet acceptable operating

conditions, floor construction is a major consideration, and must be properly designed to eliminate

future problems.

Drains

An adequate number of floor drains must be provided in all areas of the establishment. The number and

location of drains is determined by the design and volume of the operations. All drain lines must be

sloped, deep seal-trapped, properly vented to the outside air, and equipped with effective rodent

screens. Floors must slope uniformly to drain inlets, with no low spots that could collect liquids. In

critical areas, overhead drain lines should be avoided.

As a general rule, one drain inlet, 30cm x 30cm or equivalent, should be provided for each 40m2 of floor

space. The number of drain inlets and their size should be increased in areas of high water usage to

provide for constant removal of fluid wastes. Direct drainage must be provided for equipment

discharging large volumes of water in order to prevent flooding of surrounding areas.

Where several 10-cm drainage lines discharge into one trunk line, the trunk line must be proportionately

larger in order to effectively handle the fluids discharged into it.

Properly constructed valley drains are permitted if installed as an integral part of the floor. Properly

sloped gutter or channel drains are also permitted if constructed of an acceptable material (metal or

vitreous tile) and covered with removable sectional grated covers. These sectional covers should not be

longer than 120cm.

Note: All drains must be constructed of a material approved by the National Building Code. As well, all

plumbing and drainage must comply with applicable local plumbing and building codes.

Walls and Ceilings

Walls and ceilings must be smooth, level, hard and consist of impervious material such as acceptable

prefabricated panels, and be free from pitting, indentations, cracks, crevices and ledges. All corners and

junctions of walls and floors must be coved in the kill floor, coolers, condemned and processing areas,

and other areas subject to frequent cleaning and moisture. Ceilings should be at least 3.3m in height.

Ceilings of rooms intended for livestock receiving, slaughtering and dressing should be at least 4.8m in

-4-

Plant Construction, Equipment and Operation Guidelines

height. All mortar joints must be smooth and flush. Scoring cement plaster walls should be discouraged.

To promote light reflection and sanitation, wall and ceiling surfaces should be white or light-coloured.

Whenever practical, materials that do not require painting should be used. Materials that are absorbent

and difficult to keep clean must not be used. Examples of unacceptable materials include wood,

plasterboard and porous acoustic-type boards. Walls should be provided with suitable sanitary-type

bumpers or sloped curbs to protect them from damage by hand trucks or lifters.

Windowsills should be at least 1m from the floor to avoid damage on impact from chill tanks, lifters and

hand trucks.

Ceilings of interlocking, rust-resistant metal sheeting, such as heavy gauge, heavy-duty, galvanized steel,

anodized aluminum or stainless steel are permitted if fastened to the metal infrastructure by accept

able means. When galvanized metal is used, the zinc coating must be at least ASTM A525 grade G-90.

Open joist construction of ceilings is permitted, provided joists are treated to prevent rusting, corrosion,

dust accumulation and can be readily cleaned and sanitized.

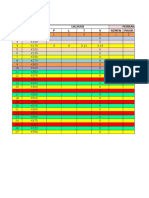

Rails in the establishment must be properly designed and constructed. The following table outlines

minimum rail heights and configurations depending on species in the various sections of an

establishment.

Rail Height Guidelines

BLEEDING

DRESSING

Minimum

distance from

top of rail to

floor

Minimum

distance from top

of rail to floor

Minimum

distance from

top of rail to

floor

Maximum distance

from top of rail to

shackle contact

point on carcass

Minimum

distance from

spacing from

walls, pillars, etc.

Cattle

3.7m

3.1m

3.1m

30cm

60cm

Calves

3.7m

(or above level of

inspection platform)

2.4m

30cm

60cm

Sheep and

Goats

2.4m

(or above level of

inspection platform)

2.0m

30cm

60cm

SPECIES

COOLER

2.4m

2.0m

Swine

Head on

Head off

Horses

2.6m

2.7m

(above slickers

platform)

3.1m

2.4m

30cm

60cm

4.3m

3.4m

3.4m

38cm

60cm

Doorways and Doors

Doorways should be a minimum of 1.5m wide so that products transferred on rails, hand trucks or lifters

do not come in contact with them. Doors and doorjambs should be made of rust-resistant material and

be self-closing. The juncture between the wall and the doorjamb must be sealed with a flexible sealing

compound. All doors leading outside must be self-closing.

Stairs

All stairs in product-handling rooms should be of impervious material with solid treads, dosed risers and

curbed sides of at least 5cm in height, measured at the front edge of the tread. Catwalks (or

mezzanines) above processing areas should be of solid masonry or metal construction with raised edges.

-5-

Plant Construction, Equipment and Operation Guidelines

Lighting

All areas of the plant must be properly lighted, and generally provided with a minimum intensity of not

less than 200 lux. Where special illumination is required for the proper conduct of work by plant

employees and inspectors, an illumination intensity of at least 1,000 lux must be in place. To prevent

glare and provide the maximum illumination, special attention must be given to the amount and

direction of lighting in inspection areas. Readings should be taken at a height of 1m or at the work

situation. The lighting intensity of beef coolers should be measured at the front shank level of carcasses

in a full cooler.

Artificial light sources must not impart illumination that distorts the normal appearance of meat. Normal

non-colour corrected lights are acceptable. Meat products must be protected from contamination

resulting from the breakage or shattering of light sources or fixtures.

Note: The electrical service must meet National Building Code standards as well as provincial and local

codes.

Ventilation

In planning and designing a plant's ventilation system, care must be taken to separate departments,

control air movement and eliminate undesirable conditions such as steam, excess moisture, odours,

dust, dirt or variations in temperature.

Airflow systems should be designed to create a positive air flow from dean to soiled areas (i.e.

processing to kill floor). Adequate means must exist to provide sufficient exchange of air in all parts of

the licensed establishment, and to keep air fresh, free of odours, steam and vapour. All refrigerated

rooms must be kept free of excessive moisture. Refrigerated rooms must be kept free of excessive

moisture with a recommendation to have at least five changes of air per hour.

Fresh air intakes should not be located in an area prone to contamination sources such as odours, dust,

or smoke. Air intakes must be equipped with effective filters, which prevent the entry of insects or dust.

In refrigerated workrooms, mechanical ventilation must keep walls and ceilings free of condensation.

All equipment that produces heat, steam, vapour, smoke or odour must be properly vented. Hightemperature edible and inedible rendering equipment, dryers and evaporators must be equipped with

condensers.

Windows in operational rooms of meat plants must be of a type and installed in such a manner that no

contamination of meat products can occur. With existing plants, windows will be acceptable subject to

site specific evaluation and time frame negotiations.

Water Supply

Hot and cold potable water, under adequate pressure, and in sufficient quantities, must be provided

throughout the plant. The operator is responsible for the water supply and must ensure the water is

bacteriologically and chemically safe. Water samples must be forwarded to a recognized municipal or

provincial laboratory at a frequency deemed necessary by the inspector based on source and/or on

historical sampling records. Water potability certificates obtained by licensed establishments must

confirm potability of water and ice according to local and provincial standards.

If non-potable water is used for fire prevention or for condensers in refrigeration systems, it must be

kept entirely separate from the potable water system, clearly identified, and never used where edible

products are processed, handled, packaged, or stored.

-6-

Plant Construction, Equipment and Operation Guidelines

If automatic chlorinators are used in a licensed establishment, management must establish procedures

to ensure quality control for water potability. Two fundamental controls include:

(a) an automatic metering device for adding chlorine in the correct concentration. A warning device to

indicate malfunction may be required,

(b) at least twice daily, tests shall be made to determine free residual chlorine level, at a specific point

following thorough mixing in the water system .

Records of residual chlorine tests must be maintained by the operator, and be made available to

inspection staff as required. A reliable chlorine test kit must be provided in order that in-plant

monitoring can be achieved.

Hand Washing Facilities, Sanitizers and Hose Connections

Hot and cold water hand washing facilities (remote control operated is recommended) must be easily

accessible to all processing and slaughtering areas. These facilities must be serviced with dispensable

soap and paper towels.

Rust-resistant metal sanitizers, of appropriate size and number must be provided, so that knives and

saws can be sanitized. Sanitizers should be able to maintain a temperature of 82C, be equipped with an

overflow, and, except in the kill floor area, connected to a drain.

In poultry establishments, sanitizers are required at the following stations: trimming, neck cutting and

giblet salvage.

To facilitate room and equipment clean-up, an adequate number of hose connections must be provided

throughout a licensed establishment. Hot water, of at least 82C must be available at the point of

discharge to sanitize equipment during slaughter, evisceration, and processing operations. For general

clean-up operations, water may be kept at a lower temperature, provided satisfactory cleaning and

sanitizing agents are used. Dial-type thermometers should be installed at hose outlets or at the source of

hot water supply. If the temperature indicator is located at the source of hot water supply, then the

distance to the outlet must be taken into consideration. The use of long hoses should be avoided. Suitable

racks or reels for hose storage should be in place.

Refrigeration

The requirements for refrigerated storage and capacity will depend on the site-specific operation and as

such, minimum sizes are not included in this document.

Carcasses must be promptly chilled and placed in adequately refrigerated and conveniently located

rooms. Unchilled carcasses must not be placed with those that have already been chilled. To properly

chill carcasses, the internal temperature (at the bone in the deep musculature) should be brought to

4C, within a minimum period of time. In order to achieve proper cooling, chill coolers should be

maintained at 2C. Holding coolers must be maintained at 4C. A suitable area must be designated in a

cooler for chilling and storing "held carcasses" and parts. This section should be segregated from the

remainder of the cooler and sealed or locked. A sufficient length of side rail, equipped with lockable

devices (i.e. lockable rail) may be sufficient for these purposes.

Offal coolers must be adequately refrigerated and constructed such that the internal offal temperature

is lowered to 4C or less as quickly as possible after evisceration.

All sharp freezers should be at -30C or less and holding freezers at -18C or less. All freezer rooms used

for the destruction of Trichinella must be equipped with locked thermographs and facilities.

-7-

Plant Construction, Equipment and Operation Guidelines

Processing rooms should be kept at a temperature of 10C. Otherwise, meat products can only be out of

refrigeration for a period of 2 hours or less and an associated HACCP-based safety protocol is required.

Waste Disposal

A)

Sewage Systems

Sewage disposal systems, either municipal or private systems must be provided at all plants and must

comply with all municipal and provincial requirements. Plan submissions will preferably be accompanied

by a letter from the authority having jurisdiction stating that the proposed system is acceptable.

B)

Condemned and Inedible Products

The requirements for handling condemned and inedible products will vary with each plant. The intent is

to provide:

(i) Proper separated storage for condemned and inedible products. In some cases, a separate room will

be required; in smaller operations use of metal containers with lids is satisfactory.

(ii) Proper means for collecting and removing from the premises these products in such a manner that

no objectionable condition occurs. It is recognized that local assessment and decision may be

necessary.

C)

Hide Storage

Where hides are salvaged, a hide storage room maintained in good sanitary condition must be provided.

In small volume plants, where hide pick-up arrangements are made for removal at the close of each

day's kill, this room may be incorporated with the condemned room.

D)

Catch Basin

Catch basins, grease traps, interceptors and other means of separating organic matter from plant

effluent should be located in the inedible section of the plant or outside. These facilities should be

constructed such that skimmings are not moved through an edible area, and that ease of maintenance

and sanitizing are achieved.

Rodent and Insect Control

Construction must be such that flies, insects, and rodents are prevented from entering the plant.

Examples of preventative measure can include items such as self closing, sealed doors, effective screens

on all windows and other openings, "fly chaser" fans, ducts, or similar devices. As well, fly and insect

control must also occur in the livestock section and plant surroundings.

Surroundings

Roadways on the premises should be properly graded, dust-proofed, and drained in order to prevent

the collection of water or dust.

No portion of an establishment can be used as living quarters unless it is permanently separated from

the establishment by a wall, floor, or ceiling. There can be no direct access from the living quarters to

any part of the establishment.

-8-

Plant Construction, Equipment and Operation Guidelines

E.

Equipment Standards

Equipment Construction & Design

In general, the equipment used should be of simple design, easily cleaned, and made of non-corrosive

and rust-resistant material such as stainless steel. The use of wood in meat production and handling

areas is prohibited other than in freezers and dry storage areas.

Stainless steel used in meat plants should be of 300 or 18/8 series because of its superior corrosion

resistance.

New materials containing plastics, resins, fibreglass, and latex must receive approval prior to installation

and use. As previously stated the main criteria for equipment approval is ease of cleaning and

inspection. To facilitate dismantling, quick-opening devices that require simple or no tools is preferred.

Contamination by drippings from bearings, lubricants, gears, and motors must be prevented. On welded

equipment, all welded joints must be continuously smooth and even. Where stuffers and grinders are

used, metal detectors should be provided.

Stationary equipment must be located in such a manner to provide sufficient access for cleaning. Long

chutes are discouraged, but if used, then must be demountable for cleaning.

Sections, Rooms, and Pens

Livestock pens, chutes and/or squeezes must be provided at all slaughtering operations. All floors,

alleyways, and chutes should be paved, properly drained, scored, cleated, and properly inclined to

prevent slipping. As well, space must be provided to observe the animals in motion for the ante-mortem

inspection.

Pre-slaughter holding pens should be constructed of acceptable masonry and metal construction. As

well, these pens must have adequate lighting and ventilation and be constructed to permit daily

washing.

Stunning and bleeding areas must be constructed to ensure the humane treatment of animals.

Bleeding areas should be curbed and adequately graded to properly sized blood and wash-up drains in

order to prevent blockage.

Regarding slaughter and dressing rooms, several basic principles must be considered to ensure the

operation is operated and maintained in a sanitary manner. These principles include:

a) Rooms of adequate size and shape to provide ample space for all operations.

b) Adequate segregation must be provided when more than one species of animals is on the same

floor.

c) Minimum rail heights and configuration depending on species.

d) A heldrail for all inspection and further trimming of carcasses.

e) Adequate spacing of carcasses to facilitate sanitary dressing.

f) Measures to prevent splashing and cross-contamination by carcass movement.

g) Sufficient and properly located hot and cold-water outlets for clean-up purposes, sanitizing and

hand-washing facilities.

h) Sufficient space and facilities for soaking, scrubbing, and cleaning of hide-on calf carcasses.

i) Adequate facilities and floor space for beef head inspection and processing.

-9-

Plant Construction, Equipment and Operation Guidelines

j) In the slaughter of swine, an adequately sized and properly located scalding tank.

k) When viscera inspection trucks are used, adequate facilities are provided, which facilitate frequent

washing and sanitizing.

l) Where edible offal is harvested, the layout and equipment must be such that this step is carried out

in a sanitary manner.

Processing rooms must be equipped with adequate lighting, ventilation, and freedom from steam and

condensation in order to ensure the sanitary production of prepared meat products. Room size and

equipment layout must be carefully planned to ensure risk from environmental, equipment, or

personnel contamination is minimized.

Processing rooms, except those used for cooking, formulation, or preparation of meat products prior to

cooking (or handling relatively stable food products) must be maintained at 10C or lower.

Smokehouses must be constructed, equipped, and drained so they can be easily and regularly cleaned.

Each smokehouse must be properly vented and equipped with an accurate recording thermometer.

Dry storage rooms must be located and designed to protect against dust, moisture, and other

undesirable conditions. These rooms must be maintained in a clean and sanitary condition at all times.

Rooms used for packaging, shipping, and receiving fresh cured and perishable meat products must be

maintained at a temperature of 10C or lower. Otherwise, meat products can only be out of

refrigeration for a period of 2 hours or less and an associated HACCP based safety protocol is required.

Shipping areas or docks must be constructed to ensure product is protected from inclement weather

conditions.

An office must be provided for the use of meat inspection staff in all meat plants. As a guide, an

appropriate office for use by one inspector is a minimum of 3m X 3.6m, and correspondingly increased

to accommodate 2 or more inspectors, and located separate from the operational area of the

establishment.

Special Requirements for Poultry Slaughtering and Processing

General construction standards are similar as for those required for other meat processing

establishments. However, because of the special operational requirements necessary in a poultry plant

additional consideration must be given regarding a poultry plant's layout. The general layout of a poultry

slaughter and processing establishment must follow the ensuing sequence: live receiving, hanging,

stunning, bleeding, scalding, plucking, singeing, washing, evisceration, inspection, trimming, washing,

chilling, further processing (if not sold in carcass form), packaging, freezing, (if not sold fresh), and

shipping. Of primary importance, is the assumption that operations are designed and laid out to reduce

contamination of the finished product.

F.

Sanitation

The production of meat and meat products under hygienic conditions is critical in ensuring a safe and

wholesome product. As such, a written sanitation program must be included in a meat plant's general

maintenance plan and is regarded as a fundamental operational requirement.

The sanitation program is a comprehensive document and outlines those cleaning and sanitizing

functions, which ensure the hygienic maintenance of the building, each piece of equipment and each

step in the operation. The contents of the sanitation program will vary between meat plants depending

on plant functions and products produced but should include the following:

- 10 -

Plant Construction, Equipment and Operation Guidelines

Those steps for cleaning and disinfecting all pieces of equipment the building interior, and the

building exterior.

General housekeeping practices (garbage collection and waste disposal both during and after

operations).

A description of critical areas within the operation and details to ensure control of these areas.

Steps to be taken during the pre-operational inspection, and the operational inspection, to ensure

the equipment and product are maintained in a sanitary manner prior to and during operations.

Personal hygiene of employees and steps management will undertake to ensure these requirements

are consistently met.

The proper storage and use of all ingredients (both meat and non-meat) with regard to freedom of

any type of extraneous contamination.

G.

Inspection Procedures and Standards

Since the production of clean and wholesome meat is the primary objective, there are particular areas

and activities in the plant that are critical to ensuring this objective. These areas and activities are briefly

outlined as follows:

Daily pre-operational inspections of all rooms and areas in which animals and/or meat products are

processed. The objective of this inspection is the maintenance of environmental, equipment and

personnel conditions that will help ensure only wholesome meat products are produced.

Ante-mortem inspections of animals.

Post-mortem inspections of animals.

Re-inspection of carcasses and/or meat products.

Daily and frequent inspections of all aspects of the process during operations from killing to final

dressing.

- 11 -

H.

Typical Layout: Red Meat Abattoir

- 12 -

I.

Typical Layout: Poultry Abattoir

- 13 -

Das könnte Ihnen auch gefallen

- Pedi-EAT Full Version 2022-1-15Dokument19 SeitenPedi-EAT Full Version 2022-1-15Sara Gomes CastroNoch keine Bewertungen

- Microbial Ecology of Foods V1: Factors Affecting Life and Death of MicroorganismsVon EverandMicrobial Ecology of Foods V1: Factors Affecting Life and Death of MicroorganismsNoch keine Bewertungen

- Introduction To Vertically Integrated Chicken ProductionDokument14 SeitenIntroduction To Vertically Integrated Chicken ProductionPearl Igboegwu UzokweNoch keine Bewertungen

- Sausages Production Unit Pre-Feasibility StudyDokument29 SeitenSausages Production Unit Pre-Feasibility StudyAhsan Hanif50% (2)

- What in The Cell Is Going On - The Battle Over PHDokument13 SeitenWhat in The Cell Is Going On - The Battle Over PHBiljana100% (1)

- Australian Wombaroo DietDokument5 SeitenAustralian Wombaroo DietBenjaminYoungNoch keine Bewertungen

- Quantum HealingDokument12 SeitenQuantum Healingvbedelli525Noch keine Bewertungen

- Training Manual For Meat HandlersDokument56 SeitenTraining Manual For Meat HandlersSoiab KhanNoch keine Bewertungen

- Food Protection and Security: Preventing and Mitigating Contamination during Food Processing and ProductionVon EverandFood Protection and Security: Preventing and Mitigating Contamination during Food Processing and ProductionShaun KennedyNoch keine Bewertungen

- Food Control System Assessment Tool: Dimension B – Control FunctionsVon EverandFood Control System Assessment Tool: Dimension B – Control FunctionsNoch keine Bewertungen

- Rice Inspection HandbookDokument337 SeitenRice Inspection HandbookAndres Felipe Aldana RicoNoch keine Bewertungen

- Food and Nutrition Handbook WFPDokument130 SeitenFood and Nutrition Handbook WFPAlice AliceNoch keine Bewertungen

- BRCGS Pack6Module10 V.3Dokument20 SeitenBRCGS Pack6Module10 V.3Anonymous XfIF3HdNoch keine Bewertungen

- EAS 742 2021 Food Grade Cassava Starch SpecificationDokument10 SeitenEAS 742 2021 Food Grade Cassava Starch SpecificationFelix MwandukaNoch keine Bewertungen

- More Dairy Output From Less Input: The New Generation of Aseptic SolutionsDokument8 SeitenMore Dairy Output From Less Input: The New Generation of Aseptic SolutionsĐivềphía Mặt TrờiNoch keine Bewertungen

- Quick Guide For Global StandardsDokument8 SeitenQuick Guide For Global StandardsMônica Miyuki Ito ScognamilloNoch keine Bewertungen

- Code of Hygienic PracticeDokument29 SeitenCode of Hygienic Practicenitu_gNoch keine Bewertungen

- Practical Manual for Meat Hygiene and Abattoir ManagementDokument147 SeitenPractical Manual for Meat Hygiene and Abattoir ManagementDr Bineesh C Vijay0% (1)

- The Classification of CottonDokument23 SeitenThe Classification of CottonTeka Weldekidan Abebe100% (1)

- Meat InspectorDokument306 SeitenMeat InspectororigatNoch keine Bewertungen

- NanotechnologyApplicationsintheFoodIndustry PDFDokument319 SeitenNanotechnologyApplicationsintheFoodIndustry PDFjesus cuevasNoch keine Bewertungen

- Comparison of BRCGS, SQF & FSSC Packaging StandardsDokument2 SeitenComparison of BRCGS, SQF & FSSC Packaging StandardsFLed NguyenNoch keine Bewertungen

- Case Study Meat ProcessingDokument2 SeitenCase Study Meat ProcessingChirag GoelNoch keine Bewertungen

- Cocu 3 - Slaughtering Hygiene and Sanitation InspectionDokument9 SeitenCocu 3 - Slaughtering Hygiene and Sanitation InspectionsyueadashebangNoch keine Bewertungen

- Food and Agricultural Import Regulations and Standards - Narrative - Tokyo - Japan - 8!19!2009Dokument12 SeitenFood and Agricultural Import Regulations and Standards - Narrative - Tokyo - Japan - 8!19!2009Nguyen Thuy100% (1)

- Modified Atmosphere PackagingDokument17 SeitenModified Atmosphere PackagingMaryam ZaraNoch keine Bewertungen

- Poultry Industry: Beef Industry Swine Industry Equine Industry Aquaculture Industry Poultry Industry Other IndustriesDokument3 SeitenPoultry Industry: Beef Industry Swine Industry Equine Industry Aquaculture Industry Poultry Industry Other IndustriesNasimNoch keine Bewertungen

- Introduction To ISO 22000Dokument32 SeitenIntroduction To ISO 22000Anil Kumar SinghNoch keine Bewertungen

- Intertek: Rice-Paddy Information.Dokument60 SeitenIntertek: Rice-Paddy Information.nsopheaNoch keine Bewertungen

- 7.microbiology of MeatsDokument21 Seiten7.microbiology of MeatsMahesh DevasigamaniNoch keine Bewertungen

- Islamic Consumer GoodsDokument20 SeitenIslamic Consumer GoodsSarah IdrisNoch keine Bewertungen

- Handbook p1-32Dokument33 SeitenHandbook p1-32api-19734900Noch keine Bewertungen

- Regulate Livestock FeedsDokument8 SeitenRegulate Livestock FeedsmelNoch keine Bewertungen

- Coleac001 Pip Module 1 Uk PP PDFDokument342 SeitenColeac001 Pip Module 1 Uk PP PDFMonica SinghNoch keine Bewertungen

- General Standard For Food Additives PDFDokument107 SeitenGeneral Standard For Food Additives PDFMercyNoch keine Bewertungen

- Food safety programs in fish processingDokument29 SeitenFood safety programs in fish processingnataliatirtaNoch keine Bewertungen

- Meat Hygiene Assessment 2nd EdDokument131 SeitenMeat Hygiene Assessment 2nd EddoctorraslanNoch keine Bewertungen

- Meat Inspection GuidelineDokument43 SeitenMeat Inspection GuidelineABOHEMEED ALY0% (1)

- Shelf Life of Australian Red Meat 2nd EditionDokument182 SeitenShelf Life of Australian Red Meat 2nd EditionLinhPhạm100% (1)

- World of Stork Poultry enDokument24 SeitenWorld of Stork Poultry enRoxana Atomei100% (1)

- Guidelines For Glass Manufacturers: Packaging MaterialsDokument23 SeitenGuidelines For Glass Manufacturers: Packaging MaterialskhalidasyNoch keine Bewertungen

- Gso 1016 2015Dokument26 SeitenGso 1016 2015Anil Yadav100% (1)

- Slaughtering AustraliaDokument47 SeitenSlaughtering AustraliaEpic ProcrackNoch keine Bewertungen

- Overview of Food Quality by M.SivarajanDokument27 SeitenOverview of Food Quality by M.SivarajanervaishaliNoch keine Bewertungen

- Forms - HACCP Implementation ManualDokument18 SeitenForms - HACCP Implementation ManualShree PunekarNoch keine Bewertungen

- Microbiology of Wheat and Flour Milling in AustraliaDokument13 SeitenMicrobiology of Wheat and Flour Milling in AustraliaTanatat BunprasopNoch keine Bewertungen

- Review of The Dairy Industry in MauritiusDokument81 SeitenReview of The Dairy Industry in MauritiusStephane RacineNoch keine Bewertungen

- GDL in Meat ProcessingDokument3 SeitenGDL in Meat Processingadiy0n9100% (1)

- HEB EspecificacionesDokument7 SeitenHEB EspecificacionesAna María SnzNoch keine Bewertungen

- Design and Construction of Food PremisesDokument62 SeitenDesign and Construction of Food PremisesAkhila MpNoch keine Bewertungen

- Final - Print Adh Lam Slit - May 6 2010Dokument22 SeitenFinal - Print Adh Lam Slit - May 6 2010cassilda_carvalho@hotmail.comNoch keine Bewertungen

- Burger FactoryDokument103 SeitenBurger FactoryAlveena JanjuaNoch keine Bewertungen

- Frying OilsDokument10 SeitenFrying OilsSuryadi XuNoch keine Bewertungen

- China GB4789.40 2010 Food Microbiological Examination Enterobacter Sakazakii PDFDokument13 SeitenChina GB4789.40 2010 Food Microbiological Examination Enterobacter Sakazakii PDFmmoradi55Noch keine Bewertungen

- PCQI BrouchureDokument6 SeitenPCQI BrouchuresuchivapgmailcomNoch keine Bewertungen

- 2073 2005 For Manufacturers FINALDokument6 Seiten2073 2005 For Manufacturers FINALjercherwinNoch keine Bewertungen

- Maximizing rice yields with proper harvesting techniquesDokument35 SeitenMaximizing rice yields with proper harvesting techniquesRiza AriannurNoch keine Bewertungen

- USDA Meat Inspection and The Humane Methods of Slaughter ActDokument6 SeitenUSDA Meat Inspection and The Humane Methods of Slaughter ActMd. Naim KhanNoch keine Bewertungen

- Ai 410 e 00Dokument27 SeitenAi 410 e 00Lukman PitonoNoch keine Bewertungen

- Navigating The Mayonnaise MazeDokument21 SeitenNavigating The Mayonnaise MazeViệt Phước LêNoch keine Bewertungen

- Animal Feed MillDokument33 SeitenAnimal Feed MillEdgar Diaz NietoNoch keine Bewertungen

- Food Safety in the Seafood Industry: A Practical Guide for ISO 22000 and FSSC 22000 ImplementationVon EverandFood Safety in the Seafood Industry: A Practical Guide for ISO 22000 and FSSC 22000 ImplementationNoch keine Bewertungen

- Control of Salmonella and Other Bacterial Pathogens in Low-Moisture FoodsVon EverandControl of Salmonella and Other Bacterial Pathogens in Low-Moisture FoodsRichard PodolakNoch keine Bewertungen

- Sim Asn - PDFDokument2 SeitenSim Asn - PDFAnonymous 49VJOeViANoch keine Bewertungen

- Wavin AW 0Dokument2 SeitenWavin AW 0Anonymous 49VJOeViANoch keine Bewertungen

- Audi LogDokument1 SeiteAudi LogAnonymous 49VJOeViANoch keine Bewertungen

- Tabel BetonDokument3 SeitenTabel BetonAnonymous 49VJOeViANoch keine Bewertungen

- Upload AhDokument1 SeiteUpload AhAnonymous 49VJOeViANoch keine Bewertungen

- Daftar Harga Sewa Alat: No. Jenis Peralatan Harga/Jam Keterangan KodeDokument1 SeiteDaftar Harga Sewa Alat: No. Jenis Peralatan Harga/Jam Keterangan KodeAnonymous 49VJOeViANoch keine Bewertungen

- Tabel BetonDokument3 SeitenTabel BetonAnonymous 49VJOeViANoch keine Bewertungen

- Tabel BetonDokument3 SeitenTabel BetonAnonymous 49VJOeViANoch keine Bewertungen

- Tabel BetonDokument3 SeitenTabel BetonAnonymous 49VJOeViANoch keine Bewertungen

- 11company Profile Profil PerusahaanDokument6 Seiten11company Profile Profil PerusahaanYogi WibisonoNoch keine Bewertungen

- Sub PasswordBreakerDokument2 SeitenSub PasswordBreakerAnonymous 49VJOeViANoch keine Bewertungen

- Tenaga AhliDokument6 SeitenTenaga AhliAnonymous 49VJOeViA100% (1)

- Supply Chain Financing, Supplier Financ PDFDokument2 SeitenSupply Chain Financing, Supplier Financ PDFAnonymous 49VJOeViANoch keine Bewertungen

- AHS 2014 - Upload OK FIX PDFDokument542 SeitenAHS 2014 - Upload OK FIX PDFAnonymous 49VJOeViANoch keine Bewertungen

- Niven Brochure Modular PDFDokument7 SeitenNiven Brochure Modular PDFAnonymous 49VJOeViANoch keine Bewertungen

- ProfessorDokument3 SeitenProfessorAnonymous 49VJOeViANoch keine Bewertungen

- Upload AhDokument1 SeiteUpload AhAnonymous 49VJOeViANoch keine Bewertungen

- Tenaga AhliDokument6 SeitenTenaga AhliAnonymous 49VJOeViA100% (1)

- Upload AhDokument1 SeiteUpload AhAnonymous 49VJOeViANoch keine Bewertungen

- Upload AhDokument1 SeiteUpload AhAnonymous 49VJOeViANoch keine Bewertungen

- Wavin AW 0Dokument2 SeitenWavin AW 0Anonymous 49VJOeViANoch keine Bewertungen

- Upload AhDokument1 SeiteUpload AhAnonymous 49VJOeViANoch keine Bewertungen

- Upload AhDokument1 SeiteUpload AhAnonymous 49VJOeViANoch keine Bewertungen

- Upload AhDokument1 SeiteUpload AhAnonymous 49VJOeViANoch keine Bewertungen

- Upload AhDokument1 SeiteUpload AhAnonymous 49VJOeViANoch keine Bewertungen

- Upload AhDokument1 SeiteUpload AhAnonymous 49VJOeViANoch keine Bewertungen

- Upload AhDokument1 SeiteUpload AhAnonymous 49VJOeViANoch keine Bewertungen

- Upload AhDokument1 SeiteUpload AhAnonymous 49VJOeViANoch keine Bewertungen

- Upload AhDokument1 SeiteUpload AhAnonymous 49VJOeViANoch keine Bewertungen

- WHLP GRADE 6 - Week 2-8Dokument4 SeitenWHLP GRADE 6 - Week 2-8jovilyn brioso83% (6)

- Benefits of planting trees and fruit-bearing treesDokument2 SeitenBenefits of planting trees and fruit-bearing treesCalNoch keine Bewertungen

- Measure Food Safety CultureDokument12 SeitenMeasure Food Safety Cultureômąŕ ĕżžãőůįNoch keine Bewertungen

- Kids in The KitchenDokument148 SeitenKids in The KitchenIvy Jorene Roman Rodriguez100% (1)

- Fish Processing: By: Laureno, Divina Villaver Dela Cruz, Cedrick P. Estor, Vanessa RDokument24 SeitenFish Processing: By: Laureno, Divina Villaver Dela Cruz, Cedrick P. Estor, Vanessa REstor, Vanessa R.Noch keine Bewertungen

- Calcium fortification in dairy products: The calcium challengeDokument4 SeitenCalcium fortification in dairy products: The calcium challengetarekscribdNoch keine Bewertungen

- TP Magazine No 100 PDFDokument48 SeitenTP Magazine No 100 PDFKhemiri WajdiNoch keine Bewertungen

- Business Plan EditedDokument38 SeitenBusiness Plan EditedAlyssa AlegadoNoch keine Bewertungen

- Functional Food and BiotechnologyDokument16 SeitenFunctional Food and BiotechnologyRuth ChrisnasariNoch keine Bewertungen

- Gujarat - Leaflet Diet On AnginaDokument2 SeitenGujarat - Leaflet Diet On AnginaAli SyedNoch keine Bewertungen

- WatermelonDokument46 SeitenWatermelonPervez Abubaker100% (2)

- Ms 1500 2009Dokument26 SeitenMs 1500 2009Mohd Takrimi Moh ArifinNoch keine Bewertungen

- Black Pepper Oleoresin Spec SheetDokument1 SeiteBlack Pepper Oleoresin Spec SheetSaid GerbrNoch keine Bewertungen

- Faina DovleacDokument9 SeitenFaina DovleacDana Iulia MoraruNoch keine Bewertungen

- Who Do You Live With?: at The MomentDokument10 SeitenWho Do You Live With?: at The MomentThuy linh Huynh thi100% (1)

- Fenugreek SeedDokument11 SeitenFenugreek SeedIJRASETPublicationsNoch keine Bewertungen

- SOAL-Latihan Soal UN Bahasa InggrisDokument4 SeitenSOAL-Latihan Soal UN Bahasa Inggrishepy handayaniNoch keine Bewertungen

- Nudge Database 1.2 PDFDokument28 SeitenNudge Database 1.2 PDFChris CooksleyNoch keine Bewertungen

- The Vintage (A Sample Business Plan Draft)Dokument23 SeitenThe Vintage (A Sample Business Plan Draft)Don Joreck SantosNoch keine Bewertungen

- Effects of Environment on Organism Life CyclesDokument7 SeitenEffects of Environment on Organism Life CyclesEfigenia Macadaan FontillasNoch keine Bewertungen

- Amezcua Bio Disc 2: Revolutionary Wellness Product for a Balanced LifestyleDokument52 SeitenAmezcua Bio Disc 2: Revolutionary Wellness Product for a Balanced LifestyleDikeyzam Tibi LandNoch keine Bewertungen

- Sugar Free Diet Sugar ControlDokument3 SeitenSugar Free Diet Sugar Controlwonder2006100% (1)

- 1 Binswanger-MkhizeDokument17 Seiten1 Binswanger-MkhizeSauby LongangNoch keine Bewertungen

- Burger King's 1991 focused Whopper advertising strategyDokument8 SeitenBurger King's 1991 focused Whopper advertising strategyChristy MachaalanyNoch keine Bewertungen

- QuimicaDokument2 SeitenQuimicaSILVIA FERNANDA ALDANA CASTELLANOSNoch keine Bewertungen

- Veggie Kitchen KidsDokument32 SeitenVeggie Kitchen KidsgregNoch keine Bewertungen