Beruflich Dokumente

Kultur Dokumente

P10C-D201 Especificaciones Model C

Hochgeladen von

William ValenciaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

P10C-D201 Especificaciones Model C

Hochgeladen von

William ValenciaCopyright:

Verfügbare Formate

WEMCO

DATA SHEET

WEMCO TORQUE-FLOW PUMPS

P10C-D201

11-11-08

Supersedes P10C-201

dated 3-15-04

WEMCO Model C Master Suggested Specification

HORIZONTAL, SEVERE-DUTY, NON-CLOGGING,

VORTEX-TYPE SLURRY

Packing or WEMCO Slurry Seal

Belt Drive or (special) Direct Connected Mounting

PART 1

Page 1

GENERAL

1.01

There shall be supplied as shown by the plans

horizontal vortex-type slurry

pumping unit(s) specifically designed to pump slurries of grit, debris and organic

solids without clogging.

1.02

QUALITY ASSURANCE

1.03

A.

All pumping equipment furnished under this Section shall be of a design

and manufacture that has been used in similar applications and it shall be

demonstrated to the satisfaction of the Owner that the quality is equal to

equipment made by that manufacturer specifically named herein.

B.

To insure a consistent high standard of quality, the manufacturer of this

pumping equipment shall comply with the requirements of the ISO 9001

Quality and ISO 14001 Environmental Management Systems, and such

compliance shall be verified by an independent certification agency

approved by the International Organization for Standardization.

Documentation shall be submitted for approval showing compliance with

this requirement, and the equipment will not be released for shipment until

approved.

C.

Unit responsibility. Pump(s), complete with motor, V-belt, baseplate,

necessary guards, and all other specified accessories and appurtenances

shall be furnished by the pump manufacturer to insure compatibility and

integrity of the individual components, and provide the specified warranty

for all components.

D.

The vortex-type pumps specified in this section shall be furnished by and be

the product of one manufacturer.

SUBMITTALS

A.

Submit shop drawings and product data under provisions of Section ______.

B.

Submit manufacturers installation instructions under provisions of Section

_____.

C.

The submittal data shall be prepared, in its entirety, by the equipment

This sheet is the property of WEIR SPECIALTY PUMPS/WEMCO PUMP, 440 West 800 South, Salt Lake City, Utah, and is loaned under the

express condition that it is not to be used in any manner directly or indirectly detrimental to WEIR SPECIALTY PUMPS.

WEMCO PUMP Data Sheet

Model C Master Specification

11-11-08

P10C-D201

Page 2

manufacturer. Shop drawings prepared by the manufacturers sales

representative, fabrication shop or other than the listed manufacturers shall

not be acceptable. No additions or modifications to the manufacturers

submittal will be accepted, with the sole exception of a cover sheet provided

by the manufacturers local representative.

1.04

1.05

OPERATION AND MAINTENANCE DATA

A.

Submit operation and maintenance data under provisions of Section

______.

B.

Include installation instructions, assembly views, lubrication instructions,

and replacement parts lists.

DELIVERY, STORAGE, AND HANDLING

A.

1.06

PART 2

2.01

Deliver, store, handle, and protect under provisions of Section ______.

SERVICES OF MANUFACTURER

A.

Furnish the services of a representative of the pump manufacturer to assist

in adjusting and testing the equipment furnished, to supervise the initial

operation, and to make final adjustments as may be necessary to assure

the OWNER that the pump(s) is (are) in satisfactory operating condition.

B.

Furnish sufficient supervision, data, and information from the manufacturer

to train operators in the proper operation and maintenance of the pump(s)

furnished.

PRODUCTS

PUMPS

A.

PERFORMANCE

1.

B.

The pumps shall be designed for continuous operation and will be

operated continuously under normal service.

OPERATION CRITERIA

Flow

GPM

TDH

FT

Max.

Pump

Solids

Min.

Passage Suction

Min.

Disch.

Min.

Motor

This sheet is the property of WEIR SPECIALTY/WEMCO PUMPS, 440 West 800 South, Salt Lake City, Utah, and is loaned under the

express condition that it is not to be used in any manner directly or indirectly detrimental to WEIR SPECIALTY PUMPS.

WEMCO PUMP Data Sheet

Model C Master Specification

11-11-08

RPM

P10C-D201

Page 3

Dia.

Dia.

Size

Design

Condition

Secondary

Condition

C.

DESIGN

1.

Since these pumps will be used to pump abrasive grit and other solids,

the pumps shall be specifically designed to both optimize wear

resistance and then maintain hydraulic performance as wear occurs.

2.

The pump(s) shall be of a fully recessed, Slurry Type design, with the

impeller mounted completely out of the flow path between the pump

inlet and discharge connection, so that solids are not required to flow

through the impeller. All flow path clearances within the pump(s) shall

be equal to or greater than the discharge diameter, so that all solids

which will pass through the discharge will pass through the pump.

3.

The impeller shall be constructed of 650 Brinell Ni-Hard or Hi-Chrome

Iron and specifically designed to maintain hydraulic pumping

performance as wear occurs.

a.

Pump

Size

The impeller shall be of cup design such that the deepest portion of

the vane is not located at the vane tips and the tips are surrounded

by a thick-sectioned rim of the following thickness:

Minimum

Minimum

Minimum

Impeller Dia. @ Rim Thickness @ Vane Thickness @

Outside Rim

Wear Area

Wear Area

Impeller

Minimum

Ni-Hard or

Hi-Chrome

Iron Weight

3 In.

14-1/16 In.

1-1/8 In.

7/8 In.

60 Lbs.

4 In.

16 In.

1-5/8 In.

7/8 In.

90 Lbs.

6 In.

20 In.

1-3/4 In.

7/8 In.

165 Lbs.

8 In.

22-1/4 In.

1-3/4 In.

1-1/8 In.

210 Lbs.

b.

The hydraulic design shall be such that the length of the impeller

vane increases as wear occurs to the rim, allowing as-new or

better pumping performance throughout the wear cycle of the

impeller.

c.

The hydraulic design of the impeller shall preferentially direct flow

to a sacrificial, independently replaceable suction piece. The

suction piece shall be easily accessible and replaceable, without

the need to disassemble any other component of the pump.

This sheet is the property of WEIR SPECIALTY/WEMCO PUMPS, 440 West 800 South, Salt Lake City, Utah, and is loaned under the

express condition that it is not to be used in any manner directly or indirectly detrimental to WEIR SPECIALTY PUMPS.

WEMCO PUMP Data Sheet

Model C Master Specification

d.

11-11-08

P10C-D201

Page 4

Pump-out vanes on the rear shroud of the impeller are not

acceptable. Impellers of the radial design that incorporate the

impeller in a recessed portion of the volute or wearplate are not

acceptable.

4. A removable wearplate of Ni-Hard or Hi-Chrome Iron shall be provided

behind the impeller designed to direct flow from behind the impeller to

the center of the volute for maximum protection to the casing.

5. The packing housing shall be a separate piece bolted to the bearing

housing for ease of removal. Designs that incorporate the stuffing box

as an integral part of the wear plate and/or backplate assembly are not

acceptable.

6. The pump casing shall be of the two-piece radially split type, with a

separate and removable suction piece designed so that the impeller

can be withdrawn without the need to remove the discharge casing or

disturb the discharge piping. The casing shall be constructed so that it

can be reversed for opposite rotation, and shall be of Ni-Hard or HiChrome Iron. To insure a liberal wear allowance, the casing and

suction piece shall be constructed, and the entire wet end weights

shall be, as follows:

Discharge

Diameter

3 In.

Casing

Minimum

Suction Piece at

Wear Area

Weight* of

Wearing Parts

9/16 In.

1 In.

340 lbs.

4 In.

3/4 In.

1-1/4 In.

500 lbs.

6 In.

3/4 In.

1-1/4 In.

800 lbs.

8 In.

7/8 In.

1-1/2 In.

1150 lbs.

*Suction piece, impeller, casing, and wearplate.

7. The pump's head vs. capacity curve shall slope upward toward shutoff in

one continuous curve with no points of inflection capable of causing

hunting at any pump operational speed.

8.

D.

Pump(s) shall be equipped with slotted raised-face flanges to receive

125 lb. standard bolting. Special case slots shall be cast in to retain

bolts and to fasten the case to the bearing housing and to the intake for

easy case removal.

MATERIALS OF CONSTRUCTION

1.

The parts exposed to abrasive wear - case, removable suction piece,

impeller, and wearplate shall be of all Ni-Hard or Hi-Chrome Iron

material conforming to ASTM Designation A532-75 Class I or Class III,

This sheet is the property of WEIR SPECIALTY/WEMCO PUMPS, 440 West 800 South, Salt Lake City, Utah, and is loaned under the

express condition that it is not to be used in any manner directly or indirectly detrimental to WEIR SPECIALTY PUMPS.

WEMCO PUMP Data Sheet

Model C Master Specification

11-11-08

P10C-D201

Page 5

Type A, and be a minimum of 650 Brinell hardness for maximum wear

resistance. Brinell values below this are not acceptable.

2.

E.

F.

Test bars shall be cast integrally with the case and suction piece and

shall remain attached to the casting upon final delivery to the owner.

Test bars shall be of sufficient thickness to represent the average

thickness of the cast part. After receipt of final delivery, the owner may

at any time prior to the final acceptance, remove the test bar and

independently verify compliance to the material and hardness

specification. Failure of the tested bars to meet the specified

requirements shall be cause for rejection.

BEARING HOUSING

1.

The bearing housing shall be of cast iron, ASTM A48CL-25.

2.

The shaft shall be of ASTM A108, Grade 1045 (or equal) steel, and

shall be protected by a removable, hardened Type 410, 416 or 420

stainless steel shaft sleeve when used with packing. (For mechanical

seals the shaft sleeve will be specified separately).

3.

Bearings shall be oil bath lubricated. The oil reservoir shall be sealed

at both ends to prevent entrance of foreign matter. The thrust bearings

shall consist of three angular contact ball bearings for maximum

protection from all thrust loads. The bearing housing will be equipped

with a pressure venting device and oil fill and drain taps. A built-in sight

glass shall be furnished to check proper oil level. The bearings shall be

rated for a minimum B10 life of 100,000 hours, without credit for any

rear pump-out vanes to balance hydraulic thrust.

SHAFT SEALING

(CHOOSE ONE ALTERNATIVE)

-

1.

EITHER

Packing

The stuffing box shall contain graphite impregnated acrylic

packing rings and Teflon lantern ring arranged for water

lubrication. The packing will be retained with a bronze split

packing gland. Any leakage shall be retained within a drainable

reservoir integral with the bearing housing and tapped with a

inch NPT hole for connection of the seal water drainage piping.

-

2.

OR

Mechanical Seal

a.

A single cartridge mechanical seal requiring no external flushing

shall be furnished in the pump. The seal shall utilize a rotational

This sheet is the property of WEIR SPECIALTY/WEMCO PUMPS, 440 West 800 South, Salt Lake City, Utah, and is loaned under the

express condition that it is not to be used in any manner directly or indirectly detrimental to WEIR SPECIALTY PUMPS.

WEMCO PUMP Data Sheet

Model C Master Specification

11-11-08

P10C-D201

Page 6

sealing ring mounted in an elastomer cup with an o-ring mounted

stationary ring loaded by a non-fouling, conical spring

encapsulated in Viton. Installation of the seal shall require no

measurements or scribe marks on the shaft.

b.

The rotational sealing ring shall be made of tungsten carbide

Grade VC 805, the surface of which shall be lapped to a flatness

not to exceed three helium light bands. The sealing ring shall be

bonded inside a Viton rubber cup, which shall have three (3)

integrally molded anti-rotational lugs to prevent the rotary seal face

from turning within the rotary body. Additionally, the rotary body

shall have three (3) 1/8" solid stainless steel pins to also prevent

the rotary seal face from turning within the rotary body.

c.

The stationary sealing ring shall be also be constructed of tungsten

carbide Grade VC 805. The surface shall be lapped to a flatness

not to exceed three helium light bands. The stationary ring shall

have a slot milled on the side opposite of the mating side, which

engages an anti-rotation pin. Stationary sealing rings of converted

carbon or other surface-only treatments are not acceptable.

d.

The spring that loads the rotational sealing ring shall be cone-type,

non-fouling design and shall run in the pumped product without

fouling or hang-up. The spring metal material shall be SAE1095

Carbon Steel, ASTM A-682 heat-treated to a Rockwell C hardness

of 45 to 50 and be totally encapsulated in Viton for protection from

the pumped fluid. The product side of the spring shall have a

minimum 1/4" thick Viton rubber covering for corrosion/abrasion

protection. Seals which use single coil, multiple coil, bellows and

rubber-in-shear designs are not acceptable.

e.

To minimize the number of points where the slurry must be sealed,

the mechanical seal assembly shall have no more than three (3) orings: one (1) shaft sleeve o-ring, one (1) stationary face o-ring,

and one (1) retainer o-ring. O-rings are to be made of Viton. Seals

using more than three (3) o-rings are not acceptable.

f.

All metal components not encapsulated in Viton shall be

constructed of abrasion-resistant CD4MCu ASTM A-743. Surface

finish shall be a maximum of 64 RMS.

g.

The seal shall be capable of running with up to 0.025" radial shaft

deflection and 0.040" axial shaft deflection without leakage,

damage, or loss of performance.

h.

A seal chamber of Hi-chrome iron, ASTM A-532, minimum 600

Brinell, shall be provided to mount the seal and to provide a

reservoir of adequate volume for the pumped product to contact

This sheet is the property of WEIR SPECIALTY/WEMCO PUMPS, 440 West 800 South, Salt Lake City, Utah, and is loaned under the

express condition that it is not to be used in any manner directly or indirectly detrimental to WEIR SPECIALTY PUMPS.

WEMCO PUMP Data Sheet

Model C Master Specification

11-11-08

P10C-D201

Page 7

and to lubricate the seal faces. The seal shall be installed into the

seal chamber from the impeller side of the pump so that only the

casing/suction piece and impeller need to be removed to gain

complete access to the seal for inspection and/or maintenance.

i.

Seals requiring a water or product flush may be furnished in lieu of

the non-flushed seal, provided the contractor furnishes, at no extra

charge, all of the external auxiliary equipment necessary for the

flushing system, including, but not limited to:

1) Isolated water/flush supply system to the seal, including pump,

reservoir, pressure reduction valve, solenoid valve, bypass

piping and check valve, all furnished in a suitable enclosure,

associated wiring, and modifications to the motor control center

to actuate the solenoid valve.

2) A pressure gauge, flowmeter, shutoff and isolation valves,

manual throttle valve, and strainer at the pump.

3) All tubing/piping shall be stainless steel.

G.

MOUNTING

(CHOOSE ONE ALTERNATIVE)

-

EITHER

1. Belt Drive

a.

The pump manufacturer shall provide a common pump and motor

base, constructed of a minimum 3/8 inch thick fabricated steel,

suitably reinforced to support the full weight of the pump, motor,

belt drive and guards.

b.

The pump manufacturer shall furnish and install a separate,

adjustable motor base with handwheel adjustment so that the motor

can be easily moved for V-belt tensioning and adjustment, TB

Woods type MC 3B, modified with a welded steel gusset, or equal.

c.

The pump manufacturer shall supply and install belts and sheaves

to drive the pump at the speed necessary to meet the rated

conditions.

d.

The drive shall be of the stationary control variable speed TB

Woods type SVS or equal, which allows a speed change by

means of an adjustment to the motor sheave when the drive is not

in operation.

e.

An approved fiberglass or thermoplastic belt guard shall be

This sheet is the property of WEIR SPECIALTY/WEMCO PUMPS, 440 West 800 South, Salt Lake City, Utah, and is loaned under the

express condition that it is not to be used in any manner directly or indirectly detrimental to WEIR SPECIALTY PUMPS.

WEMCO PUMP Data Sheet

Model C Master Specification

11-11-08

P10C-D201

Page 8

provided to safely enclose the belt drive. If metal guards are

furnished, they shall be of all 316 stainless steel construction with

suitable lifting eyes and handles to aid in removal.

2.

H.

Direct Coupled - (Note: Consult with factory before selecting)

a.

The pump manufacturer shall provide a common pump and motor

base constructed of a minimum 3/8" thick fabricated steel, suitably

reinforced to support the full weight of pump and motor.

b.

The pump supplier shall furnish and install a flexible spacer

coupling between the pump shaft and motor shaft.

c.

An approved fiberglass or thermoplastic coupling guard shall be

provided to safely enclose the coupling. If metal guards are

furnished, they shall be of all 316 stainless steel construction with

suitable lifting eyes and handles to aid in removal.

MOTOR

1.

I.

OR

Motor shall be horizontal, ______ type, ______ HP, ______Phase,

______ Cycle, _______ Volt, ______ RPM, and shall be connected to

the pump by the drive method specified. All motors shall be of

nationally known manufacture and shall conform to NEMA standards

and specifications.

OPTIONAL TESTS

1.

2.

(ADD IF DESIRED)

Hardness Testing

a.

Before final shipment, a Brinell hardness test shall be conducted

showing compliance to ASTM A532 and shall be submitted for

approval. Each individual casting shall be Brinell tested at the

manufacturer's plant to ASTM Method E-10. Each casting shall be

checked in a minimum of two places, in an area that is

representative of casting thickness.

b.

Results of the Brinell tests shall be certified by a Registered

Professional Engineer and submitted for approval before final

shipment.

c.

Hardness tests shall be witnessed by a representative of the

owner.

Performance Testing

This sheet is the property of WEIR SPECIALTY/WEMCO PUMPS, 440 West 800 South, Salt Lake City, Utah, and is loaned under the

express condition that it is not to be used in any manner directly or indirectly detrimental to WEIR SPECIALTY PUMPS.

WEMCO PUMP Data Sheet

Model C Master Specification

PART 3

3.01

11-11-08

P10C-D201

Page 9

a.

A certified shop test shall be performed on each pumping unit in

accordance with the test code of the Hydraulic Institute protocol

A. Tests shall be sufficient to determine the curves of head, input

horsepower, and efficiency for capacity from shutoff to 150% of

design flow. A minimum of five points, including shutoff, shall be

taken for each test run. At least one point of the five shall be taken

as near as possible to each specified condition.

b.

Results of the performance tests shall be certified by a Registered

Professional Engineer and submitted for approval before final

shipment.

c.

A representative of the owner shall witness the certified test.

EXECUTION

INSTALLATION

A.

Install the pumps in accordance with the manufacturers instructions.

B.

Lubricate the equipment before start-up.

C.

Conduct Field Tests to demonstrate that the pump(s) perform in accordance

with the specifications.

This sheet is the property of WEIR SPECIALTY/WEMCO PUMPS, 440 West 800 South, Salt Lake City, Utah, and is loaned under the

express condition that it is not to be used in any manner directly or indirectly detrimental to WEIR SPECIALTY PUMPS.

Das könnte Ihnen auch gefallen

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineVon EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineBewertung: 5 von 5 Sternen5/5 (1)

- Amarex KRT8041eDokument36 SeitenAmarex KRT8041eRui Alves da Silva100% (1)

- Hda Operational ManualDokument48 SeitenHda Operational ManualDouglas DuarteNoch keine Bewertungen

- Spur GearDokument18 SeitenSpur GearSam LowNoch keine Bewertungen

- Karhula - Model Z-Y100Z-2 - Manual.Dokument8 SeitenKarhula - Model Z-Y100Z-2 - Manual.German ZuletaNoch keine Bewertungen

- Horizontal & SuHorizontal & Sump Pumpmp PumpsDokument105 SeitenHorizontal & SuHorizontal & Sump Pumpmp PumpsAnonymous dHLFEZuhBa50% (2)

- Warman Pumps: Assembly, Operating and Maintenance InstructionsDokument17 SeitenWarman Pumps: Assembly, Operating and Maintenance InstructionsMamiherintsoa Issaia Ranaivoarimanana100% (2)

- Brosur Pompa KSB Type CLTDokument20 SeitenBrosur Pompa KSB Type CLThenryhh111Noch keine Bewertungen

- Vertical Turbine Pump InstallationDokument34 SeitenVertical Turbine Pump InstallationElaine Aubrey BardelosaNoch keine Bewertungen

- 4/3 AH-WRT™ - Horizontal Pump: InstallationDokument3 Seiten4/3 AH-WRT™ - Horizontal Pump: InstallationGuiver Santisteban IbañezNoch keine Bewertungen

- Weir Split Case BrochureDokument4 SeitenWeir Split Case Brochure'Muhammad Saiful Rahman HmmwNoch keine Bewertungen

- Pump Performance Curve Index: 1.5/1 AH 2/1.5 AHDokument9 SeitenPump Performance Curve Index: 1.5/1 AH 2/1.5 AHMamiherintsoa Issaia RanaivoarimananaNoch keine Bewertungen

- Sec - 1701 - Non-Jacketed 4127 Q Viking PumpDokument13 SeitenSec - 1701 - Non-Jacketed 4127 Q Viking PumpkishorsinghNoch keine Bewertungen

- HH125 Pump Installation ManualDokument41 SeitenHH125 Pump Installation Manualjacklyn ade putra0% (1)

- Manual Techniflo TB - All Pumps PDFDokument28 SeitenManual Techniflo TB - All Pumps PDFJorge Gustavo Goyechea100% (1)

- TYPE 8B1/8B1T: Elastomer O-Ring SealsDokument6 SeitenTYPE 8B1/8B1T: Elastomer O-Ring SealshukNoch keine Bewertungen

- Liquid ring vacuum pumps with magnetic coupling optimize performanceDokument7 SeitenLiquid ring vacuum pumps with magnetic coupling optimize performanceGustavo ZavalaNoch keine Bewertungen

- Windows-1256 Mechanical Seals For ABS Pumps en PDFDokument4 SeitenWindows-1256 Mechanical Seals For ABS Pumps en PDFaminjolesNoch keine Bewertungen

- Goulds 3700Dokument9 SeitenGoulds 3700JackNoch keine Bewertungen

- Ahlstar PP E00545 PDFDokument16 SeitenAhlstar PP E00545 PDFPatricia J ÁngelesNoch keine Bewertungen

- SM 3026 PDFDokument8 SeitenSM 3026 PDFMiguel CasasNoch keine Bewertungen

- SN Series Screw PumpsDokument12 SeitenSN Series Screw PumpsAlexis Ernesto Cardenas BeltranNoch keine Bewertungen

- Influence of Impeller Suction Specific Speed On Vibration LCCDokument32 SeitenInfluence of Impeller Suction Specific Speed On Vibration LCCjuan villarroelNoch keine Bewertungen

- 350q-5 Operation ManualDokument97 Seiten350q-5 Operation ManualCesar Mora100% (2)

- Ahlstar IOM 20031215 English (Links)Dokument121 SeitenAhlstar IOM 20031215 English (Links)Drese Chahaize100% (4)

- Performance Data CurveDokument57 SeitenPerformance Data Curveedwin nolberto100% (1)

- GIW pump conversions boost productivityDokument2 SeitenGIW pump conversions boost productivitymarcosandia1974Noch keine Bewertungen

- QF-450 PE & Gear Reducer Assy PDFDokument19 SeitenQF-450 PE & Gear Reducer Assy PDFCesar Mora100% (1)

- FPD 1034 e PDFDokument923 SeitenFPD 1034 e PDFBenicio Joaquín Ferrero Brebes75% (4)

- Boiler Feed Pump - KSBDokument1 SeiteBoiler Feed Pump - KSBgulmal husainNoch keine Bewertungen

- LPH 40106 - 60527 InstructionsDokument52 SeitenLPH 40106 - 60527 InstructionsPítty Jonathan Jaramillo100% (1)

- Pump Iso13709 Api610 bb3 Multistage DVMX Marelli Maintenance Manual EnglishDokument25 SeitenPump Iso13709 Api610 bb3 Multistage DVMX Marelli Maintenance Manual EnglishJuan Pablo Chumba Lara100% (1)

- Montaje Recomendado Por FabricaDokument2 SeitenMontaje Recomendado Por FabricaWilliam ValenciaNoch keine Bewertungen

- Viking Pump Product Selection GuideDokument32 SeitenViking Pump Product Selection GuideEduardo EstradaNoch keine Bewertungen

- Operation and Maintenance Manual of Holding Vacuum Pump-2BW4 252Dokument163 SeitenOperation and Maintenance Manual of Holding Vacuum Pump-2BW4 252AhmadNoch keine Bewertungen

- User Instructions: ERPN Centrifugal PumpsDokument39 SeitenUser Instructions: ERPN Centrifugal PumpsYerko NavarroNoch keine Bewertungen

- Warman Pumps: Assembly, Operating and Maintenance InstructionsDokument19 SeitenWarman Pumps: Assembly, Operating and Maintenance InstructionsMamiherintsoa Issaia RanaivoarimananaNoch keine Bewertungen

- 003 Sewatec KSBDokument52 Seiten003 Sewatec KSBClovis_sccp100% (1)

- Mantenimiento de Bomba Horizontal de Lodos WarmanDokument102 SeitenMantenimiento de Bomba Horizontal de Lodos WarmanemersonNoch keine Bewertungen

- Bombas Reciprocantes PDFDokument43 SeitenBombas Reciprocantes PDFSamuel Arias CamachoNoch keine Bewertungen

- Ahlstar: Process PumpsDokument1 SeiteAhlstar: Process Pumpsapi-3759223Noch keine Bewertungen

- E743H798Dokument14 SeitenE743H798Francho_89Noch keine Bewertungen

- VLK Installation Operation & Maintenance Manual: VLK English Language IOM-VLK-Eng Rev 0 March 2008Dokument28 SeitenVLK Installation Operation & Maintenance Manual: VLK English Language IOM-VLK-Eng Rev 0 March 2008Anatoli Karpob100% (1)

- KSB Pump Movi ManualDokument12 SeitenKSB Pump Movi ManualVenkat Dora100% (3)

- Power Stream Couplings-Specn SheetsDokument6 SeitenPower Stream Couplings-Specn SheetsAmol PatkiNoch keine Bewertungen

- Krebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsDokument4 SeitenKrebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsPhaniNoch keine Bewertungen

- WEIR-Fire Pump ManualDokument116 SeitenWEIR-Fire Pump ManualEduardo100% (2)

- Manual Bomba SihiDokument32 SeitenManual Bomba SihiAlex Serna RestrepoNoch keine Bewertungen

- Metastream TSC Coupling IOMDokument4 SeitenMetastream TSC Coupling IOMthanhphamNoch keine Bewertungen

- Thermoil Heater Etanorm, PumpDokument66 SeitenThermoil Heater Etanorm, PumpCH1253Noch keine Bewertungen

- Parker hydraulic pumps and motors overviewDokument133 SeitenParker hydraulic pumps and motors overviewNgô Văn Đạt100% (1)

- Sulzer EPD MD 150 360 SkidDokument4 SeitenSulzer EPD MD 150 360 SkidAdolfo CanceloNoch keine Bewertungen

- User Instructions: DMX/DMXD/DMXH/DMXDH Centrifugal PumpsDokument60 SeitenUser Instructions: DMX/DMXD/DMXH/DMXDH Centrifugal PumpspriscilaNoch keine Bewertungen

- 4990 Cargo Pump ManualDokument32 Seiten4990 Cargo Pump ManualPrajesh T VNoch keine Bewertungen

- Durco Mark 3 71569102 English 03-17Dokument72 SeitenDurco Mark 3 71569102 English 03-17Triod jackson0% (1)

- 80261-01 r1 Technical Data Sheet, AquaBold High Pressure Pump, 4x6x9Dokument1 Seite80261-01 r1 Technical Data Sheet, AquaBold High Pressure Pump, 4x6x9pablolz712100% (1)

- Instalacion Operacion y Mantenimiento BombasDokument92 SeitenInstalacion Operacion y Mantenimiento BombasChano Aviles-CasanovaNoch keine Bewertungen

- Pumps and Vibration IsolationDokument6 SeitenPumps and Vibration IsolationtexmoNoch keine Bewertungen

- Progressing Cavity Pumps Part 1generalDokument6 SeitenProgressing Cavity Pumps Part 1generalPipin AzrinNoch keine Bewertungen

- DeviDokument53 SeitenDeviFire Service PondyNoch keine Bewertungen

- Design Evaluation of Particulate Wet Scrubbing Systems FactorsDokument48 SeitenDesign Evaluation of Particulate Wet Scrubbing Systems FactorsAnonymous MVHQ97KEoP100% (4)

- HDX Rotary Airlock BulletinDokument2 SeitenHDX Rotary Airlock BulletinWilliam ValenciaNoch keine Bewertungen

- Manual de CapsDokument24 SeitenManual de CapsDavid Gregorio Perez AlarconNoch keine Bewertungen

- Wet ScrubberDokument17 SeitenWet Scrubberphantom131Noch keine Bewertungen

- PVB PVBQ A10vso PVHDokument38 SeitenPVB PVBQ A10vso PVHWilliam ValenciaNoch keine Bewertungen

- 2.OMA EE Fan Dust Coll TechnicalDokument19 Seiten2.OMA EE Fan Dust Coll TechnicalWilliam ValenciaNoch keine Bewertungen

- Diseño de Chimeneas PDFDokument8 SeitenDiseño de Chimeneas PDFWilliam ValenciaNoch keine Bewertungen

- 5795 F 69808 Ae 33 e 89 Fad 6 FBBDokument7 Seiten5795 F 69808 Ae 33 e 89 Fad 6 FBBWilliam ValenciaNoch keine Bewertungen

- Design Guidelines For An Optimum Scrubber SystemDokument96 SeitenDesign Guidelines For An Optimum Scrubber SystemWilliam ValenciaNoch keine Bewertungen

- Balance Energetico en VentiladoresDokument5 SeitenBalance Energetico en VentiladoresWilliam ValenciaNoch keine Bewertungen

- Medicion Experimental Del Flujo de Aire PDFDokument7 SeitenMedicion Experimental Del Flujo de Aire PDFWilliam ValenciaNoch keine Bewertungen

- Altivar 28Dokument92 SeitenAltivar 28Enrique LefiánNoch keine Bewertungen

- Seleccion Ventiladores y Ciclones PDFDokument5 SeitenSeleccion Ventiladores y Ciclones PDFWilliam ValenciaNoch keine Bewertungen

- AMCA Fan Performance PDFDokument16 SeitenAMCA Fan Performance PDFthevellin154Noch keine Bewertungen

- Oil and Gas Instrument AbbreviationsDokument4 SeitenOil and Gas Instrument AbbreviationsDjil Rezoug100% (5)

- PID 2 Heaters 3 PumpsDokument1 SeitePID 2 Heaters 3 PumpsWilliam ValenciaNoch keine Bewertungen

- MAAG S Series Brochure English PDFDokument12 SeitenMAAG S Series Brochure English PDFWilliam ValenciaNoch keine Bewertungen

- PVB PVBQ A10vso PVHDokument38 SeitenPVB PVBQ A10vso PVHWilliam ValenciaNoch keine Bewertungen

- MAAG G Series Flyer EnglishDokument2 SeitenMAAG G Series Flyer EnglishWilliam ValenciaNoch keine Bewertungen

- MAAG S Series Brochure English PDFDokument12 SeitenMAAG S Series Brochure English PDFWilliam ValenciaNoch keine Bewertungen

- Rovalve PDFDokument4 SeitenRovalve PDFWilliam ValenciaNoch keine Bewertungen

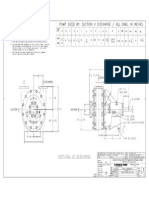

- Model 8CDokument1 SeiteModel 8CWilliam ValenciaNoch keine Bewertungen

- P35S-D225B Sumergible MaterialsDokument1 SeiteP35S-D225B Sumergible MaterialsWilliam ValenciaNoch keine Bewertungen

- Montaje Recomendado Por FabricaDokument2 SeitenMontaje Recomendado Por FabricaWilliam ValenciaNoch keine Bewertungen

- 8X6 Model CDokument1 Seite8X6 Model CWilliam ValenciaNoch keine Bewertungen

- Refer to drawing pageDokument2 SeitenRefer to drawing pageWilliam Valencia100% (1)

- Arrangement DrawingDokument1 SeiteArrangement DrawingWilliam ValenciaNoch keine Bewertungen

- Model 8CDokument1 SeiteModel 8CWilliam ValenciaNoch keine Bewertungen

- Model 8CDokument1 SeiteModel 8CWilliam ValenciaNoch keine Bewertungen

- DHV ProcedureDokument7 SeitenDHV ProcedureISPNoch keine Bewertungen

- Low Delta T Syndrome in Constant Primary and Variable Secondary Chilled Water SystemDokument4 SeitenLow Delta T Syndrome in Constant Primary and Variable Secondary Chilled Water SystemPradeep SukumaranNoch keine Bewertungen

- Centri Pump DSDokument1 SeiteCentri Pump DSVipul GandhiNoch keine Bewertungen

- 325C FM & 325C LL Electrical System: Electrical Schematic Symbols and DefinitionsDokument2 Seiten325C FM & 325C LL Electrical System: Electrical Schematic Symbols and DefinitionsLhsan RajawiNoch keine Bewertungen

- 6.0 Powerstroke Fuel Pressure Testing and Tips 1webDokument19 Seiten6.0 Powerstroke Fuel Pressure Testing and Tips 1webDavid Fuentes100% (6)

- Variable displacement hydraulic componentsDokument5 SeitenVariable displacement hydraulic componentsRICHARDNoch keine Bewertungen

- Cargas para BoquillasDokument7 SeitenCargas para Boquillasnikoonz2528Noch keine Bewertungen

- Utility - Fire Water SystemDokument17 SeitenUtility - Fire Water SystemGloria HamiltonNoch keine Bewertungen

- Manual de Servicio Motores M6 M7 DenisonDokument24 SeitenManual de Servicio Motores M6 M7 DenisonaugustoNoch keine Bewertungen

- 4516219-C0801 - 1 Hmi Parameter ListDokument9 Seiten4516219-C0801 - 1 Hmi Parameter ListDavid AponteNoch keine Bewertungen

- D8291 - 21a Standard Test Method For Evaluation of Performance of Automotive Engine Oils in The Mitigation of Low-Speed, PreigniDokument57 SeitenD8291 - 21a Standard Test Method For Evaluation of Performance of Automotive Engine Oils in The Mitigation of Low-Speed, PreigniProvocateur SamaraNoch keine Bewertungen

- Kumpulan Reading TextDokument4 SeitenKumpulan Reading TextAbi Hamdani100% (1)

- Slurry Transport Using Centrifugal Pumps - InDICEDokument5 SeitenSlurry Transport Using Centrifugal Pumps - InDICECarlos Cortés Ramos20% (5)

- Vertical Turbine PumpsDokument2 SeitenVertical Turbine PumpsMarcelino ArroyoNoch keine Bewertungen

- CatDokument13 SeitenCatDammiam GaticaNoch keine Bewertungen

- Formation Mte RotmachDokument2 SeitenFormation Mte RotmachnuncafalhaNoch keine Bewertungen

- Schwing p88Dokument2 SeitenSchwing p88Vittorio60% (5)

- 1 FT Gala Rubber Flexible Connector Double Bellows GFLEX-GS THREADEDDokument2 Seiten1 FT Gala Rubber Flexible Connector Double Bellows GFLEX-GS THREADEDNon Etabas GadnatamNoch keine Bewertungen

- Installation & Servicing Instructions for Baxi Combi Instant 80e & 105e Gas BoilersDokument48 SeitenInstallation & Servicing Instructions for Baxi Combi Instant 80e & 105e Gas BoilersKostas AstrinisNoch keine Bewertungen

- Method Statement For Pumping StationsDokument5 SeitenMethod Statement For Pumping StationsPrem Kumar83% (6)

- Catalogo WORLD AMERICAN Repuestos VariosDokument43 SeitenCatalogo WORLD AMERICAN Repuestos Variosmenendez2050Noch keine Bewertungen

- Relume FMEADokument80 SeitenRelume FMEAIndra D. WinarkoNoch keine Bewertungen

- Kawasaki HMC080 Dual Displacement Hydraulic Motor Technical ManualDokument12 SeitenKawasaki HMC080 Dual Displacement Hydraulic Motor Technical ManualMohamed ElmakkyNoch keine Bewertungen

- 4143.020.073 2 HL 270 PDF Transmission (Mechanics) Mechanical EngineeringDokument1 Seite4143.020.073 2 HL 270 PDF Transmission (Mechanics) Mechanical EngineeringАртурNoch keine Bewertungen

- Grundfos Fire Presentation - Consultants Webinar - 6-8th FebruaryDokument52 SeitenGrundfos Fire Presentation - Consultants Webinar - 6-8th FebruaryfebousNoch keine Bewertungen

- Instuctions of Use The Resin ImpResin90 To The Wood Stabilization ProcessDokument2 SeitenInstuctions of Use The Resin ImpResin90 To The Wood Stabilization ProcessjuaaltaNoch keine Bewertungen

- Booster Pump CatalogDokument42 SeitenBooster Pump CataloglizyNoch keine Bewertungen

- Section 2 Structure and Function: Group 1 Pump DeviceDokument18 SeitenSection 2 Structure and Function: Group 1 Pump DeviceAndre STANoch keine Bewertungen

- Black Out ProcedureDokument3 SeitenBlack Out Proceduremarkjames castroNoch keine Bewertungen

- Chry-45RFE VacTestDokument4 SeitenChry-45RFE VacTestAnonymous WzR5h9g8VNoch keine Bewertungen