Beruflich Dokumente

Kultur Dokumente

MS Masterflex 700

Hochgeladen von

Ajit Singh RathoreOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MS Masterflex 700

Hochgeladen von

Ajit Singh RathoreCopyright:

Verfügbare Formate

MS - AD - Masterflex 700 - 08/2012

THIS METHOD STATEMENT COVERS THE PREPARATION MIXING & APPLICATION OF

MASTERFLEX 700 (GG and PG), A 2 COMPONENT POLYSULPHIDE ELASTOMERIC

JOINT SEALANT.

METHOD STATEMENT: MASTERFLEX 700

Note:

Joint size

Joint size may range from a minimum of 5mm to a maximum of 50mm wide. Joints with cyclic

movements should have a width : depth ratio 2:1 and designed so total movement does not

exceed the 25% M.A.F. related to the joint width. Sealant depth shall not exceed joint width.

Minimum sealant depth specified:

5mm for metals, glass and other impervious surfaces.

20mm for joints exposed to hydrostatic pressures.

5mm below flush for joints exposed to traffic.

Maximum depth for joints wider than 30mm shall be 16mm.

1.

APPLICATION PROCEDURE:

JOINT PREPARATION SURFACE TREATMENT:

1.1. Concrete and masonry:

Surfaces must be clean and dry. Wire brush thoroughly and remove dust and all

contaminants.

1.2. Metals:

Clean to bright metal. De-grease the surfaces with clean cloth soaked in oil-free cleansing

solvent.

1.3. Wood (bare):

Wood surfaces must be clean and dry, cut back or abrade where necessary to sound

timber. Ensure surface is dust free.

1.4. Glass and glazed materials:

Thoroughly clean the surfaces with clean cloth soaked in oil-free cleansing solvent.

1.5. Coated surfaces:

Coating should be removed and the surfaces treated as above.

1.6. Place closed cell foam backer rod in the joint, set to the correct depth for the application. If

the base of the joint slot is set at the correct depth, place de-bonding tape in the bottom of

the joint to prevent three sided adhesion taking place.

2.

PRIMING:

2.1. The correct primer shall always be used.

2.2. Porous surfaces (such as concrete and masonry) use MASTERFLEX PRIMER NO 1.

2.3. Non-porous surfaces (such as metals, glass and glazed surfaces use MASTERFLEX

PRIMER NO 2.

Page - 1 of 3

MS - AD - Masterflex 700 - 08/2012

2.4. Application of primer shall not be carried out below 4C.

2.5. A single coat of primer shall be applied by brush to the opposing joint faces.

2.6. Do not apply primer to the backer rod or bond breaker tape.

2.7. The primer shall be allowed to dry tack free before applying MASTERFLEX 700.

2.8. MASTERFLEX 700 shall be applied within 3 hours of primer, otherwise re-priming will be

necessary.

3.

APPLICATION TEMPERATURES:

3.1. MASTERFLEX 700 should be applied only when the ambient temperature is between 4C

and 50C.

3.2. Do not apply to concrete in direct sunlight when temperatures are rising, as air / vapour

expelled from the concrete can form bubbles / blisters in the sealant.

3.3. When the temperature is below 10C storage at room temperature for several hours will

ease mixing and application.

4.

MIXING:

4.1. Mix and use one complete unit at a time. Do not sub-divide.

4.2. Both Gun grade and Pouring grade are supplied as a 2 component kit with the curing agent

contained in a smaller tin.

4.3. Combine the curing agent with the Base material and mix for 5-10 minutes using a suitable

paddle fitted to a 500 rpm electric drill moving the paddle completely through the mass of

the material. Ensure ALL curing agent is removed from its tin and combined with the Base

material.

4.4. The sides and base of the larger container should be periodically scraped down with a

palette knife to ensure all of the curing agent is completely blended with the base

compound.

4.5. Failure to completely disperse curing agent throughout the base compound will result in

uncured sealant. Once mixed, MASTERFLEX 700 should be used immediately.

5.

APPLICATION:

5.1. MASTERFLEX 700 Gun Grade is formulated to be applied using a sealant gun but may be

applied by trowel if required.

5.2. Select a nozzle of a suitable size for the application and then fill the gun with sealant.

5.3. The sealant should be gunned into the joint using an even trigger pressure, cleaning the

nozzle occasionally to avoid contamination.

5.4. Deep joints shall be filled in two or more runs, forcing the sealant into the bottom and sides

of the joint to prevent air entrapment and to ensure a good bond.

5.5. Once the sealant has been applied, a small timber, metal or plastic spatula, should be used

to compact the sealant into the joints and to achieve a smooth polished finish. Any masking

tape which has been applied should be removed before the sealant cures.

Page - 2 of 3

MS - AD - Masterflex 700 - 08/2012

5.6. Mixing and application equipment should be cleaned immediately after use.

5.7. MASTERFLEX 700 Pouring Grade is formulated to be liquid and simply poured in to the

prepared joints directly from the tin once mixed correctly.

Page - 3 of 3

Das könnte Ihnen auch gefallen

- Tribology of Graphene: Simulation Methods, Preparation Methods, and Their ApplicationsVon EverandTribology of Graphene: Simulation Methods, Preparation Methods, and Their ApplicationsBewertung: 5 von 5 Sternen5/5 (1)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionVon EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNoch keine Bewertungen

- Resistance WeldingDokument22 SeitenResistance WeldingLOKENDRA91100% (2)

- GeegDokument2 SeitenGeegjefferson100% (1)

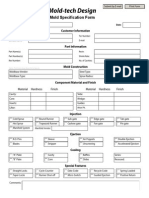

- Mold Design Spec SheetDokument1 SeiteMold Design Spec Sheetomerscheen0% (1)

- Mold SpecificationDokument1 SeiteMold SpecificationVictor Villouta LunaNoch keine Bewertungen

- MS - MasterTop 135PGDokument4 SeitenMS - MasterTop 135PGAzhar Shaikh100% (1)

- Thrust Restraint Design For DI PipeDokument24 SeitenThrust Restraint Design For DI PipefazyroshanNoch keine Bewertungen

- Rtfi ImageDokument88 SeitenRtfi ImagedhasdjNoch keine Bewertungen

- Waste Production and Utilization in The Metal Extraction Industry - Optimized PDFDokument531 SeitenWaste Production and Utilization in The Metal Extraction Industry - Optimized PDFNgoni MhondeNoch keine Bewertungen

- UL Label and British Standard Doors enDokument20 SeitenUL Label and British Standard Doors enAjit Singh RathoreNoch keine Bewertungen

- Electric Induction Furnace Definition and Working PrincipleDokument16 SeitenElectric Induction Furnace Definition and Working PrincipleMURSELIM ALINoch keine Bewertungen

- Papermaking 2017Dokument7 SeitenPapermaking 2017quizizz section4Noch keine Bewertungen

- Galvanic Corrosion: Printable VersionDokument49 SeitenGalvanic Corrosion: Printable Versionhariom6353Noch keine Bewertungen

- Formwork and Shoring: Product GuideDokument61 SeitenFormwork and Shoring: Product Guidejakeer7Noch keine Bewertungen

- 14 ThermoformingDokument27 Seiten14 Thermoformingsuhas deshpande100% (3)

- Solvent Jointing of CPVC PipesDokument20 SeitenSolvent Jointing of CPVC PipesHamza Hashim100% (1)

- Masterflex 700 SDokument3 SeitenMasterflex 700 SMichael AlbuquerqueNoch keine Bewertungen

- Masterflex 700 PGDokument3 SeitenMasterflex 700 PGHaresh BhavnaniNoch keine Bewertungen

- Masterflex 700 GGDokument3 SeitenMasterflex 700 GGHaresh BhavnaniNoch keine Bewertungen

- Nitomortar S: High Strength, Abrasion - Resistance Epoxy Reinstatement MortarDokument4 SeitenNitomortar S: High Strength, Abrasion - Resistance Epoxy Reinstatement MortarVenkata Raju KalidindiNoch keine Bewertungen

- Thioflex 600Dokument4 SeitenThioflex 600Conifer YuNoch keine Bewertungen

- Nitoseal® 200Dokument4 SeitenNitoseal® 200Venkata Raju KalidindiNoch keine Bewertungen

- Nitoseal MS600 sealant for immersed conditionsDokument4 SeitenNitoseal MS600 sealant for immersed conditionsmilanbrasinaNoch keine Bewertungen

- Solvent-Free Epoxy Lining for ManholesDokument4 SeitenSolvent-Free Epoxy Lining for ManholesmilanbrasinaNoch keine Bewertungen

- 1 - Masterseal-M-262-MsDokument2 Seiten1 - Masterseal-M-262-MsPaul ManiquisNoch keine Bewertungen

- Proofex SM PDFDokument4 SeitenProofex SM PDFmilanbrasinaNoch keine Bewertungen

- Basf Masterseal NP 474 TdsDokument3 SeitenBasf Masterseal NP 474 Tdstally3tallyNoch keine Bewertungen

- Thioflex 600 PDFDokument4 SeitenThioflex 600 PDFmilanbrasinaNoch keine Bewertungen

- Thioflex 600 Gun Grade TDSDokument3 SeitenThioflex 600 Gun Grade TDSDevendra100% (1)

- Nitoseal 200Dokument4 SeitenNitoseal 200shanon33Noch keine Bewertungen

- Thioflex 600 Sealant Technical Data SheetDokument5 SeitenThioflex 600 Sealant Technical Data Sheetalbukharir100% (1)

- Basf Masterseal NP 474 TdsDokument3 SeitenBasf Masterseal NP 474 TdsAdnan ČehajićNoch keine Bewertungen

- Durakol G HMDokument3 SeitenDurakol G HMpbodooNoch keine Bewertungen

- MASTERFLEX 700i v4Dokument2 SeitenMASTERFLEX 700i v4RUDRA KARMAKARNoch keine Bewertungen

- Expoband One : Flexible Expansion Joint MembraneDokument4 SeitenExpoband One : Flexible Expansion Joint MembraneVenkata Raju KalidindiNoch keine Bewertungen

- Sonneborn NP2Dokument4 SeitenSonneborn NP2Edward FlynnNoch keine Bewertungen

- BSI ISO Compliant Waterproofing MembraneDokument2 SeitenBSI ISO Compliant Waterproofing MembranemidaNoch keine Bewertungen

- Nitoseal MS100Dokument4 SeitenNitoseal MS100Balasubramanian AnanthNoch keine Bewertungen

- Normac-Cement-Guide-ADS_Rev2Dokument6 SeitenNormac-Cement-Guide-ADS_Rev2kenedi74Noch keine Bewertungen

- Thioflex 600: Two-Part Polysulphide SealantDokument4 SeitenThioflex 600: Two-Part Polysulphide SealantVenkata Raju KalidindiNoch keine Bewertungen

- Omega Seal Joining ProcedureDokument2 SeitenOmega Seal Joining ProcedureQUALITYNoch keine Bewertungen

- Thioflex 600 Pouring Grade TDSDokument3 SeitenThioflex 600 Pouring Grade TDSAhmed NacherNoch keine Bewertungen

- BASF MasterSeal M 790 TdsDokument9 SeitenBASF MasterSeal M 790 TdsAmar WadoodNoch keine Bewertungen

- Proofex Engage PDFDokument2 SeitenProofex Engage PDFmilanbrasinaNoch keine Bewertungen

- Expoband OneDokument4 SeitenExpoband Oneshanon33Noch keine Bewertungen

- Work Methodology R1Dokument12 SeitenWork Methodology R1Anonymous 1uGSx8bNoch keine Bewertungen

- Ai Hempadur 15500 EnglishDokument6 SeitenAi Hempadur 15500 EnglishS M ASIFNoch keine Bewertungen

- Application Guide-Cold-Applied-Tape-Elastomeric-Rev 2, 8-16 - 1 PDFDokument4 SeitenApplication Guide-Cold-Applied-Tape-Elastomeric-Rev 2, 8-16 - 1 PDFEbondNoch keine Bewertungen

- Klambon Steel PipingDokument5 SeitenKlambon Steel PipingshaunswanbyNoch keine Bewertungen

- Method Dr. Fixit Pidiseal Ps 41gDokument2 SeitenMethod Dr. Fixit Pidiseal Ps 41gRb143Noch keine Bewertungen

- Pre-applied HDPE waterproofing membraneDokument4 SeitenPre-applied HDPE waterproofing membranekalidindivenkatarajuNoch keine Bewertungen

- Fosroc GMS Nitoplate LaminateDokument6 SeitenFosroc GMS Nitoplate Laminatejohn paulNoch keine Bewertungen

- Nitoseal MS 60: Cold Applied, High Performance, Pitch Free, Polyurethane Pavement Joint SealantDokument4 SeitenNitoseal MS 60: Cold Applied, High Performance, Pitch Free, Polyurethane Pavement Joint SealantkalidindivenkatarajuNoch keine Bewertungen

- Section - 07 92 00 - Sealants and CaulkingDokument4 SeitenSection - 07 92 00 - Sealants and CaulkingEliseo LagmanNoch keine Bewertungen

- Solvent Jointing of CPVC PipesDokument20 SeitenSolvent Jointing of CPVC PipesHamza HashimNoch keine Bewertungen

- Flexible Expansion Joint MembraneDokument4 SeitenFlexible Expansion Joint MembranemilanbrasinaNoch keine Bewertungen

- Zerokorr - Method StatementDokument8 SeitenZerokorr - Method StatementAshif AkhtarNoch keine Bewertungen

- Cello FlexDokument3 SeitenCello FlexdietersimaNoch keine Bewertungen

- 05 - TDS - Mastertop 300Dokument4 Seiten05 - TDS - Mastertop 300Vimal KakNoch keine Bewertungen

- Thioflex 600: Two-Part Polysulphide SealantDokument4 SeitenThioflex 600: Two-Part Polysulphide SealantJigar JariwalaNoch keine Bewertungen

- Sikaflex 2c NS EZ Mix UsDokument3 SeitenSikaflex 2c NS EZ Mix Usتوان امتياس سامسدينNoch keine Bewertungen

- Strain GaugeDokument4 SeitenStrain GaugePURAPATAGONIANoch keine Bewertungen

- Glassflake Lining Metal TanksDokument5 SeitenGlassflake Lining Metal TanksSimbu ArasanNoch keine Bewertungen

- Mos - Flexatec 1000Dokument1 SeiteMos - Flexatec 1000Renaldo BunaidiNoch keine Bewertungen

- ESD Sight Epoxy Mortar SEP-6505 Method StatmentDokument3 SeitenESD Sight Epoxy Mortar SEP-6505 Method StatmentmakdelNoch keine Bewertungen

- Conbextra EP75Dokument4 SeitenConbextra EP75Venkata Raju KalidindiNoch keine Bewertungen

- Nitoflor ET Slurry Anti-Skid SurfaceDokument4 SeitenNitoflor ET Slurry Anti-Skid SurfaceVenkata Raju KalidindiNoch keine Bewertungen

- Nitoseal 290Dokument4 SeitenNitoseal 290shanon33Noch keine Bewertungen

- AI HEMPADUR 35760 English Fibre MatDokument4 SeitenAI HEMPADUR 35760 English Fibre MatAnonymous rYZyQQot55Noch keine Bewertungen

- QM001 Difference Between Quality Assurance and Quality ControlDokument2 SeitenQM001 Difference Between Quality Assurance and Quality ControlSandeep KumarNoch keine Bewertungen

- Door CloserDokument4 SeitenDoor CloserAjit Singh RathoreNoch keine Bewertungen

- ALIMAK SC 45 - 30 - Construction Hoists - Products - Alimak Rack and Pinion Construction and Industrial ElevatorsDokument1 SeiteALIMAK SC 45 - 30 - Construction Hoists - Products - Alimak Rack and Pinion Construction and Industrial ElevatorsAjit Singh RathoreNoch keine Bewertungen

- Saravel 3 Ton Ducted Split UnitDokument4 SeitenSaravel 3 Ton Ducted Split UnitAjit Singh RathoreNoch keine Bewertungen

- Triphosphate (Atp) As A Proxy For Bacteria Numbers in Deep-SeaDokument6 SeitenTriphosphate (Atp) As A Proxy For Bacteria Numbers in Deep-SeaAjit Singh RathoreNoch keine Bewertungen

- Iso 2531 1998Dokument52 SeitenIso 2531 1998Ajit Singh RathoreNoch keine Bewertungen

- BS 8204 ScreedsDokument45 SeitenBS 8204 ScreedsAjit Singh Rathore100% (3)

- A3 753Dokument1 SeiteA3 753Ajit Singh RathoreNoch keine Bewertungen

- Optional Accessories: R e D R o o T W o H e R U T C I P N o It P Ir C e DDokument1 SeiteOptional Accessories: R e D R o o T W o H e R U T C I P N o It P Ir C e DAjit Singh RathoreNoch keine Bewertungen

- ATP Monitoring Limits ExplainedDokument3 SeitenATP Monitoring Limits ExplainedAjit Singh RathoreNoch keine Bewertungen

- Occupations PDFDokument9 SeitenOccupations PDFraheja_ashishNoch keine Bewertungen

- ATP Bioluminescence: A Q&A on Its Uses and LimitationsDokument1 SeiteATP Bioluminescence: A Q&A on Its Uses and LimitationsAjit Singh RathoreNoch keine Bewertungen

- Environmental Cleaning Guidelines-Jun 2013 PDFDokument78 SeitenEnvironmental Cleaning Guidelines-Jun 2013 PDFAjit Singh RathoreNoch keine Bewertungen

- Technical Dimensions.: Model Size RemarksDokument1 SeiteTechnical Dimensions.: Model Size RemarksAjit Singh RathoreNoch keine Bewertungen

- F8400 Heavy Duty Commercial Door CloserDokument1 SeiteF8400 Heavy Duty Commercial Door CloserAjit Singh RathoreNoch keine Bewertungen

- Dana Composite Panels Cladding ProfilesDokument20 SeitenDana Composite Panels Cladding ProfilesAjit Singh RathoreNoch keine Bewertungen

- Nitocote ET550Dokument4 SeitenNitocote ET550waqas_11Noch keine Bewertungen

- Expansion Joint CoversDokument24 SeitenExpansion Joint CoversAjit Singh RathoreNoch keine Bewertungen

- Dana Composite Panels Cladding ProfilesDokument20 SeitenDana Composite Panels Cladding ProfilesAjit Singh RathoreNoch keine Bewertungen

- 1111Dokument2 Seiten1111cnotebookNoch keine Bewertungen

- Masterflow 648 CP GroutDokument4 SeitenMasterflow 648 CP GroutAjit Singh RathoreNoch keine Bewertungen

- Rheofinish 225D CL & VOCDokument1 SeiteRheofinish 225D CL & VOCAjit Singh RathoreNoch keine Bewertungen

- 700 BaseDokument3 Seiten700 BaseAjit Singh RathoreNoch keine Bewertungen

- Primer No.1Dokument4 SeitenPrimer No.1Ajit Singh RathoreNoch keine Bewertungen

- 700 BaseDokument3 Seiten700 BaseAjit Singh RathoreNoch keine Bewertungen

- Arcos High Nickel BrochureDokument24 SeitenArcos High Nickel BrochureJuan RodriguezNoch keine Bewertungen

- Jotamastic 87: Cookie PolicyDokument2 SeitenJotamastic 87: Cookie Policyfaizal_7138Noch keine Bewertungen

- Bohler Fox N Ev 50-1Dokument1 SeiteBohler Fox N Ev 50-1Kara WhiteNoch keine Bewertungen

- Abecote 352Dokument3 SeitenAbecote 352engramir07Noch keine Bewertungen

- Corro-Coat PE Series 50 TDSDokument3 SeitenCorro-Coat PE Series 50 TDSBiju_PottayilNoch keine Bewertungen

- SocorilDokument24 SeitenSocorilmondelNoch keine Bewertungen

- Pulp paper processesDokument4 SeitenPulp paper processesKirana Wirr's50% (2)

- Technical Presentation: Improve Water Resistance With Rheology AdditivesDokument30 SeitenTechnical Presentation: Improve Water Resistance With Rheology AdditivesAPEX SON100% (1)

- 31CrMo23 Data SheetDokument2 Seiten31CrMo23 Data SheetOrnella MancinelliNoch keine Bewertungen

- Sae Ams 2759-1e-2014Dokument13 SeitenSae Ams 2759-1e-2014Reza NooriNoch keine Bewertungen

- Sancryl Brochure - Paint CoatingDokument3 SeitenSancryl Brochure - Paint CoatingDa PrinceNoch keine Bewertungen

- Line History SheetDokument4 SeitenLine History SheetBethel NdifonNoch keine Bewertungen

- AWS D1.1 - Type of Qualification Tests Required - Welder and Welding Operator Performance Qualification - Welding and InspectionDokument1 SeiteAWS D1.1 - Type of Qualification Tests Required - Welder and Welding Operator Performance Qualification - Welding and Inspectionjyzjz6sr65Noch keine Bewertungen

- Tool Room For Sheet Metal Die MakingDokument8 SeitenTool Room For Sheet Metal Die MakingKaramjit SinghNoch keine Bewertungen

- Y%S, XLD M Dka %SL Iudcjd Ckrcfha .Eiü M %H: The Gazette of The Democratic Socialist Republic of Sri LankaDokument2 SeitenY%S, XLD M Dka %SL Iudcjd Ckrcfha .Eiü M %H: The Gazette of The Democratic Socialist Republic of Sri LankadmonlinelkNoch keine Bewertungen

- Sejahtera Pratama: PT. BakaraDokument84 SeitenSejahtera Pratama: PT. BakaraArthur BakaraNoch keine Bewertungen

- TML 10 DDokument2 SeitenTML 10 DMuhammad FikriansyahNoch keine Bewertungen

- Drilling Jigs Italiana FerramentaDokument34 SeitenDrilling Jigs Italiana FerramentaOliver Augusto Fuentes LópezNoch keine Bewertungen

- COATINGS - Industrial ChemistryDokument22 SeitenCOATINGS - Industrial ChemistrysgaclanNoch keine Bewertungen

- Dynamic Air ClassifiersDokument3 SeitenDynamic Air Classifierskensley oliveiraNoch keine Bewertungen