Beruflich Dokumente

Kultur Dokumente

Strengthen of Cold Formed Steel Column With Ferrocement Jacket Push Out Tests

Hochgeladen von

Mahfuzur Rahman0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

57 Ansichten4 SeitenStrengthen of Cold Formed Steel Column With Ferrocement Jacket Push Out Tests

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenStrengthen of Cold Formed Steel Column With Ferrocement Jacket Push Out Tests

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

57 Ansichten4 SeitenStrengthen of Cold Formed Steel Column With Ferrocement Jacket Push Out Tests

Hochgeladen von

Mahfuzur RahmanStrengthen of Cold Formed Steel Column With Ferrocement Jacket Push Out Tests

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

World Academy of Science, Engineering and Technology

International Journal of Civil, Architectural, Structural and Construction Engineering Vol:7 No:11, 2013

Strengthen of Cold-Formed Steel Column with

Ferrocement Jacket: Push out Tests

Khaled Alenezi, Talal Alhajri, M. M. Tahir, Mohamed Ragaee K. Badr, S. O. Bamaga

International Science Index Vol:7, No:11, 2013 waset.org/Publication/17413

AbstractThe population growth in the world requires an

increase in demand of residential and housing construction. Using

lightweight construction materials such as cold formed steel sections

and ferrocement could be an alternate solution to foster the

construction industry. In this study, a new composite column is

introduced. It consists of cold formed steel section and ferrocement

jacket. The ferrocement jacket was constructed using self-compacting

mortar with two wire steel mesh of 550 MPa yield strength.

Experimental push out tests was conducted to investigate the strength

capacities and behavior of proposed shear connectors namely, bolt,

bar-angle and self-drilling screw shear connectors. It was found that

bolt connector showed the best behavior followed by bar-angle. Also,

it was concluded that the ferrocement could be used to strength and

improve the behavior of cold formed steel column.

KeywordsCold formed steel, composite column, push out test,

shear connector, ferrocement, strengthen method.

I. INTRODUCTION

HE traditional construction materials such as steel and

concrete have exhibited signs of deterioration over the

years in their long-term performance, which can be attributed

to either the inherent nature of the materials or the weak

resistance offered by these materials to adverse environmental

conditions and natural disasters such as fires and earth quakes.

In addition, retrofitting or rejuvenation of structures composed

of such materials requires the use of skilled labors, heavy

equipments, excessive energy and time which results in the

escalation of the overall cost. Recent evaluation of the civil

engineering infrastructure has demonstrated that most of it

will need major repairs in the near future.

The maintenance of under-strength or deteriorated steel

structures has been a subject of concern for structural

engineers for decades. Major causes of distress or premature

deterioration pertaining to steel structures include improper

design or construction of the structure, changes in the

structural function, and modifications in the load specification,

corrosion of the steel, and exposure to impact or fire. When

the structural member is a steel column, concrete jacketing, by

encasing the existing steel section in a reinforced concrete

jacket, is a commonly used technique.

Despite wide application of concrete jacketing in

strengthening the steel columns of existing structures, research

on the jacketing of such cold-formed steel columns is still in

the early stages. From the last century, concrete jackets have

K. Alenezi,T. Alhajri, M. Tahir, S. Bamaga, UTM Construction Research

Centre, Faculty of Civil Engineering, Universiti Teknologi Malaysia, 81310

UTM, Skudai, Johor, Malaysia (corresponding author: M. Tahir; phone: 0060137201321; fax: 006-075576841; e-mail: mahmoodtahir@utm.my).

been provided primarily to serve as protection against

corrosion and fire [1], and thus were assumed not to resist

structural loading. With present-day modern steelconcrete

composite construction techniques, the stiffness and strength

gain effects have been taken into account for steel columns

strengthened with concrete jackets.

The use of ferrocement as an external jacket to cold-formed

column is investigated in this study. Ferrocement is a special

form of reinforced concrete, which exhibits a behavior

differing much from conventional reinforced concrete in

strength performance and potential application. Therefore, the

uniform dispersion of reinforcement in the matrix offers in

achieving improvement in many of the engineering properties

of the material, such as tensile and flexural strength,

toughness, fracture, crack control, fatigue resistance and an

impact resistance and in addition it also provides advantages

in fabrication [2]. In developing countries, the raw materials

for ferrocement construction are easily available, and also it

could be constructed in any complicated shape. The skill

required is of low level and it has superior strength properties

as compared to conventional reinforced concrete [3][7]. It

was proven that, jacketing with rounded corner give certain

degrees of confinement by reducing stress concentration at

corners [8], [9]. This justifies the development of innovative

rehabilitation and strengthening method by ferrocement jacket

for cold-formed steel structures. The development of

innovative rehabilitation and strengthening technique is

required to extend the life expectancy of many steel structures

and limited studies were reported for the similar work in case

of ferrocement strengthened cold-formed column.

Stud (or bolt) connectors are subjected to flexural and axial

forces in resisting the interface forces by means of dowel

action. Force transfers in composite structures depend on the

strength and stiffness of various components of the composite

beam as well as shear connectors. Therefore, it is necessary to

determine the design parameters namely, shear strength and

stiffness for stud connector prior to their use in construction.

This task is mostly accomplished by conducting experiments

on push-out specimens. Several types of push-out specimens

have been studied in past decades and reported in the

literature. Behaviour of stud shear connectors in light weight

and normal weight concrete is studied by Al-Salloum [10].

Investigation on the strength of push-out specimens have been

carried out by Ollgard [11]. Later, Hawkins [12] has

recommended various empirical equations to include the effect

of variation in material strength, on the strength of shear

connectors. Effect of transverse reinforcement on the shear

534

World Academy of Science, Engineering and Technology

International Journal of Civil, Architectural, Structural and Construction Engineering Vol:7 No:11, 2013

strength of stud shear connectors have been investigated by

Oehlers and Johnson [13] using push-out tests.

It is reported in British Standards Institute DD ENV 19941-1 [14] that the transverse reinforcement provides

confinement to the concrete in the vicinity of studs rather than

contribution to the strength. Shear stiffness, ultimate slip

capacity and shear strength of stud connectors have been

determined. The behavior of stud connectors in high strength

and normal strength concrete has been studied byOehlers and

Park [15]. Studs in normal strength concrete reported to

exhibit ductile behavior as the descending branch was gradual

and longer as compared with studs in high strength concrete.

In the present study a new composite column with high

strength self-compacting ferrocement mortar and cold-formed

steel section is proposed, tested and reported.

LVDTs. The test setup of the push out specimen and LVDTs

positions are shown in Fig. 3.

International Science Index Vol:7, No:11, 2013 waset.org/Publication/17413

II. PUSH-OUT TEST

Experimental investigation includes testing of three pushout specimens with three different types of shear connectors

and ferrocement jacket was carried out. As shown in Fig. 1, a

push-out specimen consists of full jacket ferrocement box a

rounded to the flanges of I-beam by means of shear

connectors. The I-beam was constructed using two lipped Csection cold-formed steel of 30075254mm oriented back

to back. The lipped C-section of cold-formed steel columns

was jacketed with two wire mesh layers of ferrocement

jacketing. Steel wire mesh of 1.5mm diameter and (20x20

mm) square opening of 550 MPa yield strength was used to

strengthen the ferrocment. Self-compacting mortar was

designed and used in this study. The 28day compressive

strength of 100mm cube was determined at 71 MPa.

The push out specimen was subjected to a vertical load

which produced shear load along the interface between the

ferrocement jacket and the cold-formed steel column on both

sides. The shear load was transferred to the ferrocement jacket

through shear connectors. As shown in Fig. 1, a recess of 50

mm was provided between the bottom of the jacket and the

lower end of the steel column to allow for the slip at the steelferrocement interface during testing. The objective of this

study is to investigate the strength capacity and behavior of

varied shear connectors between cold-formed steel jacketed

with ferrocement. Three types of shear connectors were used

namely, bolt (10mm diameter), L-bar angle (10mm diameter)

and self-drilling screw of 6.3mm diameter as shown in Fig. 2.

The ferrocement jacket, which used to strengthen the coldformed steel section, resulted in a uniform cross section of

400250mm2 along the full length of the cold-formed column.

The overall thickness of the ferrocement jacket of the

specimen was 50mm. For all push-out specimens in this test

program, the total number of connectors were 8 (4 bolt in each

side) with spacing of 85mm between connectors. All shear

connector were embedded 40mm inside the ferrocement

jacket. Bolt and bar-angle shear connectors were tied by two

nuts directly to the flange of cold-formed steel column.

All columns were tested using hydraulic compression

testing machine until failure. The slip between ferrocement

jacket and cold formed steel section was measured using two

Fig. 1 Details of Push-out Specimen

Fig. 2 Shear connector types

Fig. 3 Push-out specimen under testing

535

World Academy of Science, Engineering and Technology

International Journal of Civil, Architectural, Structural and Construction Engineering Vol:7 No:11, 2013

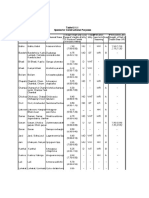

All tests results are summarized in Table I. The load-slip

curves are shown in Fig. 4. The failure mode of all test

specimens could be attributed to the failure of the shear

connectors. The specimen resisted the applied load in elastic

manner up to about 80% from the ultimate load. However, the

specimen showed plastic behavior in a very limited range

before the failure where the shear connector was sheared-off.

Longitudinal cracks were observed on the ferrocement jacket

at early stage of loading and become wider as load increase.

Fig. 5 shows the failure mode of the specimens.

According to the test results, the load slip responses of all

specimens seem to exhibit a similar pattern. It can be observed

from Fig. 4, that specimen with shear connector of 10 mm bolt

showed better resistance to the applied load and more ductile

behavior as compared to bar-angle and self-drilling screw

shear connectors with an improvement up to 45%. However,

self-drilling screw shear connector showed the lowest

resistance to the applied load. This is expected due to the

smaller diameter (6.3mm) of the screw as compared to the bolt

and bar-angle.

TABLE I

TEST RESULTS

Ultimate load

Shear connector

per connector

(kN)

specimen

Ultimate

slip

(mm)

S(1)

10mm bolt

36.062

1.16

S(2)

bar-angle

29.075

1.12

S(3)

drilling screw

24.832

0.58

(a) Bolt

Failure mode

shear-off the

bolt

shear-off the

bar-angle

shear-off the

screw

(b) Bar-angle

400

350

300

Load (kN)

International Science Index Vol:7, No:11, 2013 waset.org/Publication/17413

III. TEST RESULTS

250

200

150

Bolt (10mm)

100

Bar angle (10mm)

50

Self Drilling Screw (6.3 mm)

(c) Self drilling screw

0

0

2

Slip (mm)

Fig. 5 Failure modes of specimens

IV. CONCLUSION

Fig. 4 Load-slip curves of the specimens

New composite column consists of two C-lipped channel of

cold formed steel oriented back-to-back and jacketed with

ferrocement is proposed, tested and reported. Three types of

shear connectors were used to form the composite action

between steel column and ferrocement namely bolt, bar-angle

and self-drilling screw shear connectors. The ferrocement slab

536

World Academy of Science, Engineering and Technology

International Journal of Civil, Architectural, Structural and Construction Engineering Vol:7 No:11, 2013

was constructed using self-compacting mortar with two wire

steel mesh of 550 MPa yield strength. From the push out test it

was found that 10mm bolt shear connector showed the best

behavior as compared to others. Also, it was concluded that

ferrocement could be used to strength and improve the

behavior of the cold formed steel column.

ACKNOWLEDGMENT

The authors would like to thanks all staff in Housing&

Building National Research Centre and UTM Construction

Research Centre who has contributed to the testing and

carrying out the analytical work. Special thanks also to all

technicians at structural and materials lab, Faculty of Civil

Engineering, Universiti Teknologi Malaysia (UTM), Research

University Grant Q.J130000.2522.03H51.

International Science Index Vol:7, No:11, 2013 waset.org/Publication/17413

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

S. M. Johnson, Deterioration, maintenance and repair of structures. New

York: McGraw-Hill, 1965.

R. P. Kumar, C.B.K. Rao, "Constitutive behavior of high-performance

ferrocement under axial compression," Mag Concr Res, vol. 58, pp.

647656, 2006

R. P. Kumar, T. Oshima, S. Mikami and T. Yamazaki, "Ferrocement

confinement of plain and reinforced concrete,, Int J ProgStructEng

Mater, pp. 624151, 2004

ACI Committee 549.1R88. Guide for the design, construction and

repair of ferrocement. ACI Struct J. vol. 85, pp. 32551, 1988.

P. Balaguru, "Use of ferrocement for confinement of concrete," In 1988

Proceedings of the third international conference on ferrocement, pp.

296305.

C.B.K. Rao, A. K. Rao, "Stressstrain curve in axial compression and

Poissons ratio of Ferrocement," Journal Ferrocement, vol. 6, pp. 1728,

1988.

K. K. Singh and S. K. Kaushik, "Ferrocement composite columns," In

Proceedings 1988 of the third international conference on ferrocement,

pp. 216225.

Ganesan, J. Anil, "Strength and behavior of reinforced concrete columns

confined by ferrocement," J Ferrocement, vol. 23, pp. 99108, 1993.

L. Wang, Effect of corner radius on the performance of CFRP-confined

square concrete column. M. Phil Thesis, Department of Building and

Construction, City University of Hong Kong, 2007.

Y. A. Al-Salloum, "Influence of edge sharpness on the strength of

square concrete columns confined with FRP composite laminates,"

Composites Part B: Engineering, vol.38, pp. 640-650, 2006.

J. G. Ollgaard, R. G. Slutter and J. W. Fisher, Shear strength of stud

connectors in lightweight and normal weight concrete, Engineering

Journal AISC, vol. 8, pp. 55-64, 1971.

N. M. Hawkins, The strength of stud shear connectors, Civil

Engineering Transactions, Institution of Engineers, Australia, vol. CE33,

pp. 46-52, 1973

D. J. Oehlers and R. P. Johnson, The strength of stud shear connections

in composite beams, The Structural Engineer, June, Part B, 1987

British Standards Institution, DD ENV 1994-1-1, Design of composite

steel and concrete structures- Part 1.1, EC 4: General rules and rules for

building. London: British Standards Institution, 1994

D. J. Oehlers and S. M. Park, Shear connectors in composite beams

with longitudinally cracked slabs, Journal of Structural Engineering,

vol. 118, pp. 2004-2022, 1992.

537

Das könnte Ihnen auch gefallen

- Composite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Von EverandComposite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Bewertung: 4 von 5 Sternen4/5 (10)

- Strengthening of Shearcritical RC Columns by Highstrength Steelrod CollarsEngineering JournalDokument22 SeitenStrengthening of Shearcritical RC Columns by Highstrength Steelrod CollarsEngineering JournalAnat RuangrassameeNoch keine Bewertungen

- Sand 4Dokument17 SeitenSand 4Pavan MNoch keine Bewertungen

- Published Journal Can Be Given as ReferenceDokument15 SeitenPublished Journal Can Be Given as ReferenceSREEKUMARA GANAPATHY V S stellamaryscoe.edu.inNoch keine Bewertungen

- Experimental and Analytical Study On Fatigue Behavior of Composite Truss JointsDokument17 SeitenExperimental and Analytical Study On Fatigue Behavior of Composite Truss JointsOanh PhanNoch keine Bewertungen

- Retrofitting columns with steel jacketing enhances strengthDokument7 SeitenRetrofitting columns with steel jacketing enhances strengthfaimy josephNoch keine Bewertungen

- Numerical Study of R.C. Beams Strengthening by External Steel PlateDokument9 SeitenNumerical Study of R.C. Beams Strengthening by External Steel PlateAJER JOURNALNoch keine Bewertungen

- Flexural strength test of concrete beams with mild steel and reinforcing ironDokument5 SeitenFlexural strength test of concrete beams with mild steel and reinforcing ironKevin Paul Arca RojasNoch keine Bewertungen

- High Strength Reinforcement in Ordinary Reinforced and Fibre Reinforced Cement Composite Light Weight Concrete BramsDokument283 SeitenHigh Strength Reinforcement in Ordinary Reinforced and Fibre Reinforced Cement Composite Light Weight Concrete Bramsab8ccw5288Noch keine Bewertungen

- Study on behaviour of cold formed built-up I-section with trapezoidal corrugationDokument13 SeitenStudy on behaviour of cold formed built-up I-section with trapezoidal corrugationAsr FlowerNoch keine Bewertungen

- Excel JuDokument12 SeitenExcel JuN Hamonangan SiagianNoch keine Bewertungen

- Seminar Report Design ProjectDokument8 SeitenSeminar Report Design Projectfaimy josephNoch keine Bewertungen

- Composite Steel and Concrete Structural Systems For Seismic Engineering and Axial LoadingDokument21 SeitenComposite Steel and Concrete Structural Systems For Seismic Engineering and Axial Loadingpooria_j92Noch keine Bewertungen

- Torsional Behavior of Steel Fiber Reinforced Concrete BeamsDokument7 SeitenTorsional Behavior of Steel Fiber Reinforced Concrete BeamssokamantyNoch keine Bewertungen

- Effect of Spacing of Fasteners Used To Attach The Corrugated Shear Plate To The Envelope Frame On Its Elastic Buckling BehaviorDokument21 SeitenEffect of Spacing of Fasteners Used To Attach The Corrugated Shear Plate To The Envelope Frame On Its Elastic Buckling BehaviorEliyaHeninNoch keine Bewertungen

- Composite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemDokument27 SeitenComposite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemVladimirNoch keine Bewertungen

- Axial capacity of circular concrete-filled tube columnsDokument20 SeitenAxial capacity of circular concrete-filled tube columnsMona MahmoudNoch keine Bewertungen

- Research Article: Axial Loading Behaviour of Self-Compacting Concrete-Filled Thin-Walled Steel Tubular Stub ColumnsDokument7 SeitenResearch Article: Axial Loading Behaviour of Self-Compacting Concrete-Filled Thin-Walled Steel Tubular Stub ColumnsvardhangargNoch keine Bewertungen

- Comparison of Experimental Values With EC 4, ACI-318, AISC-LRFD of Concrete Filled Steel Fluted Columns For Concentric LoadDokument10 SeitenComparison of Experimental Values With EC 4, ACI-318, AISC-LRFD of Concrete Filled Steel Fluted Columns For Concentric Loadmohamed alyozbakiNoch keine Bewertungen

- Optimum Unbraced Length Ratios of Slender Steel Sections: Saleem M. Umair, Q. Hisham, and Zahid A. SiddiqiDokument5 SeitenOptimum Unbraced Length Ratios of Slender Steel Sections: Saleem M. Umair, Q. Hisham, and Zahid A. SiddiqimargitorsiNoch keine Bewertungen

- 1 s2.0 S0263823112000602 MainDokument9 Seiten1 s2.0 S0263823112000602 MainrudynyambiNoch keine Bewertungen

- Effect of Reinforcement StiffenersDokument13 SeitenEffect of Reinforcement Stiffenersjust meNoch keine Bewertungen

- Journal of The South African Institution of Civil EngineeringDokument15 SeitenJournal of The South African Institution of Civil Engineeringkranthi142434Noch keine Bewertungen

- Wcee2012 4133Dokument10 SeitenWcee2012 4133toyi kamiNoch keine Bewertungen

- Thesis On Steel Fibre Reinforced ConcreteDokument8 SeitenThesis On Steel Fibre Reinforced Concretedenisemillerdesmoines100% (2)

- Double Skinned Steel Tubular (DSST)Dokument68 SeitenDouble Skinned Steel Tubular (DSST)RkkodiNoch keine Bewertungen

- Elastic Buckling Behavior of Steel Frames With Corrugated Steel Shear Wall 20-12-2004Dokument16 SeitenElastic Buckling Behavior of Steel Frames With Corrugated Steel Shear Wall 20-12-2004EliyaHeninNoch keine Bewertungen

- Study On Shear Embossments in Steel-Concrete CompoDokument11 SeitenStudy On Shear Embossments in Steel-Concrete Compog401992Noch keine Bewertungen

- Behaviour of Steel To Concrete JointsDokument5 SeitenBehaviour of Steel To Concrete JointsTomNoch keine Bewertungen

- Retrofitting of Columns by Steel Jackets-8cccDokument7 SeitenRetrofitting of Columns by Steel Jackets-8cccsecond2nonnNoch keine Bewertungen

- 10.5923.j.cmaterials.20120203.02Dokument10 Seiten10.5923.j.cmaterials.20120203.02ashenafiNoch keine Bewertungen

- Encased ColumnsDokument14 SeitenEncased ColumnsjimmyfontanaNoch keine Bewertungen

- Composite Construction History ReviewDokument22 SeitenComposite Construction History Reviewsantosh bharathyNoch keine Bewertungen

- Ijciet 08 05 112Dokument12 SeitenIjciet 08 05 112nagham tariqNoch keine Bewertungen

- CFT Subjected To Pure Bending, Elchalakani, 2001Dokument28 SeitenCFT Subjected To Pure Bending, Elchalakani, 2001Ryan FenyvesNoch keine Bewertungen

- Review Article: Review On Cold-Formed Steel ConnectionsDokument12 SeitenReview Article: Review On Cold-Formed Steel ConnectionsRakeshNoch keine Bewertungen

- Copy First Phase Report MSDokument39 SeitenCopy First Phase Report MSSREEKUMARA GANAPATHY V S stellamaryscoe.edu.inNoch keine Bewertungen

- Bond Characteristics High-Strength Steel ReinforcementDokument6 SeitenBond Characteristics High-Strength Steel ReinforcementUmair BaigNoch keine Bewertungen

- Use of Bolted Steel Plates For Strengthening of Reinforced Concrete Beams and ColumnsDokument34 SeitenUse of Bolted Steel Plates For Strengthening of Reinforced Concrete Beams and Columnszakaria200811060Noch keine Bewertungen

- Applsci 13 08217Dokument20 SeitenApplsci 13 08217Jee Hock LimNoch keine Bewertungen

- Short ColumnsDokument15 SeitenShort ColumnssrividyaNoch keine Bewertungen

- Applsci 10 00822 v4 Good PaperDokument20 SeitenApplsci 10 00822 v4 Good PaperAbdulkhaliq AbdulyimahNoch keine Bewertungen

- PC Research PaperDokument5 SeitenPC Research PaperghNoch keine Bewertungen

- Performance of RC Beams With Embedded Steel TrusseDokument9 SeitenPerformance of RC Beams With Embedded Steel TrussevignamNoch keine Bewertungen

- Advances in Civil Engineering Tests of Inclined Concrete - Filled Steel Tubular Stub Columns Under Vertical Cyclic LoadingDokument12 SeitenAdvances in Civil Engineering Tests of Inclined Concrete - Filled Steel Tubular Stub Columns Under Vertical Cyclic LoadingChayanon HansapinyoNoch keine Bewertungen

- Analysis of The Behaviour of Stainless Steel Bolted ConnectionsDokument11 SeitenAnalysis of The Behaviour of Stainless Steel Bolted ConnectionsSam SamouraNoch keine Bewertungen

- Performance Investigation of Square Concrete-Fi Lled Steel Tube ColumnsDokument7 SeitenPerformance Investigation of Square Concrete-Fi Lled Steel Tube Columnsjoamirhenrique_10316Noch keine Bewertungen

- Advances in Structural EngineeringDokument12 SeitenAdvances in Structural Engineeringم. محمد أبو مرقNoch keine Bewertungen

- Performance of Pristine and Retrofitted HybridDokument32 SeitenPerformance of Pristine and Retrofitted HybridTY ZNoch keine Bewertungen

- Shear Tests of FRP-Reinforced Concrete Beams Without StirrupsDokument8 SeitenShear Tests of FRP-Reinforced Concrete Beams Without StirrupsMarcel SteoleaNoch keine Bewertungen

- Structural Behavior of Steel-Concrete Composite BeamDokument12 SeitenStructural Behavior of Steel-Concrete Composite BeamJaime Morales BazalduaNoch keine Bewertungen

- Shear Behaviour of Steel Fibre Reinforced Self-Compacting ConcreteDokument8 SeitenShear Behaviour of Steel Fibre Reinforced Self-Compacting Concretejack21abNoch keine Bewertungen

- Experimental Study On The Ferrocement PanelsDokument8 SeitenExperimental Study On The Ferrocement PanelsIJRASETPublicationsNoch keine Bewertungen

- Behaviour of FRP Jacketed Circular Steel Tubes and Cylindrical Shells Under Axial CompressionDokument12 SeitenBehaviour of FRP Jacketed Circular Steel Tubes and Cylindrical Shells Under Axial CompressionJimmy Carranza PalominoNoch keine Bewertungen

- Ejsr 22 2 05 PDFDokument13 SeitenEjsr 22 2 05 PDFtevredeNoch keine Bewertungen

- HIGH STRENGTH REBAR DESIGNDokument5 SeitenHIGH STRENGTH REBAR DESIGNChristian JaberNoch keine Bewertungen

- Concrete Filled Steel Tube Columns: S.S.G.B.C.O.E.T., BHUSAWALDokument34 SeitenConcrete Filled Steel Tube Columns: S.S.G.B.C.O.E.T., BHUSAWALTameem AnsariNoch keine Bewertungen

- Seismic Behavior of Short Coupling Beams With Different Reinforcement LayoutsDokument10 SeitenSeismic Behavior of Short Coupling Beams With Different Reinforcement LayoutsleotramontinNoch keine Bewertungen

- Practical Design of Cold-Formed Steel Z Sections With Lapped ConnectionsDokument8 SeitenPractical Design of Cold-Formed Steel Z Sections With Lapped ConnectionsJoseAngelFernandezOrtegaNoch keine Bewertungen

- ADVSteelConstKOROGLU PDFDokument16 SeitenADVSteelConstKOROGLU PDFAbdulkadir ÇevikNoch keine Bewertungen

- Crep MNSRK37Dokument6 SeitenCrep MNSRK37Mahfuzur RahmanNoch keine Bewertungen

- Chapter 10 (6) - ADokument63 SeitenChapter 10 (6) - AMahfuzur RahmanNoch keine Bewertungen

- Feed Mill Raw Material Warehouse Variation ReportDokument1 SeiteFeed Mill Raw Material Warehouse Variation ReportMahfuzur RahmanNoch keine Bewertungen

- 30m-210-10EPA V1 InfoDokument3 Seiten30m-210-10EPA V1 InfoMahfuzur RahmanNoch keine Bewertungen

- Chapter 9Dokument23 SeitenChapter 9Mahfuzur RahmanNoch keine Bewertungen

- Chapter 11Dokument38 SeitenChapter 11Mahfuzur RahmanNoch keine Bewertungen

- Tower Calculation 5Dokument92 SeitenTower Calculation 5Mahfuzur RahmanNoch keine Bewertungen

- 40M Base Plate 210kph 1m2 V1.0Dokument34 Seiten40M Base Plate 210kph 1m2 V1.0Mahfuzur RahmanNoch keine Bewertungen

- 40M Base Plate 210kph 1m2 V1.0Dokument34 Seiten40M Base Plate 210kph 1m2 V1.0Mahfuzur RahmanNoch keine Bewertungen

- Table 6.11.1 (6) - CDokument2 SeitenTable 6.11.1 (6) - CMahfuzur RahmanNoch keine Bewertungen

- Chapter 1Dokument8 SeitenChapter 1Mahfuzur RahmanNoch keine Bewertungen

- Chapter 7Dokument23 SeitenChapter 7Mahfuzur RahmanNoch keine Bewertungen

- New Chattri Hall Edited by Mahfuz 22.06.2021Dokument501 SeitenNew Chattri Hall Edited by Mahfuz 22.06.2021Mahfuzur RahmanNoch keine Bewertungen

- Chapter 12Dokument33 SeitenChapter 12Mahfuzur RahmanNoch keine Bewertungen

- Chapter 10 (6) - CDokument44 SeitenChapter 10 (6) - CMahfuzur RahmanNoch keine Bewertungen

- Table 6.11.1 Species For Constructional PurposesDokument3 SeitenTable 6.11.1 Species For Constructional PurposesMahfuzur RahmanNoch keine Bewertungen

- Chapter 3Dokument28 SeitenChapter 3Mahfuzur RahmanNoch keine Bewertungen

- Chapter 10 (6) - BDokument52 SeitenChapter 10 (6) - BMahfuzur RahmanNoch keine Bewertungen

- Chapter 1Dokument24 SeitenChapter 1Mahfuzur RahmanNoch keine Bewertungen

- Chapter 2Dokument69 SeitenChapter 2Mahfuzur RahmanNoch keine Bewertungen

- Chapter 5Dokument24 SeitenChapter 5Mahfuzur RahmanNoch keine Bewertungen

- Chapter 6Dokument78 SeitenChapter 6Mahfuzur RahmanNoch keine Bewertungen

- Chapter 4Dokument46 SeitenChapter 4Mahfuzur RahmanNoch keine Bewertungen

- Chapter 4Dokument46 SeitenChapter 4Mahfuzur RahmanNoch keine Bewertungen

- Chapter 3Dokument28 SeitenChapter 3Mahfuzur RahmanNoch keine Bewertungen

- Chapter 5Dokument24 SeitenChapter 5Mahfuzur RahmanNoch keine Bewertungen

- Chapter 2Dokument69 SeitenChapter 2Mahfuzur RahmanNoch keine Bewertungen

- AppendicesDokument14 SeitenAppendicesMahfuzur RahmanNoch keine Bewertungen

- Chapter 1Dokument24 SeitenChapter 1Mahfuzur RahmanNoch keine Bewertungen

- Appendix ADokument13 SeitenAppendix AMahfuzur RahmanNoch keine Bewertungen

- 1411 1502 PDFDokument60 Seiten1411 1502 PDFAlejandro RagoNoch keine Bewertungen

- Seahawk Cement Unit 2300 BHP AC Electric: Available OptionsDokument2 SeitenSeahawk Cement Unit 2300 BHP AC Electric: Available Optionsbruce lianNoch keine Bewertungen

- NVU Vertical Up-Blast Range BrochureDokument5 SeitenNVU Vertical Up-Blast Range BrochurekirmaniNoch keine Bewertungen

- Vortex Induced Vibration Aquatic Clean Energy Ijariie4114Dokument5 SeitenVortex Induced Vibration Aquatic Clean Energy Ijariie4114Reham El- DawyNoch keine Bewertungen

- Gate Valve Maintenance ManualDokument18 SeitenGate Valve Maintenance ManualFaizan AbbasiNoch keine Bewertungen

- Lesson Plan Fluid MechanicsDokument5 SeitenLesson Plan Fluid MechanicsPrashanth Jagadeesh100% (1)

- PDF - Download - GEA - Flex-Geko PDFDokument16 SeitenPDF - Download - GEA - Flex-Geko PDFEvangelos SotiriouNoch keine Bewertungen

- SPC Platina 125 Disc (2018 12 28)Dokument70 SeitenSPC Platina 125 Disc (2018 12 28)Willy Mansilla A100% (1)

- Válvula Relief RD-10A-25WL IB6B9 (Data Sheet)Dokument1 SeiteVálvula Relief RD-10A-25WL IB6B9 (Data Sheet)Arturo Valencia LaureanoNoch keine Bewertungen

- Ejercicios de ConfiabilidadDokument3 SeitenEjercicios de ConfiabilidadIvan Jose HerreraNoch keine Bewertungen

- Mechanical, Plumbing, Electrical Materials ListDokument3 SeitenMechanical, Plumbing, Electrical Materials ListMohamedNoch keine Bewertungen

- IDS 350PE Flyer D392004983 MKT 001Dokument2 SeitenIDS 350PE Flyer D392004983 MKT 001Juan Mata100% (1)

- Adjusting Hydraulic Conversion Brake-Park BrakeDokument2 SeitenAdjusting Hydraulic Conversion Brake-Park Brakev53Noch keine Bewertungen

- Solar Water Heaters Guidelines V1 Aug 2019Dokument49 SeitenSolar Water Heaters Guidelines V1 Aug 2019Mile DjordjevicNoch keine Bewertungen

- Bending and Transverse TensionDokument23 SeitenBending and Transverse TensionAsghar Hussain ShahNoch keine Bewertungen

- Modal Analysis Example ExcelDokument1 SeiteModal Analysis Example Excelkaranbir123Noch keine Bewertungen

- DME -II (17ME64): ASSIGNEMENT 01-03Dokument3 SeitenDME -II (17ME64): ASSIGNEMENT 01-03NAVEEN H ENoch keine Bewertungen

- Bobcat 843 Service Repair Manual PDFDokument520 SeitenBobcat 843 Service Repair Manual PDFservimaquinados plazas sas56% (9)

- NH E135B Código de Erro MotorDokument27 SeitenNH E135B Código de Erro MotorFernando SabinoNoch keine Bewertungen

- Design of PenstocksDokument28 SeitenDesign of Penstockschithirai10Noch keine Bewertungen

- Thermography ReportDokument9 SeitenThermography ReportsandrositohangNoch keine Bewertungen

- Fluid Flow Measurement Techniques and DevicesDokument75 SeitenFluid Flow Measurement Techniques and DevicesArah Louise ApostolNoch keine Bewertungen

- FEA Answers by Professor GuruprasadDokument146 SeitenFEA Answers by Professor GuruprasadManendra SaiNoch keine Bewertungen

- PFEIFER Tension Rod System: Data Sheet CollectionDokument16 SeitenPFEIFER Tension Rod System: Data Sheet Collectioncerbu_bass_cdcNoch keine Bewertungen

- Repair WeldingDokument33 SeitenRepair WeldingAkhilesh Kumar100% (1)

- Mineral and Synthetic Lubricants SummaryDokument6 SeitenMineral and Synthetic Lubricants SummaryDarmawan PutrantoNoch keine Bewertungen

- Maintenance ScheduleDokument22 SeitenMaintenance ScheduleDen100% (2)

- Modern Bulk Storage Tanks Design & ManufacturingDokument2 SeitenModern Bulk Storage Tanks Design & ManufacturingSCALE Ingeniería y ConstrucciónNoch keine Bewertungen

- Chapter 3Dokument17 SeitenChapter 3Mintesnot TadeleNoch keine Bewertungen

- Overview of Drilling OperationDokument106 SeitenOverview of Drilling OperationTemitope BelloNoch keine Bewertungen