Beruflich Dokumente

Kultur Dokumente

Insulating Flange Kits

Hochgeladen von

Andry RimanovOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Insulating Flange Kits

Hochgeladen von

Andry RimanovCopyright:

Verfügbare Formate

Datasheet 4.1.

6/8/08

17:18

Page 1

PIPELINE EARTHING & ISOLATION ACCESSORIES

DATASHEET 4.1.1

INSULATING FLANGE KITS

REVISION 1

APPLICATION

Flange insulation kits for metallic pipelines are available for all flange sizes, types, pressure ratings and materials. Flange

insulation kits are commonly installed at each end of a pipeline to electrically isolate the pipe for other buried foreign

metallic structures and plant grounding systems therefore limiting the amount of cathodic protection current required

to protect the pipeline.

FLANGE INSULATION KIT DATA

TYPE "E" GASKETS

Have the same outside diameter as the flanges, and are made

with precision-located bolt holes. They are easy to centre and

will prevent foreign material from becoming lodged between

the flange faces and "shorting out" the flange insulation.

Type "E" gaskets are available in a wide variety of materials.

TYPE "F" GASKETS

Are made to fit within the bolt hole circle of the flange faces.

The outside diameter of the gasket is slightly larger than the

inside diameter of the bolt hole circle. They are available in a

wide variety of materials.

Venture Way, Grantham, Lincs NG31 7XS UK. Tel: +44 (0)1476 590666 Fax: +44 (0)1476 570605

Email: cpc@cathodic.co.uk Website: www.cathodic.co.uk

Registered Office: Minalloy House, Regent Street, Sheffield S1 3NJ, UK VAT No. 116 8408 71, Regd in England No. 478098

DATASHEET

4.1.1

Datasheet 4.1.1

6/8/08

17:18

Page 2

PIPELINE EARTHING & ISOLATION ACCESSORIES

DATASHEET 4.1.1

INSULATING FLANGE KITS

REVISION 1

TYPE "D" GASKETS

Are made specifically to fit into the ring groove of RTJ flanges.

They are available in reinforced phenolic and other materials.

INSULATING SLEEVES AND WASHERS

Are available in complete kits, with or without a gasket.

Sleeves and washer are available as separate parts or as a

one-piece moulded unit. Sleeves and washers are enclosed

in a strong polyethylene bag to eliminate any possibility of loss.

TYPICAL SPECIFICATIONS

Standard Specification Range

Flange Isolation Kit Specification : Materials for flange isolation kits on pipes containing water, aqueous fluids or natural

gas (up to 221F, 105C) shall consist of the following components:

Isolating and Sealing Gasket : One full faced isolating and sealing gasket, LineBacker Type E, 1/8 thick, phenolic

retainer containing a precision tapered groove to accommodate the controlled compression of a nitrile quad-ring sealing

element. Sealing element placement shall accommodate either flat, raised or RTJ face flanges. The quad-ring seal shall

be pressure energized. The phenolic retainer shall have a 500 volts/mil dielectric strength and a minimum 25,000 psi

compressive strength. The full faced flange isolating gasket shall be 1/8 less in I.D. than the I.D. of the flange in which

it is installed.

Full Length Bolt Isolating Sleeves : One full length Mylar sleeve (extending half way into both steel washers) for each

flange bolt. The Mylar shall be a 1/32 thick tube with a 4000 volts/mil dielectric strength and water absorption

of 0.8% or less.

Washers : Two, 1/8 thick, glass clad phenolic isolating washers for each bolt. Their compressive strength shall be

33,000 psi, dielectric strength 500 volts/mil and water absorption 1.6% or less. Two, 1/8 thick steel washers for

each bolt. The I.D. of all washers shall fit over the isolating sleeve and both the steel and isolating washers shall have

the same I.D. and O.D.

DATASHEET

4.1.1

Venture Way, Grantham, Lincs NG31 7XS UK. Tel: +44 (0)1476 590666 Fax: +44 (0)1476 570605

Email: cpc@cathodic.co.uk Website: www.cathodic.co.uk

Registered Office: Minalloy House, Regent Street, Sheffield S1 3NJ, UK VAT No. 116 8408 71, Regd in England No. 478098

Datasheet 4.1.1

6/8/08

17:18

Page 3

PIPELINE EARTHING & ISOLATION ACCESSORIES

DATASHEET 4.1.1

INSULATING FLANGE KITS

REVISION 1

High Temperature Specification Range

Flange Isolation Kit Specification : Materials for flange isolation kits on pipes containing natural gas, oil and aqueous

fluids (up to 280F, 138C) shall consist of the following components:

Isolating and Sealing Gasket : One full faced isolating and sealing gasket, LineBacker Type E, 1/8 thick, G-10 retainer

containing a precision tapered groove to accommodate the controlled compression of a Teflon (or Viton) quad-ring

sealing element. Sealing element placement shall accommodate either flat, raised face or RTJ flanges. The quad-ring

seal shall be pressure energized. The G-10 retainer shall have a 550 volts/mil dielectric strength and a minimum

50,000 psi compressive strength. The full faced flange isolating gasket shall be 1/8 less in I.D. than the I.D. of the

flange in which it is installed.

Full Length Bolt Isolating Sleeves : One full length G-10 sleeve (extending half way into both steel washers) for each

flange bolt. The G-10 shall be a 1/32 inch thick tube with a 400 volts/mil dielectric strength and water absorption

of 0.10% or less.

Washers : Two, 1/8 thick, G-10 isolating washers for each bolt. Their compressive strength shall be 50,000 psi,

dielectric strength 550 volts/mil and water absorption 0.10% or less. Two, 1/8 thick zinc plated, hot rolled steel

washers for each bolt. The I.D. of all washers shall fit over the isolating sleeve and both the steel and isolating washers

shall have a same I.D. and O.D.

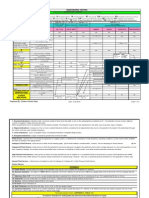

Common LineBacker & Gasket Seal Laminates/Retainers Physical Properties & Max Temperature Limits

Venture Way, Grantham, Lincs NG31 7XS UK. Tel: +44 (0)1476 590666 Fax: +44 (0)1476 570605

Email: cpc@cathodic.co.uk Website: www.cathodic.co.uk

Registered Office: Minalloy House, Regent Street, Sheffield S1 3NJ, UK VAT No. 116 8408 71, Regd in England No. 478098

DATASHEET

4.1.1

Datasheet 4.1.1

6/8/08

17:18

Page 4

PIPELINE EARTHING & ISOLATION ACCESSORIES

DATASHEET 4.1.1

INSULATING FLANGE KITS

REVISION 1

ASTM

Test Method

Plain

Phenolic

Neoprene

Faced

Phenolic

D149

Dielectric Strength

500

500

550

350-400

550

550

25,000

25,000

50,000

40,000

50,000

50,000+

G-3 Hi-Temp

(*)G-7

G-10

G-11

Phenolic Silicon Glass Epoxy Glass Epoxy Glass

Volts/Mil (short time)

D695

Compressive Strength (psi)

D229

Water Absorbtion (%)

1.60

1.60

0.70

0.07

0.10

0.10

D257

Insulation Resistance (M)

40,000

40,000

46,000

2,500

200,000

200,000

D790

Flexural Strength (psi)

22,500

22,500

60,000

27,000

60,000

75,000+

D785

Hardness Rockwell M

85

85

115

105

115

115

D256

IZOD Impact Strength

1.2

1.2

12.0

8.0

14.0

12.0

(ft-lbs/inch)

D638

Tensile Strength (psi)

20,000

20,000

42,000

25,000

45,000

43,000

D732

Shear Strength (psi)

10,000

10,000

18,000

20,000

22,000

22,000

Temperature Range (F)

-65 to

-65 to

-65 to

Cryogenic

Cryogenic

Cryogenic

+220

+175

+392

to +450

to +280

to +350

-54 to

-54 to

-54 to

Cryogenic

Cryogenic

Cryogenic

+104

+79

+200

to +232

to +138

to +177

Temperature Range (C)

(*) G-7 Material should not be used with Hydrocarbons, not even in trace amounts

For every enquiry or Order please quote:

Flange Pressure Class and Standard (ANSI, BS, DIN)

Nominal Pipe Diameter

Type E, F or D Flange Kit

Type of Insulating Material required for Central Gasket & Sleeves

Type of Product being carried by Pipeline

DATASHEET

4.1.1

Venture Way, Grantham, Lincs NG31 7XS UK. Tel: +44 (0)1476 590666 Fax: +44 (0)1476 570605

Email: cpc@cathodic.co.uk Website: www.cathodic.co.uk

Registered Office: Minalloy House, Regent Street, Sheffield S1 3NJ, UK VAT No. 116 8408 71, Regd in England No. 478098

Das könnte Ihnen auch gefallen

- Flange InsulDokument8 SeitenFlange InsulAneesh JoseNoch keine Bewertungen

- 4 1 1-InsulatingFlangeKits PDFDokument4 Seiten4 1 1-InsulatingFlangeKits PDFKykyRizkyNoch keine Bewertungen

- Flange Insulation Kits: DescriptionDokument6 SeitenFlange Insulation Kits: DescriptionLis RincónNoch keine Bewertungen

- Flange Insulation KitDokument2 SeitenFlange Insulation KitDGWNoch keine Bewertungen

- Spark Gaps: Dehn (Uk) LTDDokument8 SeitenSpark Gaps: Dehn (Uk) LTDElectromacnetist ElectrodNoch keine Bewertungen

- Flange Insulation PresentationDokument10 SeitenFlange Insulation PresentationNadeemNoch keine Bewertungen

- Hempel Galvosil 1570019840Dokument2 SeitenHempel Galvosil 1570019840Jj OredinaNoch keine Bewertungen

- HSS80 Heat Shrink Sleeve: Features & BenefitsDokument2 SeitenHSS80 Heat Shrink Sleeve: Features & BenefitsAnonymous eEJDOR2100% (1)

- BS 1595 PDFDokument9 SeitenBS 1595 PDFAdesina AlabiNoch keine Bewertungen

- Holiday TestDokument2 SeitenHoliday TestnationalfoxNoch keine Bewertungen

- Asme Section 1 - Pmi PDFDokument3 SeitenAsme Section 1 - Pmi PDFArul Edwin VijayNoch keine Bewertungen

- Interseal 670HDokument2 SeitenInterseal 670Hmadmax_mfpNoch keine Bewertungen

- T&A Flange Insulation Kits PDFDokument4 SeitenT&A Flange Insulation Kits PDFJuan CarlosNoch keine Bewertungen

- Raychem e CatalogDokument99 SeitenRaychem e Catalogarifayee-1Noch keine Bewertungen

- DISI-QA-ITPG-ME-MS-004 Rev 0, ITP For Field Application For External Heat-Shrinkable Coating of Steel Pipe Fitting and JointsDokument5 SeitenDISI-QA-ITPG-ME-MS-004 Rev 0, ITP For Field Application For External Heat-Shrinkable Coating of Steel Pipe Fitting and JointsJamal Budeiri0% (1)

- MSDS Iridium-192 Sealed Sources (Special Form) REV 2018.12.05Dokument4 SeitenMSDS Iridium-192 Sealed Sources (Special Form) REV 2018.12.05Nafiah -Noch keine Bewertungen

- Iso 4624 2016Dokument9 SeitenIso 4624 2016Luis CarneroNoch keine Bewertungen

- Barcoill Hardness Test PDFDokument2 SeitenBarcoill Hardness Test PDFProkopNoch keine Bewertungen

- NDT of PipingDokument1 SeiteNDT of PipingVu Tung LinhNoch keine Bewertungen

- Underground Insulation Specification Data SheetDokument2 SeitenUnderground Insulation Specification Data Sheetadoptvn100% (1)

- Zinc Rich Anticorrosive Primer PDFDokument53 SeitenZinc Rich Anticorrosive Primer PDFDhruv SevakNoch keine Bewertungen

- Astm A106 Ts EnglDokument4 SeitenAstm A106 Ts EnglxaviereduardoNoch keine Bewertungen

- Reliance Industries Limited Line History Sheet For CS Piping Without PWHTDokument1 SeiteReliance Industries Limited Line History Sheet For CS Piping Without PWHTRavi ShankarNoch keine Bewertungen

- Bleed Ring ReportDokument1 SeiteBleed Ring ReportRatna Giridhar KavaliNoch keine Bewertungen

- 02 Samss 006Dokument17 Seiten02 Samss 006inatt101Noch keine Bewertungen

- Vlosi Holiday Test Report No-16Dokument1 SeiteVlosi Holiday Test Report No-16Anonymous uJzSZ5100% (1)

- Data Sheet - Pipeline Barred Tee: Category Sl. Attribute ValueDokument2 SeitenData Sheet - Pipeline Barred Tee: Category Sl. Attribute ValueYusri Fakhrizal100% (1)

- Checklist For Above Ground Tanks-QueenslandDokument2 SeitenChecklist For Above Ground Tanks-QueenslandmohanumaNoch keine Bewertungen

- Chartek 1709 Ul Xr625 NuevaDokument3 SeitenChartek 1709 Ul Xr625 NuevaAndres LopezNoch keine Bewertungen

- G8s-5034-02-Bubble Leak TestDokument4 SeitenG8s-5034-02-Bubble Leak TestmaheshNoch keine Bewertungen

- Halliburton Multi Chem Batch Plant Project: Purchase Order/Contract NumberDokument7 SeitenHalliburton Multi Chem Batch Plant Project: Purchase Order/Contract NumberTahseen Ahmed100% (1)

- Wavistrong Supplemental Installation InstructionsDokument13 SeitenWavistrong Supplemental Installation Instructionsmg4myNoch keine Bewertungen

- Inspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusDokument18 SeitenInspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusoberaiNoch keine Bewertungen

- E1 Technical Data Sheet - ShortDokument2 SeitenE1 Technical Data Sheet - ShortOmaiyio M. SaginiNoch keine Bewertungen

- Paint Coating Stainless SteelsDokument2 SeitenPaint Coating Stainless SteelsSilva NumaNoch keine Bewertungen

- Tube-To-Tube Sheet Joint RequirementsDokument2 SeitenTube-To-Tube Sheet Joint RequirementsWaqas WaqasNoch keine Bewertungen

- As 4822-2008 External Field Joint Coatings For Steel PipelinesDokument8 SeitenAs 4822-2008 External Field Joint Coatings For Steel PipelinesSAI Global - APAC0% (1)

- Factory Applied External Pipeline Coatings For Corrosion ControlDokument32 SeitenFactory Applied External Pipeline Coatings For Corrosion ControlMatt AgonyaNoch keine Bewertungen

- Internal Epoxy Coating For PipelinesDokument11 SeitenInternal Epoxy Coating For PipelinesSkazemi7100% (2)

- Brittle Fracture of Carbon Steel Piping During Hydrostatic TestingDokument4 SeitenBrittle Fracture of Carbon Steel Piping During Hydrostatic TestingSH1961Noch keine Bewertungen

- Holiday Detection in Pipeline Coatings: Standard Test Methods ForDokument4 SeitenHoliday Detection in Pipeline Coatings: Standard Test Methods ForAlejandro ValdesNoch keine Bewertungen

- Cuel CPT ReportDokument103 SeitenCuel CPT ReportIkhsan Ly100% (1)

- 2 Specification For GRP PipingDokument4 Seiten2 Specification For GRP Pipinggc_panchaNoch keine Bewertungen

- ET Subsea Ball ValvesDokument9 SeitenET Subsea Ball ValvesAndrew BaileyNoch keine Bewertungen

- Inspection and Test Plan - LR Bends For Onshore Pipelines VCS-PL-ITP-004Dokument6 SeitenInspection and Test Plan - LR Bends For Onshore Pipelines VCS-PL-ITP-004Vidyut UjalaNoch keine Bewertungen

- Coating Test With The ISOTEST Holiday Detector PDFDokument6 SeitenCoating Test With The ISOTEST Holiday Detector PDFÖzgür TuştaşNoch keine Bewertungen

- Er 100 S 1Dokument1 SeiteEr 100 S 1Oliver Quezada Inostroza100% (1)

- Painting Stainless SteelDokument2 SeitenPainting Stainless SteelrmjiranNoch keine Bewertungen

- Installation of Distribution-to-Utilization Voltage TransformersDokument7 SeitenInstallation of Distribution-to-Utilization Voltage TransformersadauNoch keine Bewertungen

- PDS Na GTS65 PDFDokument2 SeitenPDS Na GTS65 PDFMoaatazz NouisriNoch keine Bewertungen

- Adhesion Test For PaintDokument44 SeitenAdhesion Test For PaintLaughlikesiao HeheNoch keine Bewertungen

- Nace Table 3Dokument2 SeitenNace Table 3gana_1783100% (1)

- Corrosion Coupan Check ListDokument2 SeitenCorrosion Coupan Check Listtrichysayee100% (1)

- TECHNICALVOLUMEIIAOFIIDokument216 SeitenTECHNICALVOLUMEIIAOFIIRanjan KumarNoch keine Bewertungen

- Insulation Kits Data SheetDokument2 SeitenInsulation Kits Data SheetCalvin WongNoch keine Bewertungen

- Water Agencies' Standards Standard SpecificationsDokument9 SeitenWater Agencies' Standards Standard SpecificationsAdelChNoch keine Bewertungen

- Spirax Sarco BTM-7Dokument3 SeitenSpirax Sarco BTM-7Bambang Agung LaxmonoNoch keine Bewertungen

- Knife Gate Valve - For Reference OnlyDokument16 SeitenKnife Gate Valve - For Reference Onlysj_scribdNoch keine Bewertungen

- Insulation Gaskets For Flange (Catalog)Dokument8 SeitenInsulation Gaskets For Flange (Catalog)OluwachidiNoch keine Bewertungen

- Sihi Pompa LPG API 610Dokument1 SeiteSihi Pompa LPG API 610Andry RimanovNoch keine Bewertungen

- 0415 Repair TechnologyDokument6 Seiten0415 Repair TechnologyAndry RimanovNoch keine Bewertungen

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Dokument2 SeitenWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- RT Acceptance CriteriaDokument3 SeitenRT Acceptance CriteriaAndry Rimanov89% (18)

- Https - Threejs - Org - Examples - Webgl - Fire - HTMLDokument9 SeitenHttps - Threejs - Org - Examples - Webgl - Fire - HTMLMara NdirNoch keine Bewertungen

- Techno Enviro EconomicanalysisofintegrateddirectchemicalloopingDokument14 SeitenTechno Enviro EconomicanalysisofintegrateddirectchemicalloopingAhmad SyauqiNoch keine Bewertungen

- Ddrive Transmission ReportDokument43 SeitenDdrive Transmission Reportelah150% (2)

- HART - Wikipedia, The Free EncyclopediaDokument3 SeitenHART - Wikipedia, The Free EncyclopediakalyanupdownNoch keine Bewertungen

- It Park Design Submission PDFDokument20 SeitenIt Park Design Submission PDFSAKET TYAGI100% (1)

- Sip Dissertation - Final - Final For CollegeDokument17 SeitenSip Dissertation - Final - Final For Collegevikashirulkar922Noch keine Bewertungen

- LTE 3GPP Band13 Test Entrance CriteriaDokument130 SeitenLTE 3GPP Band13 Test Entrance CriteriaBuchi Reddy0% (1)

- Sugar Factory InsulationDokument29 SeitenSugar Factory InsulationZerihun Negash100% (1)

- BÀI TẬP TA 9 THEO CHUYÊN ĐỀ NGỮ PHÁPDokument213 SeitenBÀI TẬP TA 9 THEO CHUYÊN ĐỀ NGỮ PHÁPhoangmaiNoch keine Bewertungen

- Iec TR 62343-6-8-2011Dokument14 SeitenIec TR 62343-6-8-2011Amer AmeryNoch keine Bewertungen

- Concrete ON MALDIVESDokument55 SeitenConcrete ON MALDIVESKãrthìçk JkrNoch keine Bewertungen

- Reason: God Had Made The Mistake of Sending Only 70 PesosDokument2 SeitenReason: God Had Made The Mistake of Sending Only 70 PesosS Vaibhav81% (21)

- Research Papers On Climate Change Global WarmingDokument4 SeitenResearch Papers On Climate Change Global Warminggw1nm9nbNoch keine Bewertungen

- 300.91C - Fire Alarm System Pre-Test and Acceptance Test Checklist 3-27-14Dokument2 Seiten300.91C - Fire Alarm System Pre-Test and Acceptance Test Checklist 3-27-14mthuyaNoch keine Bewertungen

- Orchestral Recording, January 2006Dokument10 SeitenOrchestral Recording, January 2006Rhys WilliamsNoch keine Bewertungen

- Drainage BasinsDokument4 SeitenDrainage BasinsDannySP10100% (1)

- An Adaptive Power Oscillation Damping Controllerby STATCOM With Energy StorageDokument10 SeitenAn Adaptive Power Oscillation Damping Controllerby STATCOM With Energy StorageChristian EmenikeNoch keine Bewertungen

- Elements, Compounds, MixturesDokument35 SeitenElements, Compounds, MixturesNorvieNoch keine Bewertungen

- (Nano and Energy) Gavin Buxton - Alternative Energy Technologies - An Introduction With Computer Simulations-CRC Press (2014) PDFDokument302 Seiten(Nano and Energy) Gavin Buxton - Alternative Energy Technologies - An Introduction With Computer Simulations-CRC Press (2014) PDFmarcosNoch keine Bewertungen

- EOCR 종합 EN 2015 PDFDokument228 SeitenEOCR 종합 EN 2015 PDFShubhankar KunduNoch keine Bewertungen

- National Railway Museum Annual Review 04-05Dokument40 SeitenNational Railway Museum Annual Review 04-05sol.loredo1705530Noch keine Bewertungen

- TotSK 3.0Dokument22 SeitenTotSK 3.0PedroNoch keine Bewertungen

- AT2H - Basics - Symbolism in HinduismDokument28 SeitenAT2H - Basics - Symbolism in Hinduismapi-3764210Noch keine Bewertungen

- ASTM A581 A581M-95bDokument3 SeitenASTM A581 A581M-95bFeteneNoch keine Bewertungen

- B2 - Effects of UV-C Treatment and Cold Storage On Ergosterol and Vitamin D2 Contents in Different Parts of White and Brown Mushroom (Agaricus Bisporus)Dokument6 SeitenB2 - Effects of UV-C Treatment and Cold Storage On Ergosterol and Vitamin D2 Contents in Different Parts of White and Brown Mushroom (Agaricus Bisporus)Nadya Mei LindaNoch keine Bewertungen

- Flap Designs For Flap Advancement During Implant Therapy A Systematic Review 2016 PDFDokument8 SeitenFlap Designs For Flap Advancement During Implant Therapy A Systematic Review 2016 PDFRohit ShahNoch keine Bewertungen

- Multilicative ABC IndexDokument6 SeitenMultilicative ABC IndexBalachandranNoch keine Bewertungen

- The Six Types of Simple MachinesDokument4 SeitenThe Six Types of Simple MachinesmarroNoch keine Bewertungen

- Correlation of Body Mass Index With Endometrial Histopathology in Abnormal Uterine BleedingDokument101 SeitenCorrelation of Body Mass Index With Endometrial Histopathology in Abnormal Uterine BleedingpritamNoch keine Bewertungen

- Cutting Room Agility and ExcellenceDokument8 SeitenCutting Room Agility and Excellenceperro perezNoch keine Bewertungen