Beruflich Dokumente

Kultur Dokumente

Metallic Foam-Filled Triple Tube Concentric Heat Exchanger

Hochgeladen von

Editor IJRITCCCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Metallic Foam-Filled Triple Tube Concentric Heat Exchanger

Hochgeladen von

Editor IJRITCCCopyright:

Verfügbare Formate

International Journal on Recent and Innovation Trends in Computing and Communication

Volume: 3 Issue: 5

ISSN: 2321-8169

2541 - 2547

_______________________________________________________________________________________________

Metallic Foam-Filled Triple Tube Concentric Heat Exchanger

Mishra Roshan*, Chaudhari Kiran #

*

#

Dept. of Mechanical Engineering, Rajiv Gandhi Institute of Technology, University of Mumbai

Dept. of Mechanical Engineering, Rajiv Gandhi Institute of Technology, University of Mumbai

E-mail: rmrgit@gmail.com;mkiran02@rediffmail.com

Tel: +91 7498663925

Abstract

Aim: To enhance the heat transfer rate using metal foams.

The performance of Triple tube coaxial heat exchanger is evaluated using CFD simulation technique for different mass-flow rates, where

the flow pattern is kept counter-current. A metal foam is placed in the inner annulus of the middle pipe. Water is used as a working fluid in

all the tubes but their temperatures were kept different for heat transfer to take place. Hot water flowing through the middle pipe transfers

the heat to the fluids flowing through the other pipes due to the temperature difference but in this case the amount of heat transferred is

more compared to that in plain tube due to the addition of aluminum foam. For middle pipe in which foam is placed, the temperature and

pressure drops are plotted for the hot water against the mass flow rates both for with and without foam conditions. Results shows that the

temperature drop decreases with the increase in mass flow rate whereas the pressure drop increases with the increase in mass-flow rate. The

noticeable content of the report is that, the temperature and pressure drop in tube with foam was more compared to that in tube without

foam.

Keywords: Triple tube; Metal foam; Simulation of aluminum foam using CFD.

______________________________________________*****______________________________________________

The Triple tube heat exchanger mentioned in the topic consists of three concentric tubes of different diameters & lengths. The

third pipe improves the heat transfer through an additional flow passage and a larger heat transfer area per unit exchanger length.

The key element of this heat exchanger is the aluminum foam which is placed inside the inner annulus of the middle pipe of the

heat exchanger as shown in fig no.2. The metal (aluminum) foam increases the surface area and therefore it has the capability of

enhancing the heat transfer. The main objective of this project is to find an alternative method for heat dissipation. Since the

advancement in technology demands for compactness in devices and equipment, therefore, it becomes necessary to device a

system which would for the same heat transfer acquires smaller space. The concept arises from the much higher area to volume

ratio, which is almost five times higher than finned-tube bundles. This means that the same weight of metal foam should be five

times more compact than the fins and consequently also requires much less area for setup. The need for compactness led the

researchers to focus on materials and their arrangements for enhancing the heat transfer/dissipation at comparatively higher rate.

Moreover, the use of fins also does not reduce the area to greater extent as would be expected for compactness. Metal foams could

thus be used to replace even finned tubes. The foams are rigid, and lightweight, non-poisonous structure which have high surface

area and recyclable which improve energy absorption and heat transfer in thermal applications, such as heat exchangers. Foam

ligaments in the flow direction results in boundary layer disruption and mixing. The advantages of metal-foams lie on their lowdensity, large surface area in a limited volume and high strength structure. Metal foams are very costly but due to recent

developments in the metal sintering method for foam manufacture, there costs have been reduced..Calmidi and Mahajan (1999)

[1] investigated the effective thermal conductivity of high-porosity fibrous metal foams experimentally. An empirical correlation

was developed and a theoretical model was derived. The model predictions agreed closely with the experimental data and were

used for the evaluation of metal foams as possible candidates for heat sinks in electronics cooling applications. K. Boomsma, D.

Poulikakos, F.Zwick (2003) [2] observed that open-cell metal foams with an average cell diameter of 2.3 mm were manufactured

from 6101-T6 aluminum alloy and were compressed into compact heat exchangers possessing a surface area to volume ratio of the

order of 10,000 m2/m3. They were placed into a forced convection arrangement using water as the coolant. These experiments

performed with water were scaled to estimate the heat exchangers performance when used with a 50% waterethylene glycol

solution, and were then compared to the performance of commercially available heat exchangers which were designed for the

same heat transfer application. The heat exchangers were compared on the basis of required pumping power versus thermal

resistance. The compressed open-cell aluminum foam heat exchangers generated thermal resistances that were two to three times

lower than the best commercially available heat exchanger tested, while requiring the same pumping power. W. Lua, C.Y. Zhao,

S.A.Tassou (2005) [3] presents an analytical study of the forced convection heat transfer characteristics in high porosity open-cell

2541

IJRITCC | May 2015, Available @ http://www.ijritcc.org

_______________________________________________________________________________________

International Journal on Recent and Innovation Trends in Computing and Communication

Volume: 3 Issue: 5

ISSN: 2321-8169

2541 - 2547

_______________________________________________________________________________________________

metal-foam filled pipes. Based on the analytical solutions, the velocity and temperature distributions in metal-foam filled pipes

were obtained. The effects of the microstructure of metal foams on overall heat transfer were examined. The results show that the

pore size and porosity of metal-foams play important roles on overall heat transfer performance. The use of metal-foam can

dramatically enhance the heat transfer but at the expense of higher pressure drop. ShadiMahjoob, KambizVafai (2007) [4] states

that Metal foam heat exchangers have considerable advantages in thermal management and heat recovery over several

commercially available heat exchangers. In this work, the effects of micro structural metal foam properties, such as porosity, pore

and fiber diameters, tortuosity, pore density, and relative density, on the heat exchanger performance are discussed. Three main

categories are synthesized. In the first category, the correlations for pressure drop and heat transfer coefficient based on the

microstructural properties of the metal foam are given. In the second category, the correlations are specialized for metal foam tube

heat exchangers. In the third category, correlations are specialized for metal foam channel heat exchangers. To investigate the

performance of the foam filled heat exchangers in comparison with the plain ones, the required pumping power to overcome the

pressure drop and heat transfer rate of foam filled and plain heat exchangers are studied and compared. A performance factor is

introduced which includes the effects of both heat transfer rate and pressure drop after inclusion of the metal foam. The results

indicate that the performance will be improved substantially when a metal foam is inserted in the tube/channel.M. A. Delavar and

M. Azimi (2013) [5] states that the heat transfer duty of heat exchangers can be improved by passive heat transfer enhancement

techniques. On the basis of a theoretical and experimental analysis the conclusion derived was that the best heat transfer

enhancement can be reached by the use of porous material as an inexpensive technique to extend the heat transfer area, improve

effective thermal conductivity, and mix fluid flow. G.A.Quadir, IrfanAnjumBadruddin, N.J. Salman Ahmed et al (2013) [6]

experimented the performance of a triple concentric pipe heat exchanger and carried out numerically using finite element method

(FEM) under steady state conditions for different flow arrangements and for insulated as well as non-insulated conditions of the

heat exchanger. The three fluids being considered are hot water, cold water and the normal tap water. The results are presented in

the form of the dimensionless temperature variations of the three fluids along the length of the heat exchanger for their different

flow rates. It is found that the numerical predictions of the temperature variations of the three fluids by using FEM follow closely

to those obtained from experiments both in magnitude and trend provided correct overall heat transfer coefficients are used. Triple

concentric-tube heat exchangers provide better heat transfer efficiencies compared to the double concentric-tube heat exchangers.

Nomenclature

NF

Normal fluid at 30C

HF

Hot fluid at 70C

Tc1

Inlet temperature of innermost fluid

Tc2

Outlet temperature of innermost fluid

Th1

Inlet temperature of middle fluid

Th2

Outlet temperature of middle fluid

Tc3

Inlet temperature of outermost fluid

Tc4

Outlet temperature of outermost fluid

Thermal conductivity

Cf

Inertial coefficient

Dp

Pore diameter

Df

Fiber diameter

PPI

Pores per inch

Permeability

Convective heat transfer coefficient

2542

IJRITCC | May 2015, Available @ http://www.ijritcc.org

_______________________________________________________________________________________

International Journal on Recent and Innovation Trends in Computing and Communication

Volume: 3 Issue: 5

ISSN: 2321-8169

2541 - 2547

_______________________________________________________________________________________________

The experimental model as shown in fig 1 is made on solid works as per the dimensions mentioned above and the same is

imported in Ansys 14.5 where simulation is done. The boundary conditions for the simulation are described below. All inlets are

provided with the same mass flow rate as the input. All the outlets are kept as pressure outlets. The outer wall pipe is maintained

Adiabatic. The metal foam is given a porous condition and it is been applied with necessary foam properties like porosity, inertial

resistance & viscous resistance allowed by Ansys. Porosity kept for simulation is 0.65.

Inlet NF

Metal

Inlet HF

Fddfoam

Fig 1 Model in Solid works

Fig 2 Sectional view indicating Location of metal foam

The solution methods adopted are Pressure-velocity coupling scheme SIMPLE, Spatial Discretization Gradient Green-Gauss Node

Based, Pressure Standard, Momentum Second Order Upwind, Energy Second Order Upwind. The under-relaxation factors for:

pressure =0.3, Density=1, Body forces=1, Momentum=0.7 & energy=0.7.The total no of iterations (500) are kept uniform for all

the simulations. Mesh was tetrahedral with prism layers on boundary. Simulation was done for two cases, one was for plain triple

tube i.e. without foam & another was by putting the metal foam inside the inner annular space of the middle pipe. After simulation

the results obtained are shown in table no.1 & 2 below.

Appearance

Fig 3 Truncated-octahedron foam

Fig 4 Large porosity of metal foam

2543

IJRITCC | May 2015, Available @ http://www.ijritcc.org

_______________________________________________________________________________________

International Journal on Recent and Innovation Trends in Computing and Communication

Volume: 3 Issue: 5

ISSN: 2321-8169

2541 - 2547

_______________________________________________________________________________________________

Porosity or void fraction:

It is a measure of the void (i.e. "empty") spaces in a material, and is a fraction of the volume of voids over the total volume,

between 0 and 1, or as a percentage between 0 and 100%. There are many ways to test porosity in a substance or part, such as

industrial CT scanning. The term porosity is used in multiple fields including pharmaceutics, ceramics, metallurgy, materials,

manufacturing, earth sciences, soil mechanics and engineering. Based on whether they have larger void spaces they are called as

large porosity foams or small porosity foams. As shown in fig. 5 above, it is large porosity metal foam and in fig 6 below is small

porosity metal foam.

Fig 5 Small porosity of metal foam

Placing the metal foam in the heat exchanger

Fig 6

Metal foam placed inside the heat exchanger (Solid works)

The authors also found that good thermal contact between the foam and the tube was critical to the heat transfer and noted that

more research is required to develop a cost effective and efficient attachment process to fix the metal foams to the tube cores. In

this regard, de Jaeger et al (2012) have identified four possible methods of connecting the foam to the tube:

a. Brazing

b. Co-casting

c. Thermal glue bonding and

d. Mechanical press-fitting.

For heat transfer, they found brazing to be the best technique while press-fitting was the worst.

Working:

2544

IJRITCC | May 2015, Available @ http://www.ijritcc.org

_______________________________________________________________________________________

International Journal on Recent and Innovation Trends in Computing and Communication

Volume: 3 Issue: 5

ISSN: 2321-8169

2541 - 2547

_______________________________________________________________________________________________

Inlet normal fluid

Inlet hot fluid

Fig 7 Model showing inlets and outlets

Hot water will be passed through the intermediate pipe as shown in fig.7 similarly cold water will be passed through the annular

area and the innermost pipe. Outlets of all the pipes are exposed to the atmosphere. Heat is first transferred from hot water to pipe

wall due to convection then heat is conducted through the pipe wall then finally to the cold water by convection. Here the Surface

area is been increased by putting metal foams inside the heat exchanger. This results in higher heat transfer rate. But obviously at

higher pressure drop. This concept is useful where pressure drop is not much important factor compared to the heat transfer.

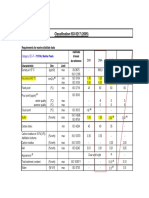

Simulation Results:

Comparison results for different mass-flow rates for pressure drop with and without foam

Table 1 Pressure drop without foam and with foam

Without foam

With foam

Mass flow rates

Pressure drop(pa)

Pressure

drop(pa)

0.0225

3.56391

4.57219

0.0235

3.85578

6.11571

0.025

4.31572

6.62488

0.035

8.0336

10.3078

0.045

12.898

13.7486

0.05

15.762

17.7831

0.06

22.3437

24.378

0.085

43.8521

49.8955

2545

IJRITCC | May 2015, Available @ http://www.ijritcc.org

_______________________________________________________________________________________

International Journal on Recent and Innovation Trends in Computing and Communication

Volume: 3 Issue: 5

ISSN: 2321-8169

2541 - 2547

_______________________________________________________________________________________________

Table 2 Temperature drop without foam and with foam

Without foam

With foam

Mass flow rates

Temperature

drop(K)

Temperature

drop(K)

0.0225

16.464

23.884

0.0235

15.919

23.2275

0.025

15.258

22.257

0.035

11.727

16.276

0.045

9.381

12.2782

0.05

8.493

10.878

0.06

7.072

8.804

0.085

4.962

5.899

Comparison of various parameters necessary for heat transfer with and without foam

Parameter comparison

Parameters

With foam

Without foam

Effectiveness ()

0.596

0.4108

Overall heat transfer coefficient (U)

0.1672

0.0947

Heat transfer (Q)

2.2469

1.5479

Conclusions of simulation results

From the simulation results we observe the following things:

With the increase in mass flow rate the pressure drop and temperature drop increases in both the cases but more in the case with

metal foam. Heat transfer could thus be increased significantly but with an increase in pressure drop. Thus we can put only 200

mm length of metal foam for 2.2469kW of heat transfer for 0.0225kg/s of mass flow rate.

References

[1] Calmidi, V.V, and Mahajan, R.L., The effective thermal conductivity of high porosity Fibrous metal foams, J. Heat Transfer, vol. 121,

pp. 466-471, 1999.

[2] Boomsma, K., Poulikakos, D., and Zwick, F., Metal foams as compact high Performance heat exchangers, Mechanics of Materials,

vol.35, pp.1161-1176, 2003.

[3] W. Lua, C.Y Zhao, S.A.Tassau, Thermal analysis on metal-foam filled heat exchangers. Part I: Metal- foam filled pipes Thermal

analysis on metal-foam filled heat exchangers. Part I: Metal-foam filled pipes (10 march 2006)

2546

IJRITCC | May 2015, Available @ http://www.ijritcc.org

_______________________________________________________________________________________

International Journal on Recent and Innovation Trends in Computing and Communication

Volume: 3 Issue: 5

ISSN: 2321-8169

2541 - 2547

_______________________________________________________________________________________________

[4] ShadiMahjoob, KambizVafai, A synthesis of fluid and thermal transport models for metal foam heat exchanger, International

Journal of Heat and Mass Transfer 51, 37013711,2008 (28 march 2008)

[5] M. A. Delavar and M. Azimi-Using Porous Material for Heat Transfer Enhancement in Heat Exchangers Journal of Engineering

Science and Technology (Jan 2013)

[6] G.A. Quadir et al, Numerical investigation of the performance of a triple concentric pipe heat exchanger International Journal of

Heat and Mass Transfer 75 (2014) 165172 (18 April 2014)

[7] K. Nawaz, J. Bock, Z. Dai, and A. Jacobi Experimental Studies to Evaluate the Use of Metal Foams in Highly Compact Air-Cooling

Heat Exchangers International Refrigeration and Air Conditioning Conference, year 2010 http://docs.lib.purdue. Edu /iracc

[8] E.farsad, Fluid flow and Heat Transfer in a Novel Microchannel Heat sink partially filled with metal foam medium Journal of

Thermal Science And Engineering Applications ( June 2014)

[9] Z.G. Qu , H.J. Xu et al Thermal Transport in Metallic Porous Media International Journal of Heat and Mass (2010) Transfer, Vol.53,

No.21, (October 2010),

2547

IJRITCC | May 2015, Available @ http://www.ijritcc.org

_______________________________________________________________________________________

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Nutrition For AthletesDokument37 SeitenNutrition For AthletesAnonymous e1sArVj5zl100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Solutions To ExercisesDokument47 SeitenSolutions To ExercisesNathan D. Gutzmann60% (5)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- 42SL80 TrainingDokument93 Seiten42SL80 Trainingvmalvica67% (3)

- Foster Wheeler Process Engineering Practices IndexDokument86 SeitenFoster Wheeler Process Engineering Practices Indexchemiesm94% (16)

- Operation Manual - WSRF-50Dokument175 SeitenOperation Manual - WSRF-50eduardo100% (2)

- General-Purpose Steam Turbines (Amendments/Supplements To Api 611)Dokument27 SeitenGeneral-Purpose Steam Turbines (Amendments/Supplements To Api 611)BiswasNoch keine Bewertungen

- GH G ConversionDokument146 SeitenGH G ConversionjorgeNoch keine Bewertungen

- Cause Effect Analysis of Oil Loss in Edible Oil IndustryDokument60 SeitenCause Effect Analysis of Oil Loss in Edible Oil IndustrySaurabh RaiNoch keine Bewertungen

- Damper mechanism details for Atlas Copco rock drills under 40 charactersDokument27 SeitenDamper mechanism details for Atlas Copco rock drills under 40 characterssalvador341100% (2)

- Image Restoration Techniques Using Fusion To Remove Motion BlurDokument5 SeitenImage Restoration Techniques Using Fusion To Remove Motion Blurrahul sharmaNoch keine Bewertungen

- Regression Based Comparative Study For Continuous BP Measurement Using Pulse Transit TimeDokument7 SeitenRegression Based Comparative Study For Continuous BP Measurement Using Pulse Transit TimeEditor IJRITCCNoch keine Bewertungen

- A Review of Wearable Antenna For Body Area Network ApplicationDokument4 SeitenA Review of Wearable Antenna For Body Area Network ApplicationEditor IJRITCCNoch keine Bewertungen

- Importance of Similarity Measures in Effective Web Information RetrievalDokument5 SeitenImportance of Similarity Measures in Effective Web Information RetrievalEditor IJRITCCNoch keine Bewertungen

- A Review of Wearable Antenna For Body Area Network ApplicationDokument4 SeitenA Review of Wearable Antenna For Body Area Network ApplicationEditor IJRITCCNoch keine Bewertungen

- IJRITCC Call For Papers (October 2016 Issue) Citation in Google Scholar Impact Factor 5.837 DOI (CrossRef USA) For Each Paper, IC Value 5.075Dokument3 SeitenIJRITCC Call For Papers (October 2016 Issue) Citation in Google Scholar Impact Factor 5.837 DOI (CrossRef USA) For Each Paper, IC Value 5.075Editor IJRITCCNoch keine Bewertungen

- Modeling Heterogeneous Vehicle Routing Problem With Strict Time ScheduleDokument4 SeitenModeling Heterogeneous Vehicle Routing Problem With Strict Time ScheduleEditor IJRITCCNoch keine Bewertungen

- Performance Analysis of Image Restoration Techniques at Different NoisesDokument4 SeitenPerformance Analysis of Image Restoration Techniques at Different NoisesEditor IJRITCCNoch keine Bewertungen

- Channel Estimation Techniques Over MIMO-OFDM SystemDokument4 SeitenChannel Estimation Techniques Over MIMO-OFDM SystemEditor IJRITCCNoch keine Bewertungen

- A Review of 2D &3D Image Steganography TechniquesDokument5 SeitenA Review of 2D &3D Image Steganography TechniquesEditor IJRITCCNoch keine Bewertungen

- Comparative Analysis of Hybrid Algorithms in Information HidingDokument5 SeitenComparative Analysis of Hybrid Algorithms in Information HidingEditor IJRITCCNoch keine Bewertungen

- A Review of 2D &3D Image Steganography TechniquesDokument5 SeitenA Review of 2D &3D Image Steganography TechniquesEditor IJRITCCNoch keine Bewertungen

- Channel Estimation Techniques Over MIMO-OFDM SystemDokument4 SeitenChannel Estimation Techniques Over MIMO-OFDM SystemEditor IJRITCCNoch keine Bewertungen

- Fuzzy Logic A Soft Computing Approach For E-Learning: A Qualitative ReviewDokument4 SeitenFuzzy Logic A Soft Computing Approach For E-Learning: A Qualitative ReviewEditor IJRITCCNoch keine Bewertungen

- Diagnosis and Prognosis of Breast Cancer Using Multi Classification AlgorithmDokument5 SeitenDiagnosis and Prognosis of Breast Cancer Using Multi Classification AlgorithmEditor IJRITCCNoch keine Bewertungen

- A Study of Focused Web Crawling TechniquesDokument4 SeitenA Study of Focused Web Crawling TechniquesEditor IJRITCCNoch keine Bewertungen

- Efficient Techniques For Image CompressionDokument4 SeitenEfficient Techniques For Image CompressionEditor IJRITCCNoch keine Bewertungen

- Prediction of Crop Yield Using LS-SVMDokument3 SeitenPrediction of Crop Yield Using LS-SVMEditor IJRITCCNoch keine Bewertungen

- Network Approach Based Hindi Numeral RecognitionDokument4 SeitenNetwork Approach Based Hindi Numeral RecognitionEditor IJRITCCNoch keine Bewertungen

- Predictive Analysis For Diabetes Using Tableau: Dhanamma Jagli Siddhanth KotianDokument3 SeitenPredictive Analysis For Diabetes Using Tableau: Dhanamma Jagli Siddhanth Kotianrahul sharmaNoch keine Bewertungen

- 45 1530697786 - 04-07-2018 PDFDokument5 Seiten45 1530697786 - 04-07-2018 PDFrahul sharmaNoch keine Bewertungen

- 44 1530697679 - 04-07-2018 PDFDokument3 Seiten44 1530697679 - 04-07-2018 PDFrahul sharmaNoch keine Bewertungen

- Itimer: Count On Your TimeDokument4 SeitenItimer: Count On Your Timerahul sharmaNoch keine Bewertungen

- A Clustering and Associativity Analysis Based Probabilistic Method For Web Page PredictionDokument5 SeitenA Clustering and Associativity Analysis Based Probabilistic Method For Web Page Predictionrahul sharmaNoch keine Bewertungen

- Hybrid Algorithm For Enhanced Watermark Security With Robust DetectionDokument5 SeitenHybrid Algorithm For Enhanced Watermark Security With Robust Detectionrahul sharmaNoch keine Bewertungen

- Safeguarding Data Privacy by Placing Multi-Level Access RestrictionsDokument3 SeitenSafeguarding Data Privacy by Placing Multi-Level Access Restrictionsrahul sharmaNoch keine Bewertungen

- A Content Based Region Separation and Analysis Approach For Sar Image ClassificationDokument7 SeitenA Content Based Region Separation and Analysis Approach For Sar Image Classificationrahul sharmaNoch keine Bewertungen

- Vehicular Ad-Hoc Network, Its Security and Issues: A ReviewDokument4 SeitenVehicular Ad-Hoc Network, Its Security and Issues: A Reviewrahul sharmaNoch keine Bewertungen

- 41 1530347319 - 30-06-2018 PDFDokument9 Seiten41 1530347319 - 30-06-2018 PDFrahul sharmaNoch keine Bewertungen

- Space Complexity Analysis of Rsa and Ecc Based Security Algorithms in Cloud DataDokument12 SeitenSpace Complexity Analysis of Rsa and Ecc Based Security Algorithms in Cloud Datarahul sharmaNoch keine Bewertungen

- 3512TA - 1000kVA - LV - Spec Sheet PDFDokument5 Seiten3512TA - 1000kVA - LV - Spec Sheet PDFavinash_1229Noch keine Bewertungen

- Syllabus of Diploma in Electrical EngineeringDokument17 SeitenSyllabus of Diploma in Electrical EngineeringJoson Chan100% (1)

- EB Welding of SS405 To GR70Dokument5 SeitenEB Welding of SS405 To GR70s_m_taheriNoch keine Bewertungen

- 568100Dokument2 Seiten568100Talha TariqNoch keine Bewertungen

- ELECTRONICDokument13 SeitenELECTRONICMahmoued YasinNoch keine Bewertungen

- Makerere University Civil Engineering Assignment on Nalubaale DamDokument8 SeitenMakerere University Civil Engineering Assignment on Nalubaale DamRobert WalusimbiNoch keine Bewertungen

- Photovoltaic Silicon Wafer - SUMCO CORPORATIONDokument21 SeitenPhotovoltaic Silicon Wafer - SUMCO CORPORATIONlawrence_yuen_3Noch keine Bewertungen

- New Tutorial 2 Solution On ThermodynamicsDokument7 SeitenNew Tutorial 2 Solution On ThermodynamicsNaveed AhmadNoch keine Bewertungen

- Short and Open Circuit Test On TransformerDokument1 SeiteShort and Open Circuit Test On TransformerRyan DagsilNoch keine Bewertungen

- Symmetry & Crystal StructuresDokument37 SeitenSymmetry & Crystal StructuresNurnajihah Sukimi JiehaNoch keine Bewertungen

- Solex Adj ProcedureDokument6 SeitenSolex Adj Procedureprivate 2Noch keine Bewertungen

- DC Machine Theory and Transformer PrinciplesDokument32 SeitenDC Machine Theory and Transformer PrinciplesPolireddi Gopala KrishnaNoch keine Bewertungen

- 39CQ Iom 06302014Dokument20 Seiten39CQ Iom 06302014Non Etabas GadnatamNoch keine Bewertungen

- GROUP 1 - PetE 3306 - Final Requirement in Engineering EconomicsDokument12 SeitenGROUP 1 - PetE 3306 - Final Requirement in Engineering Economicskevin alidoNoch keine Bewertungen

- PLF-76T Service ManualDokument40 SeitenPLF-76T Service Manualapi-3711045100% (1)

- Acoustic Variables - Kasia's E-PortfolioDokument2 SeitenAcoustic Variables - Kasia's E-Portfoliomuhammad ShoaibNoch keine Bewertungen

- Ceiling Mounted Chilled Water UnitDokument2 SeitenCeiling Mounted Chilled Water UnitPrinces Katherine VergaraNoch keine Bewertungen

- Technical Assistance Consultant's Report: Energy Storage Option For Accelerating Renewable Energy PenetrationDokument364 SeitenTechnical Assistance Consultant's Report: Energy Storage Option For Accelerating Renewable Energy PenetrationAlezsander RguezArNoch keine Bewertungen

- Masterpact NT and NW: Maintenance GuideDokument32 SeitenMasterpact NT and NW: Maintenance GuideRoshin99Noch keine Bewertungen

- Fluid MechDokument10 SeitenFluid MechPrasant KumarNoch keine Bewertungen

- Classification ISO 8217 (2005)Dokument5 SeitenClassification ISO 8217 (2005)Salah JallaliNoch keine Bewertungen