Beruflich Dokumente

Kultur Dokumente

Pengantar Pressure Vessels (Compatibility Mode)

Hochgeladen von

Wijayanto Bekasi0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten6 SeitenPengantar

Originaltitel

Pengantar Pressure Vessels [Compatibility Mode]

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenPengantar

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten6 SeitenPengantar Pressure Vessels (Compatibility Mode)

Hochgeladen von

Wijayanto BekasiPengantar

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

9/22/2015

INTRODUCTION TO

PRESSURE VESSELS

Pressure vessels are the containers for fluids

under high pressure.

They are used in a variety of industries like

Petroleum refining

Chemical

Power

Food & beverage

Pharmaceutical

PRESSURE VESSELS

There are three main types of pressure vessels

in general

Horizontal Pressure Vessels

Vertical Pressure Vessels

Spherical Pressure vessels

However there are some special types of Vessels like

Regeneration Tower, Reactors but these names are

given

according to their use only.

TYPES OF PRESSURE VESSELS

HORIZONTAL PRESSURE VESSEL

9/22/2015

The max. Shell

length to diameter

ratio for a small

vertical drum is

about 5 : 1

VERTICAL PRESSURE VESSEL

Constructed in a wider

range of shell diameter

and height.

They can be relatively

small in dia. and very

large (e.g. 4 ft dia. And

200 ft tall distillation

column.

They can be very large

in dia. and moderately

tall (e.g. 3 ft dia. And 150

ft tall tower).

Internal trays are

needed for flow

TALL

VERTICAL TOWER

distribution.

Figure shows a typical

reactor vessel with a

cylindrical shell.

The process fluid

undergoes a chemical

reaction inside a

reactor.

This reaction is normally

facilitated by the

presence of a catalyst

which is held in one or

more catalystREACTOR

beds.

VERTICAL

SPHERICAL PRESSURIZED STORAGE

VESSEL

9/22/2015

Following are the main components of

pressure

Vessels in general

Shell

Head

Nozzle

Support

It is the primary component that contains the

pressure.

Pressure vessel shells in the form of different

plates are welded together to form a

structure that has a common rotational axis.

Shells are either cylindrical, spherical or

conical in shape.

MAIN COMPONENTS OF

PRESSURE VESSEL

Horizontal drums have cylindrical shells and

are constructed in a wide range of diameter

and length.

The shell sections of a tall tower may be

constructed of different materials, thickness

and diameters due to process and phase

change of process fluid.

Shell of a spherical pressure vessel is

spherical as well.

SHELL

SHELL

All the pressure vessels must be closed at

the ends by heads (or another shell section).

Heads are typically curved rather than flat.

The reason is that curved configurations are

stronger and allow the heads to be thinner,

lighter and less expensive than flat heads.

Heads can also be used inside a vessel and

are known as intermediate heads.

These intermediate heads are separate

HEAD

sections of the pressure vessels to permit

different design conditions.

9/22/2015

A nozzle is a cylindrical component that

penetrates into the shell or head of pressure

vessel.

They are used for the following applications.

Attach piping for flow into or out of the vessel.

Attach instrument connection (level gauges,

Thermowells, pressure gauges).

Provide access to the vessel interior at MANWAY.

Provide for direct attachment of other equipment

items (e.g. heat exchangers).

NOZZLE

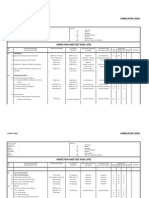

SADDLE SUPPORT:

Horizontal drums are typically supported at two

locations by saddle support.

It spreads over a large area of the shell to prevent an

excessive local stress in the shell at support point.

One saddle support is anchored whereas the other is

free to permit unstrained longitudinal thermal

expansion of the drum.

There are different types of supports which

are used depending upon the size and

orientation of the pressure vessel.

It is considered to be the non-pressurized

part of the vessel.

SUPPORT

TYPES OF SUPPORTS

LEG SUPPORT:

TYPES OF SUPPORTS

Support is used to bear all the load of

pressure vessel, earthquake and wind loads.

Small vertical drums are typically supported on legs

that are welded to the lower portion of the shell.

The max. ratio of support leg length to drum diameter

is typically 2 : 1

Reinforcing pads are welded to the shell first to

provide additional local reinforcement and load

distribution.

The number of legs depends on the drum size and

loads to be carried.

Support legs are also used for Spherical pressurized

storage vessels.

Cross bracing between the legs is used to absorb wind

or earth quake loads.

9/22/2015

SKIRT SUPPORT:

Tall vertical cylindrical pressure vessels are typically

supported by skirts.

LUG SUPPORT:

Vertical pressure vessels may

also be supported by lugs.

The use of lugs is typically

limited to pressure vessels of

small and medium diameter (1

to 10 ft)

A support skirt is a cylindrical shell section that is

welded either to the lower portion of the vessel shell

or to the bottom head (for cylindrical vessels).

The skirt is normally long enough to provide enough

flexibility so that radial thermal expansion of the shell

does not cause high thermal stresses at its junction

with the skirt.

Also moderate height to

diameter ratios in the range of

2:1 to 5:1

The lugs are typically bolted to

horizontal structural members

in order to provide stability

against overturning loads.

TYPES OF SUPPORTS

Thin wall refers to a vessel having an inner-radius-to-wallthickness ratio of 10 or more (r / t 10).

When the vessel wall is thin, the stress distribution

throughout its thickness will not vary significantly, and so

we will assume that it is uniform or constant.

TYPES OF SUPPORTS

Following this assumption, the analysis of thin walled

cylindrical and spherical pressure vessel will be carried out.

In both cases, the pressure in the vessel will be considered

to be the gauge pressure, since it measure the pressure

above atmospheric pressure existing at inside and outside

the vessels walls.

THIN WALLED PRESSURE

VESSELS

The above analysis indicates that an element of material

taken from either cylindrical or spherical pressure vessel is

subjected to biaxial stress, i.e. normal stress existing in

only two directions.

Actually material of the vessel is also subjected to a radial

stress, 3, which acts along a radial line. This stress has a

max. value equal to the pressure p at the interior wall and

decreases through the wall to zero at the exterior surface of

the vessel, since the gauge pressure there is zero.

For thin walled vessels, however, the redial stress

components are ignored because r / t = 10 results in 1 & 2

being, respectively, 5 & 10 times higher than the max. radial

stress, (3)max = p

THIN WALLED PRESSURE

VESSELS

9/22/2015

It must be emphasized that the formula derived for

thin walled pressure vessels should be used only for

cases of internal pressure.

If a vessel is to be designed for external pressure as

in the case of vacuum tank, or submarine, instability

(buckling) of the wall may occur & stress calculations

based on the formulae derived can be meaningless.

THIN WALLED PRESSURE

VESSELS

Das könnte Ihnen auch gefallen

- Surface Preparation & Painting Procedure r1Dokument4 SeitenSurface Preparation & Painting Procedure r1Wijayanto BekasiNoch keine Bewertungen

- Stresses in BeamDokument34 SeitenStresses in BeamWijayanto BekasiNoch keine Bewertungen

- Tail Lifting Lug Calculation MS WordDokument11 SeitenTail Lifting Lug Calculation MS WordWijayanto BekasiNoch keine Bewertungen

- Lifting Lug ArrangementDokument1 SeiteLifting Lug ArrangementWijayanto BekasiNoch keine Bewertungen

- Steel Beams AnalysisDokument15 SeitenSteel Beams AnalysisWijayanto BekasiNoch keine Bewertungen

- Modco Closures: Operation, Maintenance & Welding InstructionsDokument7 SeitenModco Closures: Operation, Maintenance & Welding InstructionsWijayanto BekasiNoch keine Bewertungen

- Cog CalculationDokument4 SeitenCog CalculationWijayanto BekasiNoch keine Bewertungen

- Designed by Checked by Approved by Date DateDokument1 SeiteDesigned by Checked by Approved by Date DateWijayanto BekasiNoch keine Bewertungen

- Nbi Vertical Agitator: Installation, Service and Maintenance InstructionsDokument20 SeitenNbi Vertical Agitator: Installation, Service and Maintenance InstructionsWijayanto BekasiNoch keine Bewertungen

- Sample Itp For VesselDokument10 SeitenSample Itp For VesselWijayanto BekasiNoch keine Bewertungen

- Commissioning Results On Dtvv44079 S/D Dtvv44091Dokument2 SeitenCommissioning Results On Dtvv44079 S/D Dtvv44091Wijayanto BekasiNoch keine Bewertungen

- R100 Data SheetDokument1 SeiteR100 Data SheetWijayanto BekasiNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- IRF350Dokument7 SeitenIRF350sanniviNoch keine Bewertungen

- Emergency LightingDokument32 SeitenEmergency LightingIsmet HizyoluNoch keine Bewertungen

- Unit-II Some PPT NetDokument2 SeitenUnit-II Some PPT NetbandisaidaiahNoch keine Bewertungen

- Bernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGDokument1 SeiteBernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGRhon Nem KhoNoch keine Bewertungen

- Piping Handbook - Hydrocarbon Processing - 1968Dokument140 SeitenPiping Handbook - Hydrocarbon Processing - 1968VS271294% (16)

- Ism CodeDokument9 SeitenIsm CodePraneel KurhadeNoch keine Bewertungen

- Esquema Elétrico NGD 9.3Dokument2 SeitenEsquema Elétrico NGD 9.3LuisCarlosKovalchuk100% (1)

- Phase DiagramDokument36 SeitenPhase Diagramzainal arifinNoch keine Bewertungen

- AHRLACDokument18 SeitenAHRLACVictor Pileggi100% (1)

- G270han01 V0Dokument26 SeitenG270han01 V0NemkoNoch keine Bewertungen

- GWSSB Vendor List 19.11.2013Dokument18 SeitenGWSSB Vendor List 19.11.2013sivesh_rathiNoch keine Bewertungen

- Calibration. of Storage Tanks Class # 2070 Srini Sivaraman SK JapanDokument4 SeitenCalibration. of Storage Tanks Class # 2070 Srini Sivaraman SK JapanJose Rafael Mora CasalNoch keine Bewertungen

- Electronic Dice Using LEDs Electrical Engineering ProjectDokument16 SeitenElectronic Dice Using LEDs Electrical Engineering Projectprakhar agarwal33% (3)

- Jamesbury Polymer and Elastomer Selection GuideDokument20 SeitenJamesbury Polymer and Elastomer Selection Guidesheldon1jay100% (1)

- Meai Mar 2010Dokument36 SeitenMeai Mar 2010Daneshwer VermaNoch keine Bewertungen

- Autodesk Inventor - Sheet Metal Punch IfeaturesDokument6 SeitenAutodesk Inventor - Sheet Metal Punch IfeaturesNdianabasi UdonkangNoch keine Bewertungen

- BKLT DeaeratorDokument24 SeitenBKLT Deaeratormalikgaurav01Noch keine Bewertungen

- BIOS 203: Free Energy Methods Tom MarklandDokument23 SeitenBIOS 203: Free Energy Methods Tom MarklandNemanja ĐokovićNoch keine Bewertungen

- Creating REST API Using NodeJS and Consuming in AngularJSDokument8 SeitenCreating REST API Using NodeJS and Consuming in AngularJSserignemodouNoch keine Bewertungen

- Q3 NSP - SLP - RLPDokument41 SeitenQ3 NSP - SLP - RLPRushi RavalNoch keine Bewertungen

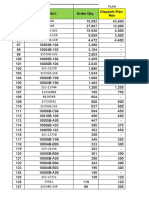

- Order Qty Vs Dispatch Plan - 04 11 20Dokument13 SeitenOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPNoch keine Bewertungen

- Makita 2708Dokument29 SeitenMakita 2708Reuel JacintoNoch keine Bewertungen

- RT L2 General Examination PaperDokument4 SeitenRT L2 General Examination PaperdaddadNoch keine Bewertungen

- Online Examination System For AndroidDokument7 SeitenOnline Examination System For AndroidSri Sai UniversityNoch keine Bewertungen

- Bazele Matematice Ale Calculatoarelor - Florian Mircea BoianDokument132 SeitenBazele Matematice Ale Calculatoarelor - Florian Mircea BoiannimsocNoch keine Bewertungen

- A Sample of Wet Soil Has A Volume of 0Dokument8 SeitenA Sample of Wet Soil Has A Volume of 0eph0% (1)

- Crankshaft Position (CKP) Sensor: 1F2-12 M161 Engine ControlsDokument6 SeitenCrankshaft Position (CKP) Sensor: 1F2-12 M161 Engine ControlsKukuh SeptiantoNoch keine Bewertungen

- Paket TrainingDokument20 SeitenPaket TrainingLukman AriyantoNoch keine Bewertungen

- PT14 Engine Monitor 1Dokument2 SeitenPT14 Engine Monitor 1BJ DixNoch keine Bewertungen

- DT NotesDokument117 SeitenDT NotestessNoch keine Bewertungen