Beruflich Dokumente

Kultur Dokumente

Baosteel CRGO Standard

Hochgeladen von

darkonikolic78Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Baosteel CRGO Standard

Hochgeladen von

darkonikolic78Copyright:

Verfügbare Formate

THE STANDARD

OF

COLD ROLLED GRAIN ORIENTED ELECTRICAL STEEL

PRODUCED BY

BAOSTEEL, CHINA

FOR

INTERNATIONAL MARKET

PRESENTED BY

M & M RESOURCES INTERNATIONAL INC.

155 Pleasant Ave. Dundas, ON. L9H 3T9, Canada

Tel: 001-905-627-2473

Fax: 001-905-627-2473

www.mmrii.com

Email: mmresources@gmail.com

Q/BQB485-2007

ENTERPRISE STANDARD OF BAOSHAN IRON & STEEL CO., LTD.

COLD-ROLLED GRAIN-ORIENTED ELECTRICAL STEEL SHEET

Q/BQB 4852007

DELIVERED IN THE FULLY-PROCESSED STATE

1 Scope

This standard is intended to briefly present the features of cold-rolled

grain-oriented electrical steel sheet delivered in the fully-processed state in

nominal thickness of 0.23mm, 0.27mm, 0.30mm and 0.35mm: definition,

classification and code name, dimension, shape, weight, technical

requirement such as magnetic ability, inspection and examination, packing,

symbol, as well as quality certificate, etc.

This Standard applies to Goss textured grain-oriented electrical steel

sheet supplied in the final annealed condition in sheets (shorted for sheets

hereinafter), and intended for the construction of magnetic circuits.

2 Normative references

The following standards contain provisions which, through reference in

this Standard, constitute provisions of this Standard. Any revised paper

(corrigenda not included) or revised edition to the dated citation is not

applicable to this standard. However, parties that come to agreement in

accordance with this standard are encouraged to work out whether the lasted

versions of the standards shall be applied.

GB/T235-1999 Metallic materials-Sheet 3mm thick or less-Reverse

bend test

GB/T

Measurement and unit of electromagnetism and

3102.5-1993

magnetism

GB/T

Methods of determination of the magnetic

3655-2000

properties of magnetic sheet by means of an Epstein

frame

GB/T

Rules for rounding off numerical values

8170-1987

GB/T

Electrotechnical Vocabulary: Magnetic materials

9637-2001

and components

GB/T

Methods of measurement of the magnetic properties

13789-1992

of magnetic sheet by means of a single sheet tester

GB/T

Methods of measurement of density, resistivity and

19289-2003

stacking factor of electrical steel sheet

M & M RESOURCES INTERNATIONAL INC. A PROFESSIONAL IN ELECTRICAL STEEL

2

Q/BQB485-2007

Q/BQB 400

Q/BQB 401

JIS C

2550-2000

Packing, symbol and quality certificate of

cold-rolled products

Dimensions, shapes, weights and tolerances of

continuous cold strip steel

Test methods of electrical steel plate

3 Terms and definition

3.1 Core lossSpecific Total Loss

Core loss is the energy loss that occurs in magnetization of samples

under AC magnetic field. When magnetizing under given frequency and

maximum magnetic flux density, core loss is indicated by P(10Bm/f), with

W/kg as unit.

Ex: P17/50 means the core loss of sample by unit of kg, when the magnetic

flux density is 1.7T and frequency is 50Hz

3.2 Characteristic of MagnetizationMagnetic Flux Density

Characteristic of magnetization is often indicated by magnetic

characteristic curves to describe certain magnetic flux density (magnetic

polarization) under certain magnetic field intensity.

Ex: B8 means the magnetic flux density when the magnetic filed intensity is

800A/m.

3.3 Number of bends

Number of bends means the number of alternate bends before the

appearance of the first crack in the base metal visible to the naked eye; it

constitutes an indication of the ductility of the material.

3.4 Other terms and definition shall comply with the requirements specified

in GB/T 9637.

4 Type and Code

4.2 Type and Code of Insulating Coating should be as specified in Table 1.

Type of Insulation Coating

Code

Inorganic Coating

S

5 Information to be supplied

The purchaser shall include the following information in his enquiry or

order.

a) number of this Standard

M & M RESOURCES INTERNATIONAL INC. A PROFESSIONAL IN ELECTRICAL STEEL

3

Q/BQB485-2007

b) grade

c) dimensions

d) weight

e) way of packing

f) end use

g) others.

6 Dimensions, shapes, weights and tolerances

6.1 The extension of nominal dimensions of steel sheets shall be as specified

in Table 2.

Table 2

Unitmm

Thickness

Width

Diameter

0.230.270.300.35 7001260

508

6.2 Tolerances of Dimensions

Tolerances on thickness, deviations of thickness in transverse direction

and tolerance on width shall be as specified in Table 3.

Table 3

Unitmm

Deviation of Deviation of

thickness in

Tolerance

Tolerance on thickness in

Thickness

transverse

on width

thickness

longitudinal

direction

direction

0.23

0.025

0.27

0.030

0.020

0+2

0.030

0.30

0.35

6.3 Flatness (Wave Factor) of steel sheet shall not exceed 1.5%.

6.4 Edge camber of steel sheet shall not exceed 1.0mm for a length of 2mm.

6.5 Measurement of dimensions and shapes

6.5.1 Measurement of dimensions and shapes shall be taken at any position

not less than 3m from the beginning and end of the steel sheet.

6.5.2 Measurement of thickness shall be taken anywhere at least 15mm from

the edge. The deviation of thickness in longitudinal direction means the

difference between the maximum and the minimum thickness measured in

transverse direction (parallel to rolling direction) at any position on a 2 m

long steel sheet. Deviation of thickness in transverse direction means the

difference between the maximum and the minimum thickness measured in a

M & M RESOURCES INTERNATIONAL INC. A PROFESSIONAL IN ELECTRICAL STEEL

4

Q/BQB485-2007

direction parallel to the longitudinal direction (vertical to rolling direction)

of the steel sheet.

6.5.3 Measurement of FlatnessWave Factor

The flatness shall be calculated by measuring the maximum height (h)

and wave length (L) of the steel sheet (ratio of wave height to wave length).

h/L100%, as specified in Table 1.

6.5.4 Method of measurement of Edge Camber shall comply with

Q/BQB401.

Table 1 Measurement of FlatnessWave Factor

6.6 Delivery shall be made in compliance with the actual weight of the steel

sheet.

7 Technological requirements

7.1 Making process and chemical composition of steel shall be decided by

the supplier.

7.2 Steel sheets shall be delivered in the state of ultimately annealed and

coated with insulation coating on both sides.

7.3 Magnetic properties (Magnetic Flux Density B8 , core loss P17/50)shall be

as specified in Table 4, Table 5 and Table 6 accordingly. The requirements

of the magnetic properties shall also be applicable to the aging samples.

7.4 Lamination Factor shall be as specified in Table 4, Table 5 and Table 6

accordingly.

7.5 Theoretical density to calculate magnetic properties and lamination

factor is 7.65kg/dm3.

7.6 Number of bends shall not be less than 1 time. This test shall be ignored

if the supplier guarantees.

7.7 Any other special requirements about residual curvature, internal stresses,

mechanical properties and process properties that required by the buyer shall

be negotiated at the time of ordering and indicated in contracts.

M & M RESOURCES INTERNATIONAL INC. A PROFESSIONAL IN ELECTRICAL STEEL

5

Q/BQB485-2007

Table 4

Magnetic Flux

Lamination

Densitya

Factore

Type

Grade

B8

%

T

Not less than

Not less than

B23G110

1.10

1.80

0.23

94.5

B23G120

1.20

1.80

B27G120

1.20

1.80

0.27

95.0

B27G130

1.30

1.80

B30G120

1.20

1.80

Regular

0.30

95.5

B30G130

1.30

1.80

B30G140

1.40

1.80

B35G135

1.35

1.80

0.35

96.0

B35G145

1.45

1.80

B35G155

1.55

1.80

a

It has been common practice for many years to give values of magnetic flux density. In fact the Epstein

frame is used to determine magnetic polarization, which is defined as follows:

J=B-0H

where

J is the magnetic polarization;

B is the magnetic flux density;

0 is the magnetic constant: 410-7H/m

H is the magnetic field strength;

in accordance with GB/T 3102.5-1993.

Core Loss

Thickness

P17/50

mm

W/kg

Not more than

Type

Grade

High

Permeability

B23P090

B23P095

B23P100

B27P095 a

B27P100

B27P110

B30P100

B30P105

Table 5

Core Loss

P17/50

Thickness

W/kg

mm

Not more

than

0.90

0.23

0.95

1.00

0.95

0.27

1.00

1.10

0.30

1.00

1.05

Magnetic Flux

Density a

B8

T

Not less than

1.87

1.87

1.87

1.88

1.88

1.88

1.88

1.88

M & M RESOURCES INTERNATIONAL INC. A PROFESSIONAL IN ELECTRICAL STEEL

6

Lamination

Factor

%

Not less than

94.5

95.0

95.5

Q/BQB485-2007

B30P110

1.10

1.88

B30P120

1.20

1.88

B35P115

1.15

1.88

0.35

96.0

B35P125

1.25

1.88

1.35

1.88

B35P135

a

It has been common practice for many years to give values of magnetic flux density. In

fact the Epstein frame is used to determine magnetic polarization, which is defined as

follows:

J=B-0H

where

J is the magnetic polarization;

B is the magnetic flux density;

0 is the magnetic constant: 410-7H/m

H is the magnetic field strength;

in accordance with GB/T 3102.5-1993.

M & M RESOURCES INTERNATIONAL INC. A PROFESSIONAL IN ELECTRICAL STEEL

7

Q/BQB485-2007

Table 6

Magnetic

Core Loss

Lamination

b

P17/50

Flux Density

Factor

Thickness

Type

Grade

W/kg

B8

%

mm

Not more

T

Not less

than

Not less than

than

B23R080

0.80

1.87

High

0.23

94.5

B23R085

0.85

1.87

Permeability,

B23R090

0.90

1.87

Domain

B27R090

0.90

1.87

Refined a

0.27

95.0

B27R095

0.95

1.87

a

The guaranteed core loss of high permeability, domain refined steel shall only

apply to the samples not being stress-relieve annealed or measured in accordance

with GB/T 13789.

b

It has been common practice for many years to give values of magnetic flux

density. In fact the Epstein frame is used to determine magnetic polarization, which

is defined as follows:

J=B-0H

where

J is the magnetic polarization;

B is the magnetic flux density;

0 is the magnetic constant: 410-7H/m

H is the magnetic field strength;

in accordance with GB/T 3102.5-1993.

7.9 Insulation Coating

The insulation coating shall be sufficiently adherent so that it does not

become detached during cutting operations or heat treatment under

conditions specified by the supplier. However, the slight chipping of the

coating at the shearing edges shall be tolerated. The insulation coating shall

be resistant to materials such as insulating varnish, transformer oil and motor

oil etc. The coating type shall be as specified in Table 7. Any special

requirement of the resistance of the insulation coating by the buyer shall be

negotiated by at the time of ordering and indicated in the contract.

Table 7

Type

Characteristic

Thin layer, high interlaminar resistance, sufficiently

Inorganic CoatingS

resistant to rust and high temperature

7.10 Surface condition

7.10.1The surfaces shall be smooth and clean, without any defect that may

M & M RESOURCES INTERNATIONAL INC. A PROFESSIONAL IN ELECTRICAL STEEL

8

Q/BQB485-2007

by detrimental to the correct use of the supplied material. Dispersed defects

such as scratches, blisters, cracks, etc. are permitted if they are within the

limits of thickness tolerances, and if they are not detrimental to the correct

use of the supplied material.

7.10.2 Some parts with defects shall be allowed, for they cannot be cut off

from the steel sheet. However, the parts with defects shall not excel 6% of

the total length of the coil.

8 Inspections and Testing

8.1 Appearance is checked by visual inspection.

8.2 Dimensions and shape shall be inspected by suitable survey tools.

8.3 Steel sheets shall be divided into acceptance units for inspection. Each

acceptance unit shall comprise 3 t of steel sheets of same grade, same

specification, with same heat treatment, and same surface insulation

resistance. For coils of more than 3 t, each coil shall constitute an acceptance

unit.

8.4 Quantity of test samples, dimensions of samples and methods of test

shall be as specified in Table 8. Samples shall be taken at any position not

less than 3 m from the beginning and end of steel sheet. Number, direction

and dimensions of test samples and test methods shall comply with Table 8.

Samples shall be taken at not less than 3 m from the beginning and end of

steel sheet.

8.5 Samples shall be subjected to a stress relief heat treatment before the

magnetic properties are tested by Epstein frame in accordance with GB/T

3655 or JIS C 2550. Arrange of annealing temperature shall be 780820

with a duration of 2 h. Samples shall not be subjected to a stress relief

heat treatment when tested by single sheet tester in accordance with GB/T

13789.

8.6 In the case of measurements of specific total loss on aged test pieces,

these shall be aged by heating at 2255 for a duration of 24 h and

shall be cooled to ambient temperature.

8.7 The radius of bending chosen shall be 5 mm on a bending test.

M & M RESOURCES INTERNATIONAL INC. A PROFESSIONAL IN ELECTRICAL STEEL

9

Q/BQB485-2007

Serial

Number

1

Test Item

Table 8

Specimen

Specimen

Quality

Direction

Core Loss

Magnetic

Flux

1 set/coil

Densitya

Dimensions

Test

Method

Length320

mm

Width320

mm

GB/T

13789

GB/T

3655 or

2

JIS C

2550

GB/T

Lamination

3

Factor

19289

Number of

Width 20 GB/T

5

235

Bends

mm

a

In the case of arbitration, GB/T 3655 or JIS C 2550 is adopted for materials

except for steel grades with high permeability.

b

The specimen quantity can be otherwise chosen by the agreement between

the concerned parties.

8.8 In case of one test result not meeting this Standard, double quantity

specimens from the same lot shall be resampled and retested. Once all the

results (including all the properties required by the specimen) meet the

requirement, the whole lot shall be accepted. In case that one single result

(including all the properties required by the specimen) fails, the retest fails.

In that case, the failed test unit shall be discarded, and the remained units in

the lot shall be retested one by one for approval.

Length

Longitudinal 280 320

mm

Width 30

mm

9 Packing, Marking and Inspection Certificate

The packing, marking and Inspection Certificate shall be in accordance

with the requirements specified in Q/BQB400. Any special requirement

shall be noted in the order.

10 Rules for rounding off numerical values

Numerical value rounding off rules shall be in accordance with GB/T

8170.

M & M RESOURCES INTERNATIONAL INC. A PROFESSIONAL IN ELECTRICAL STEEL

10

Q/BQB485-2007

Annex A

informative

Comparable steel grade with this Standard

Q/BQB

480-2007

GB/T

2521-1996

B23G110

B23G120

B27G120

B27G130

B30G120

B30G130

B30G140

B35G135

B35G145

B35G155

B23P090

B23P095

B23P100

B27P095

B27P100

B27P110

B30P100

B30P105

B30P110

B30P120

B35P115

B35P125

B35P135

B23R080

B23R085

B23R090

B27R090

B27R095

23Q110

23Q115

27Q120

27Q130

30Q120

30Q130

30Q140

35Q135

35Q145

35Q155

23QG090

23QG095

23QG100

27QG095

27QG100

27QG110

30QG100

30QG105

30QG110

30QG120

Table A.1

IEC

EN

JIS

ASTM

C

60404-8-7

10107

A876M-03

2553-2000

1998

1996

23G110

M120-23S 5

23H070 M120-23S

27G120

M130-27S 5 27G130

27H074 M130-27S

30G130

M140-30S 5 30G140

30H083 M140-30S

35G145

M150-35S 5 35G155

35H094 M150-35S

23P090

M90-23P 5

23P095

M95-23P 5

M100-23P 5 23P100

23P060 M100-23P

M103-27P 5 27P100

M103-27P

M110-27P 5 27P110

27P066

M105-30P 5 30P105

M105-30P

M111-30P 5 30P110

M111-30P

M117-30P 5 30P120

M117-30P

35P115

M125-35P 5 35P125

M135-35P 5 35P135

23R085

23R090

23Q054

27R090

27R095

27Q057

M & M RESOURCES INTERNATIONAL INC. A PROFESSIONAL IN ELECTRICAL STEEL

11

Q/BQB485-2007

Additional notes

This Standard does not correspond to IEC 60404-8-71998 and JIS C2553

2000 equivalently.

Table A is an informative Annex.

This Standard is proposed by Technical Quality Management Dept. of

Baoshan Iron and Steel Co., Ltd.

This Standard is drafted by Technical Quality Management Dept. of

Baoshan Iron and Steel Co., Ltd.

Draftsman

This is the first publication.

M & M RESOURCES INTERNATIONAL INC. A PROFESSIONAL IN ELECTRICAL STEEL

12

Das könnte Ihnen auch gefallen

- The Iron Puddler My life in the rolling mills and what came of itVon EverandThe Iron Puddler My life in the rolling mills and what came of itNoch keine Bewertungen

- 3coated SteelDokument20 Seiten3coated Steelalifakash1605Noch keine Bewertungen

- Thành Phần, Cơ Tính JIS G4801 SUP10 Steel PlateDokument2 SeitenThành Phần, Cơ Tính JIS G4801 SUP10 Steel PlateĐình Sỹ TTPNoch keine Bewertungen

- Stainless Steel Alloys Comparsion ChartDokument3 SeitenStainless Steel Alloys Comparsion Chartsengcyan100% (1)

- Products GuideDokument12 SeitenProducts GuideWK SinnNoch keine Bewertungen

- Fit Tolerance For Plastic PartsDokument16 SeitenFit Tolerance For Plastic PartsA_JANNESNoch keine Bewertungen

- Arcelor Deep Draw MaterialDokument7 SeitenArcelor Deep Draw MaterialJayDadrassNoch keine Bewertungen

- JIS G 3141 Commercial Cold Rolled SPCC SteelsDokument6 SeitenJIS G 3141 Commercial Cold Rolled SPCC SteelsAnonymous 8lxxbNcA0sNoch keine Bewertungen

- Hot Dip Galvanizing of Sheet Metal-SpangleDokument6 SeitenHot Dip Galvanizing of Sheet Metal-SpangleAgustine SetiawanNoch keine Bewertungen

- How To Select Carbon Brushes For Motors and GeneratorsDokument16 SeitenHow To Select Carbon Brushes For Motors and GeneratorsKalidass BackNoch keine Bewertungen

- Brush Wear GuideDokument3 SeitenBrush Wear GuideSomkene MbakweNoch keine Bewertungen

- Types of Steel and StandardsDokument2 SeitenTypes of Steel and Standardsewva12Noch keine Bewertungen

- Continuously Hot-Rolled Low Carbon Steel Sheet and Strip For Cold FormingDokument12 SeitenContinuously Hot-Rolled Low Carbon Steel Sheet and Strip For Cold FormingudayNoch keine Bewertungen

- The Manual of Fastening EN 8100 PDFDokument106 SeitenThe Manual of Fastening EN 8100 PDFOleh SmolovyiNoch keine Bewertungen

- Brushless MotorsDokument3 SeitenBrushless MotorsHossam DawoodNoch keine Bewertungen

- CR StandardsDokument6 SeitenCR Standardsalpha_beta48Noch keine Bewertungen

- Hot Dip Galvanizing For FastenersDokument3 SeitenHot Dip Galvanizing For FastenersIrwin CastroNoch keine Bewertungen

- Indian Galvanised & Colour Coated Steel IndustryDokument7 SeitenIndian Galvanised & Colour Coated Steel Industrytejindersingh001Noch keine Bewertungen

- Material Comparisons For Astm and JisDokument2 SeitenMaterial Comparisons For Astm and JisNitesh GargNoch keine Bewertungen

- Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesDokument8 SeitenHot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesradziNoch keine Bewertungen

- Corrosion Resistance ofDokument44 SeitenCorrosion Resistance ofalkem7Noch keine Bewertungen

- Fastener Technical ManualDokument70 SeitenFastener Technical ManualGANESH GNoch keine Bewertungen

- Comparison Table Between Steel Grades in GOST and Other Countries, International Standard. GOST Nearest Equivalents, GOST Steel Grade AnaloguesDokument6 SeitenComparison Table Between Steel Grades in GOST and Other Countries, International Standard. GOST Nearest Equivalents, GOST Steel Grade Analoguesdhineshbabu rNoch keine Bewertungen

- Jfe Steel Catalogue PDFDokument35 SeitenJfe Steel Catalogue PDFjitendertalwar1603Noch keine Bewertungen

- Plastic Gears: Size WiseDokument4 SeitenPlastic Gears: Size Wise28192175100% (1)

- Ch13 Materials ApplicationsDokument63 SeitenCh13 Materials ApplicationsThefairman UnkownNoch keine Bewertungen

- Screw PointDokument2 SeitenScrew PointGaurav RelanNoch keine Bewertungen

- Maryland Metrics - Thread Data Charts PDFDokument3 SeitenMaryland Metrics - Thread Data Charts PDFEnmanuel GuzmanNoch keine Bewertungen

- DFM CH 3Dokument44 SeitenDFM CH 3Trâp A NâtïøñNoch keine Bewertungen

- CastingDokument74 SeitenCastingParth Maldhure100% (1)

- Alsheet: Hot-Dip Aluminum-Coated Steel SheetsDokument12 SeitenAlsheet: Hot-Dip Aluminum-Coated Steel SheetshadiNoch keine Bewertungen

- Solidification ShrinkageDokument4 SeitenSolidification ShrinkagesubavlNoch keine Bewertungen

- Layout and Design: Hot Runner GuideDokument15 SeitenLayout and Design: Hot Runner Guidenam0% (1)

- ME 330 Manufacturing Processes Mechanical Assembly: Joining Methods (Cont.)Dokument23 SeitenME 330 Manufacturing Processes Mechanical Assembly: Joining Methods (Cont.)mhafizanNoch keine Bewertungen

- Difference Between Forging and CastingDokument2 SeitenDifference Between Forging and CastingMOHAMMAD ALINoch keine Bewertungen

- Nisshin Steel Cold Rolled Special Steel StripDokument28 SeitenNisshin Steel Cold Rolled Special Steel StripekopujiantoeNoch keine Bewertungen

- China Steel PDFDokument38 SeitenChina Steel PDFKalpeshNoch keine Bewertungen

- Jfe CRDokument27 SeitenJfe CRkhwanta-btaNoch keine Bewertungen

- Plastic Processing ResourcesDokument9 SeitenPlastic Processing ResourcesRatul MohsinNoch keine Bewertungen

- Introduction To PCB PDFDokument18 SeitenIntroduction To PCB PDFOviantoNoch keine Bewertungen

- Topic 1 - Mechanical Fastening 2Dokument11 SeitenTopic 1 - Mechanical Fastening 2nazirulhakimNoch keine Bewertungen

- Casting DefectDokument90 SeitenCasting DefectNayan PatelNoch keine Bewertungen

- Brushed DC Motor FundamentalsDokument10 SeitenBrushed DC Motor Fundamentalsgeorgescribd1103Noch keine Bewertungen

- DIN - ASME - STANDARD - HeadsDokument3 SeitenDIN - ASME - STANDARD - HeadsHong Dae YoonNoch keine Bewertungen

- Chinese To DinDokument7 SeitenChinese To DinDamla KaymakçıNoch keine Bewertungen

- Riview On Cold Drawing Process PDFDokument7 SeitenRiview On Cold Drawing Process PDFAmandeep Singh GujralNoch keine Bewertungen

- Threaded Fasteners For PlasticsDokument32 SeitenThreaded Fasteners For PlasticsStefano BarbieriNoch keine Bewertungen

- How To Calculate The Torsional Stiffness of Rubber Shock MountsDokument4 SeitenHow To Calculate The Torsional Stiffness of Rubber Shock MountsspibluNoch keine Bewertungen

- Small Book EN en NLDokument1.595 SeitenSmall Book EN en NLOxbown91Noch keine Bewertungen

- DCMotors DesignGuideDokument12 SeitenDCMotors DesignGuidenaruto256Noch keine Bewertungen

- Adiabatic Shear Localization: Frontiers and AdvancesVon EverandAdiabatic Shear Localization: Frontiers and AdvancesBradley DoddNoch keine Bewertungen

- Information Symposium Measurement and Control Techniques in Rolling: Luxembourg, 2 and 3 September 1981Von EverandInformation Symposium Measurement and Control Techniques in Rolling: Luxembourg, 2 and 3 September 1981Noch keine Bewertungen

- Diamond Chemical Vapor Deposition: Nucleation and Early Growth StagesVon EverandDiamond Chemical Vapor Deposition: Nucleation and Early Growth StagesNoch keine Bewertungen

- Mould & Core Material for the Steel Foundry: The Commonwealth and International Library: Foundry Technology DivisionVon EverandMould & Core Material for the Steel Foundry: The Commonwealth and International Library: Foundry Technology DivisionNoch keine Bewertungen

- Baosteel CRGO StandardDokument12 SeitenBaosteel CRGO StandardNdrew TobingNoch keine Bewertungen

- Steel Wire, Plain, For Concrete ReinforcementDokument7 SeitenSteel Wire, Plain, For Concrete ReinforcementCPA BTKNoch keine Bewertungen

- CasesDokument4 SeitenCasesSheldonNoch keine Bewertungen

- La Naval Drug Co Vs CA G R No 103200Dokument2 SeitenLa Naval Drug Co Vs CA G R No 103200UE LawNoch keine Bewertungen

- Ultra Wideband TechnologyDokument21 SeitenUltra Wideband TechnologyAzazelNoch keine Bewertungen

- Trahar (2013) - Internationalization of The CurriculumDokument13 SeitenTrahar (2013) - Internationalization of The CurriculumUriel TorresNoch keine Bewertungen

- People/Occupancy Rules of Thumb: Bell - Ch10.indd 93 8/17/07 10:39:31 AMDokument8 SeitenPeople/Occupancy Rules of Thumb: Bell - Ch10.indd 93 8/17/07 10:39:31 AMPola OsamaNoch keine Bewertungen

- Product Information DIGSI 5 V07.50Dokument56 SeitenProduct Information DIGSI 5 V07.50g-bearNoch keine Bewertungen

- ETA-1 Service PDFDokument44 SeitenETA-1 Service PDFgansolNoch keine Bewertungen

- Network Protection Automation Guide Areva 1 PDFDokument500 SeitenNetwork Protection Automation Guide Areva 1 PDFEmeka N Obikwelu75% (4)

- BSC IT SyllabusDokument32 SeitenBSC IT Syllabusஜூலியன் சத்தியதாசன்Noch keine Bewertungen

- Successfully Allocating Risk and Negotiating A PPP ContractDokument12 SeitenSuccessfully Allocating Risk and Negotiating A PPP ContractWilliam Tong100% (1)

- MF 660Dokument7 SeitenMF 660Sebastian Vasquez OsorioNoch keine Bewertungen

- Work Order TemplateDokument2 SeitenWork Order TemplateRed DragonNoch keine Bewertungen

- Management by ObjectivesDokument30 SeitenManagement by ObjectivesJasmandeep brar100% (4)

- ABMOM q2 mod5OrgAndMngmnt Motivation - Leadership and Communication in Organizations-V2Dokument18 SeitenABMOM q2 mod5OrgAndMngmnt Motivation - Leadership and Communication in Organizations-V2Zoren Jovillanos EmbatNoch keine Bewertungen

- 9a Grundfos 50Hz Catalogue-1322Dokument48 Seiten9a Grundfos 50Hz Catalogue-1322ZainalNoch keine Bewertungen

- Routing Fundamentals: How A Juniper Device Makes Forwarding DecisionsDokument8 SeitenRouting Fundamentals: How A Juniper Device Makes Forwarding DecisionsLarsec LarsecNoch keine Bewertungen

- Chapter 3 SampleDokument12 SeitenChapter 3 Samplesyarifah53Noch keine Bewertungen

- RVT Liquid DistributorDokument5 SeitenRVT Liquid DistributorimeagorNoch keine Bewertungen

- Blockchain Unit Wise Question BankDokument3 SeitenBlockchain Unit Wise Question BankMeghana50% (4)

- Fashion Designing Sample Question Paper1Dokument3 SeitenFashion Designing Sample Question Paper1Aditi VermaNoch keine Bewertungen

- 1.2 Installation of SSH Keys On Linux-A Step-By Step GuideDokument3 Seiten1.2 Installation of SSH Keys On Linux-A Step-By Step GuideMada ChouchouNoch keine Bewertungen

- REID CatalogDokument54 SeitenREID Catalogzhaoye maoNoch keine Bewertungen

- Output Vat Zero-Rated Sales ch8Dokument3 SeitenOutput Vat Zero-Rated Sales ch8Marionne GNoch keine Bewertungen

- Questions & Answers On CountersDokument24 SeitenQuestions & Answers On Counterskibrom atsbha100% (2)

- ADAMDokument12 SeitenADAMreyNoch keine Bewertungen

- Partnership Law (Chapter 1 and 2) - ReviewerDokument9 SeitenPartnership Law (Chapter 1 and 2) - ReviewerJeanne Marie0% (1)

- Roundup WG Bula MonsantoDokument16 SeitenRoundup WG Bula MonsantodandanyddNoch keine Bewertungen

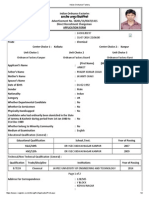

- Indian Ordnance FactoryDokument2 SeitenIndian Ordnance FactoryAniket ChakiNoch keine Bewertungen

- MushroomDokument8 SeitenMushroomAkshay AhlawatNoch keine Bewertungen

- HANA Heroes 1 - EWM Lessons Learned (V2)Dokument40 SeitenHANA Heroes 1 - EWM Lessons Learned (V2)Larissa MaiaNoch keine Bewertungen