Beruflich Dokumente

Kultur Dokumente

May 8, 1962 W. - Carlson, JR: 3 2e034 002 Feipqbqz

Hochgeladen von

Victor Von DoomOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

May 8, 1962 W. - Carlson, JR: 3 2e034 002 Feipqbqz

Hochgeladen von

Victor Von DoomCopyright:

Verfügbare Formate

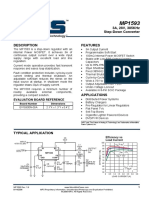

518-11

FEIPQBQZ

3 2e034002

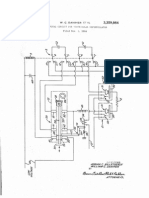

3,034,002

May 8, 1962

w. |_. CARLSON, JR

CONDUCTIVE FLUID POWER TRANSFORMER

Filed June 1'7, 1958

H5 V

60

D.C. OUTPUT

D CH

D.C. OUTPUT

17.4

INVENTOR.

WILLIAM L. CARLSON, JR.

BY

901

A T70R11; 2

rice

1

3,034,002

CONDUCTIVE FLUID POWER TRANSFORMER

William L. Carlson, Jr., Bloomington, Minu., assignor

to Minneapolis-Honeywell Regulator Company, Mm

neapolis, Minm, a corporation of Delaware

Filed June 17, 1958, Ser. No. 742,558

2 Claims. (Cl. 310-11)

3,034,002

Patented May 8, 1962

2

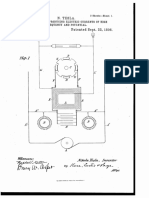

Referring ?rst to the device disclosed in FIGURES 1

and 2, a conductive ?uid pump is generally disclosed at

10. This pump consists of a C-shaped magnetic member

11 which is encircled by an energizing coil 12. The coil

12 can be of any convenient construction and merely

must have a su?icient resistance or reactance to limit the

current passing through it to an appropriate level. Leads

13 and 14 are connected to coil 12 to supply the appro

When an appropriate energizing

?uid power transformer capable of converting levels of 10 source is connected between leads 13 and 14 the coil 12

electrical energy. More speci?cally, the present novel de

sets up a magnetic ?eld in core 11 which passes between

vice utilizes conductive ?uid or liquid metal pumps to

the pole ends 15 and 16. This provides the magnetic ?eld

The present invention is directed to a novel type of

create a ?ow of a conductive ?uid and the ?ow is then

converted back into electrical energy by means of a con

priate energization.

for a Faraday type of electromagnetic pump.

In order to supply the mutually perpendicular current

ductive ?uid or liquid metal current generating device.

15 for the ?ux between poles 15 and 16, a conventional

The principles involved in the operation of a conduc

transformer arrangement is supplied on a core 20. Core

tive ?uid or liquid metal pump have been known for

20 is a rectangular closed magnetic circuit having two

many years and were originally recognized by Faraday

coils 21 and 22. The coils 21 and 22 are of any con

in approximately 1850. Faraday recognized that a con

venient design and the coil 21 will usually have a sub

ductive ?uid could be caused to ?ow under the mutually

stantially greater number of turns as compared to coil

perpendicular in?uence of a current passing through the

22 to provide a step down type of transformation of

?uid when acted on by a magnetic ?eld. This principle

electrical energy. The coil 21 has leads 23 and 24 so

has been utilized both to create a ?ow of a ?uid as well

that an input of electrical power can be supplied. The

as to detect the ?ow of a ?uid and in turn supply an

lead 14 of the coil 12 is connecetd to lead 23 of the coil

electrical signal which would be indicative of the rate of 25 21 to complete a series connection of this coil so that

?ow. Conductive ?uid systems have used conductive

the coils 12 and 21 may be conveniently energized to

?uid ?ow meters to indicate the rate of ?ow of ?uid.

form a source of power which has been represented as

115 volts, 60 cycles. It is apparent that the energization

However, the applicant is unaware of the use of this prin

ciple as a means of power transformation as opposed to

of coils 12 and 21 by an alternating current source will

a mere indication that a ?uid ?ow existed.

30 provide a magnetic ?ux between the poles 15 and 16 and

It will be appreciated that in a liquid metal or con

ductive ?uid system wherein a Faraday type pump cre

ates the movement or a generator of the conductive ?uid

also an energization of the primary winding or coil 21

so as to induce a current in coil 22. The current induced

in coil 22 is of a low voltage and exceedingly high cur

type is used, that there is but one moving part. That

rent. The current developed in coil 22 is supplied by

moving part is the conductive ?uid or liquid metal itself. 35 conductors 25 and 26 to electrodes 27 and 28. The elec

Since this system has but one moving part, it is obvious

trodes 27 and 28 are inserted into a ?uid passage means

that a highly e?icient and mechanically simple arrange

or ?uid ?ow circuit 30. The insertion of the electrodes

ment is yielded. This type system provides a simplicity

27 and 28 into the ?uid passage 30 can best be seen in

FIGURE 2. The electrodes 27 and 28 are at right

formation where a strict limit must be placed on the 40 angles to the poles 15 and 16 and therefore are at right

which is needed in certain applications of power trans

types or number of moving parts. This is particularly

true where the system is subjected to vibration, shock,

poles. Upon energizing the pump 10, the magnetic ?eld

or acceleration.

and electric current are supplied perpendicular to one

angles to the magnetic ?eld which is generated at these

It is the primary object of the present application to

another and according to the teachings of Faraday this ar

disclose direct current to direct current, alternating cur 45 rangement will create a mutually perpendicular force in

rent to direct current, or alternating current to alternating

a conductive ?uid or liquid metal contained in the pas

current type power transforming devices which utilize

sage means 30. This force will then immediately cause

the same basic construction.

the conductive ?uid to be pumped around the channel

A further object of the present novel device is to dis

30 in a continuous manner.

The ?uid passage 30 is made up of two U-shaped tubes

of insulating material which are joined by collars 31 and

32. It will be understood that the tubes of passage 30

could be made of metal if the resistance of the metal is

substantially greater than the resistance of the conductive

or acceleration forces.

Still a further object of the present disclosure is to 55 ?uid or liquid metal contained in the passage 30. When

describe a highly simpli?ed and inexpensive construction

utilizing such conductive ?uids as sodium-potassium, so

close a power transformer that has a conductive ?uid or

liquid metal as its transforming medium.

Yet another object is to provide a unique power trans

forming device that is substantially immune to vibration

for a power transforming device.

dium or potassium, as well as mercury, it is possible to

build the conductive ?uid passage 30 of a high resistance

steel and still obtain a satisfactory level of operation.

ci?cation, wherein:

60 The electrodes 27 and 28 can be conveniently built into

the side of the passage 30 by welding or soldering and

FIGURES 1 and 2 are an elevation and cross section

a completely ?uid tight passage can be thus developed.

of an embodiment of the novel device, and

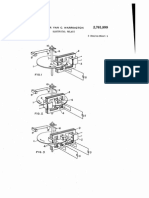

FIGURES 3 and 4 are an elevation and cross section

A ?uid converter is shown generally at 40 and con

of a second embodiment of the device.

sists of a device quite similar to a portion of the pump

These and other objects will become apparent when the

attached drawings are considered with the present spe

3,034,002

disclosed at ill). The converter consists of two electrodes

direct current energizing source could be replaced by a

permanent magnetic core alone.

41 and 42 which are inserted into the walls of the pas

sage 30 so as to be in contact with the conductive ?uid

Placed between the pole faces 64 and 65 are two con

ductive ?uid passages 66 and 67. These passages are

to the direction of ?uid ?ow and to the two electrodes 41 5 insulated from one another and from the poles 64 and 65

and 42 there is placed a lG-shaped magnetic structure 43.

by means of an insulating material 70. The passages 66

The magnetic structure 43 has an energizing coil 44 which

and 67 are joined at their opposite ends by two U-shaped

is conveniently connected to any source of direct cur

passage members 71 and 72. By joining the passages 66

and 67 together a conductive ?uid passage is provided

rent by means of conductors 45 and 46. It will be ap

preciated that upon energization of the coil 44 by a di

and this passage is ?lled with a conductive ?uid or liquid

metal. It will be noted that'the passages 66 and 67 are

rect current, a magnetic ?ux appears between the pole

pieces 47 and 48. The magnetic ?ux is perpendicular to

of different cross sectional areas and any movement of

?uid in the passages will necessitate different velocity

the electrodes 41 and 42 and the electrodes and ?ux are

mutually perpendicular to the line of ?ow of the conduc

since the passages are closed upon each other by the

tive ?uid.

15 U-shaped members 71 and 72. If a direct current source

is supplied to conductors 73 and 74 and to electrodes 75

If the pump 10 is operating so as to circulate a con

ductive ?uid around the closed passage means 30, and a

and 76 of the ?ow channel, it is apparent that a current

magnetic ?ux is generated between pole pieces 47 and

will ?ow across the conductive ?uid channel 66 in a

contained within the passage.

Mutually perpendicular

48, the requisite conditions of generation of an electric

perpendicular relationship to the magnetic ?eld between

current have been met. It will be appreciated that an

electric current will therefore be available between elec

poles 64 and 65. The construction is that of a Faraday

pump and the conductive ?uid in channel 66 is pumped

out of that channel. This pumping action in turn cir

culates the conductive ?uid in the U-shaped end members

trodes 41 and 42 and that conductors 50 and 51 can be

utilized to provide a direct current output from the

device as described. The magnitude of the direct cur~

71 and 72 and causes the ?uid to ?ow in the lower chan

rent output will be a function of the velocity of the con 25 nel 67. It is obvious that since the channels 66 and 67

ductive ?uid passing through the passage means 30 and

of the magnetic ?eld between poles 47 and 48. It be

are connected by the U-shaped members 71 and 72, that

current is capable of being taken out of the device.

In considering the device disclosed in FIGURES l and

the poles 64 and 65 and establishes a conductive ?uid

generating means. It is therefore apparent that elec

2 it is pointed out that the pump 10, while shown as an

trodes 80 and 81 will have a direct current available to

the ?ow in the two channels 66 and 67 must be of dif

ferent velocity since the cross sectional areas of these two

comes apparent that a power transformation device has

been described wherein a level of alternating current has

channels are different. The conductive ?uid ?owing in

been put into the device and a different level of direct 30 the channel 67 crosses a constant magnetic ?eld between

alternating current device, can be conveniently replaced

them which can be in turn taken out of the device by

This can be ac

35 conductors '82 and 83. A direct current to direct current

complished readily by energizing the coil 12 with a di

transforming device has thus been described. In order

to select the ratio of transformation it is merely neces

sary to select the relative cross sections of channels 66

by a direct current operated device.

rect current or by making the core structure 11 of a

permanent magnetic material. In addition to these

changes the power supplied to electrodes 27 and 28 would

be of a direct current type. If a direct current and a con

and 67 to provide the desired ratio. Further, any diifer

40 ence in the lengths of the channels 66 and 67 will vary

stant magnetic ?eld react, the same type of pumping pres

the ratio of transformation.

sure would be supplied in the passage means 30 as is

The device disclosed in FIGURES 3 and 4 can be

modi?ed readily to make it an alternating current trans

former and the transformation ratio is again related to

pointed out by the alternating current device speci?cally

disclosed in FIGURES 1 and 2.

It will be appreciated that the device disclosed in FIG 45 the areas or the cross sections of channels 66 and 67.

URES 1 and 2 does not limit transformation of any level

The present application has described in detail two

of alternating current to a direct current, or any level

embodiments of a magnetic power transforming means

utilizing a conductive ?uid as the transforming medium.

of direct current to any other level of direct current. A

further modi?cation of FIGURES 1 and 2 can be easily

A number of possible variations have been speci?cally

accomplished to convert alternating current to alternating

described in order to more fully disclose the principle and

current. This modi?cation is merely a substitute of al

possible applications of the device. The speci?c embodi

ternating current to the coil 44 and the resultant genera

ments described are for illustrative purposes only and are

tion of an alternating current between electrodes 41 and

not by any means to be considered as limitations as to

42. It is apparent that one of the primary objects of the

the scope of the present invention. The scope of the in

present invention can be readily attained by the selective

energization of the unit described. It will be appreciated

that this device provides a transforming function not

normally available in more conventional type devices.

vention is limited only by the appended claims.

I claim as my invention:

1. An electrical transforming device of the class de

scribed: closed passage means ?lled with a liquid metal;

It is a further object of the present device that the sole

magnetic flux generating means adjacent said passage

moving part is a conductive ?uid which ?lls the passage

means and generating a magnetic ?ux across said passage

means 30. This arrangement is obviously not subject to

means; current generating means including a pair of elec

disruption or interferences by vibration, acceleration or

trodes; said current generating means passing a current

similar types of disturbances.

between said electrodes across a portion of said passage

A modi?cation of the device disclosed in FIGURES l

and 2 is shown in FIGURES 3 and 4. The device dis~ 65 means mutually perpendicular to said magnetic ?ux and

said liquid metal; said magnetic ?ux and said current

closed in FIGURES 3 and 4 utilizes the same basic prin

causing said liquid metal to ?ow around said closed pas

ciple but differs in that the unit utilizes a single magnetic

sage means; and a second pair of electrodes across said

?eld and a single magnetic core. This core is presented

passage in alignment with said ?rst pair of electrodes;

as 60 and is disclosed as a c-shaped core member.

Around the core 60 is formed a coil 61 which is ener 70 said second pair of electrodes mutually perpendicular to

gized, in the disclosed embodiment, by a direct current

source on conductors 62 and 63. It is obvious that the

energization of coil 61 by a direct current source will

provide a magnetic ?eld of a constant nature between

said magnetic ?ux and said liquid metal ?ow; said second

pair of electrodes collecting a current generated by the

?ow of said liquid metal through said magnetic ?eld.

2. An electrical transforming device of the class de

poles 64 and 65. It is further apparent that the coil and 75 scribed: closed passage means ?lled with a conductive

3,034,002

?uid; magnetic ?ux generating means adjacent said pas

current generated by the ?ow of said ?uid through said

magnetic ?eld.

sage means and generating a magnetic ?ux across said

passage means; current generating means including elec

trode means; said current generating means passing a

current between said electrode means across a portion of

said passage means mutually perpendicular to said mag

netic ?ux and said ?uid; said magnetic ?ux and said cur

rent causing said ?uid to flow around said closed passage

References Cited in the ?le of this patent

UNITED STATES PATENTS

2,490,009

Thomas __________ _'_____ Nov. 29, 1949

2,669,873

2,715,190

Gardner et a1 __________ __ Feb. 23, 1954

Brill _________________ .._ Aug. 9, 1955

means mutually perpendicular to said magnetic ?ux and 10 2,838,001

2,978,985

said ?uid ?ow; said second electrode means collecting a

Robinson _____________ __ June 10, 1958

Lindenblad ___________ __ Apr. 11, 1961

means; and second electrode means acnoss said passage

Das könnte Ihnen auch gefallen

- A Practical Guide To Free Energy' DevicesDokument6 SeitenA Practical Guide To Free Energy' DevicesFelipe EscuderoNoch keine Bewertungen

- Jan. 17, 195 J, C, Marsh 2,731,589: Filed Sept. 13, 1954Dokument4 SeitenJan. 17, 195 J, C, Marsh 2,731,589: Filed Sept. 13, 1954Victor Von DoomNoch keine Bewertungen

- Z/Jizvlzz: March 28, 1961 C - H Rlchards Eta), ' 2,977,526Dokument5 SeitenZ/Jizvlzz: March 28, 1961 C - H Rlchards Eta), ' 2,977,526Victor Von DoomNoch keine Bewertungen

- Figqi.: R-F GeneratorDokument12 SeitenFigqi.: R-F GeneratorVictor Von DoomNoch keine Bewertungen

- GB 763062Dokument6 SeitenGB 763062jean-doe06Noch keine Bewertungen

- TT Brown's Electrokinetic Generator PatentDokument7 SeitenTT Brown's Electrokinetic Generator PatentJason Warden0% (1)

- Electrical Circuit For Ventricular Defibrillator: W. C. Daniher Et AlDokument4 SeitenElectrical Circuit For Ventricular Defibrillator: W. C. Daniher Et AlRanajay MandalNoch keine Bewertungen

- Patente Del Señor Edwin H. Colpitts 1918 US1624537Dokument5 SeitenPatente Del Señor Edwin H. Colpitts 1918 US1624537Adrian GarciaNoch keine Bewertungen

- Electric RegeneratorDokument3 SeitenElectric RegeneratorLucianMirceaNoch keine Bewertungen

- A Practical Guide To Free Energy' DevicesDokument7 SeitenA Practical Guide To Free Energy' DevicesitaloNoch keine Bewertungen

- J. W. Mayo Etal Electrical-Connector: Filed June 1965Dokument3 SeitenJ. W. Mayo Etal Electrical-Connector: Filed June 1965Kevin CooperNoch keine Bewertungen

- A Practical Guide To Free Energy' DevicesDokument7 SeitenA Practical Guide To Free Energy' DevicesVlad AdrianNoch keine Bewertungen

- Us 13,610,971Dokument8 SeitenUs 13,610,971Сергей КолесниковNoch keine Bewertungen

- Motionless Electromagnetic GeneratorDokument9 SeitenMotionless Electromagnetic GeneratorViswa TejaNoch keine Bewertungen

- U.S. Patent 2,719,942, Entitled "Motor Control System", To Kallenbach, Oct. 4, 1955.Dokument6 SeitenU.S. Patent 2,719,942, Entitled "Motor Control System", To Kallenbach, Oct. 4, 1955.Anonymous a7S1qyXNoch keine Bewertungen

- Capacitance Type FqisDokument16 SeitenCapacitance Type FqisVinay SinghNoch keine Bewertungen

- Chapter-6&7 Ncert Practice QuestionsDokument16 SeitenChapter-6&7 Ncert Practice QuestionsRAHIM MDNoch keine Bewertungen

- Aug. 22, 1967 J. Baude 3,337,785:: H 3/) LL D/ I!Dokument6 SeitenAug. 22, 1967 J. Baude 3,337,785:: H 3/) LL D/ I!GIZETONoch keine Bewertungen

- (Free Energy) Kunel PatentDokument9 Seiten(Free Energy) Kunel PatentIra Weinstein100% (1)

- US568176 - TeslaDokument4 SeitenUS568176 - TesladaveklodavekloNoch keine Bewertungen

- Circuito de ControlDokument4 SeitenCircuito de ControlEmer nelsonNoch keine Bewertungen

- Us 1745175Dokument4 SeitenUs 1745175Lily SternNoch keine Bewertungen

- Circuito de Años PasadosDokument11 SeitenCircuito de Años PasadosEmer nelsonNoch keine Bewertungen

- Class 12 - HY2 - RevisionDokument6 SeitenClass 12 - HY2 - RevisionSam SolomonNoch keine Bewertungen

- PHYSICS HOLIDAY HOMEWORK CLASS XII Docx 2023Dokument3 SeitenPHYSICS HOLIDAY HOMEWORK CLASS XII Docx 2023unknownNoch keine Bewertungen

- MET-2.2 QuestionsDokument20 SeitenMET-2.2 QuestionsApoorv SinghNoch keine Bewertungen

- Unit Iv PDFDokument18 SeitenUnit Iv PDFMonte CarloNoch keine Bewertungen

- US3018394Dokument5 SeitenUS3018394kartikkeyyanNoch keine Bewertungen

- Prentice Earth Energy TapDokument7 SeitenPrentice Earth Energy TapGeorggeNoch keine Bewertungen

- 300 PDFDokument3 Seiten300 PDFmohamed hemdanNoch keine Bewertungen

- Circuit Analysis II. 5. Magnetically Coupled CircuitsDokument48 SeitenCircuit Analysis II. 5. Magnetically Coupled Circuits10mq33Noch keine Bewertungen

- .Jy 2L, 1953 ' L.. J. Glacoletto 2,6533: .Pazza/W06@ '40Dokument13 Seiten.Jy 2L, 1953 ' L.. J. Glacoletto 2,6533: .Pazza/W06@ '40dllabarreNoch keine Bewertungen

- Class 12 - HY2 - RevisionDokument6 SeitenClass 12 - HY2 - RevisionSam SolomonNoch keine Bewertungen

- Us 4550284Dokument7 SeitenUs 4550284booky_mookyNoch keine Bewertungen

- Documento de ElectrónicaDokument3 SeitenDocumento de ElectrónicaEmer nelsonNoch keine Bewertungen

- Sept. 6, 1949. M. A. Ssman 2,481,132: Filed April 25, 1946Dokument4 SeitenSept. 6, 1949. M. A. Ssman 2,481,132: Filed April 25, 1946Emer nelsonNoch keine Bewertungen

- High-Voltage Direct Current Transmission: Power Super Highway or An Electrical Super Highway)Dokument27 SeitenHigh-Voltage Direct Current Transmission: Power Super Highway or An Electrical Super Highway)AtiqMarwatNoch keine Bewertungen

- Wo 2013104043 A 1Dokument9 SeitenWo 2013104043 A 1Mladen MuskinjaNoch keine Bewertungen

- Bruce DePalma - Free Energy - Homopolar GeneratorDokument17 SeitenBruce DePalma - Free Energy - Homopolar GeneratorZsolt Szakács100% (1)

- Electric Gas Lighting How to Install Electric Gas Ignition ApparatusVon EverandElectric Gas Lighting How to Install Electric Gas Ignition ApparatusNoch keine Bewertungen

- A Practical Guide To Free Energy' Devices: United States Patent 6,362,718 Dated: 26th March 2002 InventorsDokument18 SeitenA Practical Guide To Free Energy' Devices: United States Patent 6,362,718 Dated: 26th March 2002 InventorsitaloNoch keine Bewertungen

- Emi and Ac AssignmentDokument5 SeitenEmi and Ac AssignmentMohammed AmmaarNoch keine Bewertungen

- Sept. 17, 1940.: L. Hammond 2,214,764Dokument4 SeitenSept. 17, 1940.: L. Hammond 2,214,764Guilherme NominatoNoch keine Bewertungen

- Minted States Patent 1191 1111 3,760,286: Kelly (45) Sept. 18, 1973Dokument6 SeitenMinted States Patent 1191 1111 3,760,286: Kelly (45) Sept. 18, 1973Victor Von DoomNoch keine Bewertungen

- POWER SUPPLY SYSTEM. ServicesDokument76 SeitenPOWER SUPPLY SYSTEM. ServicesnwanabossNoch keine Bewertungen

- Kromrey Converter US3374376Dokument8 SeitenKromrey Converter US3374376kishbud100% (1)

- Physics ProjectDokument8 SeitenPhysics ProjectXigfon SqitroNoch keine Bewertungen

- cos d sin d d d: NBA t NBA t Φ N VDokument2 Seitencos d sin d d d: NBA t NBA t Φ N VchrismarieayopNoch keine Bewertungen

- Generation of Energy Usig MagnetsDokument26 SeitenGeneration of Energy Usig MagnetsSridhar PatilNoch keine Bewertungen

- Us 3514566Dokument3 SeitenUs 3514566emernelsonmanNoch keine Bewertungen

- Ac DC Solution 1Dokument4 SeitenAc DC Solution 1John Miko JavierNoch keine Bewertungen

- High Current Plasma Source: PatentsDokument5 SeitenHigh Current Plasma Source: PatentsVictor Von DoomNoch keine Bewertungen

- Tesla Patent,,,,Rotating Magnetic Field Using... Und A Ferrite Toroid1Dokument5 SeitenTesla Patent,,,,Rotating Magnetic Field Using... Und A Ferrite Toroid1anakedya13Noch keine Bewertungen

- 1 Mark Questions 1.: Question BankDokument4 Seiten1 Mark Questions 1.: Question Bankharipriya3011Noch keine Bewertungen

- Worksheet For Volume - 1Dokument3 SeitenWorksheet For Volume - 1pranavtsababayagaNoch keine Bewertungen

- Sept. 4, 1956 A. R. Van C. Warrington 2,761,999: Electrical Relays 2 Sheets-Sheet 1Dokument4 SeitenSept. 4, 1956 A. R. Van C. Warrington 2,761,999: Electrical Relays 2 Sheets-Sheet 1ajalbornozNoch keine Bewertungen

- Electromagnetic Effects: 300 Turns 30 TurnsDokument23 SeitenElectromagnetic Effects: 300 Turns 30 TurnsEdgardo Leysa100% (5)

- Class 12 - AC Mains QuestionsDokument6 SeitenClass 12 - AC Mains QuestionsGreeshma ReddyNoch keine Bewertungen

- A New System of Alternating Current Motors and TransformersVon EverandA New System of Alternating Current Motors and TransformersBewertung: 1 von 5 Sternen1/5 (1)

- Us 20140051044Dokument80 SeitenUs 20140051044Victor Von DoomNoch keine Bewertungen

- Us 20140367201Dokument16 SeitenUs 20140367201Victor Von DoomNoch keine Bewertungen

- United States: (12) Patent Application Publication (10) Pub. No.: US 2014/0183875 A1Dokument21 SeitenUnited States: (12) Patent Application Publication (10) Pub. No.: US 2014/0183875 A1Victor Von DoomNoch keine Bewertungen

- A Gravito-Electric Power Generating Unit: (19) United StatesDokument11 SeitenA Gravito-Electric Power Generating Unit: (19) United StatesVictor Von DoomNoch keine Bewertungen

- Us 20140319933Dokument21 SeitenUs 20140319933Victor Von DoomNoch keine Bewertungen

- Us 20130261420Dokument12 SeitenUs 20130261420Victor Von DoomNoch keine Bewertungen

- Us 20130292944Dokument11 SeitenUs 20130292944Victor Von DoomNoch keine Bewertungen

- TEPZZ 6798 A - T: European Patent ApplicationDokument28 SeitenTEPZZ 6798 A - T: European Patent ApplicationVictor Von DoomNoch keine Bewertungen

- Us 4831627Dokument5 SeitenUs 4831627Victor Von DoomNoch keine Bewertungen

- Us 20120168676Dokument3 SeitenUs 20120168676Victor Von DoomNoch keine Bewertungen

- Us 20040070299Dokument3 SeitenUs 20040070299Victor Von Doom100% (1)

- Us 20130121449Dokument54 SeitenUs 20130121449Victor Von DoomNoch keine Bewertungen

- Us 20080074083Dokument65 SeitenUs 20080074083Victor Von DoomNoch keine Bewertungen

- Us 20100038914Dokument39 SeitenUs 20100038914Victor Von DoomNoch keine Bewertungen

- Us 20120090534Dokument28 SeitenUs 20120090534Victor Von DoomNoch keine Bewertungen

- Us 20120112552Dokument43 SeitenUs 20120112552Victor Von DoomNoch keine Bewertungen

- Us 20110316678Dokument13 SeitenUs 20110316678Victor Von DoomNoch keine Bewertungen

- US20090292158Dokument9 SeitenUS20090292158Victor Von DoomNoch keine Bewertungen

- United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0072823 A1Dokument21 SeitenUnited States: (12) Patent Application Publication (10) Pub. No.: US 2010/0072823 A1Victor Von DoomNoch keine Bewertungen

- Us 20090135676Dokument17 SeitenUs 20090135676Victor Von DoomNoch keine Bewertungen

- United States: (12) Patent Application Publication (10) Pub. No.: US 2009/0082612 A1Dokument10 SeitenUnited States: (12) Patent Application Publication (10) Pub. No.: US 2009/0082612 A1Victor Von DoomNoch keine Bewertungen

- United States: (12) Patent Application Publication (10) Pub. N0.: US 2009/0059460 A1Dokument12 SeitenUnited States: (12) Patent Application Publication (10) Pub. N0.: US 2009/0059460 A1Victor Von DoomNoch keine Bewertungen

- Us 20070084496Dokument18 SeitenUs 20070084496Victor Von DoomNoch keine Bewertungen

- United States: (12) Patent Application Publication (10) Pub. No.: US 2004/0119967 A1Dokument19 SeitenUnited States: (12) Patent Application Publication (10) Pub. No.: US 2004/0119967 A1Victor Von DoomNoch keine Bewertungen

- Us 20040196943Dokument8 SeitenUs 20040196943Victor Von DoomNoch keine Bewertungen

- Frequency Locked Loop DC Motor Speed ControlDokument47 SeitenFrequency Locked Loop DC Motor Speed ControlRakesh Kumar50% (2)

- 30-12-19 - SR - Icon All - GTM-7 - CODE-B - Question Paper Key and SolutionsDokument41 Seiten30-12-19 - SR - Icon All - GTM-7 - CODE-B - Question Paper Key and SolutionsGowri ShankarNoch keine Bewertungen

- Interturn Short-Circuit Detector For Turbine-Generator Rotor WindingsDokument6 SeitenInterturn Short-Circuit Detector For Turbine-Generator Rotor WindingsEng Bagaragaza Romuald100% (1)

- Implementation of The Neumann Formula For Calculating The Mutual Inductance Between Planar PCB InductorsDokument7 SeitenImplementation of The Neumann Formula For Calculating The Mutual Inductance Between Planar PCB InductorsAbdul Halil AbdullahNoch keine Bewertungen

- OSS Engineering Control Ver 2 1 PNDokument80 SeitenOSS Engineering Control Ver 2 1 PNRagav SasthriNoch keine Bewertungen

- Drunk & Drive Prevention SystemDokument9 SeitenDrunk & Drive Prevention SystemNitheshksuvarnaNoch keine Bewertungen

- Transmission Line, Transformer & Protection LaboratoryDokument28 SeitenTransmission Line, Transformer & Protection LaboratoryVenkata Rajkumar ChNoch keine Bewertungen

- Science Grade 5 Electromagnet Lesson Plan MaputeDokument10 SeitenScience Grade 5 Electromagnet Lesson Plan MaputeRosedel Peteros MaputeNoch keine Bewertungen

- Discovery 3300 Detector ManualDokument24 SeitenDiscovery 3300 Detector ManualladymarqNoch keine Bewertungen

- FP Medium Voltage Transformer CatalogDokument36 SeitenFP Medium Voltage Transformer CatalogCiro LeonNoch keine Bewertungen

- ssp381 - Audi TT Coupé 07 - Suspension SystemDokument48 Seitenssp381 - Audi TT Coupé 07 - Suspension SystemGabriel VetreneanuNoch keine Bewertungen

- Power System Protection and Switchgear: Fundamentals of Protective Relaying VDokument17 SeitenPower System Protection and Switchgear: Fundamentals of Protective Relaying VSampath AnbuNoch keine Bewertungen

- Design and Simulation of PFC Circuit For AC/DC Converter Based On PWM Boost RegulatorDokument5 SeitenDesign and Simulation of PFC Circuit For AC/DC Converter Based On PWM Boost RegulatorSEP-PublisherNoch keine Bewertungen

- Fiitjee: JEE (Advanced), 2017Dokument17 SeitenFiitjee: JEE (Advanced), 2017AbhijeetNoch keine Bewertungen

- Build Your Own Doug Coil MachineDokument139 SeitenBuild Your Own Doug Coil MachineЗорица Ћирић100% (1)

- Measurement and InstrumentationDokument4 SeitenMeasurement and InstrumentationAbirami RajendranNoch keine Bewertungen

- Wireless Power Transmission in Electric Vehicle ApplicationsDokument5 SeitenWireless Power Transmission in Electric Vehicle ApplicationsGRD JournalsNoch keine Bewertungen

- 3A, 28V, 385Khz Step-Down Converter: The Future of Analog Ic TechnologyDokument11 Seiten3A, 28V, 385Khz Step-Down Converter: The Future of Analog Ic TechnologyerdaNoch keine Bewertungen

- Bd9483f Leds DriverDokument32 SeitenBd9483f Leds Driveraries2010mx0% (1)

- Industrial Electronics Final EdDokument83 SeitenIndustrial Electronics Final EdAdriano Mercedes Jr. CanoNoch keine Bewertungen

- 3A, 28V, 385Khz Step-Down Converter: The Future of Analog Ic TechnologyDokument13 Seiten3A, 28V, 385Khz Step-Down Converter: The Future of Analog Ic TechnologyIoan TivgaNoch keine Bewertungen

- BLANK Commission Sheet RAV VRF v1.41Dokument11 SeitenBLANK Commission Sheet RAV VRF v1.41Hush SNoch keine Bewertungen

- LM3478MM PDFDokument22 SeitenLM3478MM PDFkarimNoch keine Bewertungen

- Measurements Andcontrol Question PapersDokument66 SeitenMeasurements Andcontrol Question PapersvenkatNoch keine Bewertungen

- BR Unit 21Dokument8 SeitenBR Unit 21Amir YonanNoch keine Bewertungen

- Motor and Drive System Resonance Problems and SolutionsDokument4 SeitenMotor and Drive System Resonance Problems and SolutionsYernohjNoch keine Bewertungen

- 'Numerical Optimization of The Tube-Cored Induction Magnetometer Weight' Under Copied Noise AnalysisDokument62 Seiten'Numerical Optimization of The Tube-Cored Induction Magnetometer Weight' Under Copied Noise AnalysisRostyslav SKLYAR, Dr. (Eng)Noch keine Bewertungen

- Coils and InductanceDokument6 SeitenCoils and InductanceJoseGarciaRuizNoch keine Bewertungen

- MicroInverter 01444ADokument54 SeitenMicroInverter 01444ArqwertyNoch keine Bewertungen

- WalkietalkieDokument8 SeitenWalkietalkieThanhha NguyenNoch keine Bewertungen