Beruflich Dokumente

Kultur Dokumente

M30

Hochgeladen von

sugandaraj522Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

M30

Hochgeladen von

sugandaraj522Copyright:

Verfügbare Formate

.

M30

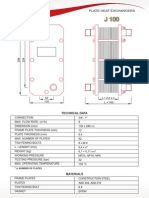

Plate Heat Exchanger

Applications

General heating and cooling duties.

Standard design

The plate heat exchanger consists of a pack of corrugated

metal plates with portholes for the passage of the two fluids

between which heat transfer will take place.

The plate pack is assembled between a fix frame plate and a

movable pressure plate and compressed by tightening bolts.

The plates are fitted with a gasket, which seals the interplate

channel and directs the fluids into alternate channels. The

number of plates is determined by the flow rate, physical

properties of the fluids, pressure drop and temperature

program. The plate corrugations promote fluid turbulence and

support the plates against differential pressure.

The plate and the pressure plate are suspended from an

upper carrying bar and located by a lower guiding bar, both

of which are fixed to a support column.

Connections are located in the frame plate or, if either or both

fluids make more than a single pass within the unit, in the

frame and pressure plates.

M30-FG

Typical capacities

Liquid

flow rate

.

Up to 650 kg/s (10400 gpm), depending on media, permitted

pressure drop and temperature program.

Plate types

M30 and M30D plates

Frame types

FM, FG and FD

Working principle

Channels are formed between the plates and the corner ports

are arranged so that the two media flow through alternate

channels. The heat is transferred through the plate between

the channels, and complete counter-current flow is created

for highest possible efficiency. The corrugation of the plates

provides the passage between the plates, supports each

plate against the adjacent one and enhances the turbulence,

resulting in efficient heat transfer.

Flow principle of a plate heat exchanger

Dimensions

STANDARD MATERIALS

Frame plate

Mild steel, Epoxy painted

W

596 (23.5")

Plates

Stainless steel Alloy 304, Alloy 316, Alloy C276, Alloy 254

SMO or Titanium

Other grades and material available on request.

Gaskets

Nitrile, EPDM or Viton

Other grades and material available on request.

1845 (72.6")

Nozzles

Carbon steel

Metal lined: Stainless steel, Titanium, Alloy C276

1585-5235 (62.4-206.1")

TECHNICAL DATA

Mechanical design pressure (g) / temperature

FM PED, pvcALSTM

1.0 MPa / 190C

FG PED, pvcALSTM

1.6 MPa / 180C

FG ASME

150 psig / 320F

FD PED, pvcALSTM

2.5 MPa / 190C

FD ASME

300 psig / 320F

Measurements mm (inch)

Type

M30-FM

M30-FG

M30-FD

H*

2882 (113.5)

2882 (113.5)

2920 (115)

W

1150 (45.3)

1170 (46.1)

1190 (46.9)

h

470 (18.5)

470 (18.5)

506 (19.9)

* +200 mm (7.9) for carrying bars > 3600 mm (141.7) The number of

tightening bolts may vary depending on the pressure rating.

Connections

FM pvcALSTM

FM PED

FG pvcALSTM

FG PED

FG ASME

FD pvcALSTM

Size:

300/350

300/350

300/350

300/350

12/14

300/350

FD PED

FD ASME

300/350 mm

12/14

mm

mm

mm

mm

mm

DIN PN10, ASME Cl. 150, JIS 10K

DIN PN10, ASME CI. 150

DIN PN16, ASME Cl. 150, JIS 16K

DIN PN16, ASME CI. 150

ASME Cl. 150

DIN PN25, ASME Cl. 150/300, JIS

20K

DIN PN25, ASME CI. 150/300

ASME Cl. 300

Particulars required for quotation

- Flow rates or heat load

- Temperature program

- Physical properties of liquids in question (if not water)

- Desired working pressure

- Maximum permitted pressure drop

- Available steam pressure

.

Maximum heat transfer surface

1400 m2 (14980 sq. ft)

PCT00080EN 1202

How to contact Alfa Laval

Up-to-date AlfaLaval contact details for

all countries are always available on our

website on www.alfalaval.com

Alfa Laval reserves the right to change specifications without prior notification.

Das könnte Ihnen auch gefallen

- Minister Brief 3 EnglishDokument2 SeitenMinister Brief 3 Englishsugandaraj522Noch keine Bewertungen

- Decision Doc 2022 - FinalDokument8 SeitenDecision Doc 2022 - Finalsugandaraj522Noch keine Bewertungen

- New Electricity Tariff RatesDokument2 SeitenNew Electricity Tariff RatesAda DeranaNoch keine Bewertungen

- Animles Worksheet 1-6867e956-Aac4-4...Dokument5 SeitenAnimles Worksheet 1-6867e956-Aac4-4...sugandaraj522Noch keine Bewertungen

- Learn to Teach & Teach to LearnDokument29 SeitenLearn to Teach & Teach to Learnsugandaraj522Noch keine Bewertungen

- Boost productivity with compact sinus-jevi band heatersDokument22 SeitenBoost productivity with compact sinus-jevi band heaterssugandaraj522Noch keine Bewertungen

- TempleDokument29 SeitenTemplesugandaraj522Noch keine Bewertungen

- Verbs - Note & ActivityDokument3 SeitenVerbs - Note & Activitysugandaraj522Noch keine Bewertungen

- Exam Papers 2018Dokument17 SeitenExam Papers 2018sugandaraj522Noch keine Bewertungen

- Personal and common objectsDokument9 SeitenPersonal and common objectssugandaraj522Noch keine Bewertungen

- TMPDokument1 SeiteTMPsugandaraj522Noch keine Bewertungen

- This / These & That / Those This - Used For One Thing That Is Close by These - Used For Many Things That Are Close byDokument3 SeitenThis / These & That / Those This - Used For One Thing That Is Close by These - Used For Many Things That Are Close bysugandaraj522Noch keine Bewertungen

- SM Incinerators AnnDokument11 SeitenSM Incinerators AnnPasindu PramodNoch keine Bewertungen

- Rubber Wood As A Potential Biomass Feedstock For Biochar Via Slow PyrolysisDokument6 SeitenRubber Wood As A Potential Biomass Feedstock For Biochar Via Slow Pyrolysissugandaraj522Noch keine Bewertungen

- Animals Around Us-WorksheetDokument2 SeitenAnimals Around Us-Worksheetsugandaraj522Noch keine Bewertungen

- Rules - of - Thumb AIR FILTRATION PDFDokument3 SeitenRules - of - Thumb AIR FILTRATION PDFJomyJoseNoch keine Bewertungen

- IR Thermometers ExplainedDokument4 SeitenIR Thermometers Explainedsugandaraj522Noch keine Bewertungen

- KKU Engineering Journal: Characterization and Elemental Composition of Lignite and Rubber Wood Sawdust PelletsDokument4 SeitenKKU Engineering Journal: Characterization and Elemental Composition of Lignite and Rubber Wood Sawdust Pelletssugandaraj522Noch keine Bewertungen

- Axial Flow Fans Performance Data: How The Performance Curves WorkDokument1 SeiteAxial Flow Fans Performance Data: How The Performance Curves WorkAbd NaamiNoch keine Bewertungen

- Data Sheet Standard ChannelsDokument2 SeitenData Sheet Standard Channelsmanan_mansoorNoch keine Bewertungen

- 1619260590allowed Charges For CEB 2021Dokument7 Seiten1619260590allowed Charges For CEB 2021sugandaraj522Noch keine Bewertungen

- INDIAN Steel TableDokument8 SeitenINDIAN Steel Tablezaveeq80% (5)

- Lighting Recommended Light LevelsDokument4 SeitenLighting Recommended Light Levelssugandaraj522Noch keine Bewertungen

- Purolator Commercial Industrial Selection GuideDokument4 SeitenPurolator Commercial Industrial Selection Guidesugandaraj522Noch keine Bewertungen

- Lighting Recommended Light LevelsDokument4 SeitenLighting Recommended Light Levelssugandaraj522Noch keine Bewertungen

- Cooling Load CalculationsDokument6 SeitenCooling Load CalculationssamuelNoch keine Bewertungen

- Purolator Commercial Industrial Selection GuideDokument4 SeitenPurolator Commercial Industrial Selection Guidesugandaraj522Noch keine Bewertungen

- Cogeneration Heat Power CHPDokument10 SeitenCogeneration Heat Power CHPMKOZERDEMNoch keine Bewertungen

- Sample Low Harmonic VFD Specification: Adjustable Speed Drives 10 To 125 HP and From 240, 480 and 600 VAC GeneralDokument8 SeitenSample Low Harmonic VFD Specification: Adjustable Speed Drives 10 To 125 HP and From 240, 480 and 600 VAC GeneralAlex SalazarNoch keine Bewertungen

- Monthly Progress Report of BSESC for April 2021Dokument5 SeitenMonthly Progress Report of BSESC for April 2021sugandaraj522Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Gasketed Plate Heat Exchangers Equipment DesignDokument8 SeitenGasketed Plate Heat Exchangers Equipment DesignAldren Delina RiveraNoch keine Bewertungen

- Advanced Methods of Modelling and Design of Plate Heat ExchangersDokument5 SeitenAdvanced Methods of Modelling and Design of Plate Heat Exchangerschiali samirNoch keine Bewertungen

- Mtu Engine Model 20V4000G63L A. LT CIRCUIT (410 KW@ 30 M /HR) Heat Exchanger: Gl-13Lx36 Duty RequirementsDokument4 SeitenMtu Engine Model 20V4000G63L A. LT CIRCUIT (410 KW@ 30 M /HR) Heat Exchanger: Gl-13Lx36 Duty RequirementsbaljeetjatNoch keine Bewertungen

- Plate heat exchangers for ethylene glycol and waterDokument2 SeitenPlate heat exchangers for ethylene glycol and waterHakkı YılmazNoch keine Bewertungen

- CB16Dokument2 SeitenCB16fredyNoch keine Bewertungen

- Gasketed Plate Heat Exchanger: Mme 9516 Hvac 1 Project PresentationDokument16 SeitenGasketed Plate Heat Exchanger: Mme 9516 Hvac 1 Project PresentationrudyNoch keine Bewertungen

- Unit 14 Heat Exchangers: StructureDokument36 SeitenUnit 14 Heat Exchangers: StructureShrungar GowdaNoch keine Bewertungen

- Alfalaval Cip1800l and Cip2800l Pps00064enDokument2 SeitenAlfalaval Cip1800l and Cip2800l Pps00064engmatweakNoch keine Bewertungen

- GEA PHE NT enDokument2 SeitenGEA PHE NT enVLASTAR100% (2)

- Shape Optimization of Welded Plate Heat Exchangers Based On GreyDokument9 SeitenShape Optimization of Welded Plate Heat Exchangers Based On GreySandro Chuqui PorteroNoch keine Bewertungen

- Department of Mechanical Engineering Indian Institute of Engineering Science and Technology, ShibpurDokument15 SeitenDepartment of Mechanical Engineering Indian Institute of Engineering Science and Technology, ShibpurSuraj Kumar0% (1)

- APV Paraflow Plate HX ManualDokument31 SeitenAPV Paraflow Plate HX ManualAnonymous gwldee5100% (2)

- Compact Heat Exchanger DesignDokument52 SeitenCompact Heat Exchanger DesignoperationmanagerNoch keine Bewertungen

- SGL Information Sheet PT DIABON Graphite PHX ENDokument2 SeitenSGL Information Sheet PT DIABON Graphite PHX ENpatmos666Noch keine Bewertungen

- NT Plate HXDokument2 SeitenNT Plate HXpumanomerNoch keine Bewertungen

- DKQBPD000B102Dokument4 SeitenDKQBPD000B102amar.ranaNoch keine Bewertungen

- Analysis and Optimization of Spiral Plate Heat Exchanger Using Computational Fluid DynamicsDokument10 SeitenAnalysis and Optimization of Spiral Plate Heat Exchanger Using Computational Fluid DynamicsIJRASETPublicationsNoch keine Bewertungen

- Introduction To Enhanced Heat Transfer: Sujoy Kumar Saha Hrishiraj Ranjan Madhu Sruthi Emani Anand Kumar BhartiDokument111 SeitenIntroduction To Enhanced Heat Transfer: Sujoy Kumar Saha Hrishiraj Ranjan Madhu Sruthi Emani Anand Kumar Bhartiebrar totoNoch keine Bewertungen

- Kelvion-All ModelsDokument36 SeitenKelvion-All ModelsAli NorouziNoch keine Bewertungen

- Profile PDFDokument5 SeitenProfile PDFprabhuNoch keine Bewertungen

- SoldadasDokument4 SeitenSoldadasmiroslavacrNoch keine Bewertungen

- ME-495 Laboratory Exercise - Number 5 Me Dept, Sdsu - KassegneDokument5 SeitenME-495 Laboratory Exercise - Number 5 Me Dept, Sdsu - Kassegnesagarchawla13Noch keine Bewertungen

- Plate Heat Exchangers: Technical DataDokument15 SeitenPlate Heat Exchangers: Technical DataIvanNoch keine Bewertungen

- Shell and Tube Heat Exchanger: Wall ThicknessDokument10 SeitenShell and Tube Heat Exchanger: Wall ThicknessZeke KazamiNoch keine Bewertungen

- Ameridex InformationDokument2 SeitenAmeridex InformationJamil Moreira QuirozNoch keine Bewertungen

- Heat Exchanger 0Dokument40 SeitenHeat Exchanger 0HoongNoch keine Bewertungen

- Lab2 FluidDokument18 SeitenLab2 FluidKhaliefah AlabdouliNoch keine Bewertungen

- Types of Heat ExchangersDokument3 SeitenTypes of Heat ExchangersSeth Patrick ArceoNoch keine Bewertungen

- Kelvion Plate Heat Exchanger QuotationDokument2 SeitenKelvion Plate Heat Exchanger QuotationJafarNoch keine Bewertungen

- Thermowave Competence Refrigeration enDokument21 SeitenThermowave Competence Refrigeration enTechnill Serviços e RepresentaçõesNoch keine Bewertungen