Beruflich Dokumente

Kultur Dokumente

Cellulose Acetate

Hochgeladen von

cmmalbaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cellulose Acetate

Hochgeladen von

cmmalbaCopyright:

Verfügbare Formate

Alpha and Beta linkages are found in disaccharides and polysaccharides.

These glycosidic

linkages are the bonds between two simple sugars within a disaccharide or polysaccharide. Alpha

linkages are easily digested by the human body.

Cellulose acetate

Cellulose acetate, synthetic compound derived from the acetylation of the plant Read More:

substance cellulose. Cellulose acetate is spun into textile fibres known variously as acetate rayon,

acetate, or triacetate. It can also be molded into solid plastic parts such as tool handles or cast

into film for photography or food wrapping, though its use in these applications has diminished.

Cellulose is a naturally occurring polymer obtained from wood fibres or the short fibres (linters)

adhering to cotton seeds. It is made up of repeating glucose units that have the chemical formula

C H O (OH) and the following molecular structure:

In unaltered cellulose, the X in the molecular structure represents hydrogen (H), indicating the

presence in the molecule of three hydroxyl (OH) groups. The OH groups form strong hydrogen

bonds between cellulose molecules, with the result that cellulose structures cannot be loosened

by heat or solvents without causing chemical decomposition. However, upon acetylation, the

hydrogen in the hydroxyl groups is replaced by acetyl groups (CH3-CO). The resultant cellulose

acetate compound can be dissolved in certain solvents or softened or melted under heat, allowing

the material to be spun into fibres, molded into solid objects, or cast as a film.

Cellulose acetate is most commonly prepared by treating cellulose with acetic acid and then with

acetic anhydride in the presence of a catalyst such as sulfuric acid. When the resultant reactions

are allowed to proceed to completion, the product is a fully acetylated compound known as

primary cellulose acetate, or, more properly, cellulose triacetate. Triacetate is a high-melting (300

C [570 F]), highly crystalline substance that is soluble only in a limited range of solvents

(usually methylene chloride). From solution, triacetate can be dry-spun into fibres or, with the

aid of plasticizers, cast as a film. If the primary acetate is treated with water, a hydrolization

reaction can occur in which the acetylation reaction is partially reversed, producing a secondary

cellulose acetate, or cellulose diacetate. Diacetate can be dissolved by cheaper solvents such as

acetone for dry-spinning into fibres. With a lower melting temperature (230 C [445 F]) than

triacetate, diacetate in flake form can be mixed with appropriate plasticizers into powders for

molding solid objects, and it can also be cast as a film.

Cellulose acetate was developed in the late 19th century as part of an effort to design industrially

produced fibres based on cellulose. Treatment of cellulose with nitric acid had produced

cellulose nitrate (also known as nitrocellulose), but the difficulties of working with this highly

flammable compound encouraged research in other areas. In 1865 Paul Schtzenberger and

Laurent Naudin of the Collge de France in Paris discovered the acetylation of cellulose by

acetic anhydride, and in 1894 Charles F. Cross and Edward J. Bevan, working in England,

patented a process for preparing chloroform-soluble cellulose triacetate. An important

commercial contribution was made by British chemist George Miles in 190305 with the

discovery that, when the fully acetylated cellulose was subjected to hydrolysis, it transformed

into a less highly acetylated compound (cellulose diacetate) that was soluble in cheap organic

solvents such as acetone.

The full exploitation on a commercial scale of the acetone-soluble material was accomplished by

two Swiss brothers, Henri and Camille Dreyfus, who during World War I built a factory in

England for the production of cellulose diacetate to be used as a nonflammable dope for the

coating of fabric airplane wings. After the war, faced with no further demand for acetate dope,

the Dreyfus brothers turned to the production of diacetate fibres, and in 1921 their company,

British Celanese Ltd., began commercial manufacture of the product, trademarked as Celanese.

In 1929 E.I. du Pont de Nemours & Company (now DuPont Company) began production of

acetate fibre in the United States. Acetate fabrics found wide favour for their softness and

graceful drape. The material does not wrinkle easily when worn and, because of its low moisture

absorption when properly treated, does not easily retain certain types of stains. Acetate garments

launder well, retaining their original size and shape and drying in a short time, though they have

a tendency to retain creases imparted when wet. The fibre has been used, alone or in blends, in

apparel such as dresses, sportswear, underwear, shirts, and ties and also in carpets and other

home furnishings.

Das könnte Ihnen auch gefallen

- Chemistry and Reactions of Cellulose PDFDokument5 SeitenChemistry and Reactions of Cellulose PDFAditya ShrivastavaNoch keine Bewertungen

- Dextrin AsDokument16 SeitenDextrin AsJo An MeMeNoch keine Bewertungen

- Cellulose Derivatives DiagramDokument4 SeitenCellulose Derivatives DiagramDemeke Gezahegn TeseraNoch keine Bewertungen

- Synthesis of Cellulose AcetateDokument4 SeitenSynthesis of Cellulose AcetateBea Trixia Gales100% (1)

- Viscose ManufacturingDokument4 SeitenViscose Manufacturingabhinav_nathany7136Noch keine Bewertungen

- Textile Dictionary by Md. Jakir HossenDokument152 SeitenTextile Dictionary by Md. Jakir HossenMd. Jakir HossenNoch keine Bewertungen

- Cellulose Plastics: by Lakhan SinghDokument17 SeitenCellulose Plastics: by Lakhan SinghlakhancipetNoch keine Bewertungen

- Assignment Cellulose AcetateDokument4 SeitenAssignment Cellulose AcetateIqra MubeenNoch keine Bewertungen

- Cellulose Based CoatingsDokument8 SeitenCellulose Based CoatingsJHuvieCLaireNoch keine Bewertungen

- Cellulose Cross and BevanDokument2 SeitenCellulose Cross and BevanHorácio Henrique CampeloNoch keine Bewertungen

- GAMA Article Prf1Dokument6 SeitenGAMA Article Prf1gunjanbanasthaliNoch keine Bewertungen

- Resin FinishingDokument10 SeitenResin FinishingSam BanerjeeNoch keine Bewertungen

- Ioncell-F: A High-Strength Regenerated Cellulose FibreDokument15 SeitenIoncell-F: A High-Strength Regenerated Cellulose FibreLarisse BatalhaNoch keine Bewertungen

- Chemistry Sample ISC Board Project-PolymersDokument16 SeitenChemistry Sample ISC Board Project-PolymersCode Lyoko Fan 10Noch keine Bewertungen

- Cellulose: Chemistry of Natural and Biodegradable Polymers Final ReportDokument16 SeitenCellulose: Chemistry of Natural and Biodegradable Polymers Final Reportchip_daleNoch keine Bewertungen

- Plastics: Hermann Staudinger, Who Was Awarded The Nobel Prize in Chemistry inDokument5 SeitenPlastics: Hermann Staudinger, Who Was Awarded The Nobel Prize in Chemistry inAJAYNoch keine Bewertungen

- Regenerated FibresDokument31 SeitenRegenerated Fibreszxy_cbe100% (1)

- Study of Cellulose Degrading Bacteria and Dtermiation of Their Cellulolytic ActivityDokument4 SeitenStudy of Cellulose Degrading Bacteria and Dtermiation of Their Cellulolytic ActivitySuresh DhumalNoch keine Bewertungen

- Cellulose Complex Plant TechnologyDokument13 SeitenCellulose Complex Plant TechnologyDemeke Gezahegn TeseraNoch keine Bewertungen

- Cellulose Fibers, RegeneratedDokument39 SeitenCellulose Fibers, Regeneratedyemresimsek100% (1)

- AccetateDokument2 SeitenAccetateShikhaYadavNoch keine Bewertungen

- Synthesis of PolymersDokument8 SeitenSynthesis of PolymersMuhammad WildanNoch keine Bewertungen

- ChemistyDokument12 SeitenChemistydevikannan3086Noch keine Bewertungen

- Acetate FibreDokument5 SeitenAcetate FibreSatadeep DattaNoch keine Bewertungen

- Growing Paints On Trees: Quelle/Publication: Ausgabe/Issue: Seite/Page: European Coatings Journal 12/2005 36Dokument8 SeitenGrowing Paints On Trees: Quelle/Publication: Ausgabe/Issue: Seite/Page: European Coatings Journal 12/2005 36Ahmad Ma'rupNoch keine Bewertungen

- RayonDokument9 SeitenRayonRahul GuptaNoch keine Bewertungen

- Cellulose: by Kisar BittarDokument17 SeitenCellulose: by Kisar Bittaralin425Noch keine Bewertungen

- Plastic 1Dokument378 SeitenPlastic 1Sakthivel KumaresanNoch keine Bewertungen

- Easy-Care and Durable Press Finishes: Easy Care Is The Property Associated With An Improved Maintenance ofDokument7 SeitenEasy-Care and Durable Press Finishes: Easy Care Is The Property Associated With An Improved Maintenance ofCimaNoch keine Bewertungen

- Synthetic FibersDokument18 SeitenSynthetic Fibersaayush_vijayvargiaNoch keine Bewertungen

- InTech-Direct Dissolution of Cellulose Background Means and ApplicationsDokument36 SeitenInTech-Direct Dissolution of Cellulose Background Means and ApplicationsMichael PearsonNoch keine Bewertungen

- CelluloseDokument10 SeitenCellulosesonnynoerNoch keine Bewertungen

- Emissions and ControlsDokument7 SeitenEmissions and ControlsDrVishwanatha HNNoch keine Bewertungen

- Man-Made Fibres GLDokument5 SeitenMan-Made Fibres GLLinh NguyenNoch keine Bewertungen

- Science InveCornstarch (Amylum) As Additives in Concrete Masonary Unit (CMU) BIO-PLASTIC CMU StigatoryDokument27 SeitenScience InveCornstarch (Amylum) As Additives in Concrete Masonary Unit (CMU) BIO-PLASTIC CMU StigatoryAlmer Chris Calma TuayonNoch keine Bewertungen

- Acetate RayonDokument3 SeitenAcetate Rayonmaya_muthNoch keine Bewertungen

- Lyocell: Lyocell Is A Regenerated Cellulose Fiber Made From Dissolving PulpDokument3 SeitenLyocell: Lyocell Is A Regenerated Cellulose Fiber Made From Dissolving PulpMiraz HossainNoch keine Bewertungen

- Kongu Polytechnic College: PerunduraiDokument18 SeitenKongu Polytechnic College: PerunduraiSRUTHI SNoch keine Bewertungen

- Us 5362842Dokument7 SeitenUs 5362842giovanniNoch keine Bewertungen

- PlasticDokument27 SeitenPlasticKishore Kmr KumarNoch keine Bewertungen

- Modified Cellulose Fibers: Acetate and TriacetateDokument10 SeitenModified Cellulose Fibers: Acetate and TriacetateNidhie ✫ SinghNoch keine Bewertungen

- Zeolites Really Rock!: Answer: AnswerDokument5 SeitenZeolites Really Rock!: Answer: AnswerBagus TruesdaleNoch keine Bewertungen

- Polymer FoamsDokument17 SeitenPolymer FoamsSachin PatilNoch keine Bewertungen

- CelluloseDokument21 SeitenCelluloseabsuneelNoch keine Bewertungen

- Esterification and ProductsDokument7 SeitenEsterification and Productsdevraj raikarNoch keine Bewertungen

- Sandeep ChemistryDokument21 SeitenSandeep ChemistrySandeep Nandan MishraNoch keine Bewertungen

- Preliminary Chemistry Notes NSWDokument56 SeitenPreliminary Chemistry Notes NSWfocuc980% (1)

- Biopolymers Casein Its Preparation And Use A Practical HandbookVon EverandBiopolymers Casein Its Preparation And Use A Practical HandbookNoch keine Bewertungen

- Synthetic Rubber PDFDokument8 SeitenSynthetic Rubber PDFmjunaidNoch keine Bewertungen

- Good Manufacturing Practice For The Handling of AcetateDokument9 SeitenGood Manufacturing Practice For The Handling of Acetateherna_reyesNoch keine Bewertungen

- The Structure of CelluloseDokument6 SeitenThe Structure of CelluloseMeyLaa KrisnaNoch keine Bewertungen

- Regular Rayon (Or Viscose) Is The Most Widely Produced Form of Rayon. This Method of RayonDokument11 SeitenRegular Rayon (Or Viscose) Is The Most Widely Produced Form of Rayon. This Method of RayonManda Ramesh BabuNoch keine Bewertungen

- خط الصناعةDokument14 Seitenخط الصناعةمحمد السعيديNoch keine Bewertungen

- Polyester: History Forms Manufacturing Process Properties Future UsesDokument28 SeitenPolyester: History Forms Manufacturing Process Properties Future UsesAron Solanki100% (3)

- CelluloseDokument24 SeitenCelluloseAbrar nazirNoch keine Bewertungen

- The Art of Paper-Making: A Practical Handbook of the Manufacture of Paper from Rags, Esparto, Straw, and Other Fibrous Materials, Including the Manufacture of Pulp from Wood FibreVon EverandThe Art of Paper-Making: A Practical Handbook of the Manufacture of Paper from Rags, Esparto, Straw, and Other Fibrous Materials, Including the Manufacture of Pulp from Wood FibreNoch keine Bewertungen

- The Vegetable Tanning Process - A Collection of Historical Articles on Leather ProductionVon EverandThe Vegetable Tanning Process - A Collection of Historical Articles on Leather ProductionNoch keine Bewertungen

- National Level Quiz On Mathemaics 2022Dokument1 SeiteNational Level Quiz On Mathemaics 2022cmmalbaNoch keine Bewertungen

- What Is Electromagnetic Radiation - Live ScienceDokument11 SeitenWhat Is Electromagnetic Radiation - Live SciencecmmalbaNoch keine Bewertungen

- Index Journal 2Dokument5 SeitenIndex Journal 2cmmalbaNoch keine Bewertungen

- JEE MainDokument7 SeitenJEE MaincmmalbaNoch keine Bewertungen

- Molecular Weight PolymerDokument14 SeitenMolecular Weight PolymerJesus AmbrosioNoch keine Bewertungen

- Mono Sac Cha RideDokument6 SeitenMono Sac Cha RidecmmalbaNoch keine Bewertungen

- Classification of PolymersDokument8 SeitenClassification of Polymerscmmalba100% (1)

- Assesment of Solar Energy Conversion Technologies and Research OpportunitiesDokument45 SeitenAssesment of Solar Energy Conversion Technologies and Research OpportunitiescmmalbaNoch keine Bewertungen

- Ides and Actinides in Ionic LiquidsDokument23 SeitenIdes and Actinides in Ionic LiquidscmmalbaNoch keine Bewertungen

- Luminescent Organic-Inorganic Hybrid Materials BasedDokument5 SeitenLuminescent Organic-Inorganic Hybrid Materials BasedcmmalbaNoch keine Bewertungen

- Magnetic Nanoparticles For Drug Delivery REVIEWDokument11 SeitenMagnetic Nanoparticles For Drug Delivery REVIEWcmmalbaNoch keine Bewertungen

- Good THTDokument1 SeiteGood THTcmmalbaNoch keine Bewertungen

- Unit 1 Task 1.: True/FalseDokument58 SeitenUnit 1 Task 1.: True/FalseВика МакароваNoch keine Bewertungen

- OIC ChecklistDokument5 SeitenOIC ChecklistTash MarshallNoch keine Bewertungen

- 2022 Catalogue West AfricaDokument52 Seiten2022 Catalogue West AfricaCharles WatsonNoch keine Bewertungen

- BT Nghe TA11Dokument21 SeitenBT Nghe TA11Hùng PhạmNoch keine Bewertungen

- Perspectives in PharmacyDokument7 SeitenPerspectives in Pharmacygizelle mae pasiolNoch keine Bewertungen

- Tools and Equipment in Preparing DessertsDokument5 SeitenTools and Equipment in Preparing DessertsMARY JOY VILLARUEL100% (10)

- Everlasting FruitcakeDokument2 SeitenEverlasting FruitcakerzasaNoch keine Bewertungen

- Week 12 Tuesday Maths Worksheet.205007256Dokument2 SeitenWeek 12 Tuesday Maths Worksheet.205007256fspamNoch keine Bewertungen

- Saffron Foodies G9 IsbDokument2 SeitenSaffron Foodies G9 IsbSarfraz Khan50% (2)

- Maggie Noodles SurveyDokument2 SeitenMaggie Noodles SurveyAmit67% (9)

- Lnpresume 2019Dokument3 SeitenLnpresume 2019api-354195905Noch keine Bewertungen

- Test No 1 English 7 B. LANGUAGE FOCUS: (3,5 Marks)Dokument2 SeitenTest No 1 English 7 B. LANGUAGE FOCUS: (3,5 Marks)Huyền MátNoch keine Bewertungen

- Laundry Stain Remover ChartDokument1 SeiteLaundry Stain Remover ChartEva TuáNoch keine Bewertungen

- Case Study #2Dokument4 SeitenCase Study #2Sara AlbogamiNoch keine Bewertungen

- The HayloftDokument164 SeitenThe Hayloftcgarcia001Noch keine Bewertungen

- Underactive Thyroid 101Dokument44 SeitenUnderactive Thyroid 101Mihaela BrailescuNoch keine Bewertungen

- Definition, Composition, Standards and Processing of CreamDokument15 SeitenDefinition, Composition, Standards and Processing of CreamRonak Rawat100% (3)

- Message Nutrition Month CelebrationDokument7 SeitenMessage Nutrition Month CelebrationJuan Vicente Caliguiran CalimagNoch keine Bewertungen

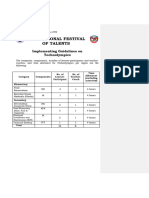

- Draft 2024 NFOT Guidelines Sining RevisedDokument83 SeitenDraft 2024 NFOT Guidelines Sining RevisedCHRISVIE MIRALLESNoch keine Bewertungen

- Progress Chart RevisedDokument19 SeitenProgress Chart RevisedChester Ladera CabanaNoch keine Bewertungen

- Ichha PradhanangaDokument120 SeitenIchha PradhanangaMonika DhitalNoch keine Bewertungen

- North Jersey Jewish Standard, April 25, 2014Dokument56 SeitenNorth Jersey Jewish Standard, April 25, 2014New Jersey Jewish StandardNoch keine Bewertungen

- Speakout Grammar Extra Upper Intermediate Unit 8Dokument2 SeitenSpeakout Grammar Extra Upper Intermediate Unit 8xacobeoNoch keine Bewertungen

- Interchange4thEd Level1 Vocabulary Worksheets AnswerKeyDokument2 SeitenInterchange4thEd Level1 Vocabulary Worksheets AnswerKeyFlux MillsNoch keine Bewertungen

- The Annihilation of Superfluous EatersDokument10 SeitenThe Annihilation of Superfluous EatersPatrickRosenbergNoch keine Bewertungen

- Equipment VA Consumption ReferenceDokument5 SeitenEquipment VA Consumption ReferenceFerdinand Ramos EspirituNoch keine Bewertungen

- Complete The Questions Below: Exercise 2Dokument1 SeiteComplete The Questions Below: Exercise 2Jynn YeowNoch keine Bewertungen

- Lab 5 Cell Membrane Structure and Function FinalDokument12 SeitenLab 5 Cell Membrane Structure and Function Finalannekemp100% (2)

- Qsi 220 245Dokument103 SeitenQsi 220 245freddNoch keine Bewertungen

- ColivaDokument6 SeitenColivaalinaluca30Noch keine Bewertungen