Beruflich Dokumente

Kultur Dokumente

Sulfate Attack and Reinforcement Corrosion in Concrete With Recycled Concrete Aggregates and Supplementary Cementing Materials

Hochgeladen von

little bunny foo fooCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sulfate Attack and Reinforcement Corrosion in Concrete With Recycled Concrete Aggregates and Supplementary Cementing Materials

Hochgeladen von

little bunny foo fooCopyright:

Verfügbare Formate

Int. J. Electrochem. Sci.

, 6 (2011) 613 - 621

International Journal of

ELECTROCHEMICAL

SCIENCE

www.electrochemsci.org

Sulfate Attack and Reinforcement Corrosion in Concrete with

Recycled Concrete Aggregates and Supplementary Cementing

Materials

Corral-Higuera R.1,2,*, Arredondo-Rea S.P.1,2, Neri-Flores M.A.2, Gmez-Sobern J.M.3, Almeraya

Caldern F.2, Castorena-Gonzlez J.H.1, Almaral-Snchez J.L.1

1

Universidad Autnoma de Sinaloa, Facultad de Ingeniera Mochis, Fuente de Poseidn y ngel

Flores s/n, Ciudad Universitaria, C.P. 81223, Los Mochis, Sinaloa, Mxico.

2

Centro de Investigacin en Materiales Avanzados, S.C., Ave. Miguel de Cervantes 120, Complejo

Industrial Chihuahua, C.P. 31109, Chihuahua, Chihuahua, Mxico.

3

Universidad Politcnica de Catalua, Departamento de Construcciones Arquitectnicas II, Avenida

Gregorio Maran 44-50, Z.C. 08028, Barcelona, Espaa

*

E-mail: rmn1779@gmail.com

Received: 20 January 2011 / Accepted: 29 January 2011 / Published: 1 March 2011

As strategies to contribute to the concrete industry sustainability, reinforced concrete was fabricated

using recycled concrete coarse aggregate and replacing partially portland cement with supplementary

cementing materials as fly ash and silica fume. On test specimens, partially immersed in 3.5% Na2SO4

aqueous solution, the effect of the recycled and supplementary materials against sulfate attack and

reinforcement corrosion was evaluated. For such aim, weight loss of concrete and corrosion potentials,

corrosion current density of reinforcement were determined by means of electrochemical techniques as

open circuit potential and linear polarization resistance, respectively.

Keywords: Recycled aggregate concrete, Sulfate attack, Supplementary cementing materials,

Corrosion

1. INTRODUCTION

Concrete exposed to sulfate solutions can be attacked and suffer deterioration by expansion.

The deterioration of reinforced concrete by sulfate attack causes the reinforcing steel to be exposed to

the action of aggressive agents starting the corrosion of the reinforcement [1]. It is known that the

concrete resistance to sulfates can be significantly improved producing a dense waterproof concrete.

However, with the urgent need of using recycled materials to contribute in sustainability, from the year

Int. J. Electrochem. Sci., Vol. 6, 2011

614

2000 the number of studies of Recycled Aggregate Concrete (RAC) has significantly increased [2-11],

with the purpose of using it in the construction of structures of plain concrete and reinforced concrete.

By the nature of the recycled concrete aggregates, RAC is more permeable and has a lower density

than conventional concrete and therefore, sulfates attack on RAC could be more aggressive than on

conventional concrete. It is necessary to know the characteristics of RAC exposed to sulfates, so that

necessary precautions can be taken to minimize the deterioration to insignificant levels. Unlike

conventional concrete, there is little research [12-16] about the performance of RAC with

Supplementary Cementing Materials (SCM) but no of these investigations approaches the subject of

external sulfate attack. This phenomena is well known and is described in other works [17,18].

The objective of this work was to evaluate the behavior of RAC with SCM exposed to sulfate

solution. The deterioration of concrete (weight loss) and corrosion rate of reinforcement by means of

electrochemical techniques were evaluated.

2. EXPERIMENTAL PART

It was produced three sets of specimens with water-cementing material ratio of 0.48: one series

made with 100% recycled coarse concrete aggregate (RCA) and 100 % Compound Portland Cement

(CPC) [19], series made with 100% RCA and 30% FA as a partial replacement of the CPC, and finally,

series made with 100% RCA and 10% SF as a partial replacement of the CPC. These specimens were

cured for 28 days in a chamber with temperature of 23 2 C and 98 1% of RH. Characteristics and

proportions of mixtures are presented in Table 1.

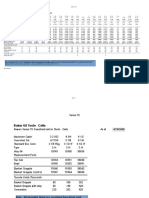

Table 1. Characteristics and proportion of the test mixtures (by 1m3 of concrete).

Materials

(Kg)

Water

Mixtures identification

RA 100% CPC

RA 30% FA

RA 10% SF

213.31

213.31

213.31

RCA

870.58

870.58

870.58

Sand

915.35

915.35

915.35

Cement

444.44

311.11

400.00

SCM

0.000

133.33

44.44

2.1. Materials

RCA comes from the crushing of concrete specimens made with natural aggregates, CPC with

a water-cement ratio of 0.50 and curing for a 28-day period with controlled temperature and relative

humidity (RH) of 23 2 C and 98 1%. Natural aggregates come from quarry crushed rock (coarse)

and river sand (fine). Table 2 shows some of the physical properties of these aggregates.

Int. J. Electrochem. Sci., Vol. 6, 2011

615

Table 2. Physical properties of the aggregates used in concrete mixtures

Type of

aggregate

Recycled

coarse

Natural

coarse

Natural

fine

Relative

density

(g/cm3)

2.19

Absorption Humidity

(%)

(%)

6.55

2.14

Fineness

module

(%)

-

Maximum

size

(mm)

19

2.50

0.44

0.28

19

2.43

4.08

6.66

2.73

4.76

As SCM, Mexican Class F FA according to ASTM C618 [20] and SF North-American with the

requirements of ASTM C1240 [21] were used. Table 3 shows the physical and chemical properties of

these materials.

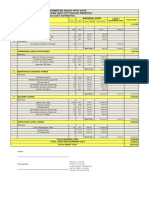

Table 3. Physico-chemical properties of cementing materials.

Material

CPC

FA

SF

CPC

FA

SF

Chemical composition (% of weight)

Al2O3

Fe2O3

CaO

SO3

4.40

2.97

63.50

3.08

16.72

3.52

7.35

0.13

0.08

2.37

0.26

0.11

Physical properties

Density (g/cm3)

Specific surface, BET (m2/kg)

3.15

1400

2.35

1200

2.27

19600

SiO2

19.94

58.84

95.22

K2O

0.42

0.79

0.56

Na2O

0.12

0.94

0.30

MgO

1.76

0.24

Average size (m)

15-25

5-15

0.1-0.2

2.2 Methods

Concrete cylinders, 15 cm in diameter and 30 cm in height, with two centrally-embedded

reinforcing bars, were used to study the effect of sulfate environment on the weight loss of concrete

and rebar corrosion of reinforcing steel. The test specimens were exposed in a 3.5% of Na2SO4

aqueous solution and the reduction/increase in weight of the reinforced concrete specimens was

evaluated periodically, whereby the specimens were retrieved, air-dried for one day in a laboratory

environment (21 2C) and weighed. The weight loss (WL) was determined using the following

relationship:

W Wt

WL(%) i

x100

Wi

Int. J. Electrochem. Sci., Vol. 6, 2011

616

Where Wi = average initial weight of triplicate specimens (g); and Wt = average weight of

triplicate specimens after a prescribed exposure period (g).

Reinforcement corrosion of the embedded steel was monitored by measuring the corrosion

potentials and polarization resistance at regular intervals. The corrosion potentials (Ecorr) were

measured using a high impedance voltmeter and recording the potentials with respect to a

copper/copper sulfate (Cu/CuSO4) reference electrode. The linear polarization resistance (LPR)

technique was used to measure the polarization resistance (Rp) in a Potentiostat/Galvanostat of ACM

Instruments. Details of the electrochemical techniques can be found in another work [22]. The test

parameters were a potential scan of 20 mV to a scan speed of 10 mV/min. The basics principles of

electrochemical corrosion of reinforced concrete is well known [23,24] and the experimental testing is

shown in Figure 1.

Figure 1. Experimental scheme for testing LPR.

From the curves potential against current density the Rp of the systems in study was obtained,

same that was used to calculate the corrosion current density (icorr) of the systems through Equation 1

Int. J. Electrochem. Sci., Vol. 6, 2011

617

[25], where B is a Tafel constant with recommended value [26-29] of 0.052 V for the passive corrosion

of steel in concrete.

icorr

B

Rp

(1)

3. RESULTS AND DISCUSSION

3.1. Concrete weight loss

The data on the weight loss of reinforced concrete specimens exposed to sulfate solution are

schematically presented as a function of the exposure time in Figure 2. These data indicate that the

weight loss of concretes initially decreased due to an increase in the weight of specimens upon

exposure to the test solution compared with their initial weights. Thereafter, the weight loss increased

considerably after four months in the RA 100% CPC concrete. For the specimens with SCM the

increase of weight loss is not considerable and it appears after four months. This behavior obeys to that

at the beginning the capillary pore system is filled by little expansive reaction products compacting the

cementing matrix and increasing the weight. Immediately, the expansion of these products is increased

to a great extent generating fractures in the cementing matrix, loosening of material and therefore the

weight of specimen decreases.

RA 100% CPC

RA 30% FA

RA 10% SF

Weight loss (%)

3

2

1

0

-1

0

Exposure time (month)

Figure 2. Weight loss of concrete in sulfate environment.

The maximum weight loss was 2.8% after six months of exposure in the RA 100% CPC

concrete specimens followed by a weight loss of 0.37% in the RA 30% FA concrete, and the minimum

weight loss (0.14%) was in RA 10% SF concrete. From these results is evident the contribution of

SCM in pore refinement of cementing matrix, which prevents the easy penetration of sulfate ions

Int. J. Electrochem. Sci., Vol. 6, 2011

618

towards and within concrete. Another probable cause of the effectiveness of the SCM in decrease the

deterioration by sulfate attack is the calcium hydroxide [Ca(OH)2 or CH] consumption during the

pozzolanic reaction, which means that the amount of formed gypsum can be smaller in the mixtures

with SCM with respect to mixtures with 100% CPC.

3.2. Corrosion potentials

In Figure 3 the results of corrosion potentials of evaluated test specimens are shown. The

horizontal broken lines show the limits corresponding to the corrosion probability criterion suggested

in the norm ASTM C876 [30].

-100

-150

RA 100% CPC

RA 30% FA

RA 10% SF

10% Probability of corrosion

-200

-250

Uncertainty zone

ECORR (mV)

-300

-350

-400

90% Probability of corrosion

-450

-500

-550

-600

-650

-700

-750

Exposure time (month)

Figure 3. Variation of Ecorr of the reinforcement steel as a function of the exposure time.

In Figure 3 it can be observed that in the six months of exposure the corrosion potentials, of all

the reinforced concrete systems, show fluctuation ranging from -550 to -400 mV / Cu-CuSO4 with a

slight decrease during the months, towards more noble values; according ASTM C 876 these Ecorr

values indicate that exists a 90% probability of active corrosion during all the exposure period;

however, the criterion is based on partially saturated specimens and in this study the specimens were

totally saturated, indicating that the ASTM C 876 criterion is not applicable to evaluate the corrosion

of reinforcement in these concrete specimens. Therefore, it can be concluded that all steel bars were in

a passive state during the six months of immersion in the sulfate solution.

However, it can be observed that the SCM that could have a greater efficiency against

corrosion is SF since the system with this material presented the most noble corrosion potentials during

the exposure period. The RA 30% FA system presented corrosion potentials similar to the RA 100%

CPC system, which could indicate that FA does not contribute significantly to inhibit the corrosion of

the reinforcement. It is necessary to clarify that the corrosion potential technique provides qualitative

information on reinforcement corrosion. Therefore, quantitative information on reinforcement

Int. J. Electrochem. Sci., Vol. 6, 2011

619

corrosion was developed by determining the polarization resistance using the linear polarization

resistance technique.

3.3. Polarization resistance

From the curves potential against current density Rp was obtained for all the systems in study

and icorr was calculated representing the results in Figure 4; the horizontal broken line point out the

threshold of active to passive corrosion [31].

RA 100% CPC

RA 30% FA

RA 10% SF

Threshold [31]

Active state

2

icorr (A/cm )

0.1

Passive state

0.01

1E-3

1

Exposure time (month)

Figure 4.Variation of icorr of the reinforcement steel as a function of the exposure time

In Figure 4 it can be observed that the system steel-concrete that presents a highest corrosion

resistance induced by sulfates is RA 10% SF, because its corrosive activity was the lowest in the

exposure time and decreased significantly until it reached a low level of corrosion (0.008 A/cm2) at

the end of the period. The RA 30% FA system showed levels of corrosion between 0.06 and 0.02

A/cm2, slightly superiors to the system RA 100% CPC, which means that FA does not contribute

significantly to inhibit the corrosion of the reinforcement in the initial six months.

The negligible effect of FA on corrosion current density at initial months is mainly attributed to

the delay of the kinetics of texturing of the cementing paste due to the slowness of the pozzolanic

reaction of the FA with CH by the curing conditions which the test specimens were exposed. As to the

RA 10% SF system, its significantly effect on corrosion is due to the SF accelerating effect during the

hydration process of the cementing paste, as well as the possible dense structure of pores formed.

Previous researches [32-35] reported that FA hydration produces a compact texture of calcium-silicatehydrated glass (CSH) result of the reaction of the silica of the pozzolan with the hydrated phases

contained in the mixture interstitial solution. This pozzolanic reaction delays the cement hydration

speed because of the difficulty to dissolve the crystalline phase, which could be achieved at early ages

Int. J. Electrochem. Sci., Vol. 6, 2011

620

increasing considerably the cure temperature. Other researchers [36-39] define SF as a high reactivity

pozzolan that has an accelerating effect in the hydration of the cement paste, besides that for the

fineness of its particles, creates very dense pore structures. Table 3 shows that the SF is approximately

100 times finer than cement and FA, providing much SiO2. Because hydration and pozzolanic

reactions are surface phenomena, it is deduced that the microstructure of concrete with SF becomes

denser than the rest of the systems due to the production of more CSH which replaces CH and

generates pore refinement, and therefore, it reports a decrease in both, sulfate ion penetrability and

corrosion current density.

4. CONCLUSIONS

With the results obtained in the concrete test specimens made with 100% recycled coarse

aggregate, the following can be concluded: fly ash and silica fume contribute in increase the resistance

of recycled aggregate concrete to sulfate attack. The addition of 10% of SF as a partial replacement of

cement, reduces around 20 times the weight loss, whereas the addition of 30% of FA as a partial

replacement of cement, reduces around 8 times the weight loss by sulfate attack; with respect to the

concrete without supplementary cementing materials. Silica fume contribute significantly in increase

the steel corrosion resistance, due to cementing matrix densification and pore refinement. Therefore,

the durability of the reinforced recycled aggregate concrete structures exposed to underground water or

filtrations with high sulfate content can increase significantly using supplementary cementing

materials, as a partial replacement of cement, contributing to the concrete industry sustainability.

ACKNOWLEDGEMENTS

The authors thank to CONACYT by its support to accomplish their PhD studies, with the scholarship

number 185273. Also to the Universidad Autnoma de Sinaloa and DGIP by the scholarship offered in

its young PhD-professionals program and to the Advanced Materials Research Center, SC by the

support in the samples characterization and analysis of results.

References

1. Red DURAR, Manual de Inspeccin, Evaluacin y Diagnostico de Corrosin en estructuras de

Hormign Armado, CYTED, Espaa, (1998).

2. A.Ajdukiewicz and A. Kliszczewicz, Cement and Concrete Composites, 24 (2002) 269.

3. H. Chen, T. Yen and K. Chen, Cement and Concrete Research, 33 (2003) 125.

4. A.Katz, Cement and Concrete Research, 33 (2003) 703.

5. C.S. Poon, Z.H. Shui, L. Lam, H. Fok and S.C. Kou, Cement and Concrete Research, 34 (2004)

31.

6. I. Topu and S. Sengel, Cement and Concrete Research, 34 (2004) 1307.

7. T. Tu, Y. Chen and C. Hwang, Cement and Concrete Research, 36 (2006) 943.

8. I.Martnez and C. Mendoza, Ingeniera Investigacin y Tecnologa, 7 (2006) 151.

9. K. Rahal, Building and Environment, 42 (2007) 407.

Int. J. Electrochem. Sci., Vol. 6, 2011

621

10. M. Casuccio, M.C. Torrijos, G. Giaccio and R. Zerbino, Construction and Buildings Materials, 22

(2008) 1500.

11. A.K. Padmini, K. Ramamurthy and M.S. Mathews, Construction and Buildings Materials, 23

(2009) 829.

12. K.Y. Ann, H.Y. Moon, Y.B. Kim and J. Ryou, Waste Management, 28 (2008) 993.

13. B. Gonzlez and F. Martnez, Building and Environment, 43 (2008) 429.

14. S.C. Kou, C.S. Poon and D. Chan, Materials and Structures, 41 (2008) 1191.

15. M.L. Berndt, Construction and Buildings Materials, 23 (2009) 2606.

16. V. Corinaldesi and G. Moriconi, Construction and Buildings Materials, 23 (2009) 2869.

17. O.S.B. Al-Amoudi, Building and Environment, 33 (1998) 53.

18. E.F. Irassar, Cement and Concrete Research, 39 (2009) 241.

19. ONNCCE, NMX-C-414-04, Especificaciones y mtodos de prueba del cemento hidrulico,

Instituto Mexicano del Cemento y el Concreto Mxico, (2004).

20. ASTM International, ASTM C618-99 (1999).

21. ASTM International, ASTM C1240-05 (2005).

22. H.W. Song and V. Saraswathy, International Journal of Electrochemical Science, 2 (2007) 1.

23. L.T.N. Dao, V.T.N. Dao, S.H. Kim and K.Y. Ann, International Journal of Electrochemical

Science, 5 (2010) 302.

24. A.Bentur, S. Diamond and N.S. Berke, Steel corrosion in concrete, EFN Spon, (1998) 7.

25. M. Stern and A. Geary, Journal of the electrochemical society, 104 (1957) 56.

26. R.K. Dhir, M.R. Jones and M.J. McCarthy, Cement and Concrete Research, 23 (1993) 1443.

27. J.A. Gonzlez, E. Ramrez, A. Bautista and S. Feli, Cement and Concrete Research, 26, (1996)

501.

28. K.R. Gowers and S.G. Millard, Corrosion Science, 35 (1993) 1593.

29. P.S. Mangat and B.T. Molloy, Materials and Structures, 25 (1992) 404.

30. ASTM International, ASTM C876-08 (2008).

31. C. Andrade and C. Alonso, Construction and Building Materials, 10 (1996) 15.

32. W. Roszczynialski, Proc. 9th Int. Cong. Chem. Cem., 4, 698 (1992).

33. A.Xu, Structure of Hardened Cement-Fly Ash Systems and their Related Properties, Division of

Building Materials, Chalmers University of Technology, Goteborg (1992).

34. A.L.A. Fraay, J.M. Bijen, Y.M. Haan, Cement and Concrete Research, 19 (1989) 235.

35. J.M. Bijen, H. Pietersen, Advances in Cement and Concrete, (1994).

36. J.A. Larbi, J.M. Bijen, Cement and Concrete Research, 20 (1990) 461.

37. R.F. Feldman, Y.H. Cheng, Cement and Concrete Research, 15 (1985) 943.

38. M.D. Cohen, M. Klitsika, Indian Concrete Journal, 11 (1986) 296.

39. M.D. Cohen, Indian Concrete Journal, 9 (1990) 429.

2011 by ESG (www.electrochemsci.org)

Das könnte Ihnen auch gefallen

- Secretary'S Certificate: Annex DDokument1 SeiteSecretary'S Certificate: Annex Dlittle bunny foo foo0% (1)

- YebahuDokument1 SeiteYebahulittle bunny foo fooNoch keine Bewertungen

- 654654Dokument1 Seite654654little bunny foo fooNoch keine Bewertungen

- WorkpieceDokument1 SeiteWorkpiecelittle bunny foo fooNoch keine Bewertungen

- Bio Kinesis SsssDokument1 SeiteBio Kinesis Sssslittle bunny foo fooNoch keine Bewertungen

- YebahuDokument1 SeiteYebahulittle bunny foo fooNoch keine Bewertungen

- WorkpieceDokument1 SeiteWorkpiecelittle bunny foo fooNoch keine Bewertungen

- WorkpieceDokument1 SeiteWorkpiecelittle bunny foo fooNoch keine Bewertungen

- Welcom To WorldDokument1 SeiteWelcom To Worldlittle bunny foo fooNoch keine Bewertungen

- Hellu UfosDokument1 SeiteHellu Ufoslittle bunny foo fooNoch keine Bewertungen

- Starbucks CaseDokument16 SeitenStarbucks Caselittle bunny foo fooNoch keine Bewertungen

- Secretu PloadDokument1 SeiteSecretu Ploadlittle bunny foo fooNoch keine Bewertungen

- Critical ReviewDokument4 SeitenCritical ReviewChendie ChantiqueNoch keine Bewertungen

- Welcom To WorldDokument1 SeiteWelcom To Worldlittle bunny foo fooNoch keine Bewertungen

- Mutants and Masterminds TablesDokument3 SeitenMutants and Masterminds TablesRaiu1994100% (4)

- Very Important 5657Dokument1 SeiteVery Important 5657little bunny foo fooNoch keine Bewertungen

- Yamaha DX7 ManualDokument34 SeitenYamaha DX7 Manualx7Noch keine Bewertungen

- FIFA Statutes: August 2009 EditionDokument88 SeitenFIFA Statutes: August 2009 EditionrugczarNoch keine Bewertungen

- Management) Handbook For Small BusinessDokument48 SeitenManagement) Handbook For Small BusinesskayusiNoch keine Bewertungen

- Mutants & Masterminds - Third Edition - Power Profile - Air PowersDokument6 SeitenMutants & Masterminds - Third Edition - Power Profile - Air PowersVera MillerNoch keine Bewertungen

- Bad StructuresDokument1 SeiteBad Structureslittle bunny foo fooNoch keine Bewertungen

- From The SAGE Social Science Collections. All Rights ReservedDokument39 SeitenFrom The SAGE Social Science Collections. All Rights Reservedlittle bunny foo fooNoch keine Bewertungen

- StudyDokument11 SeitenStudylittle bunny foo fooNoch keine Bewertungen

- Intro To Software Design and ArchiteturesDokument11 SeitenIntro To Software Design and Architetureslittle bunny foo fooNoch keine Bewertungen

- Problem Set 2 E2012 1Dokument3 SeitenProblem Set 2 E2012 1little bunny foo fooNoch keine Bewertungen

- StudyDokument11 SeitenStudylittle bunny foo fooNoch keine Bewertungen

- OutmanDokument1 SeiteOutmanJan KorenNoch keine Bewertungen

- The Night WatchDokument4 SeitenThe Night WatcharslongavitaNoch keine Bewertungen

- TestDokument1 SeiteTestlittle bunny foo fooNoch keine Bewertungen

- Total Upload by ArjunDokument1 SeiteTotal Upload by Arjunlittle bunny foo fooNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- All OvershotsDokument25 SeitenAll OvershotsnjileoNoch keine Bewertungen

- Air ConditioningDokument20 SeitenAir ConditioningJohanne Franz Calacday100% (1)

- A Mini-Project Report Course Code: 17AE4DCAP-I: "Model of Air-Compressor Using A Syringe"Dokument9 SeitenA Mini-Project Report Course Code: 17AE4DCAP-I: "Model of Air-Compressor Using A Syringe"Shreya Giri0% (1)

- Rigging JSA SafetyDokument5 SeitenRigging JSA SafetyaQiLGunawanNoch keine Bewertungen

- Oilgear Designers HandbookDokument250 SeitenOilgear Designers HandbookMarco Hernandez100% (1)

- Plant Design of Acetone ProductionDokument20 SeitenPlant Design of Acetone ProductionMary Grace VelitarioNoch keine Bewertungen

- 9 EÈ Ú ºÃ ÄÑ Ï°×ÊÁÏDokument80 Seiten9 EÈ Ú ºÃ ÄÑ Ï°×ÊÁÏnabil160874100% (2)

- Full Download Automation Production Systems and Computer Integrated Manufacturing 4th Edition Groover Solutions ManualDokument36 SeitenFull Download Automation Production Systems and Computer Integrated Manufacturing 4th Edition Groover Solutions Manualardellazusman100% (37)

- Strength of Concrete Containing Basalt Fibre: Parvez Imraan Ansari, Rajiv ChandakDokument5 SeitenStrength of Concrete Containing Basalt Fibre: Parvez Imraan Ansari, Rajiv ChandakPathipati NarasimharaoNoch keine Bewertungen

- Manual RM648-848 Enatelv1.2Dokument13 SeitenManual RM648-848 Enatelv1.2TRỊNH VĂN THIỆN100% (1)

- EstimateDokument1 SeiteEstimateAlemar Soriano MalintadNoch keine Bewertungen

- Distribution ReservoirsDokument14 SeitenDistribution ReservoirsBinyam KebedeNoch keine Bewertungen

- B-Sa4T Series: Maintenance ManualDokument45 SeitenB-Sa4T Series: Maintenance ManualTonyandAnthonyNoch keine Bewertungen

- Aws - The Practical Welding Engineer PDFDokument154 SeitenAws - The Practical Welding Engineer PDFSEGO4EVER100% (5)

- Dstan 03-25Dokument26 SeitenDstan 03-25jmills7560Noch keine Bewertungen

- Polymer Engineering FundamentalsDokument20 SeitenPolymer Engineering FundamentalsNoor FatimaNoch keine Bewertungen

- Ecological and Energetic Assessment of Re-Refining Used Oils To Base OilsDokument104 SeitenEcological and Energetic Assessment of Re-Refining Used Oils To Base OilsFernando SImonelliNoch keine Bewertungen

- Effect of Indium Doping On Physical Properties of Nanocrystallized SNS Zinc Blend Thin Films Grown by Chemical Bath Deposition.Dokument1 SeiteEffect of Indium Doping On Physical Properties of Nanocrystallized SNS Zinc Blend Thin Films Grown by Chemical Bath Deposition.atswallaNoch keine Bewertungen

- McQuay AWS User Manual EngDokument37 SeitenMcQuay AWS User Manual EngHermelindo Samuel Rabanales Cifuentes50% (2)

- Concrete Design Exam-15Dec11Dokument6 SeitenConcrete Design Exam-15Dec11zci69Noch keine Bewertungen

- Effects of Processing Condition On The Filtration Performances of Nonwovens For Bag Filter MediaDokument6 SeitenEffects of Processing Condition On The Filtration Performances of Nonwovens For Bag Filter Mediaapi-3733260Noch keine Bewertungen

- Ign-4-32-18c - HDPE Pipes - SDR PNDokument17 SeitenIgn-4-32-18c - HDPE Pipes - SDR PNgeofoun100% (2)

- Wind GeneratorDokument119 SeitenWind Generatorivan.vazdar5482Noch keine Bewertungen

- 2000 Evtm RangerDokument121 Seiten2000 Evtm RangertheclockworkNoch keine Bewertungen

- kVA kVA kVA: Air-Cooled Gas Engine Generator SetsDokument4 SeitenkVA kVA kVA: Air-Cooled Gas Engine Generator Setseng_hopaNoch keine Bewertungen

- Technicalinfo 6066670Dokument2 SeitenTechnicalinfo 6066670petriNoch keine Bewertungen

- CanberraDokument4 SeitenCanberraBooksNoch keine Bewertungen

- Farrat Plate BrochureDokument12 SeitenFarrat Plate BrochureShaneLinehanNoch keine Bewertungen

- Accounting EssayDokument5 SeitenAccounting Essaylorie anne valleNoch keine Bewertungen

- MRT 460 Multi-Range Transducer Data SheetDokument6 SeitenMRT 460 Multi-Range Transducer Data SheetBlAdE 12Noch keine Bewertungen