Beruflich Dokumente

Kultur Dokumente

In Service Weld TTI TR11

Hochgeladen von

Freddy Rondonil SCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

In Service Weld TTI TR11

Hochgeladen von

Freddy Rondonil SCopyright:

Verfügbare Formate

IN-SERVICE WELDING

PRACTICES AND PROCEDURES

structured for all pipeline personnel and provides an

understanding of the theory and practices regarding inservice welding but most importantly how to solve non

typical in-service welding problems under various

conditions.

Documentation & Course Materials:

All delegates will receive a detailed set of lecture notes,

providing an invaluable reference document. In addition

a CD with the lecture notes and an evaluation version of

the PRCI Hot Tap Cooling Rate model software will be

included.

Why: Performing welding operations onto operating

pipelines for maintenance purposes or to attach branch

connections is very dangerous. These operations

require proper procedures, welder qualifications, and

must address safety issues successfully. Published

documentation and recommended practices and

procedures regarding in-service welding, commonly

referred to as hot-tapping or hot-tap welding, are

continually being updated and pipeline engineers are

constantly faced with problem solving in this arena. This

course describes the concerns, design, implementation,

inspection, and testing of in-service welds.

In addition to the lecture portion of the training course,

this course is designed to enable participants to

successfully run Hot Tap weld cooling rate prediction

software and interpret the results. The software is

designed to support the development and/or selection of

qualified in-service welding procedures intended for use

on operating pipelines. The PRCI Hot Tap software is

applicable to pipelines that contain a variety of different

pressurized gases or liquids. The first portion of the

course provides participants with a clear understanding

of the factors that contribute to burnthrough or cracking

and serves as the foundation for understanding how Hot

Tap can be used as a significant component of a

company's welding technology program. The second

part of the course teaches participants the details of how

to use and interpret the results of the program. In

addition, participants will learn the highlights of various

technical resources that supplement the Hot Tap

program to provide a more comprehensive body of

technical information pertaining to welding onto

operating pipelines.

What: This course will address in-service welding onto

gas and liquid pipelines under both typical and nontypical conditions, with particular emphasis on

regulation/compliance review, recommended practices

and case studies. The course will also cover current

research done by Edison Welding Institute (EWI), GTI

(formerly GRI), the Pipeline Research Council

International, Inc. (PRCI) and other organizations. The

In-Service Welding Practices & Procedures Course is

Who Should Attend:

Welders

Engineers, technicians, and service

professionals involved with construction,

maintenance, inspection, and repair of

liquids, gas, and products pipelines.

Project managers with oversight for third party

engineering or maintenance.

Project and facility managers concerned with

system integrity and maintenance.

Where:

Technical Toolboxes

3801 Kirby Dr. #501

Houston TX 77098

713-630-0505

When:

TBA

One and a half day training course

Price:

$1,695.00 per person

Instructor:

Matt Boring, P.E.

Senior Welding Engineer

Kiefner and Associates/ApplusRTD

Mr. Boring is a senior welding engineer at Kiefner and

Associates responsible for all welding related research

projects which include construction and in-service

welding. Prior to Kiefner and Associates he worked as a

welding engineer at EWI for 15 years, responsible for oil

and gas research projects. Matt Boring is the co-chair of

the API 1104 Subcommittee on In-service Welding as

well as the Chair of the Welded Repair Subgroup of

ASME Post-Construction Subcommittee on Repair and

Testing (PCC-2).

713-630-0505 www.ttoolboxes.com

IN-SERVICE WELDING

PRACTICES AND PROCEDURES

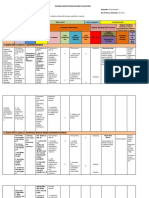

In-Service Welding Practices and Procedures

Training Course Agenda/Outline

Day 1

1. Introduction

2. Burnthrough

2.1. Factors influencing burnthrough

2.2. Determining burnthrough risk

2.3. Recent research

Break

3. Hydrogen cracking

3.1. Failures attributed to hydrogen cracking

3.2. Factors influencing hydrogen cracking

3.3. Hydrogen cracking mitigation

Lunch ~11:30

4. In-service welding applications

4.1 Full-encirclement repair sleeves

4.2 Hot-tapped branch connections

4.3 Weld metal deposition

Break

5.Developing in-service welding procedures

5.1 Procedure options

5.2 Selecting appropriate procedures

6. What the applicable codes and standards say

about in-service welding

6.1. API 1104 Appendix B

6.2 ASME codes

6.3 CSA Z662

End of Day 1

Day 2

7. Things to do before you in-service weld

7.1. Pre-weld inspection

7.2 Heat input monitoring

7.3 Field Guidance

7.4 Other in-service welding concerns

8. Things to do after you perform an in-service weld

8.1. Non-destructive testing methods

8.2. Confirmation coupons

Break

9. Lessons to be learned from past in-service

welding incidents and general rules of thumb

9.1. Reported incidents

9.2. Previously unreported incidents

9.3. Five general rules of thumb

10. The Role of Hot Tap in developing and selecting

welding procedures for use on pressurized pipes

10.1. History of thermal analysis models

10.2. Interpolating between qualified

procedures

10.3. Doing what-if scenarios and sensitivity

analyses

10.4. Operating the Hot Tap model

10.5. Interpreting the Hot Tap software

results

10.6. Case studies

10.7. Sources of error and conservatism

10.8. Hot Tap software version 5.0

introduction

The schedule is subject to change.

Please complete the attached form

and fax to TTI at 713-630-0560

Course Cost: $1695.00 per student

Course Date:

Name

Company

Address

Address

City, State, ZIP

Country

Phone/Mobile

Fax

E-mail

Payment by Credit Card

Circle One:

VISA

MasterCard

AMEX

CC Number

Expiration Date

Signature*

* By signing above I commit to paying the course fee when invoiced

Terms and Conditions: Terms and conditions: One registration is

required per person. Upon receipt of your above registration, an

invoice will be generated for payment. Payment is due 30 days

from receipt of invoice. Full price of the course fee will be

refunded provided written cancellation is received 3 weeks prior

to course date. A cancellation after the deadline will receive full

credit towards a future date for the same course.

Technical Toolboxes

3801 Kirby Drive, Suite 520

Houston, TX 77098

Tel: 713-630-0505

Fax: 713-630-0560

Email: training@ttoolboxes.com

713-630-0505 www.ttoolboxes.com

Louisville KY

Das könnte Ihnen auch gefallen

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985Von EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985Noch keine Bewertungen

- Which Process?: A Guide to the Selection of Welding and Related ProcessesVon EverandWhich Process?: A Guide to the Selection of Welding and Related ProcessesNoch keine Bewertungen

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceVon EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNoch keine Bewertungen

- Welding Procedures and Inspection Methodology For In-Service WeldingDokument14 SeitenWelding Procedures and Inspection Methodology For In-Service WeldingEl_memitoNoch keine Bewertungen

- Arc Welding 101 Bead WidthDokument3 SeitenArc Welding 101 Bead WidthMalcolm Diamond100% (1)

- 10 Residual StressDokument21 Seiten10 Residual StressAlaaNoch keine Bewertungen

- Want To Be A Certified Welding InspectorDokument19 SeitenWant To Be A Certified Welding InspectorKentDemeterioNoch keine Bewertungen

- Visual Testing of Welds.Dokument9 SeitenVisual Testing of Welds.maheshNoch keine Bewertungen

- Gas Metal Arc Welding - PulseDokument68 SeitenGas Metal Arc Welding - Pulsegreatsteel100% (1)

- Welding Process and ConsumableDokument64 SeitenWelding Process and Consumablenizar_ikmps100% (1)

- WeldingDokument54 SeitenWeldingAbdullah changNoch keine Bewertungen

- Kobe Welding Handbook 2004Dokument183 SeitenKobe Welding Handbook 2004Nasywafi AlyaNoch keine Bewertungen

- ARC WeldingDokument41 SeitenARC WeldingAravind Raj100% (1)

- T, K & Y Shape Joint Steel StructureDokument23 SeitenT, K & Y Shape Joint Steel StructurePrabu VenkatNoch keine Bewertungen

- Finite Element Analysis and Opmization of Weld Distortion ChassisDokument6 SeitenFinite Element Analysis and Opmization of Weld Distortion ChassisJuan Sebastian CameroNoch keine Bewertungen

- WeldDecayTesting TechSheet Sfs PDFDokument0 SeitenWeldDecayTesting TechSheet Sfs PDFNooruddin SheikNoch keine Bewertungen

- Asme Sec Ix-WpqDokument47 SeitenAsme Sec Ix-WpqKaushal Sojitra100% (1)

- Welding Inspection HandbookDokument7 SeitenWelding Inspection HandbookDeepak Malhotra0% (1)

- PEGS-0710-COR-038 - External Cathodic Protection of Onshore Deep Well CasingDokument34 SeitenPEGS-0710-COR-038 - External Cathodic Protection of Onshore Deep Well CasingĐiệnBiênNhâm0% (1)

- Calibration-Validation - Good ArticleDokument12 SeitenCalibration-Validation - Good ArticleVijay KumarNoch keine Bewertungen

- AWS Authorized Testing Facility Initial Audit App PKG v3Dokument12 SeitenAWS Authorized Testing Facility Initial Audit App PKG v3greatsteelNoch keine Bewertungen

- Lincoln Diagnostic UtilityDokument19 SeitenLincoln Diagnostic UtilityMicheal SmithNoch keine Bewertungen

- WeldingDokument13 SeitenWeldingAna Hidayah SyuhadaNoch keine Bewertungen

- Appendix B3-10 Welding Procedure Specification EPI-11-WP6 Rev.1 - A4A2E9Dokument24 SeitenAppendix B3-10 Welding Procedure Specification EPI-11-WP6 Rev.1 - A4A2E9Tahir AliNoch keine Bewertungen

- Numerical Analysis On The Effect of Welding Parameters in TIG Welding For INCONEL 625 AlloyDokument7 SeitenNumerical Analysis On The Effect of Welding Parameters in TIG Welding For INCONEL 625 AlloyErin BarryNoch keine Bewertungen

- Welding PositionsDokument116 SeitenWelding PositionsASAPASAPASAPNoch keine Bewertungen

- Residual Stress in Metal Additive ManufacturingDokument6 SeitenResidual Stress in Metal Additive ManufacturingAli NasserNoch keine Bewertungen

- NDT Training Course BrochureDokument10 SeitenNDT Training Course Brochuresatya srinivas anasuriNoch keine Bewertungen

- Arclog X Manual 1.19Dokument55 SeitenArclog X Manual 1.19davmac79Noch keine Bewertungen

- Lincoln Stainless Welding GuideDokument40 SeitenLincoln Stainless Welding GuideAnonymous yQ7SQr100% (1)

- Advanced Gas Metal Arc Welding ProcDokument20 SeitenAdvanced Gas Metal Arc Welding ProcjavadmohammadiNoch keine Bewertungen

- Mathematical Modelling of GTAW and GMAWDokument240 SeitenMathematical Modelling of GTAW and GMAWpatriciatavares2009100% (2)

- CSWIP 3.1-2010 The Welding Inspection of SteelDokument317 SeitenCSWIP 3.1-2010 The Welding Inspection of Steelapply19842371100% (1)

- Ca1a Cadweld Cathodic Protection Connections Catalog Lt0398Dokument22 SeitenCa1a Cadweld Cathodic Protection Connections Catalog Lt0398Jose Luis ZimicNoch keine Bewertungen

- A WPS Is A Document That Describes How Welding Is To Be Carried Out in ProductionDokument3 SeitenA WPS Is A Document That Describes How Welding Is To Be Carried Out in Productionukavathekar100% (1)

- Cswip 3.1 2011Dokument400 SeitenCswip 3.1 2011Anonymous SA40GK6Noch keine Bewertungen

- What Is A Welding CertificationDokument12 SeitenWhat Is A Welding Certificationmjinspector100% (1)

- Weld Cracking PDFDokument5 SeitenWeld Cracking PDFjuanNoch keine Bewertungen

- Welding Engineering - FALL2021-22 - Module 1Dokument44 SeitenWelding Engineering - FALL2021-22 - Module 1dhaya nidhiNoch keine Bewertungen

- Ipc2012 90605Dokument8 SeitenIpc2012 90605Marcelo Varejão CasarinNoch keine Bewertungen

- 2 Welding TerminologyDokument26 Seiten2 Welding TerminologynaguNoch keine Bewertungen

- Miller RMDDokument4 SeitenMiller RMDRony Lesbt100% (1)

- Failure Analysis of Natural Gas PipesDokument20 SeitenFailure Analysis of Natural Gas PipesHeru BerianNoch keine Bewertungen

- Importance of Welding SoftwareDokument3 SeitenImportance of Welding SoftwareAshfaq AnwerNoch keine Bewertungen

- Fab 01 QA of Welds, ISO 3834, RWC Etc.Dokument17 SeitenFab 01 QA of Welds, ISO 3834, RWC Etc.Raghu vamshiNoch keine Bewertungen

- In-Service Welding of Pipelines Industry Action PlanDokument13 SeitenIn-Service Welding of Pipelines Industry Action Planعزت عبد المنعم100% (1)

- 2019 Inspection Summit Training Course Descriptions 8-2-18 - v2Dokument6 Seiten2019 Inspection Summit Training Course Descriptions 8-2-18 - v2Costas AggelidisNoch keine Bewertungen

- 07 Codes and Standards 30-03-07 PDFDokument6 Seiten07 Codes and Standards 30-03-07 PDFvineet chandra khanduriNoch keine Bewertungen

- Training ASME-VIII-Division-1-2-Pressure-Vessel-Series PDFDokument6 SeitenTraining ASME-VIII-Division-1-2-Pressure-Vessel-Series PDFumeshNoch keine Bewertungen

- Codes and Standards:: The Welding InstituteDokument0 SeitenCodes and Standards:: The Welding InstituteBhavani PrasadNoch keine Bewertungen

- DASH Training ProgramsDokument16 SeitenDASH Training ProgramsdashNoch keine Bewertungen

- Visual Inspection of Welds PDFDokument13 SeitenVisual Inspection of Welds PDFr0m14r100% (1)

- Welding InspectorDokument10 SeitenWelding InspectorRob Clarke100% (1)

- ASME VIII Division 1 & 2 Pressure Vessel SeriesDokument6 SeitenASME VIII Division 1 & 2 Pressure Vessel SeriesThanh Phuc NguyenNoch keine Bewertungen

- NDT Overview M1 Part2Dokument55 SeitenNDT Overview M1 Part2Leon Heart FC100% (1)

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AVon EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANoch keine Bewertungen

- Rebar Coupler: Barlock S/CA-Series CouplersDokument1 SeiteRebar Coupler: Barlock S/CA-Series CouplersHamza AldaeefNoch keine Bewertungen

- FIRE FIGHTING ROBOT (Mini Project)Dokument21 SeitenFIRE FIGHTING ROBOT (Mini Project)Hisham Kunjumuhammed100% (2)

- Jerome4 Sample Chap08Dokument58 SeitenJerome4 Sample Chap08Basil Babym100% (7)

- Fake PDFDokument2 SeitenFake PDFJessicaNoch keine Bewertungen

- Labstan 1Dokument2 SeitenLabstan 1Samuel WalshNoch keine Bewertungen

- Exp. 5 - Terminal Characteristis and Parallel Operation of Single Phase Transformers.Dokument7 SeitenExp. 5 - Terminal Characteristis and Parallel Operation of Single Phase Transformers.AbhishEk SinghNoch keine Bewertungen

- Building and Other Construction Workers Act 1996Dokument151 SeitenBuilding and Other Construction Workers Act 1996Rajesh KodavatiNoch keine Bewertungen

- Fidp ResearchDokument3 SeitenFidp ResearchIn SanityNoch keine Bewertungen

- Lending OperationsDokument54 SeitenLending OperationsFaraz Ahmed FarooqiNoch keine Bewertungen

- Ss 7 Unit 2 and 3 French and British in North AmericaDokument147 SeitenSs 7 Unit 2 and 3 French and British in North Americaapi-530453982Noch keine Bewertungen

- Digital LiteracyDokument19 SeitenDigital Literacynagasms100% (1)

- Forecasting of Nonlinear Time Series Using Artificial Neural NetworkDokument9 SeitenForecasting of Nonlinear Time Series Using Artificial Neural NetworkranaNoch keine Bewertungen

- Interoperability Standards For Voip Atm Components: Volume 4: RecordingDokument75 SeitenInteroperability Standards For Voip Atm Components: Volume 4: RecordingjuananpspNoch keine Bewertungen

- GL 186400 Case DigestDokument2 SeitenGL 186400 Case DigestRuss TuazonNoch keine Bewertungen

- QUIZ Group 1 Answer KeyDokument3 SeitenQUIZ Group 1 Answer KeyJames MercadoNoch keine Bewertungen

- Internship ReportDokument46 SeitenInternship ReportBilal Ahmad100% (1)

- An RambTel Monopole Presentation 280111Dokument29 SeitenAn RambTel Monopole Presentation 280111Timmy SurarsoNoch keine Bewertungen

- Everlube 620 CTDSDokument2 SeitenEverlube 620 CTDSchristianNoch keine Bewertungen

- Micron Interview Questions Summary # Question 1 Parsing The HTML WebpagesDokument2 SeitenMicron Interview Questions Summary # Question 1 Parsing The HTML WebpagesKartik SharmaNoch keine Bewertungen

- PeopleSoft Application Engine Program PDFDokument17 SeitenPeopleSoft Application Engine Program PDFSaurabh MehtaNoch keine Bewertungen

- Walmart, Amazon, EbayDokument2 SeitenWalmart, Amazon, EbayRELAKU GMAILNoch keine Bewertungen

- SAS SamplingDokument24 SeitenSAS SamplingVaibhav NataNoch keine Bewertungen

- Ludwig Van Beethoven: Für EliseDokument4 SeitenLudwig Van Beethoven: Für Eliseelio torrezNoch keine Bewertungen

- TSR KuDokument16 SeitenTSR KuAngsaNoch keine Bewertungen

- Tivoli Performance ViewerDokument4 SeitenTivoli Performance ViewernaveedshakurNoch keine Bewertungen

- Rofi Operation and Maintenance ManualDokument3 SeitenRofi Operation and Maintenance ManualSteve NewmanNoch keine Bewertungen

- Tanzania Finance Act 2008Dokument25 SeitenTanzania Finance Act 2008Andrey PavlovskiyNoch keine Bewertungen

- Termination LetterDokument2 SeitenTermination Letterultakam100% (1)

- Sustainable Urban Mobility Final ReportDokument141 SeitenSustainable Urban Mobility Final ReportMaria ClapaNoch keine Bewertungen

- Ajp Project (1) MergedDokument22 SeitenAjp Project (1) MergedRohit GhoshtekarNoch keine Bewertungen