Beruflich Dokumente

Kultur Dokumente

Lecture 1 - Introduction

Hochgeladen von

wdmalikCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lecture 1 - Introduction

Hochgeladen von

wdmalikCopyright:

Verfügbare Formate

ME466 ~ FINITE ELEMENT

METHOD

An Introduction to

Finite Element Analysis

Using

DR. MUHAMMAD ABID

Faculty of Mechanical Engineering

Ghulam Ishaq khan Institute of Engineering Sciences

and Technology, Topi

Pakistan

January 2004

ME466 FINITE ELEMENT METHODS

Spring Semester 2004 Class Information:

Lectures

Lectures run on 02 days in Lecture Hall and 01day in Computer Lab in the Faculty of

Mechanical Engineering. Occasionally, some excursions into the slot may be required to

complete material.

Tutorials

Tutorials are based on the doctors surgery format. One/two members of staff will be

present in Computer Lab on following days to provide help/ support/advice on all aspects of

running the software and helping with approaches to the coursework. Tutorials will start

after Lecture 2.

ANSYS 7 is installed in all computers of CM Lab. In addition, Pro-E is also installed on all

computers if someone wants to use.

Timetable for Computer Lab - FME

10 - Pentium IV (Windows XP)

Spring Semester 2004

Times

Monday

Lecture

Tuesday

Wednesday

Thursday

Friday

Lab

Accessing the PC-Network

It is essential that you have a PC username and Password. These can be obtained from

administrator/ Lab Engineer Computer Lab FME. Thereafter, ANSYS can be found using the

START bar button of WindowsNT. STARTProgramsANSYS 7Interactive. Fill in the

requred parameters and run.

On-line Help

Although a hard copy of ANSYS manuals is available in catalogue of Computer Lab,

however these are all on-line and it is essential that you spend some time familiarising

yourself with them.

STARTProgramsANSYS 7Help System will get you started. NavigateTable Of

ContentsAnalysis Guides or Workbook Examples will be of good use.

1

ME466 FINITE ELEMENT METHODS

Internet Support

All course material including past exercises and example input fileswill be made available

during the Semester. Lecture notes will be available from Central Services. However,

students can access this material via the internet using the following URL address,

http://192.168.151.50 and by following the links shown. In addition, excellent web-based

ANSYS tutorials from the University of Alberta have been made available. These can be

viewed on-line or by downloading and uncompressing using the Winzip utility.

Educational Version of ANSYS5.4 and ??

A node and element limited version is available from market and can be arranged by

yourself for your working at home.

Finally

If you have any problems with the class, please e-mail me abid@giki.edu.pk. Dont just

drop in at my room. I will probably not see you as I have a very busy semester. The best

way to cope with this class is to undertake all the exercises, which are giventake plenty of

time over them in the early stages and then work on course works as they are given. Dont

wait till the dead lines are upon you!

ME466 FINITE ELEMENT METHODS

ME466

FINITE ELEMENT ANALYSIS

1.0 PRACTICAL STRESS ANALYSIS

Introduction

This class aims to present the essentials for performing modern computer aided engineering

design specifically pertaining to stress analysis and strength design. In essence, the basic

principles from previous mechanics courses will be adopted, identifying the following:

* Stresses from simple components

* Material behaviour & failure mechanisms

* Fatigue & fracture

* Simple component design

However, the main emphasis of the course will develop advanced concepts of stress analysis

as presently utilised within modern industry. The main technique for performing stress

analysis and strength design is the finite element method. In addition to studying and

mastering this technique, we will also examine important lessons from the past.

Finite element analysis is the most popular means of simulating an engineering system. It is

used daily by industry, indeed, hundreds of thousands of engineers world-wide have used the

method for a variety of technical disciplines. For example, FEA has been used to simulate

structural, mechanical, thermal, fluid flow, electrical and chemical systems. In fact, such is

the uptake of the technique by engineers that over $5 billion is spent yearly on FEA in the US

alone.

In addition to the industrial uptake of the technique, thousands of engineers, scientists and

mathematical are performing research into FEA. Over 10,000 articles in professional

journals, more than 6,000 Ph.D. & Masters theses, more than 300 textbooks & monographs

are available on the subject.

It can be reasonably concluded that FEA is rapidly becoming an essential part of design

improvement, optimisation, production process simulation and failure assessment.

3

ME466 FINITE ELEMENT METHODS

Why Finite Element Analysis ?

The reasons for needing the finite element method and its popularity can be appreciated if

one imagines the problem of stresses and strains in components and structures in almost any

branch of engineering. Most modern structures are complex in the extreme. Sometimes,

however, a component may have a simple form, for example, a beam or a plate as in an

automobile or aircraft structure. These forms can be solved straightforwardly by classical

analysis using differential equations with one or two variables. However, real structures

involve three dimensions and therefore are much more complicated to analyse. Even if they

are assemblages of beams, the local forces require to be resolved prior to analysing the beam

in question.

Therefore, the main aim is to develop a technique of analysing complex geometries in the

first instance. Once the geometry can be adequately described, the laws of equilibrium,

motion, strain compatibility and stress-strain relations can be invoked and the process of

analysis can begin.

The essence of the approach is to use a computer to describe the geometry of the complex

structure using a discretised approach, where the geometric shape or internal stress-straindisplacement fields are described by a series of points or coordinates scattered over the

surface or through the interior of the structure. The structure is hypothetically divided into

finite elements which are small enough that the shape of the displacement field can be

approximated without too much error, then the magnitude must be found. It is possible to

assume allowable displacement shapes for these elements, for example, linear, quadratics,

polynomials, trigonometric functions as so on. Thereafter, the individual elements must be

assembled together in such a way as to ensure the displacements and stresses are continuous

in some fashion across the element interfaces, the internal stresses are in equilibrium with

each other and the applied loads and the prescribed boundary conditions are satisfied.

Various engineers have been attributed to being the father of FEA, e.g., Courant (1943),

however, the arrival of the digital computer especially in the aircraft industry led to a rapid

interest in activity in the Boeing Corporation in the early 1950's. The Structural Dynamics

Unit, led by M J Turner, formulated the method in 1954 and published it in 1956.

The North American B-70 bomber was the first production airplane designed using FEA. The

World Trade Center in New York and the John Hancock Centre in Chicago were the first

buildings designed on the basis of FEA.

4

ME466 FINITE ELEMENT METHODS

Some Very Important Points.

It is really important to remember that FEA technology is very recent. It is therefore a very

lively and evolving area of technology. Any engineer who commits a career to this discipline

commits to an area requiring continuing education in new concepts. It is therefore to be

expected that engineers who are knowledgeable and experienced command high salaries and

are at a premium.

The computer is an essential part of FEA, for various activities

*

solid modelling, mesh generation, plotting

model checking, solution

results display and evaluation

It is also a real nuisance unless the engineer learn with someone knows the computer well. It

is recognised that the learning time associated with the computer is really frustrating.

YOU ARE WARNED!!

Whilst the computer solves the mathematical equations and can be used to manipulate

geometry on screen, the main role of the engineer is to interpret the results. This

responsibility is both professional and (in some countries) legal. The importance of the

engineer to structural safety is reflected in the US in the price of liability and malpractice

insurance to the design firm: often 3-5% of gross income - this figure being higher the costs

associated with a physician (doctor). To fulfil these responsibilities, engineers must exercise

a healthy.

The second responsibility is to ensure relevancy and accuracy. In essence, this is the main

purpose of this course.

ME466 FINITE ELEMENT METHODS

2.0 THE BASIC PRINCIPLES

Basic Finite Element Concept

In solving any structural problem, what ever the type of structure, whatever the type of

loading, be it static or dynamic, and what ever the nature of the structural material, there are

only three types of argument which can be deployed. These are quite separate and distinct

and it is important to understand their simplicity especially when considering the intricacies

of the finite element method. These arguments are

* Equilibrium

These arguments relate stress to the applied forces, or often to other stresses whether

there are applied forces or not. For example, in some dynamic problems, inertia forces

can be inserted into the equations of equilibrium as if the problem was static. If the

displacements are small, then the equations of equilibrium are linear.

* Compatibility

These arguments relate strains to displacements and are purely geometrical arguments

which depend on the definition of strain and the type of deformation and geometry of

the particular structure. If the displacements are small, then the compatibility equations

are also linear.

* Stress-Strain Law

These constitutive relations are empirical and depend on experimental evidence. They

may included thermal effects, and for ferrous materials the relationship may be elastoplastic with irreversible plasticity. For many structural materials within their useful

working range these laws may be taken as linear.

It is worth recalling that in stress analysis, the basic equations for displacement, stress and

strain are known, but cannot be solved for complex geometries. However, the basic equations

can be solved for simple shapes such as triangles or quadrilaterals, known as elements.

The basic concept in the finite element method is that the real component is approximated by

a finite element model made up of an assembly of these simpler shapes i.e. elements joined at

common nodes. The actual problem is then solved by invoking the arguments of equilibrium,

compatibility at the common nodes for each element, incorporating the appropriate stressstrain law, and applying the known restraints and forces.

6

ME466 FINITE ELEMENT METHODS

Basic Finite Element Analysis Procedure

The basic finite element analysis procedure can be broken down into three simple steps. In

fact, these steps also represent the major processors within typical finite element programs,

e.g. ANSYS.

They comprise:

* PREPROCESSING

Enter the appropriate preprocessor (e.g. /PREP7)

Define the analysis job title

Define the element type(s)

Define the element real constants

Define the element properties (e.g. material properties)

Define the geometry (solid) model

Define the mesh type and element size

Generate the finite element model

Save the database

Exit the preprocessor

* SOLUTION

Enter the solution processor (e.g. /SOLUTION)

Define the analysis type (e.g. static stress analysis) and options

Apply the known boundary conditions

Apply the known loads

Execute the solver

Exit the solution processor

* POSTPROCESSING

Enter the postprocessor (e.g. /POST1)

Read in the results from appropriate load step (SET,LAST)

Plot, print, graph, sort, combine results

Exit postprocessor

ME466 FINITE ELEMENT METHODS

ANSYS Analysis Procedures

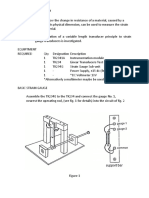

It is worth having a look at a simple two dimensional stress analysis problem prior to

understanding the mathematics involved with the finite element method. For this we will

consider a simple bracket with a hole, fully restrained at one end and subject to a point load

at the lowest point of the hole. In this example, the following points need to be examined:

* Techniques of geometry modelling

- Keypoints, lines and areas

- Geometric construction (arcs, intersections, fillets)

* Simple Mesh Generation

- Choice of elements (STIF2 or STIF42)

- Element (material properties)

- Element shape (tri/quad)

- Mesh density (element size)

- Automatic generation of FE model

- Model optimisation

* Boundary Conditions

- Selecting

- Symmetry

- Pressure surfaces

* Solution & Postprocessing

- Model database, results files

- Plotting, printing etc.. results

* Analysis Checking

- Is it correct ?

This is the common route for carrying out an FE analysis of a component, however, it is not

the procedure for formulating the `Engineering Problem'.

ME466 FINITE ELEMENT METHODS

Practical Stress Analysis using FEA

The best approach to performing useful, practical stress analysis using FEA is to know the

code which you are working with and it capabilities really well, and then to keep away from

the computer until the problem has been fully formulated on paper. This is the key to

successful FE analysis. It is essential that the problem is clearly defined. Practical stress

analysis is best carried out using the following approach.

1) Define the Engineering Problem

Objectives:

What is the problem to be solved? Why is the analysis being carried out? Is this the

most appropriate method? What do I expect to get out of the analysis? What results

are required and to what accuracy?

Geometry:

How realistic is the geometry model suggested? Do I need to consider all the small

holes and fillet radii? Do I need a submodel? What about symmetry? Are there any

other simplifications I can make? Are there drawing available? Is there a CAD

model? Can I Use IGES translation? Does the component conform to the drawing?

What are the manufacturing tolerances?

Loading:

What is the location and magnitude of the load. Is it applied over time or ramped on

in one step? Static or dynamic? Is there any interaction between the various load

steps?

Constraints:

Are the supports rigid or flexible? What type are required e.g. rigid, roller, spring,

gap, frictional contact..? How does the constraint effect the stresses? Where does the

effect of the constraint die away?

2) Derive the Mechanical Model

Model the Geometry:

Symmetric, axi-symmetric, cyclic symmetric, tolerances ?

ME466 FINITE ELEMENT METHODS

Model the Material:

How accurate is the data? Linear or non-linear relationships? Limitations: yield

strength, ultimate strength, fatigue life.

Model the Loads:

Is it a point load or distributed? Does this make any difference?

Model the Restraints:

Are boundary conditions rotational and/or translational? What is the worst case?

3) Generate the Finite Element Model and Analyse

Create the geometry or solid model

Select the element type and shape

Control the mesh density

Generate the mesh

Apply the loads and restraints

Execute a solution

4) Checking and Debugging - Refining the Model

Interpretation of the Results:

Selecting the correct load step, and plotting, listing, printing the results. Stress

contour plots, reactions, displaced shapes, etc. Use the most appropriate graphics

features which are available. Check nodal versus element solution.

Assessment of the Results:

Are the results what I expect? Do either the load representation or boundary

conditions dominate the results? What is the error in the model? Is this good enough?

Can it be improved? Do I have enough element in the region of highest stress? Do I

have too many?

Procedure for Remodelling:

Should I carry out one or two more runs? What about submodelling?

10

ME466 FINITE ELEMENT METHODS

These procedures may, at first appear simple and have an obvious common-sense approach.

However, it is very clear that the majority of poor or incorrect analyses can be overcome by

adopting the above procedures.

It is also worth mentioning the existence of NAFEMS*, formerly the National Agency for

Finite Element Methods and Standards (now a private DTI funded company) which publishes

various documents and now issues conformance certificates to companies who have approved

documented procedures for carrying out and checking finite element analyses to BS 5750 and

ISO9000/1.

* For further reading, see `A Finite Element Primer' produced by NAFEMS (1987),

Birniehill, East Kilbride, Glasgow

11

Das könnte Ihnen auch gefallen

- IELTS Practice Tests Plus 3 (Enhanced)Dokument192 SeitenIELTS Practice Tests Plus 3 (Enhanced)wdmalikNoch keine Bewertungen

- Maxim Australia - December 2017Dokument100 SeitenMaxim Australia - December 2017wdmalik60% (5)

- How To Write Great EssaysDokument127 SeitenHow To Write Great Essaysa100% (25)

- 0118 Gearsolutions PDFDokument60 Seiten0118 Gearsolutions PDFdesetekNoch keine Bewertungen

- Reliabilitycenteredmaintenanceparaslideshare 121129181739 Phpapp01Dokument48 SeitenReliabilitycenteredmaintenanceparaslideshare 121129181739 Phpapp01wdmalikNoch keine Bewertungen

- Cs3000 Operation With FfcsDokument106 SeitenCs3000 Operation With FfcsNikhil S Pillai100% (3)

- RCM101 PPSXDokument37 SeitenRCM101 PPSXwdmalikNoch keine Bewertungen

- CPM322E CH1 Planning PDFDokument38 SeitenCPM322E CH1 Planning PDFRamesh BabuNoch keine Bewertungen

- RCM ImplementationDokument7 SeitenRCM ImplementationwdmalikNoch keine Bewertungen

- Fans & Blowers-Calculation of PowerDokument20 SeitenFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- PMP Certification FlowchartDokument1 SeitePMP Certification FlowchartwdmalikNoch keine Bewertungen

- Professional Project Management - SBookDokument174 SeitenProfessional Project Management - SBookwdmalikNoch keine Bewertungen

- Pump BasicsDokument34 SeitenPump BasicswdmalikNoch keine Bewertungen

- Pump BasicsDokument34 SeitenPump BasicswdmalikNoch keine Bewertungen

- ® Control Valve HBK - MasoneilanDokument36 Seiten® Control Valve HBK - Masoneilantucker-r100% (1)

- Shale Gas Viability and Prospects For PakistanDokument136 SeitenShale Gas Viability and Prospects For Pakistanwdmalik0% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 117BP - CNC Technologies PDFDokument8 Seiten117BP - CNC Technologies PDFvenkiscribd444Noch keine Bewertungen

- Chapter 2 Modern Control SystemsDokument19 SeitenChapter 2 Modern Control SystemsDilamo FelekeNoch keine Bewertungen

- PEX250í 1200 Instruction ManualDokument10 SeitenPEX250í 1200 Instruction ManualSebastian Aguila RaipanNoch keine Bewertungen

- Gabion Wall Design - 4.0 MTR Above GLDokument8 SeitenGabion Wall Design - 4.0 MTR Above GLAnkush SharmaNoch keine Bewertungen

- Development Length of Reinforcing Bars - Need To Revise Indian Code ProvisionsDokument8 SeitenDevelopment Length of Reinforcing Bars - Need To Revise Indian Code ProvisionsAvijitNoch keine Bewertungen

- Gestión de Formación Profesional Integral Procedimiento Desarrollo Curricular Guía de Aprendizaje 1. Identificación de La Guia de AprenizajeDokument9 SeitenGestión de Formación Profesional Integral Procedimiento Desarrollo Curricular Guía de Aprendizaje 1. Identificación de La Guia de AprenizajeMilena Sánchez LópezNoch keine Bewertungen

- Cat Apem Ermec Nuevo Catalogo General de Pulsadores Interruptores Apem Big Blue 2011 12Dokument589 SeitenCat Apem Ermec Nuevo Catalogo General de Pulsadores Interruptores Apem Big Blue 2011 12Josue BerzunzaNoch keine Bewertungen

- Canal Top Solar Power Plant by S RathoreDokument61 SeitenCanal Top Solar Power Plant by S RathoreguruprasadshikhareNoch keine Bewertungen

- Wopho 13 Prob7-Final PDFDokument3 SeitenWopho 13 Prob7-Final PDFPeter JonesNoch keine Bewertungen

- Vib PDFDokument2 SeitenVib PDFprasanna1990Noch keine Bewertungen

- Identification of Transport Mechanism in Adsorbent Micropores From Column DynamicsDokument9 SeitenIdentification of Transport Mechanism in Adsorbent Micropores From Column DynamicsFernando AmoresNoch keine Bewertungen

- Bp8-Tension: User Defined Applied Forces at Interface Basic DimensionsDokument4 SeitenBp8-Tension: User Defined Applied Forces at Interface Basic DimensionsMallesh NenkatNoch keine Bewertungen

- Curriculum I Semester: SL - No Subject Code Subject Name Category L T P CreditsDokument23 SeitenCurriculum I Semester: SL - No Subject Code Subject Name Category L T P CreditsRathinaKumarNoch keine Bewertungen

- Advanced Som SyllabusDokument1 SeiteAdvanced Som SyllabusRaj Kumar0% (1)

- Department of Mathematics I.I.T Madras MA1101: Functions of Several Variables Assignment-I (A) (July-Nov, 2017)Dokument2 SeitenDepartment of Mathematics I.I.T Madras MA1101: Functions of Several Variables Assignment-I (A) (July-Nov, 2017)RahulNoch keine Bewertungen

- A New Fatigue Damage Accumulation Rating Life Model of Ball Bearings Under Vibration LoadDokument11 SeitenA New Fatigue Damage Accumulation Rating Life Model of Ball Bearings Under Vibration LoadAlbertoNoch keine Bewertungen

- Design Calculations For Bottom RaftDokument3 SeitenDesign Calculations For Bottom RaftRahulNoch keine Bewertungen

- 3516BDokument392 Seiten3516Bmuhammad arif95% (22)

- Design, Analysis, Fabrication and Testing of A Formula Car ChassisDokument10 SeitenDesign, Analysis, Fabrication and Testing of A Formula Car ChassisSavalia HardikNoch keine Bewertungen

- Vivo Nex 3 5GDokument11 SeitenVivo Nex 3 5GEvery DayNoch keine Bewertungen

- Chapter 9 Powerpoint Notes 2008Dokument39 SeitenChapter 9 Powerpoint Notes 2008Umar AsimNoch keine Bewertungen

- WLP Creative WritingDokument12 SeitenWLP Creative Writingsheena balaisNoch keine Bewertungen

- Sports and Building AerodynamicsDokument13 SeitenSports and Building AerodynamicsMaria Cielo VarelaNoch keine Bewertungen

- Report 3 Schlieren Visualisation of Over-Expanded NozzleDokument6 SeitenReport 3 Schlieren Visualisation of Over-Expanded NozzleAbhishek DhakneNoch keine Bewertungen

- Strain GuageDokument6 SeitenStrain GuageChristian EspanolNoch keine Bewertungen

- 2011 Exam GeotechnicalDokument9 Seiten2011 Exam GeotechnicalAhmed AwadallaNoch keine Bewertungen

- 27 Excel Add-InsDokument10 Seiten27 Excel Add-Insgore_11Noch keine Bewertungen

- D R 800 Dust Concentration Meter: Before Starting Any Work, Read The Operating Instructions (The Manual) !Dokument154 SeitenD R 800 Dust Concentration Meter: Before Starting Any Work, Read The Operating Instructions (The Manual) !Phạm Thanh SơnNoch keine Bewertungen

- Formulario Magnitudes Corriente Alterna Monofásica Corriente Alterna Trifásica P Q S VDokument2 SeitenFormulario Magnitudes Corriente Alterna Monofásica Corriente Alterna Trifásica P Q S VMario Andrade100% (1)

- Crankshaft Axial Vibration AnalysisDokument8 SeitenCrankshaft Axial Vibration Analysisanmol6237100% (1)