Beruflich Dokumente

Kultur Dokumente

What Is The Value Method

Hochgeladen von

Lokesh NarasimhaiahOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

What Is The Value Method

Hochgeladen von

Lokesh NarasimhaiahCopyright:

Verfügbare Formate

What is the Value Method?

Previous

Next Page

The Value Method is a highly efficient and productive decision-making process. It

uses:

Systematic and organized procedural processes

Creative methods to generate alternatives

Essential functional approach

Comparisons of worth as opposed to Life-Cycle Costs (defined as value).

General Introduction

The Value Method was originally developed by Larry Mills (General Electric) in 1943. It

has been highly refined and honed by many over the years. It's designed to use

highly efficient procedures that are consistent with sound management techniques

and is tuned to achieve maximum performance, in the minimum amount of time

required. As a complete and mature process with more than 50-years of successful

application, it has been used in almost any endeavor contemplated.

Key Characteristics

Several characteristics differentiate the Value Method from other techniques.

These help ensure that the customer obtains the kind of product they need

and want.

Value-based decision process

Uses functional approach

Follows a very systematic and organized "job plan"

Directs efforts towards maximum possible alternatives through

creativity techniques

It is Success Oriented

Good results are produced by taking the appropriate action at the appropriate

time. Unfortunately, the appropriate action and timing are rarely sufficiently

clear. Also, there are natural organizational and human limitations that must

be contended with by everyone. The Value Method takes human and

organizational limitations into account in the key characteristic of its processes.

When the fundamental "requirements" of the Value Method are adhered to by

those making use of it, success is virtually guaranteed.

Doing a "good job"

o

o

o

o

In general, all organizations and people want to do a good job. They want to

meet the needs of their customers. When an organization or person

consistently fails to meet the needs of the customers well, they eventually fail:

few plan to fail. Unfortunately, the best direction is not always clear. The

limitations of time, money, expertise, and other resources require us to take

shortcuts or make decisions that may not be based as well as we would like.

Each person must also contend with our own human limitations such as how

many items we can keep in the forefront of our mind at the same time, the

number of times it takes us to develop understanding and comfort in any new

item, and the limited experiences that we have been exposed to in our

lifetime.

When people decide they want to do something optimally, the results are

astonishing. To decide to do something better is the first step. To use good

techniques to do it is the second step. The third step is acquiring those skills.

As people acquire those skills, they and their employer benefit. Whether

applied by the individual, team, or organizationally, the Value Method is one of

those skills that produces great benefits without having to endure hard lessons

through the "school of hard knocks."

You may have heard of it.

Applications of the Value Method are known by several common names. Value

Engineering (VE), Value Analysis (VA), Value Management (VM), and Value

Planning (VP) are some of the most common names used. These names

describe small variations in the general Value Method process related to the

timing, selection, type of activity, or other specific application. Application of

the Method is usually referred to as value studies. Each year companies save

billions of dollars in expenditures; improve quality, service while improving

customer satisfaction; and increasing revenue, market share, and profits.

Keywords

Systematic and organized

The Value Method process uses tested and

successful procedures that are directed

toward achieving success in meeting the

purposes for the "project" by all involved.

The process instills "common

understanding", generates high production

and high performing team activities, reduces the time necessary to obtain a

product, and focuses the efforts on the purposes behind the project or activity

being studied. A standard "job plan" is used to guide the entire process.

Alternatives

The Value Method generates, examines, and refines creative

alternatives toward the concept of producing an end product

that produces high customer acceptance. The process

endeavors to widen the number and scope of the available

alternatives. This is done to increase the potential for

enhanced satisfaction, and take advantage of the added expertise brought into

the studied activity through the value study process.

Functions and FAST

One of the most unique and useful qualities of the Value Method is its use of

functions to describe the activity or product being studied. The value study

breaks the "project" into components so as to avoid misunderstanding of the

planned intents for the project. Then a Functional Analysis is conducted on

each component. In the Value Method process, functions are limited to the

shortest sentence possible. Just two words are usually allowed: a verb (active

preferred) and a noun (measurable preferred). The main functional purpose for

the component being studied is the primary function. Of course, things often

happen as a result of the choice of a component, or something must be done

to make the selected component work as needed. These functions are called

supporting or secondary functions. The results of the functional analysis are

placed into a function-logic diagram called a FAST (a short term for Functional

Analysis System Technique).

Value

The true value of a activity or product is its relationship to its perceived worth

as opposed to its life-cycle costs. In Value Method terms: Value = Worth /

Cost. When an item has a Value greater than 1.0, the item is perceived to be a

fair or good value. When an item has a Value is less than 1.0, the item is

perceived to be a poor value or bad value. When the perceived worth far

exceeds the life-cycle cost, we usually consider purchasing the item.

Worth

The worth of a product involves many features. The most common cited

are: benefits received, services obtained, satisfaction of the product

performance, quality, safety, and convenience. The worth of the product

is a measure of what is in it for the customers involved. It is a measure

of how well the end product meets the involved essential needs and the

added desires of those that have a voice in the product selection or its

use. An end product must always supply the essential need, or its worth

will be poor

Life-Cycle Costs

The true cost of an item is not just the amount of money that you pay

when you buy it. Much more is involved. When you buy something, you

also buy its long-term effects. The initial costs plus these long-term

costs are called life-cycle costs. This includes things like the time

involved to get the project done, the people needed (number, expertise

and so on), the degree of difficulty involved, availability of money or

other resources, the amount of maintenance needed, and the money

that must be expended and kept in reserve.

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- HB 3996 LVDokument57 SeitenHB 3996 LVLokesh NarasimhaiahNoch keine Bewertungen

- Wing Assembly System For British Aerospace Airbus For The A320Dokument8 SeitenWing Assembly System For British Aerospace Airbus For The A320Lokesh NarasimhaiahNoch keine Bewertungen

- P RaveenaDokument1 SeiteP RaveenaLokesh NarasimhaiahNoch keine Bewertungen

- IamplDokument2 SeitenIamplLokesh NarasimhaiahNoch keine Bewertungen

- Mil DTL 3476jDokument20 SeitenMil DTL 3476jLokesh NarasimhaiahNoch keine Bewertungen

- Faq - Published by Karnataka Government Explaining Survey WorksDokument6 SeitenFaq - Published by Karnataka Government Explaining Survey WorksSridhara babu. N - ಶ್ರೀಧರ ಬಾಬು. ಎನ್100% (1)

- Raw Material Standard: ASTM B-211MDokument1 SeiteRaw Material Standard: ASTM B-211MLokesh NarasimhaiahNoch keine Bewertungen

- Format 2 - 1Dokument1 SeiteFormat 2 - 1Lokesh NarasimhaiahNoch keine Bewertungen

- BDA Layouts PDFDokument16 SeitenBDA Layouts PDFLokesh NarasimhaiahNoch keine Bewertungen

- Constitution of IndiaDokument12 SeitenConstitution of IndiaLokesh NarasimhaiahNoch keine Bewertungen

- Supplier GroupDokument1 SeiteSupplier GroupLokesh NarasimhaiahNoch keine Bewertungen

- Flow Chart For Recipt of Order BookDokument1 SeiteFlow Chart For Recipt of Order BookLokesh NarasimhaiahNoch keine Bewertungen

- Glossary of Terms in CADDokument9 SeitenGlossary of Terms in CADLokesh NarasimhaiahNoch keine Bewertungen

- Diesel Locomotive: How It Works.: Oliver Keating LexcieDokument4 SeitenDiesel Locomotive: How It Works.: Oliver Keating LexcieLokesh NarasimhaiahNoch keine Bewertungen

- Hyderabad ContactsDokument4 SeitenHyderabad ContactsLokesh Narasimhaiah100% (1)

- Basic Sample TestDokument20 SeitenBasic Sample TestLokesh NarasimhaiahNoch keine Bewertungen

- How Gas Turbine Engines WorkDokument7 SeitenHow Gas Turbine Engines WorkLokesh NarasimhaiahNoch keine Bewertungen

- Geometric Dimensioning & Tolerancing TrainingDokument5 SeitenGeometric Dimensioning & Tolerancing TrainingLokesh NarasimhaiahNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- ObjectionDokument10 SeitenObjectionMy-Acts Of-SeditionNoch keine Bewertungen

- 1577168581final Exam Routine - Mor ShiftDokument19 Seiten1577168581final Exam Routine - Mor ShiftNafiz Iqbal MugdhoNoch keine Bewertungen

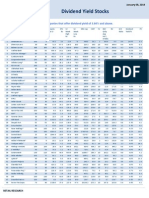

- High Dividend Yield StocksDokument3 SeitenHigh Dividend Yield StockskaizenlifeNoch keine Bewertungen

- Group Technology UnitDokument20 SeitenGroup Technology UnitsumanNoch keine Bewertungen

- Aaltola 2018Dokument27 SeitenAaltola 2018YukiNoch keine Bewertungen

- Unit 2 Consumer BehaviourDokument14 SeitenUnit 2 Consumer Behaviournileshstat5Noch keine Bewertungen

- Leading Through Digital Disruption AmazonDokument13 SeitenLeading Through Digital Disruption AmazonMaham Tariq0% (1)

- Chai Qawali AssignmentDokument15 SeitenChai Qawali AssignmentCadet SaqlainNoch keine Bewertungen

- Od 126044903266212000Dokument1 SeiteOd 126044903266212000ABHINAV VELAGANoch keine Bewertungen

- Life Cycle Cost Based Procurement Decisions A Case Study of Norwegian Defence Procurement ProjectsDokument10 SeitenLife Cycle Cost Based Procurement Decisions A Case Study of Norwegian Defence Procurement ProjectsEric QuanhuiNoch keine Bewertungen

- Revenue Cycle ReportDokument15 SeitenRevenue Cycle ReportKevin Lloyd GallardoNoch keine Bewertungen

- REBUTTAL REPORT OF DR. ROBERT McCORMICK IN SUPPORT OF ANTITRUST PLAINTIFFS' MOTION FOR CLASS CERTIFICATIONDokument199 SeitenREBUTTAL REPORT OF DR. ROBERT McCORMICK IN SUPPORT OF ANTITRUST PLAINTIFFS' MOTION FOR CLASS CERTIFICATIONInsideSportsLawNoch keine Bewertungen

- Jetro Restaurant Depot AgreementDokument28 SeitenJetro Restaurant Depot AgreementUFCW770Noch keine Bewertungen

- Surfcam Velocity BrochureDokument8 SeitenSurfcam Velocity BrochureLuis Chagoya ReyesNoch keine Bewertungen

- Amadeus Training Catalogue PDFDokument88 SeitenAmadeus Training Catalogue PDFDeyae SerroukhNoch keine Bewertungen

- Zambia in FiguresDokument24 SeitenZambia in FiguresChola Mukanga100% (1)

- Booking Holidays Online: BBC Learning English 6 Minute EnglishDokument6 SeitenBooking Holidays Online: BBC Learning English 6 Minute EnglishMonica. RicardoNoch keine Bewertungen

- Nash EquilibriumDokument5 SeitenNash EquilibriumNiyati44100% (1)

- Chapter 1 MGMT481 - Summer 2021Dokument23 SeitenChapter 1 MGMT481 - Summer 2021Jelan AlanoNoch keine Bewertungen

- Bachelor of Business AdministrationDokument66 SeitenBachelor of Business AdministrationKamala Kanta DashNoch keine Bewertungen

- PDFDokument7 SeitenPDFNikhilAKothariNoch keine Bewertungen

- Hizon Notes - Transportation Laws (Jarodelyn Mabalot - S Conflicted Copy)Dokument120 SeitenHizon Notes - Transportation Laws (Jarodelyn Mabalot - S Conflicted Copy)Jimcris Posadas Hermosado100% (1)

- Peergraded Assignment The Importance of DelegationDokument2 SeitenPeergraded Assignment The Importance of DelegationImayan GabrielNoch keine Bewertungen

- All India GST JurisdictionDokument2 SeitenAll India GST JurisdictionCafe 31Noch keine Bewertungen

- Application For Leave CSC Form No. 6: 1. Agency 2. Name (Last) (First) (Middle) Deped Cabanatuan CityDokument1 SeiteApplication For Leave CSC Form No. 6: 1. Agency 2. Name (Last) (First) (Middle) Deped Cabanatuan CityJean Claudine MandayNoch keine Bewertungen

- MARS Brochure NewDokument13 SeitenMARS Brochure NewMars FreightsNoch keine Bewertungen

- Grovy Alcove, JVC Dubai +971 4553 8725Dokument19 SeitenGrovy Alcove, JVC Dubai +971 4553 8725SandeepNoch keine Bewertungen

- Anthony Mosha CVDokument6 SeitenAnthony Mosha CVanthony_mosha2445Noch keine Bewertungen

- Strategic Marketing Planning VOLVO: Ali AbdurahimanDokument14 SeitenStrategic Marketing Planning VOLVO: Ali AbdurahimanAli Abdurahiman100% (1)

- Ogutu - The Role of National Housing Corporation in The Provision of Housing in KenyaDokument95 SeitenOgutu - The Role of National Housing Corporation in The Provision of Housing in KenyaboneylouNoch keine Bewertungen