Beruflich Dokumente

Kultur Dokumente

Cost Effective Led Driving PDF

Hochgeladen von

Nandor KermeciOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cost Effective Led Driving PDF

Hochgeladen von

Nandor KermeciCopyright:

Verfügbare Formate

Design Idea

Cost Effective Driving of Standard LEDs from 10VDC up to 110/230VAC with Current Limiting Diodes

Cost Effective Driving of Standard LEDs from 10VDC

up to 110/230VAC with Current Limiting Diodes

Standard LEDs are widely used for all kind of lighting purposes such as optical

indicators and signal lights, marking lights, display backlights, interior and furniture

lighting and much more. New approaches even use standard LED arrays to replace

fluorescent lights (neon tubes), especially in areas

where no high-level lighting is required, e. g. floor

lightings, wash and lunch room luminaire, outdoor

lights etc. Standard LEDs are robust, long-living and

Mike Deal aka ZoneDancer

available in high volumes at low costs; their power

consumption is on a very low level below 100mW. The driving current of such

devices is typically 20mA1, resulting in a forward voltage drop between 2 and

4V. The following describes a cost effective solution to drive such LEDs by

means of the Current Limiting Diodes CL20M45 and CL40M45 offered by

Diotec.

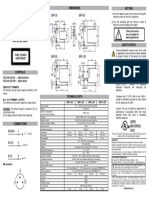

Current Limiting Diodes (CLD)

Like a Zener diode keeps a voltage constant over a

wide range of Zener current, the Current Limiting

Diode or CLD keeps a current constant over a wide

range of forward voltage. The left figure shows the

typical IF vs VF curve of such CLD device, including

the symbol and current/voltage definitions. When

applying a positive voltage from anode to the

cathode (indicated by cathode mark), the current

rises until it reaches a constant value IP. The start of

this current limiting area is defined by the limiting

voltage VL, above which IL = 80% of IP is reached. IP

remains constant, unless a maximum admissible

voltage VAK is reached, above which a breakdown

happens and the device can be destroyed. In

reverse direction, the voltage VR is quite quickly

reached. So operating voltage range is between VL

and VAK, where current is kept to a constant value IP;

the reverse direction is normally not used.

Taking the function of the CLD into account, such device

can be used to drive LEDs with a constant current IP from a

variable voltage source VIN, see right figure. The only

condition is to limit the voltage across the CLD to a value

less than VAK; that voltage is the difference between V IN

and the voltage drop at the LED, VF-LED.

The CL20M45 is designed for an IP of 20mA, which is the

typical driving current for Standard LEDs; the VAK is 45V. So

in the easiest case, this CLD can be used to drive a single

LED from a voltage source ranging from about 10VDC up

to 45VDC. For higher driving currents, the CL40M45 offers an IP of 40mA. CLDs can be even operated in

parallel; of course then the power dissipation / power losses will increase as well.

One should not mix up Standard LEDs with Power LEDs, where driving current is in the range of 350 to 700mA

(thereabout refer to the Application Note Diotec Products for Power LED Drivers)

Diotec Semiconductor AG

http://www.diotec.com/

2011-05-04

1/3

Cost Effective Driving of Standard LEDs from 10VDC up to 110/230VAC with Current Limiting Diodes

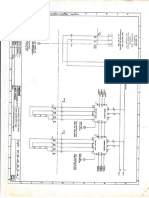

However, in most cases there is an AC voltage source, so additionally a (bridge) rectifier device is required.

If the circuit is connected directly to the 110V/230VAC mains, VIN can reach quite high levels up to 350V peak.

So existing designs require a lot of additional devices, in order to reduce the incoming voltage to an

acceptable level; they further require electrolytic capacitors to keep that voltage constant. As a result, such

circuits are complex and expensive, and their lifetime is limited mainly by the electrolytic capacitors used.

The following describes how by means of just a bridge rectifier, one or two CLDs, either an array of LEDs or

an AC capacitor, a circuit for direct operation at 110VAC or 230VAC mains can be build2.

Solution up to now: requiring 5 components, having limited lifetime

The right picture shows

how up to now LEDs are

driven at AC mains. The

Zener diode, electrolytic

capacitor

and

power

resistor is required to keep

the forward current IF

through the LED constant.

The electrolytic capacitor

has got the shortest lifetime of all components in

the circuit and is the

limiting element. During

turn-on, a current peak can occur at the bridge, caused during initial charge of the AC and electrolytic

capacitor. Therefore here the S250 by Diotec is used, featuring a very high forward surge rating of 40A (at

50Hz).

New Solution, Example 1: only 3 components and improved lifetime

The circuit on the left simply needs 3

components to drive one (or more)

Standard LEDs at a wide input range. The

AC capacitor C has got a certain dynamic

impedance XC = 1/(2fC). Depending on the

output power (and related to that, the input

or mains current), there is a voltage drop

across this impedance. C has to be chosen

such way that the voltage drop is big

enough to ensure that VAK of the CLD is not

exceeded.

2/3

This design idea describes an application proposal and shall not considered as assured and proven characteristic of a circuit. No

warranty or guarantee, expressed or implied is made regarding the capacity, performance or suitability of any circuit etc, neither

does it convey any license under its patent rights of others.

2011-02-07

http://www.diotec.com/

Diotec Semiconductor AG

Design Idea

Cost Effective Driving of Standard LEDs from 10VDC up to 110/230VAC with Current Limiting Diodes

New Solution, Example 2: only 2 components for driving LED arrays at 110VAC

Here not only one, but an

array of Standard LEDs is

used. The resulting voltage

drop across the series of

LEDs is big enough to ensure

VAK is not exceeded. Thus, by

only one rectifier bridge and

one single CLD a complete

LED luminaire, operated at

110VAC, can be done. Since

there is no inrush current,

the lower cost MS series of

bridge rectifiers can be used.

LED array driven at 110VAC by a

bridge rectifier and a CLD

New Solution, Example 3: only 3 components for driving LED arrays at 230VAC

Here the same circuit, but

operated at 230VAC mains.

Due to the higher peak

voltage, more LEDs have to

be connected in series, and

also two CLD are used.

Anyway, a single rectifier

bridge is enough to complete

the whole circuit!

In the above circuits, no electrolytic capacitors are needed nor other complex devices 3. One may add a

simple inductor (coil) in series to the LEDs, in order to reduce the (small) ripple in driving current (occurring

during the zero-crossing of mains voltage). Furthermore, a mains fuse can provide circuit protection in case

of any unforeseen shorts.

This design idea describes an application proposal and shall not considered as assured and proven characteristic of a circuit. No

warranty or guarantee, expressed or implied is made regarding the capacity, performance or suitability of any circuit etc, neither

does it convey any license under its patent rights of others.

Diotec Semiconductor AG

http://www.diotec.com/

2011-05-04

3/3

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- SMD CatalogDokument80 SeitenSMD Catalogpbradaric91% (11)

- CatalogDokument204 SeitenCatalogNandor KermeciNoch keine Bewertungen

- SRFlaser Slotsensors Manual RevF EngDokument1 SeiteSRFlaser Slotsensors Manual RevF EngNandor KermeciNoch keine Bewertungen

- 30 LED ProjectsDokument31 Seiten30 LED ProjectsVlatko KrstevskiNoch keine Bewertungen

- Vitafonbook PDFDokument141 SeitenVitafonbook PDFxenniaxNoch keine Bewertungen

- General Terms and Conditions GTCS: 1. ScopeDokument4 SeitenGeneral Terms and Conditions GTCS: 1. ScopeNandor KermeciNoch keine Bewertungen

- Datalogic SR31 ManualDokument2 SeitenDatalogic SR31 ManualNandor KermeciNoch keine Bewertungen

- Ba Ds 019 02 10 en LowDokument40 SeitenBa Ds 019 02 10 en LowNandor KermeciNoch keine Bewertungen

- Img 0006Dokument6 SeitenImg 0006Nandor KermeciNoch keine Bewertungen

- SRFlaser Slotsensors Manual RevF EngDokument1 SeiteSRFlaser Slotsensors Manual RevF EngNandor KermeciNoch keine Bewertungen

- Lubricators LOE, D SeriesDokument14 SeitenLubricators LOE, D SeriesNandor KermeciNoch keine Bewertungen

- Dok 1Dokument1 SeiteDok 1Nandor KermeciNoch keine Bewertungen

- Lubricators LOE, D SeriesDokument14 SeitenLubricators LOE, D SeriesNandor KermeciNoch keine Bewertungen

- Promag w400Dokument92 SeitenPromag w400Nandor KermeciNoch keine Bewertungen

- Datalogic SR31 ManualDokument2 SeitenDatalogic SR31 ManualNandor KermeciNoch keine Bewertungen

- GBDokument2 SeitenGBNandor KermeciNoch keine Bewertungen

- GBDokument4 SeitenGBNandor KermeciNoch keine Bewertungen

- ADokument1 SeiteANandor KermeciNoch keine Bewertungen

- Avances de Desarrollos TIC - Simenes - Marzo - 09Dokument65 SeitenAvances de Desarrollos TIC - Simenes - Marzo - 09sacostaNoch keine Bewertungen

- PT4115 LED Step-DownDokument18 SeitenPT4115 LED Step-DownNandor KermeciNoch keine Bewertungen

- BDokument3 SeitenBNandor KermeciNoch keine Bewertungen

- P586gb (Generation C)Dokument28 SeitenP586gb (Generation C)Nandor KermeciNoch keine Bewertungen

- GBDokument2 SeitenGBNandor KermeciNoch keine Bewertungen

- GBDokument6 SeitenGBNandor KermeciNoch keine Bewertungen

- G3 Profibus DP - Technical ManualDokument72 SeitenG3 Profibus DP - Technical ManualNandor KermeciNoch keine Bewertungen

- Goldstar Repair Tips (ET)Dokument11 SeitenGoldstar Repair Tips (ET)Nandor KermeciNoch keine Bewertungen

- Avances de Desarrollos TIC - Simenes - Marzo - 09Dokument65 SeitenAvances de Desarrollos TIC - Simenes - Marzo - 09sacostaNoch keine Bewertungen

- Elcobrandt Microwave Oven Technical TrainingDokument56 SeitenElcobrandt Microwave Oven Technical TrainingNandor KermeciNoch keine Bewertungen

- Datasheet SD6109 PDFDokument10 SeitenDatasheet SD6109 PDFNandor KermeciNoch keine Bewertungen

- Electrical Machines - I Electrical Machines - I: EE 2107 EE 2107Dokument9 SeitenElectrical Machines - I Electrical Machines - I: EE 2107 EE 2107Raihan KhanNoch keine Bewertungen

- Em-Ii Assignment: Excitation of Synchronous GeneratorsDokument3 SeitenEm-Ii Assignment: Excitation of Synchronous GeneratorsZain Ur RahmanNoch keine Bewertungen

- BreakersDokument48 SeitenBreakersdanh17Noch keine Bewertungen

- Lamp IndicatorDokument2 SeitenLamp IndicatorNurdin FahimNoch keine Bewertungen

- S100-NF, S100-GF: Ratings and SpecificationsDokument2 SeitenS100-NF, S100-GF: Ratings and SpecificationsHenry RosaNoch keine Bewertungen

- SM Volvo A25f Articulated Dump TruckDokument23 SeitenSM Volvo A25f Articulated Dump TruckAhmet Kartal100% (2)

- Floating Neutral Impacts in Power DistributionDokument11 SeitenFloating Neutral Impacts in Power DistributiondusktodawnNoch keine Bewertungen

- 52TU Valve PDFDokument3 Seiten52TU Valve PDFdespotovicdejanNoch keine Bewertungen

- Leaflet UG ZS1 DBB Rev 2013 09 enDokument2 SeitenLeaflet UG ZS1 DBB Rev 2013 09 enIvanNoch keine Bewertungen

- Heritage Trail Map Pondicherry PDFDokument2 SeitenHeritage Trail Map Pondicherry PDFjosekrNoch keine Bewertungen

- Arcing Fault Current and The Criteria For Setting Ground Fault Relays in Solidly-Grounded Low Voltage SystemsDokument7 SeitenArcing Fault Current and The Criteria For Setting Ground Fault Relays in Solidly-Grounded Low Voltage SystemsSantanu RoutNoch keine Bewertungen

- Compact Studio Flash: GODOX Photo Equipment Co., LTDDokument6 SeitenCompact Studio Flash: GODOX Photo Equipment Co., LTDsayutiNoch keine Bewertungen

- Push Button FlyerDokument2 SeitenPush Button FlyerskodgeNoch keine Bewertungen

- Fuses Q & ADokument28 SeitenFuses Q & AKhaled RabeaNoch keine Bewertungen

- Contactors MCDokument20 SeitenContactors MCSamuel Martinez RomeroNoch keine Bewertungen

- Data Sheet - KM01Dokument4 SeitenData Sheet - KM01Jose Manuel Carcamo SaezNoch keine Bewertungen

- LFL PDFDokument13 SeitenLFL PDFmangal deo pathak100% (1)

- All Quantities Are Provisional and Subject For RemeasurementDokument13 SeitenAll Quantities Are Provisional and Subject For RemeasurementMatt CerosNoch keine Bewertungen

- Npqs ContentDokument1 SeiteNpqs ContentGaryNoch keine Bewertungen

- FTr3 2000 - 3000 1beDokument4 SeitenFTr3 2000 - 3000 1beAbdellah abdouNoch keine Bewertungen

- Medium-Voltage Electrical System ProtectionDokument8 SeitenMedium-Voltage Electrical System ProtectiontechtricNoch keine Bewertungen

- EEE 314 Conduit Layout Lecture 1 PDFDokument18 SeitenEEE 314 Conduit Layout Lecture 1 PDFAnonymous YGLKp0kK100% (1)

- F0126405 PB OLTCsDokument24 SeitenF0126405 PB OLTCsshahramkh59100% (1)

- Honeywell GLAC01A4J DatasheetDokument52 SeitenHoneywell GLAC01A4J DatasheetFranco MaderaNoch keine Bewertungen

- 180 07 282 04 Cp-M2f-Acr10-41 (Ahu-2-11)Dokument13 Seiten180 07 282 04 Cp-M2f-Acr10-41 (Ahu-2-11)TuấnNoch keine Bewertungen

- Sizing The DOL Motor Starter PartsDokument4 SeitenSizing The DOL Motor Starter Partsat35Noch keine Bewertungen

- Substation DesignDokument7 SeitenSubstation DesignAnkit Patel100% (1)

- Sigmatone: TRIAC Switch To Control High Voltage DevicesDokument2 SeitenSigmatone: TRIAC Switch To Control High Voltage DevicesMariGanesh100% (2)

- ABB Price Book 518Dokument1 SeiteABB Price Book 518EliasNoch keine Bewertungen

- Lista de Precios Nexxt Infrastructure-MINIMOSDokument13 SeitenLista de Precios Nexxt Infrastructure-MINIMOSMarco Antonio RubinaNoch keine Bewertungen