Beruflich Dokumente

Kultur Dokumente

Lida

Hochgeladen von

rakacyu0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

71 Ansichten4 SeitenThe document describes LIDA tubular anodes for cathodic protection, which have high current output over a long life at an economical cost; the anodes come in various sizes and are designed to operate in soils, waters, and mud for up to 30 years; the anodes undergo quality control testing and are lightweight and easy to install.

Originalbeschreibung:

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe document describes LIDA tubular anodes for cathodic protection, which have high current output over a long life at an economical cost; the anodes come in various sizes and are designed to operate in soils, waters, and mud for up to 30 years; the anodes undergo quality control testing and are lightweight and easy to install.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

71 Ansichten4 SeitenLida

Hochgeladen von

rakacyuThe document describes LIDA tubular anodes for cathodic protection, which have high current output over a long life at an economical cost; the anodes come in various sizes and are designed to operate in soils, waters, and mud for up to 30 years; the anodes undergo quality control testing and are lightweight and easy to install.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

LIDA TUBULAR ANODES

ICP 0012

High Current Output

Anode current density in carbonaceous backfill is 100 A/m (9.3 A/ft).

Groundbeds are installed in a wide range of operating conditions: current

output may range from a few amps to 100 amps; soil resistivities vary from a

few hundred to over 20,000 ohm-cm; various backfill material such as

metallurgical coke or calcined petroleum coke (although the use of a high

quality calcined petroleum coke is highly recommended).

Long Life

Each LIDA groundbed assembly is designed for a nominal 20 years life. The

anhydrous mixed metal oxide coating is an excellent electrical conductor

which shows a very high chemical stability, even in environments with pH

values below one.

Economical

Savings versus graphite or silicon iron anodes may be realised on an

installed cost basis. These savings may result from using a smaller hole

diameter, reduced length of cable and overall lower materials and

installation costs.

Cathodic Protection Technology Pte Ltd

No. 4 Tuas Drive 1 Singapore 638671 Tel: (65) 68623551 Fax: (65) 68616436

Email: cptech@singnet.com.sg

http://www.cptech.net

Patented LIDA Cable to Anode Connection

The LIDA connection and seal is not dependent on a mastic or resin

sealant. The electrical connection is made by crimping the tube onto a

section of stripped conductor. The seal is accomplished by plastic

deformation of the tube on the copolymer cable cover.

Quality Assurance

LIDA anodes are assembled in a dedicated facility and undergo 100%

Quality Control testing including electrical and chemical tests on the cable,

helium leak test on the connection and electrochemical tests on the anode

coating.

Easy to Install

LIDA anode cable assemblies are lightweight, rugged, flexible and have an

outside diameter of one inch or less. LIDA strings are easy to transport and

handle.

Background

LIDA mixed metal oxide coated titanium anodes are based on electrode

technology developed in the early 1960's for chlor-alkali production. These

anodes have been used extensively worldwide for cathodic protection in

hundreds of deep and shallow groundbeds.

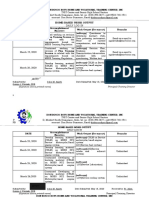

The following table

characteristics:

lists

Designation

Soil

S.T. 2.5/50

S.T. 2.5/100

S.T. 1.6/50

S.T. 1.6/100

Fresh - Brackish Water

FW.T. 2.5/50

FW.T. 2.5/100

FW.T. 1.6/50

FW.T. 1.6/100

Sea Water

SW.T. 2.5/50

SW.T. 2.5/100

SW.T. 1.6/50

SW.T. 1.6/100

Mud

M.T. 2.5/50

M.T. 2.5/100

the

tubular

anodes

available

and

their

Diameter

cm/in

Length

cm/in

Current Output

Amp

2.5/1.00

2.5/1.00

1.6/0.63

1.6/0.63

50/19.7

100/39.4

50/19.7

100/39.4

4.00

8.00

2.50

5.00

2.5/1.00

2.5/1.00

1.6/0.63

1.6/0.63

50/19.7

100/39.4

50/19.7

100/39.4

4.00

8.00

2.50

5.00

2.5/1.00

2.5/1.00

1.6/0.63

1.6/0.63

50/19.7

100/39.4

50/19.7

100/39.4

25

50

15

30

2.5/1.00

2.5/1.00

50/19.7

100/39.4

2-4 (see note 5)

4-8

Note:

1)

2)

3)

4)

5)

The 1.6cm (0.63") diameter tubular anodes are assembled on LIDA

EPR/CSPE 16mm (6 AWG) cable.

The 2.5cm (1") diameter tubular anodes are assembled on LIDA

EPR/CSPE 50mm (1/0 AWG) cable.

Anodes installed in soil or fresh water are operated for a nominal

design life of 30 years. SW.T. anodes are operated in flowing seawater

for a 20 years nominal design life. Anodes installed in brackish water

or mud are operated for a 20 years nominal design life.

All anodes are installed with protective PTFE plastic sleeves on the

cable extending approx. 10cm from both anode ends.

The performance of mixed metal oxide anodes in mud is temperature

dependent. Low temperature applications should be discussed with

the CP Tech Engineer.

How to Order LIDA

When ordering LIDA anodes, please specify the following:

Type of assembly (multiple or single anode per cable)

Anode type (e.g. S.T. 1.6/50)

Number of anodes per cable

End to end spacing between anodes along the cable

Cable tail (above the top anode)

Total cable length (sum of lengths of anodes, spaces and tail)

Current output

Electrolyte details

Das könnte Ihnen auch gefallen

- Grounding and BondingDokument47 SeitenGrounding and BondingCharles BenwariNoch keine Bewertungen

- Electrodynamics Class NotesDokument237 SeitenElectrodynamics Class NotesSwashy Yadav80% (5)

- Modular Transfomer Substation PDFDokument12 SeitenModular Transfomer Substation PDFrakacyuNoch keine Bewertungen

- Modular Transfomer Substation PDFDokument12 SeitenModular Transfomer Substation PDFrakacyuNoch keine Bewertungen

- Modular Transfomer Substation PDFDokument12 SeitenModular Transfomer Substation PDFrakacyuNoch keine Bewertungen

- Miller 652 and 812 Owners Manualo278aj - MilDokument44 SeitenMiller 652 and 812 Owners Manualo278aj - MilrobertoarellanocastiNoch keine Bewertungen

- Arc Welding ElectrodesDokument6 SeitenArc Welding ElectrodeswaleedyossefNoch keine Bewertungen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Subsea Pipeline Design Report.Dokument26 SeitenSubsea Pipeline Design Report.Luke6nNoch keine Bewertungen

- Saudi Arabian Oil Company: NotesDokument1 SeiteSaudi Arabian Oil Company: Noteshany mohamedNoch keine Bewertungen

- Catalogo de Partes Compresor Ingersoll Rand PDFDokument34 SeitenCatalogo de Partes Compresor Ingersoll Rand PDFHarold Joel Zurita LinaresNoch keine Bewertungen

- Esab DublexDokument8 SeitenEsab DublexSuphi YükselNoch keine Bewertungen

- Olex Arial CatalogueDokument15 SeitenOlex Arial CatalogueMike WesleyNoch keine Bewertungen

- Caltex Lubricants Product Guide 2016Dokument193 SeitenCaltex Lubricants Product Guide 2016Arsalan Badar WastiNoch keine Bewertungen

- Lincoln Vantage 300 CaracterísticasDokument8 SeitenLincoln Vantage 300 CaracterísticasJean MunozNoch keine Bewertungen

- Ponchon Savarit MethodDokument34 SeitenPonchon Savarit Methodppga410100% (7)

- MODULE No. E-14: Cathodic ProtectionDokument32 SeitenMODULE No. E-14: Cathodic ProtectionLâm Thanh100% (1)

- Spec - Ohe - Cat (Cu MG) 0120 (11 - 12Dokument21 SeitenSpec - Ohe - Cat (Cu MG) 0120 (11 - 12hardeep08Noch keine Bewertungen

- Prysmian Draka Cable Catalogue NEK606 BFOU RFOUDokument82 SeitenPrysmian Draka Cable Catalogue NEK606 BFOU RFOUmr3478Noch keine Bewertungen

- BHEL - Agitator Specification PDFDokument68 SeitenBHEL - Agitator Specification PDFRiyaz100% (1)

- Lida Tubular AnodesDokument2 SeitenLida Tubular AnodesDivisión Petróleo Gas y MineríaNoch keine Bewertungen

- Corrosion: Corrosion ControlVon EverandCorrosion: Corrosion ControlL L ShreirBewertung: 5 von 5 Sternen5/5 (1)

- Surgical DiathermyDokument27 SeitenSurgical DiathermyNimi Batubo100% (1)

- Lida Tubular Anodes PDFDokument4 SeitenLida Tubular Anodes PDFVCNoch keine Bewertungen

- Mixed Metal Anodes Data Sheet: Pipeline Maintenance LimitedDokument5 SeitenMixed Metal Anodes Data Sheet: Pipeline Maintenance LimitedDotty RoseNoch keine Bewertungen

- Corrpro Magnesium AnodesDokument4 SeitenCorrpro Magnesium Anodeswhah11Noch keine Bewertungen

- 12730729302.0 Impressed Current Cathodic Protection SectionDokument58 Seiten12730729302.0 Impressed Current Cathodic Protection SectionAby BabuNoch keine Bewertungen

- Is 12560Dokument10 SeitenIs 12560Srikanth VoletiNoch keine Bewertungen

- MMO Wire AnodesDokument2 SeitenMMO Wire AnodesCosimo TermiteNoch keine Bewertungen

- CopperClad Wire and StrandDokument20 SeitenCopperClad Wire and Strandpriyanka236Noch keine Bewertungen

- 1.5-1 MMO Tubular AnodeDokument2 Seiten1.5-1 MMO Tubular Anodealisoltani100% (1)

- 12730729302.0 Impressed Current Cathodic Protection SectionDokument58 Seiten12730729302.0 Impressed Current Cathodic Protection SectionAnonymous HsNodUwz100% (1)

- Solid High Silicon Cast Iron Anode: Impressed Current Cathodic Protection (ICCP)Dokument2 SeitenSolid High Silicon Cast Iron Anode: Impressed Current Cathodic Protection (ICCP)Fahmi AtriadiNoch keine Bewertungen

- Spec - Ohe - Cat (Cu MG) 0120 (11 - 12 PDFDokument21 SeitenSpec - Ohe - Cat (Cu MG) 0120 (11 - 12 PDFanuj sharmaNoch keine Bewertungen

- 1.10 Mixed Metal Oxide Tubular AnodesDokument2 Seiten1.10 Mixed Metal Oxide Tubular AnodesalisoltaniNoch keine Bewertungen

- Encorewire THHN SseDokument1 SeiteEncorewire THHN SsealvinchriscgNoch keine Bewertungen

- EEE Dept DC Machines LabDokument22 SeitenEEE Dept DC Machines LabProject Engineer ElectricalNoch keine Bewertungen

- PetroCor BrochureDokument14 SeitenPetroCor BrochuredediodedNoch keine Bewertungen

- Lida Tubular AnodesDokument2 SeitenLida Tubular AnodesMarioNoch keine Bewertungen

- Marine FlexenDokument67 SeitenMarine FlexenpayaljeevaNoch keine Bewertungen

- Design and Analysis of Double Gate MOSFET Devices Using High-K DielectricDokument8 SeitenDesign and Analysis of Double Gate MOSFET Devices Using High-K Dielectricabhimanyu_bhate6264Noch keine Bewertungen

- Mmo Anodes DatasheetDokument5 SeitenMmo Anodes Datasheetanonymous542Noch keine Bewertungen

- Encorewire THHN SseDokument1 SeiteEncorewire THHN SseFernandoGabrielNoch keine Bewertungen

- Ranger2 TerminationsDokument6 SeitenRanger2 TerminationsMoisésIxbaNoch keine Bewertungen

- Bs 6883 657tq Type Swa Cable 1Dokument5 SeitenBs 6883 657tq Type Swa Cable 1shipbuilderNoch keine Bewertungen

- Stratco Selection Use and MaintenanceDokument6 SeitenStratco Selection Use and MaintenanceAmjad PervazNoch keine Bewertungen

- Effects of High-K Dielectrics With Metal Gate For Electrical Characteristics of Soi Tri-Gate Finfet TransistorDokument4 SeitenEffects of High-K Dielectrics With Metal Gate For Electrical Characteristics of Soi Tri-Gate Finfet TransistordebmallyNoch keine Bewertungen

- ICCPDokument4 SeitenICCPVyas SrinivasanNoch keine Bewertungen

- Catalog PDF Related Equipment Cathodic Protection Pipeline SuppliesDokument2 SeitenCatalog PDF Related Equipment Cathodic Protection Pipeline SuppliesrudrakrNoch keine Bewertungen

- EMI Filters - CeramicDokument81 SeitenEMI Filters - CeramicmetamendNoch keine Bewertungen

- LS Cast Resin Transformers CatalogueDokument16 SeitenLS Cast Resin Transformers CatalogueaderezossNoch keine Bewertungen

- 03 Web Xlpe Guide enDokument8 Seiten03 Web Xlpe Guide endes1982100% (1)

- (2001) Impressed Current Retrofits On Offshore PlatformsDokument15 Seiten(2001) Impressed Current Retrofits On Offshore PlatformsGinka WidiantoNoch keine Bewertungen

- URB25Dokument4 SeitenURB25malika_00Noch keine Bewertungen

- Future MOSFET Devices Using High-K (TiO2) DielectricDokument6 SeitenFuture MOSFET Devices Using High-K (TiO2) DielectricIJRASETPublicationsNoch keine Bewertungen

- Copper-Nickel Products: Copper-Nickel Tubing Fittings, Flanges, Sheet, Plate and RodDokument70 SeitenCopper-Nickel Products: Copper-Nickel Tubing Fittings, Flanges, Sheet, Plate and RodchocohmxNoch keine Bewertungen

- Encorewire THHN SseDokument1 SeiteEncorewire THHN SsepganoelNoch keine Bewertungen

- Conector y Ubs TationDokument4 SeitenConector y Ubs Tationvvc737Noch keine Bewertungen

- Clipsal ConduitDokument66 SeitenClipsal Conduitalexwongks611850% (2)

- IntroductionDokument11 SeitenIntroductionAnu ChNoch keine Bewertungen

- Hanwha FCCL Tech InfoDokument3 SeitenHanwha FCCL Tech InfoChowkidar Chandru GowdaNoch keine Bewertungen

- 6.1 - Distribution Riser Support Cat DDokument3 Seiten6.1 - Distribution Riser Support Cat DHeather HertzNoch keine Bewertungen

- What Is Rogers AD255C PCBDokument6 SeitenWhat Is Rogers AD255C PCBjackNoch keine Bewertungen

- ConsumablesDokument28 SeitenConsumablesadeoye_okunoyeNoch keine Bewertungen

- Type TC-VFDDokument2 SeitenType TC-VFDCristhJuliangNoch keine Bewertungen

- Terminations Cold ContractileDokument2 SeitenTerminations Cold ContractileAlberto UchihaNoch keine Bewertungen

- Power MVDokument39 SeitenPower MVFani Dwi PutraNoch keine Bewertungen

- Oil&Gas Draka MOG 2015 Catalog v16 With Glands UpdatedeverythingDokument96 SeitenOil&Gas Draka MOG 2015 Catalog v16 With Glands UpdatedeverythingJimmy F HernandezNoch keine Bewertungen

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PVon EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNoch keine Bewertungen

- Tehnicka Preporuka 5 PDFDokument25 SeitenTehnicka Preporuka 5 PDFDuško TovilovićNoch keine Bewertungen

- TCS System Overview PDFDokument2 SeitenTCS System Overview PDFrakacyuNoch keine Bewertungen

- TCS Video Interfon Model AVC11010-uk PDFDokument12 SeitenTCS Video Interfon Model AVC11010-uk PDFrakacyuNoch keine Bewertungen

- Guide InternationalDokument76 SeitenGuide InternationalRosibel Rios RenteriaNoch keine Bewertungen

- Kablovi PP00 PDFDokument2 SeitenKablovi PP00 PDFrakacyuNoch keine Bewertungen

- Gromobranske Instalacije PDFDokument3 SeitenGromobranske Instalacije PDFrakacyuNoch keine Bewertungen

- Eki 1522 PDFDokument1 SeiteEki 1522 PDFrakacyuNoch keine Bewertungen

- Yokogawa DTSX PDFDokument4 SeitenYokogawa DTSX PDFrakacyuNoch keine Bewertungen

- TR30 RTD PDFDokument8 SeitenTR30 RTD PDFrakacyuNoch keine Bewertungen

- ABB Glossary 12.10.2012Dokument52 SeitenABB Glossary 12.10.2012mauro_mac1156Noch keine Bewertungen

- Reles Finder CatalogoDokument4 SeitenReles Finder CatalogoAnonymous 8yIYmMH146Noch keine Bewertungen

- Tmax UL Technical Catalog PDFDokument288 SeitenTmax UL Technical Catalog PDFrakacyuNoch keine Bewertungen

- Marking Electrical Equipment Ex PDFDokument1 SeiteMarking Electrical Equipment Ex PDFrakacyuNoch keine Bewertungen

- Telpro Data Sheets 2014 PDFDokument26 SeitenTelpro Data Sheets 2014 PDFrakacyuNoch keine Bewertungen

- PS300 Brosura PDFDokument2 SeitenPS300 Brosura PDFrakacyuNoch keine Bewertungen

- Abb NGC 8206 DS - 2101164-En PDFDokument8 SeitenAbb NGC 8206 DS - 2101164-En PDFrakacyuNoch keine Bewertungen

- Tmax UL Technical Catalog PDFDokument288 SeitenTmax UL Technical Catalog PDFrakacyuNoch keine Bewertungen

- Telpro Data Sheets 2014 PDFDokument26 SeitenTelpro Data Sheets 2014 PDFrakacyuNoch keine Bewertungen

- TR30 RTD PDFDokument8 SeitenTR30 RTD PDFrakacyuNoch keine Bewertungen

- NGC8200 User's ManualDokument300 SeitenNGC8200 User's ManualpalebejoNoch keine Bewertungen

- Telpro Data Sheets 2014 PDFDokument26 SeitenTelpro Data Sheets 2014 PDFrakacyuNoch keine Bewertungen

- Contavac Pumps - PIII1 PDFDokument18 SeitenContavac Pumps - PIII1 PDFrakacyuNoch keine Bewertungen

- Lewa Smart Control - enDokument4 SeitenLewa Smart Control - enrakacyuNoch keine Bewertungen

- D1-170 Ecosmart en PDFDokument8 SeitenD1-170 Ecosmart en PDFrakacyuNoch keine Bewertungen

- Buhler Rice Processing Catalogue Global 2015 PDFDokument32 SeitenBuhler Rice Processing Catalogue Global 2015 PDFdoniNoch keine Bewertungen

- D Aerator SS6000 Liquid Settlement System de Airing Unit SSB0011BDokument1 SeiteD Aerator SS6000 Liquid Settlement System de Airing Unit SSB0011BMiguel Angel BoldúNoch keine Bewertungen

- What Is Pump Priming and Why It Is Required With PDFDokument9 SeitenWhat Is Pump Priming and Why It Is Required With PDFAnas Al’BazzazNoch keine Bewertungen

- TC1044S Charge Pump DC-TO-DC Voltage Converter: Features General DescriptionDokument11 SeitenTC1044S Charge Pump DC-TO-DC Voltage Converter: Features General DescriptionAlex Lorz BalboaNoch keine Bewertungen

- PWM Control IC: BM1P107FJDokument30 SeitenPWM Control IC: BM1P107FJArokiaraj RajNoch keine Bewertungen

- FMC Flowline Products & Services Catalog PDFDokument80 SeitenFMC Flowline Products & Services Catalog PDFsekead67% (3)

- Cho Loss Model Radial TurbineDokument13 SeitenCho Loss Model Radial TurbineNicolasNoch keine Bewertungen

- Isv5 0-Web PDFDokument2 SeitenIsv5 0-Web PDFperulapiaNoch keine Bewertungen

- MONTZ Main Cataloque PDFDokument69 SeitenMONTZ Main Cataloque PDFswaminathanNoch keine Bewertungen

- TGEL BatteryDokument4 SeitenTGEL BatteryharishwarreddyNoch keine Bewertungen

- 1 Home Base Work March 19-MRCH 31Dokument3 Seiten1 Home Base Work March 19-MRCH 31Celso AmotoNoch keine Bewertungen

- Plumbing - HVAC August 2010Dokument48 SeitenPlumbing - HVAC August 2010aurelian177100% (1)

- Transformers and Rectifiers IndiaDokument26 SeitenTransformers and Rectifiers IndiaPravesh RaoNoch keine Bewertungen

- Mic Electronics Research ReportDokument17 SeitenMic Electronics Research ReportSudipta BoseNoch keine Bewertungen

- 37, 41, 42MT SSL Solenoids PDFDokument4 Seiten37, 41, 42MT SSL Solenoids PDFjuanNoch keine Bewertungen

- Heat Transfer ActivityDokument4 SeitenHeat Transfer ActivityMark Angelo UyNoch keine Bewertungen

- Module3 PDFDokument174 SeitenModule3 PDFAhallya JaladeepNoch keine Bewertungen

- IRF460 Hexfet Transistors THRU-HOLE (TO-204AA/AE) 500V, N-CHANNELDokument8 SeitenIRF460 Hexfet Transistors THRU-HOLE (TO-204AA/AE) 500V, N-CHANNELJoseph SantanaNoch keine Bewertungen

- Sungrow Hybrid SH5K-30 5kW Inverter ManualDokument154 SeitenSungrow Hybrid SH5K-30 5kW Inverter Manualraymknd gerard macarineNoch keine Bewertungen

- 3 Section-5 Technical Specification (Annexure-B)Dokument102 Seiten3 Section-5 Technical Specification (Annexure-B)Umamaheshwarrao VarmaNoch keine Bewertungen