Beruflich Dokumente

Kultur Dokumente

pg37 44

Hochgeladen von

bentsopoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

pg37 44

Hochgeladen von

bentsopoCopyright:

Verfügbare Formate

Centro-Matic Automated Lubrication Systems

System Controls

Selecting the right controls for your automated lubrication system is one of the last steps in the design process.

Several different models may be chosen to control power-operated pumps, depending on the degree of automation

and monitoring required. Your Lincoln representative will assist you in specifying the correct model.

Options range from simple timers to fully-automated system controllers and monitors. Basic timers allow you to set the

interval between lubrication cycles. More sophisticated monitors control the frequency of lubrication, oversee system

performance and can sense lubricant flow to each bearing while showing system status and alarms on a LCD display

panel. Monitors may be interfaced with machine control systems to protect your equipment from harm.

You may customize your installation with air and lubricant filters to prolong system life, pressure gauges for monitoring,

shut-off valves to ease future maintenance and even automated filling systems to utilize bulk lubricant storage.

All of these possibilities, and more, have made Lincoln Automated Lubrication Systems the choice of industry for over

80 years.

Model 84501 Program TimerSolid State

Designed to control the lubrication cycle frequency of air-operated single-stroke

pumps. Timer turns pump on/off at programmed intervals via a 3-way or 4-way

air solenoid valve (not included) installed in the air line to pump.

Off Time

(Cycle Time)

Min

Max

20 Sec.

24 Hrs.

On Time

(Pumping Time)

Min

Max

1 Min.

10 Sec.

24 Sec.

Built-In Program Options

3 Hr. Program

Memory

Yes

No

Prelube

Function

Yes

No

Power

Approvals

Requirements

120/230 VAC

50/60 Hz

120 VAC, 5 Amps

UL, CSA 230 VAC, 1.5 Amps

Ambient Operating

Temperature Range

Enclosure

Rating

Dimensions-in./mm

Height Width Depth

NEMA #1

8

210

6

173

Switch

Capacity

4

125

Minimum

Maximum

0F

-18C

130F

54C

Note:

Refer to Technical Manual for a full explanation of available program options.

Model 84511 Economy Timer for

Single Stroke Pumps

Uses a timing motor, cam and switch to turn pump off and on. NEMA 1

enclosure, UL and CSA listed. Switch capacity 10 amps non-inductive.

Off Time

(Cycle Time)

Min

Max

5 Min.

1 Hr.

On Time

(Pumping Time)

Min

Max

30 Sec.

90 Sec.

Power

Approvals

Requirements

Switch

Capacity

120 VAC, 60 Hz

10 Amps

UL, CSA

Note: Off-time selectable in 5 minute intervals.

Rating

NEMA 1

Enclosure

Dimensions - in. / mm

Height

Width

Depth

5 / 127

3 / 82.5

3 / 89

37

Centro-Matic Automated Lubrication Systems

System Controls

Model 84015 Timer12-24V DC

Solid-state microprocessor-based controller for automated lubrication systems on

mobile equipment or where AC power is not available. Rugged construction with

liquid- and dust-tight enclosure. Includes manual push-button for remote initiation

of a lube cycle.

Off Time**

(Cycle Time)

Min.

Max.

2.5 Min.

* Less load.

Rating

NEMA 12

Fixed On Time

(Pumping Time)

Power

Requirements

Switch

Capacity

75 Sec.

10-30 VDC

25 MA*

5 Amps

80 Min.

** Available selections are 2.5, 5, 10, 20, 40 or 80 minutes.

Enclosure

Dimensions-in. / mm

Depth

Height

Width

5 / 133

3 / 79

Ambient Operating Temperature Range

3 / 76

Minimum

Maximum

0F / -18C

131F / 55C

Model 85520 Programmable Controller

Microprocessor-controlled, 120 volt AC unit is fully programmable. Controller has a

wider off-time range than timers, features an adjustable pressure switch (280-3000

psi) and a memory switch to turn pre-lube option on or off.

Off Time

(Cycle Time)

Min.

Max.

30 Sec.

Rating

NEMA 12

30 Hours

On Time (Pumping/

Alarm Time)

Min.

Max.

30

2

Sec.

Min.

Power

Requirements

21-30 DC

100 MA*

Enclosure

Dimensions-in. / mm

Depth

Height

Width

7 / 191

4 / 125

3 / 89

Switch Capacity

Inductive Load at 30VDC

Load Relay

Alarm Relay

2

2

Amps

Amps

Ambient Operating Temperature Range

Minimum

Maximum

0F / -18C

130F / 55C

* Less load.

Model 85525 Programmable Controller

Same as Model 85520 except includes pressure switch and mounting brackets.

Model 85535 System Controller24V DC

Same as Model 85520 except is a 24-volt DC.

38

Centro-Matic Automated Lubrication Systems

System Controls

Model 85530 Lubrication System Controller

Controls lubrication frequency and monitors supply line pressure. The LCD displays

operating status.

Lube Cycle

Timer Mode

Counter Mode

Off-Time

Off-Counts

Min.

Max.

Min.

Max.

1

Minute

9,900

Minutes

1

Count

99,000

Counts

Max.

Count

Rate*

Pumping Time

Before Alarm

Min.

Max.

30/Sec.

@ 50%

Duty Cycle

1

Minute

99

Minutes

* Minimum duration of count signal is 33 milliseconds.

Power Requirements (less load)

Voltage

Current

120 VAC, 50/60 Hz

230 VAC, 50/60 HZ

24 VDC

85 MA

45 MA

250 MA

Pump,

Solenoid,

or Alarm

Capacity

Ambient

Temperature

Range

Rating

360 VA

32 to 122F

0 to +50 C

NEMA

12

5 Amps

Enclosure

Dimensions-in. / mm

Height Width Depth

9

241

8

227

4

105

Note: Model 85530 is CSA/NRTL approved.

Model 85209 Panel Mounted

Pneumatic Control System

Panel mounted units control lubrication frequency and monitor supply line pressure.

Includes Model 85530 Controller (specifications above), Model 69630 Pressure

Switch and solenoid-operated air valve.

Lube Cycle

Timer

Mode

Off Time

Min.

Max.

1

Minute

9,900

Minutes

Counter

Mode

Off Counts

Min.

Max.

1

Count

Power Requirements

Current

Voltage

(less load)

120 VAC, 60 Hz

110 VAC, 50 Hz

47 VA

99,000

Counts

Max.

Count

Rate

30/

Sec.

External

Alarm

Load

Capacity

360 VA

Pumping

Time

Before

Alarm

Min.

Max.

1

Minute

99

Minutes

Ambient

Temperature

Range

32 to 122F

0 to +50C

Connections

Air

Lube

"

"

NPTF(F) NPTF(F)

Panel

Dimensions

in. / mm

Height

Width

12

305

18

464

Model 85208

Same as Model 85209 except 220 VAC, 50-60 Hz power.

39

Centro-Matic Automated Lubrication Systems

System Controls

Model 85500 System Sentry II

The ultimate automated lubrication system controller/monitor now features greater

monitoring accuracy with less sensitivity to lubricant flow rates, feed line length, or

bearing back pressure. System Sentry II is always on the job, making sure that every

lube point is lubricated when its supposed to be.

Solid-state controller with LCD status display and 16-button keypad for

system programming

Controls up to two pumps with as many as two lube zones per pump

Fully programmable monitoring and alarm functions

Be set up to monitor every lube point for lubricant flow during each lubrication

event

Easy to understand prompts reported by simple English language messages in

real time

Some functions require optional accessories. See chart on page 38. Use a

maximum or 48 sensors and three accessory Sensor Boards (order separately16

sensors per board) to monitor lube points. For more than 48 sensors, use Model

85510 Satellite plus additional Sensor Boards for a maximum of 1536 lube points.

Lube Cycle

Timer Mode

Off-Time

Min.

Max.

1

Second

Max.

Count

Rate*

Counter Mode

Off-Counts

Min.

Max.

9,900

Minutes

1

Count

99,000

Counts

Pumping Time

Before Alarm

Min.

Max.

30/Sec.

1

@ 50%

Second

Duty Cycle

Net

Wt.

99

18 lbs.

Minutes 8.1 kg

* Minimum duration of count signal is 33 milliseconds.

Power Requirements (less load)

Voltage

Current

120 VAC, 50/60 Hz

230 VAC, 50/60 HZ

24 VDC

250 MA*

125 MA*

600 MA*

Pump,

Solenoid,

or Alarm

Capacity

Ambient

Temperature

Range

Rating

360 VA

32 to 122F

0 to +50 C

NEMA

12

5 Amps

Note: Model 85500 is CSA/NRTL approved.

* No external load, no sensors.

40

Enclosure

Dimensions-in. / mm

Height Width Depth

11

241

14

227

4

105

Centro-Matic Automated Lubrication Systems

System Controls

Model 247333 Pressure Transducer

Pressure Transducer signals actual system pressure via LCD display of System

Sentry II. Comes with 72 inch (1.8m) shielded 24-gauge connecting wire.

Maximum length of wire between transducer and monitor is 30 (9.1m) feet.

Range Accuracy

0 to

4000 psi

276 bar

1%

Proof

Pressure

Connection

Ambient

Temp.

Input

7500 psig

" NPT

-20 to 180 F

517 bar Male Thread -29 to 82 C

Voltage

Output

Offset

1-6

VDC

1

VDC

10 to

30

VDC

Enclosure

NEMA 4X

Rating

300 Series

Stainless

Steel

Model 250365 Sensor Board

Plug-in accessory board used with Model 85500 that allows the attachment of up

to 16 lube flow sensors. (Model 85500 comes without boards installed and can

hold up to a total of three.)

Sensor Assemblies

Sensor assemblies consist of a check body and lube sensor with attached 30'

cable. Cables are epoxy potted into the sensors for a watertight seal. Sensors

have a 38" pipe thread for conduit connection and a Viton O-ring seal. Check

bodies terminate in a 18" NPTF male thread for attachment to a bearing or other

lubricant inlet. Maximum working pressure 6,000 psi (414 bar). Maximum wire

run from sensor to monitor is 500 feet (152m).

Model

Description Construction

Lubricant

Temp. Range

Straight Sensor

Assembly

Brass Sensor

90 Sensor & Plated Steel

Check Body

250490

Assembly

Min. Flow

Per Event

Inlet/

Outlet

Min. Interval

Between Lube

Flow Event

1/8"

30 Seconds

250400

.004 cu.in./.066 cc

@ 32F / 0 C to

125F / 52C

32 to 145 F

0 to 63 C

Straight Sensor

316

.008 in3 / .131cc

250500

Assembly

Stainless Steel

@ 126F / 53C to

90 Sensor

Sensor &

145F / 63C

250590

Assembly

Check Body

Model 243100 Sensor Wire

100 foot (30.5 meters) coil of two conductor 22-gauge wire for connecting sensors

to monitor. Maximum length of wire between sensor and monitor is 500 feet

(152 meters).

41

Centro-Matic Automated Lubrication Systems

System Controls

Use This Guide to Select Accessories for

Model 85500 System Sentry II

Function

Lube Controller

1 Pump, 1 Zone

Pressure

Switch

#69630

Pressure

Transducer

#247333

Sensor

Board

#250365

Sensors

Sensor Wire

#243100 (100')

Note 2

Note 3

Optional 1

Optional 1

Required

Required 1

(3 Max.)

Required 2

(1 per Pump)

Note 1

Lube Controller,

1 Pump, 1 per Zone

Up to 3 Zones

Lube Controller,

2 Pumps, 1 Zone

Per Pump

No

Lube Controller,

2 Pumps, Up to 2

Zones Per Pump

Required

1 per Zone

(4 Max.)

Required 2

(1 per Pump)

Lube Point

Monitoring

48 Points

Required

1 per each

16 Sensors

Required

1 per

Lube Point

Required

Quantity

As Needed

Lube Point

Monitoring

> 48 1536 Points

Required

1 per each

16 Sensors

Required

1 per

Lube Point

Required

Quantity

As Needed

Note 1: Controller may be operated without a pressure switch or pressure transducer but will not be

able to monitor and alarm for lube system pressure failures.

Note 2: Sensors include 30' (9.1m) cable pigtail. Select brass/plated steel or stainless steel sensors in

straight or 90 configuration as required.

Note 3: Maximum distance between monitor and sensor is 500' (152 meters).

Note 4: Satellite monitor includes one 250365 sensor board and accepts two additional boards

(optional) for connection of up to 48 sensors per satellite. Maximum 31 satellites per system.

42

Centro-Matic Automated Lubrication Systems

System Controls

Electric Solenoid-Operated Air Valves

Electrical Characteristics

Power

Inrush Holding Air

Model Type

Requirements Current Current Inlet/

Amps Amps Outlet

110 VAC, 50 Hz

350244

120 VAC, 60 Hz .11

.07

8.4 VA

4-Way

220 VAC, 50 Hz

350245

240 VAC, 60 Hz .055

.035

1

8.4 VA

4"

110 VAC, 50 Hz

NPT(F)

350241

120 VAC, 60 Hz .11

.07

8.4 VA

220 VAC, 50 Hz

350242

240 VAC, 60 Hz .055

.035

3-Way

8.4 VA

12 VDC

350282

1

6 Watts

8"

N/A

N/A

24 VDC

NPT(F)

350283

6 Watts

3

120V, 60 Hz

8"

68586 2-Way

.2

.1

NPT(F)

12 VA

1

4"

24 VDC

274398 3-Way

N/A

N/A

8.5 Watts

NPT(F)

3

110 VAC, 50 Hz

8"

244727 3-Way 120 VAC, 60 Hz .12

.09

NPT(F)

11 VA

Ambient

Cv

Max.

Conduit

Temperature Factor Pressure Connection

Range

psi / bar

0 to 120F

-18 to 49C

1.2

2" NPS(F)

150

10.3

.18

0 to 140F

-18 to 60C

N/A

2.4

" NPT(F)

1

2

.5

0 to 120F

-18 to 49C

4.4

N/A

2" NPT(F)

Model 249605 Sealed Cycle Timer

Sealed timer attaches to Lincoln 16:1 Hydraulic Pumps and generates timed pulse

signal to control pump reciprocating cycle rate.

Power

Requirement

24 VDC

Cycle Rate/Minute

Min.

Max.

6

60

Model 84360 System Alarm

System Alarm includes Model 84297 Reset Timer and Model 69630 Pressure

Switch. Signals alarm if system pressure is not detected within preset intervals.

Power

Requirement

(less load)

115 VAC, 60 Hz

7.5 VA

Count Down Interval

Before Alarm Signal

Min.

Max.

9 Min.

5 Hours

Reset

Timer

Enclosure

Lube

Connection

Increasing Pressure

Switch Adjustment

psi / bar

Min.

Max.

NEMA 1

" NPTF(F)

280 / 19 3000 / 207

43

Centro-Matic Automated Lubrication Systems

System Controls

End-of-Line Monitors

Designed to detect system pressure utilizing normally open or normally closed

switch.

Model

Switch

Rating

Operating Range - psig / bar

Min.

Max.

83898

125, 250

1200 / 83

2500 / 172

83899

480 VAC,

15 Amps

700 / 48

1150 / 79

Lube

Inlet

Dimensions - in / mm

Conduit

Height

Width Connection

"

NPTF(F)

5 / 146

" NPSM

2 / 57

Model 83354 Signal Monitor

Designed to provide visual and audible indication of system operation and failure.

Utilizes signal from system controller. Includes Model 69606 Alarm Horn mounted

on enclosure door.

Power

Requirement

Power

On

115 VAC

50/60 Hz

35 VA

Indicator Lamps

Lube

System

System On Failure

Green

Amber

Red

Dimensions - in / mm

Audible

Alarm

Height

69606 Horn

(included)

10

254

Width Depth

8

203

6

152

Note: Lamps and horn are U.L. listed.

Model 69606 Alarm Horn

Use with controllers or System Alarm Model 84360 for audible failure signal.

Model

Power Requirement

69606

120 VAC, 50/60 Hz, 15 VA

Note: U.L. listed.

Model 69630 Pressure Switch

Senses supply line pressure rise/fall to signal system operation to controller or

system alarm.

Switch Capacity

Type

AC

10 Amps at

Single

Contact

DC

Adjustable Range - psig / bar

Decreasing

Increasing

Min. Max. Min. Max.

Lube

Electrical

" hole

15 Amps @ 6 VDC

5 Amps @ 24 VDC

125, 250 or

.03 Amps @

480 VDC

250 VDC

250

17

2775

191

280

19

3000

207

Note: Pressure switch has a NEMA 3 housing and UL listed switching elements.

44

Connections

" NPT(F)

for "

conduit

connector

Das könnte Ihnen auch gefallen

- Steering Poti Set UpDokument2 SeitenSteering Poti Set UpbentsopoNoch keine Bewertungen

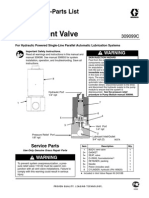

- Manual HydraulicVentValveDokument4 SeitenManual HydraulicVentValvebentsopoNoch keine Bewertungen

- 5 Fuse & Relay For ChassisDokument7 Seiten5 Fuse & Relay For ChassisbentsopoNoch keine Bewertungen

- GL-11 Injector: InstructionsDokument2 SeitenGL-11 Injector: InstructionsbentsopoNoch keine Bewertungen

- 309099c - Vent ValveDokument2 Seiten309099c - Vent ValvebentsopoNoch keine Bewertungen

- 308953e - GL-1Dokument4 Seiten308953e - GL-1bentsopoNoch keine Bewertungen

- pg37 44Dokument8 Seitenpg37 44bentsopoNoch keine Bewertungen

- Centro-Matic Automated Lubrication Systems: Flowmaster Hydraulic PumpDokument1 SeiteCentro-Matic Automated Lubrication Systems: Flowmaster Hydraulic PumpbentsopoNoch keine Bewertungen

- 3a0522b - Simple Pressure ReliefDokument4 Seiten3a0522b - Simple Pressure ReliefbentsopoNoch keine Bewertungen

- Centro-Matic automated lubrication systems with electric grease pumps and manual oil pumpDokument1 SeiteCentro-Matic automated lubrication systems with electric grease pumps and manual oil pumpbentsopoNoch keine Bewertungen

- Centro-Matic Automated Lubrication Systems: Flowmaster Electric PumpsDokument2 SeitenCentro-Matic Automated Lubrication Systems: Flowmaster Electric PumpsbentsopoNoch keine Bewertungen

- pg37 44Dokument8 Seitenpg37 44bentsopoNoch keine Bewertungen

- Centro-Matic Automated Lubrication Systems: Hydraulic-Powered Grease PumpsDokument1 SeiteCentro-Matic Automated Lubrication Systems: Hydraulic-Powered Grease PumpsbentsopoNoch keine Bewertungen

- Centro-Matic Automated Lubrication Systems: Manual Grease PumpsDokument1 SeiteCentro-Matic Automated Lubrication Systems: Manual Grease PumpsbentsopoNoch keine Bewertungen

- Centro-Matic Automated Lubrication Systems: Manual Grease PumpsDokument1 SeiteCentro-Matic Automated Lubrication Systems: Manual Grease PumpsbentsopoNoch keine Bewertungen

- Atf 110-5Dokument3 SeitenAtf 110-5bentsopoNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- ABB PowerCubeDokument18 SeitenABB PowerCubemixed25465688Noch keine Bewertungen

- Ot8gb 1SCC301020C0201 21-08Dokument186 SeitenOt8gb 1SCC301020C0201 21-08BilalNoch keine Bewertungen

- Airtec Pneumatic ValveDokument9 SeitenAirtec Pneumatic ValveArif BinorikaNoch keine Bewertungen

- STW21NM50N MosfetDokument16 SeitenSTW21NM50N MosfetrigowNoch keine Bewertungen

- Infinity-Reference5760 5761 CarampDokument33 SeitenInfinity-Reference5760 5761 CarampJeff ReikenNoch keine Bewertungen

- Preliminary: 01/05/2023 1.0E Initial Version Published. Package FPG676A SupportedDokument44 SeitenPreliminary: 01/05/2023 1.0E Initial Version Published. Package FPG676A SupportedJOSE FRANÇANoch keine Bewertungen

- K46CM Repair Guide: Jul/23/2012 John - Jin Csc-GrmaDokument5 SeitenK46CM Repair Guide: Jul/23/2012 John - Jin Csc-Grmaanas symbianNoch keine Bewertungen

- 5600 Single Phase Circuit DiagramDokument11 Seiten5600 Single Phase Circuit DiagramPaulmankeNoch keine Bewertungen

- DUALPULSEbom 4Dokument1 SeiteDUALPULSEbom 4FritzNoch keine Bewertungen

- Katalog ERMAX 2015Dokument80 SeitenKatalog ERMAX 2015Jasmin BijedicNoch keine Bewertungen

- ALLDATA Repair - pdf2Dokument3 SeitenALLDATA Repair - pdf2Yassir PerezNoch keine Bewertungen

- HCIA-Data Center Facility V1.0 Mock ExamDokument3 SeitenHCIA-Data Center Facility V1.0 Mock ExamaguilaspyNoch keine Bewertungen

- Power DevicesDokument63 SeitenPower DevicesMohib Ullah KhanNoch keine Bewertungen

- L V P C C: Phelps Dodge Conductor Type CVDokument2 SeitenL V P C C: Phelps Dodge Conductor Type CVgari_monsantoNoch keine Bewertungen

- Aceflex RV KeDokument2 SeitenAceflex RV KejhongeralpeNoch keine Bewertungen

- 77.tec-Saukem-Loi003-E01-092 V1 R2Dokument13 Seiten77.tec-Saukem-Loi003-E01-092 V1 R2Purushothaman SeenuNoch keine Bewertungen

- CAPCICTOR - Pricelist 2023Dokument32 SeitenCAPCICTOR - Pricelist 2023MaharudraMahajanNoch keine Bewertungen

- Product Line Overview of IEC ContactorsDokument1 SeiteProduct Line Overview of IEC ContactorsJaime IngaNoch keine Bewertungen

- Class Rk5 - Idsr Series Indicator Fuses: Powr-Gard Fuse DatasheetDokument2 SeitenClass Rk5 - Idsr Series Indicator Fuses: Powr-Gard Fuse DatasheetJesus Emmanuel AlanisNoch keine Bewertungen

- Zelio Logic SR3B101FUDokument6 SeitenZelio Logic SR3B101FUFernando Estrada ZapataNoch keine Bewertungen

- PLL 2138 PDFDokument208 SeitenPLL 2138 PDFRaj KumarNoch keine Bewertungen

- Description Features: Maximizing IC PerformanceDokument6 SeitenDescription Features: Maximizing IC PerformanceHernan De OtoNoch keine Bewertungen

- ABB REG 650 ManualDokument740 SeitenABB REG 650 ManualMysha ShaqeenaNoch keine Bewertungen

- Bdx33B Bdx33C Bdx34B Bdx34C: Complementary Silicon Power Darlington TransistorsDokument5 SeitenBdx33B Bdx33C Bdx34B Bdx34C: Complementary Silicon Power Darlington TransistorsJavier BendekNoch keine Bewertungen

- Standard EIA RESISTOR SMD CODEDokument3 SeitenStandard EIA RESISTOR SMD CODEWatu MetrosNoch keine Bewertungen

- Power Quality Issues and Recommendations: Copper Development Association IncDokument2 SeitenPower Quality Issues and Recommendations: Copper Development Association IncJulio SamaméNoch keine Bewertungen

- Cable Selection Table For CapacitorDokument1 SeiteCable Selection Table For CapacitorShashiSharmaNoch keine Bewertungen

- IEC - Standards, UPS Types and MethodsDokument1 SeiteIEC - Standards, UPS Types and MethodsMarco AntonioNoch keine Bewertungen

- Pruebas en Transformadores IeeeDokument9 SeitenPruebas en Transformadores IeeeMarcelo VillarNoch keine Bewertungen

- Here We Are Building A Wireless FM Transmitter Which Uses RF Communication To Transmit The Medium or Low Power FM SignalDokument6 SeitenHere We Are Building A Wireless FM Transmitter Which Uses RF Communication To Transmit The Medium or Low Power FM SignalsravanNoch keine Bewertungen