Beruflich Dokumente

Kultur Dokumente

API Oil Water Separator Discussion

Hochgeladen von

Arun KumarCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

API Oil Water Separator Discussion

Hochgeladen von

Arun KumarCopyright:

Verfügbare Formate

Industrial Wastewater Engineering Solutions

API

Oil water Separators

Selecting the right API oil water

separator for the application is key to

the successful outcome of the entire

treatment system performance.

The API separator design is based

on the American Petroleum Institute

(API) Monographs on Refinery

Environmental Control, Design and

Operation of Oil-Water Separators.

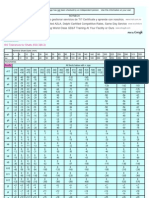

The flow capacities of the design are

based on an influent of fresh water

and No. 2 fuel oil at 40F operating

temperature. The API guide has

established optimum depth to width

ratios with controlled velocities

allowing oil droplets of 150 microns

diameter or larger to separate from

the water phase as predicted by

Stokes Law. The rectangular shape of

the API separator along with an

efficient diffusion baffle and weirs

creates a consistent laminar flow

throughout the separation chamber

cross section. This allows optimum

use of the working volume.

Operation

Flow Diffusion

API separator uses a special

diffusion baffle to diffuse the flow

prior to the separation chamber.

Oil Skimming

Oil skimming utilizes the specific

gravity differential between lighter oil

and heavier water. The oil floats on

the surface and in so doing displaces

the water. Since oil has a lower

specific gravity than water the level of

the oil upstream of the oil baffle rises

above the water level set by the water

weir plate.

As the oil continues to accumulate

the level rises until it spills into the oil

skimmer reservoir and automatically

exits the separator via gravity flow.

Skimmer Types

Three types of skimmers can be

provided, fixed weir oil skimming

baffle integrated with an oil reservoir,

adjustable rotating slotted pipe

skimmer and the drum skimmer.

Sludge scrapers, sludge screw

augers hopper bottoms and inverted

pyramid bottoms can be provided

depending on the style of sludge

removal required or desired for a

particular application.

The drum skimmer design is a motor

driven stainless steel drum spanning

the tank width partially submerged in

the water. As the drum rotates oil

attaches to the drum and is removed

via a blade riding on the drum face.

Chain & Flight Skimmers

Three styles of flight skimmers are

offered to remove solids and oils

depending on the required design to

fit the application.

Solids Removal

Solids are typically present in varying

amounts in waste water. The API

design is excellent for handling solids

without upset. If the solids loading is

light, a flat bottom design may be

sufficient. However, when heavier

solids loads are expected hopper

bottoms should be used to allow easy

solids removal and prevent solids

accumulation from reducing the

effective volume of the separation

chamber.

As each application is different and

solids occur in a wide range of sizes,

different concentrations and densities

ultimate solids settling performance is

quite variable and each application

must be reviewed for proper API

design.

Refinery sludge can be highly viscous

with high concentrations of solids and

oils

mixed

together.

These

characteristics need to be considered

during system design for sludge

removal as well as cleanout during

maintenance.

Inlet screens can be provided as

required or desired.

Type 1: surface drag skimmer located

at the tank top to move floating oils to

the oil skimmer.

Type 2: sludge scraper located at

tank bottom to move settled sludge

from the effluent end toward a sludge

collecting v-hopper at the influent

end.

Type 3: types 1 & 2 are combined

into a single system that skims the

surface and scrapes the bottom to

perform both oil movement and

sludge movement.

Chain & flight construction can be

provided

as

hardened

carbon/stainless chain, sprockets &

shafts or polymeric chain &

sprockets. Each material has differing

life expectancies, stretch modulus

and liquid compatibilities. The flight

construction of preference is a

fiberglass channel design where

strength vs. length and liquid

compatibilities are usually excellent.

Wearing components such as flight

shoes, guide strips and other

components are typically UHMWPE

or XLPE.

Industrial Wastewater Engineering Solutions

discharge oil concentration of 10

PPM or less with an oil droplet size of

20 or 30-micron oil droplet.

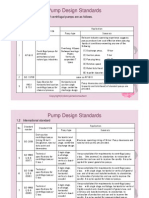

API Features

Some typical API features as dictated

by the API 421 are:

Depth-to-width ratio 0.3-0.5

Length-to-width ratio of 5:1

Horizontal

velocity

no

greater than 3 feet per

second

Removal of oil droplets 150

micron & larger

Influent diffuser or reaction

jet design

Separator Types

API421 outlines two types of

separator: 1. API gravity differential

separator and 2. API coalescing

separator.

Covers

Multi-sectional covers are provided to

contain vapors. Each section is

attached to the tank and to

neighboring covers via gasket and

bolts.

Gravity Separation vs. Coalescing

Plate Separators

Two basic types of oil water separator

exist today in varying types of design,

but all are derived from these two

types

of

design.

Hatches can be provided for

inspections without having to remove

bolts and heavy cover sections.

The first and oldest type is gravity or

conventional

separation,

simple

separation via gravity (density

differential between two immiscible

liquids leads to one of them rising

above the other). This design, when

designed

properly

(or

even

improperly) provides a certain tank

length, width and depth that provides

a wide, quiet spot in the pipeline to

give oils time to rise. This design

(also known as an API separator)

generally provides a discharge oil

concentration of +/-100 PPM based

on a 150-micron droplet size. The API

type design relies on a large water

volume shaped as dictated by the

API421

criteria

to

maximize

separation.

Nitrogen

blanketing

and

GAC

vapor/vent scrubbers can be provided

to remove VOCs from vapor space

content.

API Performance

While the API421 guide typically

provides for an effluent discharge

performance of 100 mg/L, 150 micron

oil droplets it is possible with a

properly designed API to provide

performance in the 50 mg/L and

larger range.

These performance figures are

typically independent of the influent

concentrations and are calculated as

if in an ideal environment, which is

not accurate to real-world experience.

Actual

performance

is

highly

dependent on the type of waste

entering the separator and the

conditions within the separator.

System Considerations

The API separator is not a complete

system in and of itself. A full

treatment system also consists of

peripheral components such as

sludge pumps, oil pumps, feed

pumps, walkways, alarms and other

components needed to complete the

application.

Tank Construction

The API design can be provided as a

factory assembled, A36 coated

carbon steel design for above or

below grade or concrete for below

ground installations.

What is the Difference

Between Separator

Types?

The API design has its origin in the

refineries of the world where the

excess volumes are advantageous

for reducing a wide variety of oil &

solids types and characteristics.

The coalescing design is known by

many names i.e. parallel plate

interceptor,

corrugated

plate

interceptor, slant rib coalescer so on

and so forth. However, the concept,

operation and design are generally

the same. The coalescing concept is

based on having a large surface area

in contact with the wastestream

(coalescing plates). The more surface

area provided, the more enhanced

the separation process will typically

be. By using the coalescing media,

the size of the tank is reduced and a

higher performance is attained than

by gravity separation. Pan America's

Flopak coalescing design provides a

Coalescing Oil Water Separators

are passive, physical, oil water

separator systems designed for

removal of oils, fuels, hydraulic fluids,

LNAPL and DNAPL products from

water. Environmental's designed

performance can be described by a

combination of Stoke's Law and

current coalescing plate theory,

wherein; the oil droplet rise rate and

other parameters dictate the surface

area required for gravity & coalescing

separation.

Gravity Separators also referred to

as API oil water separators are also

passive, physical separation devices

where the tank is basically an empty,

baffled design that provides sufficient

retention time to allow oils to

separate. This type of oil water

separator is very common and lower

in performance than a coalescing

design.

Separation Process: The water/oil

mixture enters the separator and is

spreadout horizontally, distributed

through an energy and turbulencediffusing device. The mixture enters

the Flopak coalescing media where

laminar and sinusoidal flow is

established and the oils impinge on

the

media

surface.

As

oils

accumulate they coalesce into larger

droplets, rising upward through the

pack corrugations until they reach the

top of the pack, where they detach

and rise to the water's surface. At the

same time solids encounter the

media

and

slide

down

the

corrugations, falling into the v-hopper

under

the

Flopak

media.

Stoke's Law: This equation relates

the terminal settling or rise velocity of

a smooth, rigid sphere in a viscous

fluid of known density and viscosity to

the diameter of the sphere when

subjected to a known force field

(gravity). The equation is:

Industrial Wastewater Engineering Solutions

V

=

(2gr)(d1-d2)/9

where

V = velocity of rise (cm sec-),

g = acceleration of gravity (cm sec-),

r = "equivalent" radius of particle

(cm),

dl = density of particle (g cm -),

d2 = density of medium (g cm-), and

= viscosity of medium (dyne sec

cm-).

Coalescence: Gravity separation

utilizes the difference in specific

gravity between the oil and water. Oil

separates from a fluid at a rate

explained by Stoke's Law. The

formula predicts how fast an oil

droplet will rise or settle through

water based on the density and size

of the oil droplet size and the distance

the object must travel.

Our separators are built to exploit the

variables

of

Stokes

Law.

With the use of our Flopak media oil

only need rise a short distance before

encountering

the

oleophilic,

coalescing media plates inside the

separation chamber as opposed to

rising a great distance in gravity

separation before reaching the

waters surface. Upon impinging on

the plates the oils coalesce (gather)

into larger droplets until the droplet

buoyancy is sufficient to pull away

from the media and rise to the water's

surface. The design will meet

particular design criteria as indicated

below:

The hydraulic distribution of the

influent flow must assure full usage

of the cross-sectional area of the

media to fully utilize the plate pack's

surface area.

Flow control and direction must be

determined to prevent hydraulic short

circuiting around, under or over the

media pack.

A laminar flow condition must be

maintained (Reynolds "Re" number

less than 500) in order to assist

droplets to rise. Per the American

Petroleum Institutes (API)

Publication 421 of February 1990.

Horizontal flow through velocities

in the separator must not exceed 3

feet per minute or 15 times the rate

of rise of the droplets whichever is

smaller.

The media containment chamber

design, plate design/angle and

spacing sufficient to facilitate removal

of accumulating solids. Plates are to

be angled at 60 from the horizontal.

Flopak Coalescing Media Design

Pan America's Flopak coalescing

media provides a laminar flow path

that creates a quiescent zone to

facilitate the impact with and

attachment of oils to the media

surface by reducing waste stream

turbulence and velocity. This control

of the waste stream creates a more

ideal environment for oil removal.

By virtue of our Flopak media design,

solids will also collide with the media

and settle to the separator bottom to

some degree, depending on the

solids characteristics and loading.

Due to oil typically being lighter than

water, they (oils) will rise up the

coalescing plate. As the oil droplets

rise up the plate they will coalesce or

come together with other droplets,

creating progressively larger droplets.

Once the droplet size is sufficient or

the droplet reaches the top of the

media plate the droplet pulls away

from the plate and rises to the water

surface. To some degree, the solids

replicate this process in reverse

(settling).

Oil Descriptions

Oils and fuels can exist in a variety

of states depending on the forces

exerted on them.

Free Oils: Oils in a natural state will

typically be a free and/or dispersed

product, meaning it will maintain its

typical

characteristics,

(oily,

hydrophobic) and will eventually form

into a layer separate from the water

phase. The free phase oil can also be

dispersed or spread throughout the

body of the water due to being broken

into a range of droplet sizes.

Dispersed Oils: Are oil droplets that

have been spread throughout the

body of the water due to an oil droplet

smaller than the free droplet.

Emulsions: oils can be changed to

an emulsified state where the oil

droplet size is drastically reduced and

with it, its electrical strength. This is

achieved by mechanical shearing

forces where the reduced oil

molecule becomes a temporary

companion to water molecule or by a

third, chemical component that

controls the oil molecule and forces it

into contact with the water molecule.

The chemical being the bridge

between the water and oil holds it in a

stable, permanent or semi-permanent

state.

Dissolved: The oils are dissolved

into solution with the water due to

their innate characteristics, nature

and external influences.

Crude Oils

Crude oil is

characteristics.

classified

by

its

Class A: Light, Volatile Oils. these

oils are highly fluid, often clear,

spread rapidly on solid or water

surfaces, have a strong odor, a high

evaporation rate, and are usually

flammable. They penetrate porous

surfaces such as dirt and sand, and

may be persistent in such a matrix.

They do not tend to adhere to

surfaces;

flushing

with

water

generally removes them. Class A oils

may be highly toxic to humans, fish,

and other biota. Most refined

products and many of the highest

quality light crudes can be included in

this class.

Class B: Non-Sticky Oils. These oils

have a waxy or oily feel. Class B oils

are less toxic and adhere more firmly

to surfaces than Class A oils,

although they can be removed from

surfaces by vigorous flushing. As

temperatures rise, their tendency to

penetrate

porous

substrates

increases and they can be persistent.

Evaporation of volatiles may lead to a

Class C or D residue. Medium to

heavy paraffin-based oils fall into this

class.

Class C: Heavy, Sticky Oils. Class C

oils are characteristically viscous,

sticky or tarry, and brown or black.

Flushing with water will not readily

remove this material from surfaces,

but the oil does not readily penetrate

porous surfaces. The density of Class

C oils may be near that of water and

they often sink. Weathering or

evaporation of volatiles may produce

solid or tarry Class D oil. Toxicity is

low, but wildlife can be smothered or

drowned when contaminated. This

class includes residual fuel oils and

medium to heavy crudes.

Industrial Wastewater Engineering Solutions

Class D: Non fluid Oils. Class D oils

are relatively non-toxic, do not

penetrate porous substrates, and are

usually black or dark brown in color.

When heated, Class D oils may melt

and coat surfaces making cleanup

very difficult. Residual oils, heavy

crude oils, some high paraffin oils,

and some weathered oils fall into this

class.

These classifications are dynamic in

that the characteristics can change

depending

on

temperature

or

evaporation or other conditions. So,

one class can become another and

can also revert to its class depending

on external influences.

Custom twin APIs

Reference System Photos

API before paint

Concrete API-CPI 6,000 GPM

Elevated API combined with CRT chemical treatment system and DAF

Das könnte Ihnen auch gefallen

- API Separators - SolutionsDokument8 SeitenAPI Separators - SolutionsnorthstarleoNoch keine Bewertungen

- API Oil SeparatorsDokument3 SeitenAPI Oil SeparatorsDiana Catalina Molano BayonaNoch keine Bewertungen

- The Difference Between API, DIN, IsO, ASME PumpsDokument1 SeiteThe Difference Between API, DIN, IsO, ASME PumpstoicantailieunhatNoch keine Bewertungen

- The Mathematics of Pumping Water: AECOM Design BuildDokument9 SeitenThe Mathematics of Pumping Water: AECOM Design Buildmabrouk2013Noch keine Bewertungen

- EvapPond SizingDokument2 SeitenEvapPond Sizingtpgovind100% (1)

- Sizing Small Stormwater Pump StationsDokument5 SeitenSizing Small Stormwater Pump Stationspeggy nirmalaNoch keine Bewertungen

- Separator Sizing - PPTDokument21 SeitenSeparator Sizing - PPTD K SNoch keine Bewertungen

- HydraulicsDokument42 SeitenHydraulicsAslam ChohanNoch keine Bewertungen

- C3 Recovery StudyDokument15 SeitenC3 Recovery StudyengmohosmanNoch keine Bewertungen

- Cped p2Dokument1 SeiteCped p2Queenie Balisong0% (1)

- DemisterDokument4 SeitenDemistermariniabrahanNoch keine Bewertungen

- Medium Velocity Water Spray NozzleDokument6 SeitenMedium Velocity Water Spray NozzlehariridkNoch keine Bewertungen

- Pulsator - P ER 003 EN 1603 - v2 PDFDokument2 SeitenPulsator - P ER 003 EN 1603 - v2 PDFpjrapanutNoch keine Bewertungen

- Gas Treatment Processes-1Dokument17 SeitenGas Treatment Processes-1m sohailNoch keine Bewertungen

- Hydrate Inhibition With MethanolDokument11 SeitenHydrate Inhibition With Methanolsachin2010Noch keine Bewertungen

- KRAL Screw Pumps BrochureDokument28 SeitenKRAL Screw Pumps BrochureRené Mora-CasalNoch keine Bewertungen

- 14 Draw Off Nozzle Hydraulics PDFDokument12 Seiten14 Draw Off Nozzle Hydraulics PDFMohsin EhsanNoch keine Bewertungen

- A Study of Foaming and Carry-Over Problems in Oil and Gas SeparatorsDokument6 SeitenA Study of Foaming and Carry-Over Problems in Oil and Gas SeparatorsWendy V. DomínguezNoch keine Bewertungen

- Enhanced Gravity OWS Sizing SpreadsheetDokument1 SeiteEnhanced Gravity OWS Sizing Spreadsheetdeion29Noch keine Bewertungen

- KJPS1J-1J0-SK-0602 - 1 - PS1-J P&ID Main PumpsDokument1 SeiteKJPS1J-1J0-SK-0602 - 1 - PS1-J P&ID Main PumpsMuhammad rizwanNoch keine Bewertungen

- CPI BrochureDokument2 SeitenCPI Brochuremashonk okNoch keine Bewertungen

- Open Pan EvaporatorDokument5 SeitenOpen Pan EvaporatorsenthilNoch keine Bewertungen

- Lab DI Water SystemsDokument6 SeitenLab DI Water SystemsHaidee Che RizminNoch keine Bewertungen

- 19.2. Dewatering of Sludge by FiltrationDokument46 Seiten19.2. Dewatering of Sludge by FiltrationClaudia AvramNoch keine Bewertungen

- Comparing CoalescersDokument12 SeitenComparing Coalescersmohamed_sahnoun_enisNoch keine Bewertungen

- PumpLab Book 1 PreviewDokument11 SeitenPumpLab Book 1 Previewcorey6Noch keine Bewertungen

- TextileDokument36 SeitenTextileDr-Sheetanshu Pandey0% (1)

- Coke Slurry PresentationDokument27 SeitenCoke Slurry PresentationAnupam VermaNoch keine Bewertungen

- Cpi O&m ManualDokument36 SeitenCpi O&m Manualprasad336Noch keine Bewertungen

- Engine Lubricating Oil System: Design Iv Machinery System Department of Marine EngineeringDokument20 SeitenEngine Lubricating Oil System: Design Iv Machinery System Department of Marine EngineeringSean Chen GyarinoNoch keine Bewertungen

- Design Calculations UnitankDokument7 SeitenDesign Calculations UnitankThành Luân NguyễnNoch keine Bewertungen

- Static MixerDokument8 SeitenStatic MixerEric ToroNoch keine Bewertungen

- Chemical Dosing Unit - Standard SpecificationsDokument61 SeitenChemical Dosing Unit - Standard SpecificationsSong Nguyen Nguyen100% (1)

- Sand Filtration Units150Dokument3 SeitenSand Filtration Units150Smriti PrasadNoch keine Bewertungen

- Passavant E&E Company Profile-4th QTRDokument77 SeitenPassavant E&E Company Profile-4th QTRSami Sawalha100% (1)

- Volume and Wetted Area of Partially Filled Vertical VesselsDokument18 SeitenVolume and Wetted Area of Partially Filled Vertical VesselsChandra Sekhar MadiniNoch keine Bewertungen

- Tpi and CpiDokument9 SeitenTpi and Cpitelugukhan13Noch keine Bewertungen

- 3.6 Pumps - Revised (Table Format)Dokument11 Seiten3.6 Pumps - Revised (Table Format)mtpiping2572Noch keine Bewertungen

- Demin PlantDokument9 SeitenDemin PlantBlitz XyrusNoch keine Bewertungen

- Calculating Pressure LossDokument2 SeitenCalculating Pressure LossAhmed MoustafaNoch keine Bewertungen

- Mixed Bed Resin Loading ProcedureDokument2 SeitenMixed Bed Resin Loading ProcedurePramudito Aji WicaksonoNoch keine Bewertungen

- Pump MathsDokument10 SeitenPump MathsSakib RafeeNoch keine Bewertungen

- Selección de CompresoresDokument23 SeitenSelección de CompresoresjowarNoch keine Bewertungen

- VGS Vane Separators Are Recommended ForDokument1 SeiteVGS Vane Separators Are Recommended ForSanthu PeelaNoch keine Bewertungen

- EgcsDokument21 SeitenEgcshein chanNoch keine Bewertungen

- 10.6. Liquid-Liquid Separation: 10.6.1. Decanters (Settlers)Dokument6 Seiten10.6. Liquid-Liquid Separation: 10.6.1. Decanters (Settlers)ashishkapoorsrmNoch keine Bewertungen

- 77 Two Stage Uasb Treatment of Industrial Wastewater With Internal CirculationDokument10 Seiten77 Two Stage Uasb Treatment of Industrial Wastewater With Internal CirculationngocdungmtNoch keine Bewertungen

- Hydraulic TransientsDokument58 SeitenHydraulic TransientsjulianvillajosNoch keine Bewertungen

- Application of Multiphase Desander Technology To Oil and Gas ProductionDokument19 SeitenApplication of Multiphase Desander Technology To Oil and Gas ProductionJose Rodrigo Salguero DuranNoch keine Bewertungen

- Plate Type Wet ScrubberDokument6 SeitenPlate Type Wet ScrubberRoger IsidoreNoch keine Bewertungen

- DesalterDokument2 SeitenDesalterHimanshu SharmaNoch keine Bewertungen

- Abu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003Dokument8 SeitenAbu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003fermortaraNoch keine Bewertungen

- Edr 2 ElarmoDokument15 SeitenEdr 2 ElarmoArfel Marie FuentesNoch keine Bewertungen

- Design of Separation Equipment of Heterogeneous MixDokument32 SeitenDesign of Separation Equipment of Heterogeneous Mixbakhtyar21Noch keine Bewertungen

- API Separators - The Workhorse of Refinery Wastewater Treatment SystemsDokument8 SeitenAPI Separators - The Workhorse of Refinery Wastewater Treatment SystemsAntoNoch keine Bewertungen

- API Separators Article SolutionsDokument8 SeitenAPI Separators Article SolutionsRenalyn TorioNoch keine Bewertungen

- OWS Design BasisDokument21 SeitenOWS Design BasisAnonymous G9t3IVfL4J100% (1)

- Api Oil Water Separator Discussion PDFDokument4 SeitenApi Oil Water Separator Discussion PDFAhmed Moustafa100% (1)

- Oil/Water Separation Design & ApplicationDokument6 SeitenOil/Water Separation Design & ApplicationSushil RajakNoch keine Bewertungen

- E4 Lab Sheet Minor Losses in PipeDokument17 SeitenE4 Lab Sheet Minor Losses in PipeHoongNoch keine Bewertungen

- Understanding Gas Turbine PerformanceDokument42 SeitenUnderstanding Gas Turbine Performancesenthil03127793% (15)

- Aqua-Cache - Dissolved Air Flotation D.ADokument4 SeitenAqua-Cache - Dissolved Air Flotation D.AArun KumarNoch keine Bewertungen

- Purposes and Types of Fill: Thermal ScienceDokument4 SeitenPurposes and Types of Fill: Thermal SciencesriguruprasathsNoch keine Bewertungen

- Coupling Selection Method PDFDokument2 SeitenCoupling Selection Method PDFArun KumarNoch keine Bewertungen

- GEN01A 214 B5 7FA-Gas-Turbine-Major-Inspections Example r1 PFDokument14 SeitenGEN01A 214 B5 7FA-Gas-Turbine-Major-Inspections Example r1 PFsarathkumar100% (1)

- Coupling Selection Method PDFDokument2 SeitenCoupling Selection Method PDFArun KumarNoch keine Bewertungen

- Splash Fills Vs Film Fills in Cooling TowersDokument2 SeitenSplash Fills Vs Film Fills in Cooling TowersArun KumarNoch keine Bewertungen

- Conductivity TDS RelationshipDokument7 SeitenConductivity TDS Relationshipanonymous manNoch keine Bewertungen

- Power Plant Best Practices 2015 PDFDokument107 SeitenPower Plant Best Practices 2015 PDFFairoza AmalinnaNoch keine Bewertungen

- GEN01A 214 B5 7FA-Gas-Turbine-Major-Inspections Example r1 PFDokument14 SeitenGEN01A 214 B5 7FA-Gas-Turbine-Major-Inspections Example r1 PFsarathkumar100% (1)

- Gas ExpanderDokument12 SeitenGas ExpanderArun KumarNoch keine Bewertungen

- K Value of FittingsDokument4 SeitenK Value of FittingsJoydip Misra100% (6)

- K Value of FittingsDokument4 SeitenK Value of FittingsJoydip Misra100% (6)

- CCPP Flow Diagram PDFDokument1 SeiteCCPP Flow Diagram PDFArun KumarNoch keine Bewertungen

- Gas ExpanderDokument12 SeitenGas ExpanderArun KumarNoch keine Bewertungen

- GEN01A 214 B5 7FA-Gas-Turbine-Major-Inspections Example r1 PFDokument14 SeitenGEN01A 214 B5 7FA-Gas-Turbine-Major-Inspections Example r1 PFsarathkumar100% (1)

- Pump Standards ComparisonDokument4 SeitenPump Standards ComparisonAnish Dani50% (2)

- CCPP Flow Diagram PDFDokument1 SeiteCCPP Flow Diagram PDFArun KumarNoch keine Bewertungen

- K Value of FittingsDokument4 SeitenK Value of FittingsJoydip Misra100% (6)

- ASME PTC 22 Gas Turbine Test Code PDFDokument46 SeitenASME PTC 22 Gas Turbine Test Code PDFDaru CahyoNoch keine Bewertungen

- K Value of FittingsDokument4 SeitenK Value of FittingsJoydip Misra100% (6)

- Purposes and Types of Fill: Thermal ScienceDokument4 SeitenPurposes and Types of Fill: Thermal SciencesriguruprasathsNoch keine Bewertungen

- What Is Reverse OsmosisDokument15 SeitenWhat Is Reverse OsmosisArun KumarNoch keine Bewertungen

- Basics of Ion Exchange ResinsDokument11 SeitenBasics of Ion Exchange ResinsVenkat RaguNoch keine Bewertungen

- CCPP Flow Diagram PDFDokument1 SeiteCCPP Flow Diagram PDFArun KumarNoch keine Bewertungen

- CCPP Flow Diagram PDFDokument1 SeiteCCPP Flow Diagram PDFArun KumarNoch keine Bewertungen

- Resin LiteratureDokument6 SeitenResin LiteratureArun KumarNoch keine Bewertungen

- Bod & CodDokument11 SeitenBod & CodSurendra ReddyNoch keine Bewertungen

- Antico Priming ChamberDokument2 SeitenAntico Priming ChamberArun KumarNoch keine Bewertungen

- Smeaton ProjectDokument18 SeitenSmeaton ProjectNemesisRepublic@blogspot.comNoch keine Bewertungen

- Decree enDokument9 SeitenDecree enmalakayjr100% (1)

- Rate December 2008Dokument1 SeiteRate December 2008lkovijayNoch keine Bewertungen

- en 10213 2007 Steel Castings For Pressure Purposes PDFDokument29 Seitenen 10213 2007 Steel Castings For Pressure Purposes PDFPramod NautiyalNoch keine Bewertungen

- Muller Tapping MachineDokument8 SeitenMuller Tapping MachineKUMAARRRNoch keine Bewertungen

- Processes For Recycling: 4.4.1.2.1 Conventional Kroll ProcessDokument14 SeitenProcesses For Recycling: 4.4.1.2.1 Conventional Kroll Processelma watNoch keine Bewertungen

- Method Statement: Conceal PVC Conduit/Trunking and Junction Boxes in Concrete CeilingDokument2 SeitenMethod Statement: Conceal PVC Conduit/Trunking and Junction Boxes in Concrete Ceilingfatinjamal22Noch keine Bewertungen

- Cement 12Dokument24 SeitenCement 12prashannapandit832Noch keine Bewertungen

- Tdg50 Portable Line Boring Machine-DthmachinesDokument16 SeitenTdg50 Portable Line Boring Machine-DthmachinesAvaa AmgaaNoch keine Bewertungen

- DesaltingDokument25 SeitenDesaltingOmar GamalNoch keine Bewertungen

- Synthesis and Characterization of Erbium Doped Nickel Zinc Ferrites NanoparticlesDokument30 SeitenSynthesis and Characterization of Erbium Doped Nickel Zinc Ferrites Nanoparticlessaleem saleemNoch keine Bewertungen

- Elective Course (2) - Composite Materials MET 443Dokument16 SeitenElective Course (2) - Composite Materials MET 443يوسف عادل حسانينNoch keine Bewertungen

- ISO - 286-2 Shaft Limits TolerancesDokument2 SeitenISO - 286-2 Shaft Limits TolerancesMixtli Garcia100% (1)

- Operation & Maintenance of Plug Valves PDFDokument5 SeitenOperation & Maintenance of Plug Valves PDFعزت عبد المنعمNoch keine Bewertungen

- LNG Tank Oerlikon PDFDokument32 SeitenLNG Tank Oerlikon PDFElias Kapa100% (1)

- Dr. S P Sivapirakasam Associate Professor Department of Mechanical Engineering NIT TiruchirappalliDokument28 SeitenDr. S P Sivapirakasam Associate Professor Department of Mechanical Engineering NIT Tiruchirappallisuman pandianNoch keine Bewertungen

- MSDS CR2032 DBV 2017Dokument5 SeitenMSDS CR2032 DBV 2017Humberto GarciaNoch keine Bewertungen

- Duct Accessories - RevDokument5 SeitenDuct Accessories - RevLuis Gabriel BautistaNoch keine Bewertungen

- 100128175847preview - SS 214-2009Dokument5 Seiten100128175847preview - SS 214-2009MEHDI FARROKHINoch keine Bewertungen

- The Effect of ShearDokument11 SeitenThe Effect of Shearanakren296Noch keine Bewertungen

- Product Mix of HavellsDokument4 SeitenProduct Mix of HavellsPriyanka Agarwal100% (1)

- Toyotomi FF V30TDokument24 SeitenToyotomi FF V30TEnzoNoch keine Bewertungen

- Reinforcing Steel Bars and TendonsDokument31 SeitenReinforcing Steel Bars and TendonsJebone Stein Web JuarbalNoch keine Bewertungen

- 카달로그 - Metal Plug ValveDokument22 Seiten카달로그 - Metal Plug Valvetazghat beghdadiNoch keine Bewertungen

- Basics in Turbomachinery&Gas TurbineDokument85 SeitenBasics in Turbomachinery&Gas TurbineAhmed Adel IbrahimNoch keine Bewertungen

- Ipc TM 650 Test Methods ManualDokument3 SeitenIpc TM 650 Test Methods ManualPiere Salas HerreraNoch keine Bewertungen

- 5R110W Assembly PDFDokument16 Seiten5R110W Assembly PDFLuis VelazquezNoch keine Bewertungen

- PSM 2Dokument23 SeitenPSM 2luisNoch keine Bewertungen

- Steel8 PDFDokument18 SeitenSteel8 PDFJon LawheadNoch keine Bewertungen