Beruflich Dokumente

Kultur Dokumente

11 Shipyard Layout

Hochgeladen von

Stevanus KrisandyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

11 Shipyard Layout

Hochgeladen von

Stevanus KrisandyCopyright:

Verfügbare Formate

Ch11-H8070.

fm Page 111 Wednesday, October 18, 2006 6:55 AM

11

Shipyard Layout

The past two or three decades have seen the emergence of a substantial

number of new shipyards, primarily in Asia and Eastern Europe, that

have been specifically planned to construct the larger ships being ordered

today, using contemporary shipbuilding practices and production methods.

A number of traditional shipbuilders have also established new yards

where they can also build larger ships and/or exploit the new technology

and production methods. In general the remaining shipbuilders will

have had to re-configure their site in order to utilise new technology

and improve production, whilst continuing to build ships. In many

cases the latter will still be restrained as to the size and type of ship

that can be built.

An ideal layout for a modern shipyard is based on a production flow

basis, with the yard extending back from the river or shore at which the

berths or building dock are located. The furthest area from the berths is

reserved for the material stockyard, and between the two are arranged in

sequence the consecutive work and shop processes. Too often existing shipyards follow the river bank, and are restricted by their location in a built up

area or the physical river bank slope from extending back from the river, so

that modified production flow lines are required.

Planning a new shipyard, or re-planning an existing one, will involve decisions to be made on the following:

Size and type of ship to be built.

Material production per year to be achieved.

Material handling equipment to be supplied.

Machining processes to be installed.

Unit size and weight to be fabricated and erected.

Amount of outfit and engine installation to be undertaken.

Control services to be supplied.

Administration facilities required.

Shipyards usually have a fitting out basin or berth where the virtually

completed ship is tied up after launching and the finishing off work and

static trails may be carried out.

Ch11-H8070.fm Page 112 Wednesday, October 18, 2006 6:55 AM

Ship Construction

112

Before considering the actual layout of the shipyard it is as well to

consider the relationship of the work processes involved in building a ship

as illustrated in Figure 11.1.

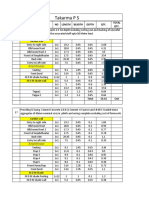

An idealized layout of a new shipyard is indicated in Figure 11.2 which

might be appropriate for a smaller yard specializing in one or two standard

type ships with a fairly high throughput so that one covered building dock

or berth was sufficient.

At this point it may be convenient to mention the advantages and disadvantages of building docks as opposed to building berths. Building docks

can be of advantage in the building of large vessels where launching costs

are high, and there is a possibility of structural damage owing to the large

stresses imposed by a conventional launch. They also give good crane

Plate

stowage

Section

stowage

Shotblast/prime

Shotblast/prime

Cutting

Marking

Shaping

Bending

cutting

Outfit materials

and bought in

items

Pipe bending

Outfit

fabrication

and assembly

Panel

Matrix

Subassemblies assemblies assemblies

Curved

unit

assemblies

Outfit

palletisation

and

modules

Block

assembly

Block and unit

erection

Final outfit

FIGURE 11.1 Shipbuilding process

Ch11-H8070.fm Page 113 Wednesday, October 18, 2006 6:55 AM

Shipyard Layout

113

Plate and section stockyard

Admin

offices

Marshalling and preparation

Plate

and

section machining

Module

assembly

Unit

assembly areas

and pallet

preparation

Pipe and

engine shop

Block fabrication

Covered

building

dock

Outfit

shops

Fitting out

basin

FIGURE 11.2 Shipyard layout

clearance for positioning units. The greatest disadvantage of the building

dock is its high initial cost.

Many yard re-constructions have incorporated undercover construction

facilities in the form of docks or slipways within building halls. Others

have building halls at the head of the slipway with advanced transfer systems installed so that the hull can be extruded out of the hall onto the

slipway for launching. Such facilities permit ship construction in a factory

type environment providing protection from the worst effects of weather

and darkness.

Ch11-H8070.fm Page 114 Wednesday, October 18, 2006 6:55 AM

114

Ship Construction

Further Reading

Brandnew Portsmouth complex for VT, The Naval Architect, July/August,

2003.

Chinese shipbuilders on the way to the top, The Naval Architect, September

2005.

Covered hall benefit for Bijlsma, The Naval Architect, May 2002.

Some Useful Web Sites

Shipyards

www.marine.alstom.com

www.shi.samsung.co.kr

see Building a ship construction phases

take the virtual tour of the Geoje Shipyard

Das könnte Ihnen auch gefallen

- L1 - 2 - Shipyard Productivity PDFDokument33 SeitenL1 - 2 - Shipyard Productivity PDFattiori fabriceNoch keine Bewertungen

- Lean Manufacturing Methodologi ShipyardDokument12 SeitenLean Manufacturing Methodologi ShipyardLukman Tarigan SumatraNoch keine Bewertungen

- Shipyard LayoutDokument9 SeitenShipyard Layoutcaptnathan100% (3)

- (TUGAS) Resume Shipyard LayoutDokument12 Seiten(TUGAS) Resume Shipyard Layoutfajar2311Noch keine Bewertungen

- Chapter 2 Shipyard-Layout Lecture Notes From South Hampton UniversityDokument10 SeitenChapter 2 Shipyard-Layout Lecture Notes From South Hampton UniversityJonnada KumarNoch keine Bewertungen

- Ship Design and Building: Seung Kyun ParkDokument9 SeitenShip Design and Building: Seung Kyun ParkVini Nur RachmawatiNoch keine Bewertungen

- Week2 GEM314e-2012Dokument36 SeitenWeek2 GEM314e-2012Kendal YeltekinNoch keine Bewertungen

- KSY ProjectDokument48 SeitenKSY Projectisrat jahanNoch keine Bewertungen

- Shipyard Planning ServicesDokument3 SeitenShipyard Planning Servicesjack donaldsonNoch keine Bewertungen

- Lamb T.World-Class Shipbuil.2001.TRANS PDFDokument24 SeitenLamb T.World-Class Shipbuil.2001.TRANS PDFairlanggaputraNoch keine Bewertungen

- Integrated Hull Construction Outfitting and Painting (IHOP) - 2.dioDokument33 SeitenIntegrated Hull Construction Outfitting and Painting (IHOP) - 2.diocappoxNoch keine Bewertungen

- Refman Cost SamplesDokument16 SeitenRefman Cost SamplesosamaNoch keine Bewertungen

- 02 - The Building of A Ship PDFDokument6 Seiten02 - The Building of A Ship PDFPungky Dan Ksatrya100% (1)

- Overview of STX Shipyard Facilities - Rev.1Dokument25 SeitenOverview of STX Shipyard Facilities - Rev.1emba2015Noch keine Bewertungen

- Advanced Welding Techniques in Ship ManufacturingDokument15 SeitenAdvanced Welding Techniques in Ship Manufacturingmadhan_kumar2000Noch keine Bewertungen

- Integrating Cost Estimating Withتصميم the Ship Design Process دمج تقدير التكلفةDokument24 SeitenIntegrating Cost Estimating Withتصميم the Ship Design Process دمج تقدير التكلفةMaharAl-hasan50% (2)

- L4 - Hull Production PhasesDokument35 SeitenL4 - Hull Production PhasesMahmud HasanNoch keine Bewertungen

- Integration Between Shipbuilding CAD Systems and A Generic PLM Tool in Naval Projects. Computer Science and ApplicationsDokument11 SeitenIntegration Between Shipbuilding CAD Systems and A Generic PLM Tool in Naval Projects. Computer Science and ApplicationsHarshad Khire100% (1)

- LNG MitsubishiDokument4 SeitenLNG Mitsubishireade2011Noch keine Bewertungen

- L6 - 1 - OutfittingDokument28 SeitenL6 - 1 - OutfittingFlavio MoraesNoch keine Bewertungen

- Industrial Training at ABG Shipyard by Naval ArchitectDokument41 SeitenIndustrial Training at ABG Shipyard by Naval ArchitectNikhil Ambattuparambil Gopi100% (2)

- Presentation-Ship Repair, Maintenance & Modernization Cost ModelDokument33 SeitenPresentation-Ship Repair, Maintenance & Modernization Cost ModelJulio Mario De CastroNoch keine Bewertungen

- AustalDokument5 SeitenAustalAntay KorakotNoch keine Bewertungen

- Interaction Ship Repair-Conversion and ShipbuildingDokument31 SeitenInteraction Ship Repair-Conversion and ShipbuildingJorge CiprianoNoch keine Bewertungen

- Cost Estimation - Orv Sagar Kanya GeneralisedDokument35 SeitenCost Estimation - Orv Sagar Kanya Generalisedpramodkb_cusatNoch keine Bewertungen

- Virtual Manufacturing Concept For ShipbuildingDokument16 SeitenVirtual Manufacturing Concept For ShipbuildingsimalaraviNoch keine Bewertungen

- Research in Seamanship: Group 1 - Batch 1Dokument16 SeitenResearch in Seamanship: Group 1 - Batch 1Jlria Mae Bjocx100% (1)

- Estimating The Cost-Ship RepairDokument29 SeitenEstimating The Cost-Ship RepairMohammad Sholikhan Arif100% (1)

- TextbookrevcsmallDokument359 SeitenTextbookrevcsmallngungtuandoNoch keine Bewertungen

- Planning and Production Control 2012Dokument60 SeitenPlanning and Production Control 2012Mahmoud ElsokkariNoch keine Bewertungen

- A Practical Approach For Ship Construction Cost EstimatingDokument13 SeitenA Practical Approach For Ship Construction Cost EstimatingdrthuhanNoch keine Bewertungen

- Risk Assessment of Aging Ship Hull Structures - FatigueDokument21 SeitenRisk Assessment of Aging Ship Hull Structures - FatiguetrollgueleNoch keine Bewertungen

- Design For ProductionDokument3 SeitenDesign For ProductionchandranNoch keine Bewertungen

- ShipyardsDokument27 SeitenShipyardsimran5705074Noch keine Bewertungen

- ShipbuildingDokument5 SeitenShipbuildinghemanthvdkNoch keine Bewertungen

- Sname - Podac Cost ModelDokument17 SeitenSname - Podac Cost ModelTanti SaraswatiNoch keine Bewertungen

- Advanced OutfittingDokument43 SeitenAdvanced OutfittingChandan Kumar100% (3)

- Shipyard Act White PaperDokument3 SeitenShipyard Act White PaperNEWS CENTER MaineNoch keine Bewertungen

- Layout 1 Design of A Small Shipyard Facility Layout OptimisedDokument30 SeitenLayout 1 Design of A Small Shipyard Facility Layout OptimisedHeba Adel100% (1)

- Royal HaskoningDHV Shipyards Brochure PDFDokument20 SeitenRoyal HaskoningDHV Shipyards Brochure PDFharyanto99Noch keine Bewertungen

- Maintenance of Ship's Engine Room CraneDokument6 SeitenMaintenance of Ship's Engine Room Cranemister_no34Noch keine Bewertungen

- Ship Design and EngineeringDokument19 SeitenShip Design and EngineeringNader Ragab AmmarNoch keine Bewertungen

- CostManagementBook Excerpt 3Dokument0 SeitenCostManagementBook Excerpt 3yapsguanNoch keine Bewertungen

- Cost Estimation Ship ConstructionDokument10 SeitenCost Estimation Ship ConstructionJoseramirezjlrt100% (1)

- Shipyards in AsiaDokument200 SeitenShipyards in AsiaUnmesh Lohite100% (1)

- Conceptual Ship Desing KnowlegdeDokument24 SeitenConceptual Ship Desing KnowlegdeJorge CiprianoNoch keine Bewertungen

- Ship Repair & BuildingDokument91 SeitenShip Repair & BuildingAntonio LeeNoch keine Bewertungen

- L1 - 1 - Shipbuilding ProcessDokument22 SeitenL1 - 1 - Shipbuilding Processhector_547Noch keine Bewertungen

- Big Ship ShipbuildingDokument37 SeitenBig Ship ShipbuildingPeter John PackiarajNoch keine Bewertungen

- IMC 2017 Full-Paper-Challenges in Naval Ship Maintenance-ArshadKunjumon R140717Dokument9 SeitenIMC 2017 Full-Paper-Challenges in Naval Ship Maintenance-ArshadKunjumon R140717arshadtk1923Noch keine Bewertungen

- Ship Product ModelingDokument16 SeitenShip Product ModelingSunil Kumar P GNoch keine Bewertungen

- Production ManagementDokument28 SeitenProduction ManagementMarkNoch keine Bewertungen

- Hindustan Shipyard-10Dokument75 SeitenHindustan Shipyard-10anshul21Noch keine Bewertungen

- Yard Patrol From 108' Concept To DeliveryDokument22 SeitenYard Patrol From 108' Concept To Deliverybrenno100% (1)

- Training New BuildingDokument88 SeitenTraining New BuildingIrdhan Kabutono WunaNoch keine Bewertungen

- Design of YachtDokument77 SeitenDesign of YachtMelissa Rios100% (1)

- Shipyard LayoutDokument5 SeitenShipyard LayouttxjiangNoch keine Bewertungen

- Ship Production and Management AbhinavDokument7 SeitenShip Production and Management AbhinavASPIN RAJNoch keine Bewertungen

- Carte An 2. Sem 1 PDFDokument89 SeitenCarte An 2. Sem 1 PDFMarinescuNoch keine Bewertungen

- Regional Report On The Approved Construction Safety & Health Program (CSHP) Dole-MimaropaDokument20 SeitenRegional Report On The Approved Construction Safety & Health Program (CSHP) Dole-MimaropaKevin ValonesNoch keine Bewertungen

- Composite Column DesignDokument95 SeitenComposite Column DesignYanfei JinNoch keine Bewertungen

- Takarma PDFDokument60 SeitenTakarma PDFvarni groupNoch keine Bewertungen

- DPL3023: Fundamentals of Warehouse OperationDokument9 SeitenDPL3023: Fundamentals of Warehouse OperationAliff IqmalNoch keine Bewertungen

- Bioclimati C House: Coordinator: Stéphane RoddierDokument27 SeitenBioclimati C House: Coordinator: Stéphane RoddierTEOFAN Simion0% (1)

- Truss 0402Dokument35 SeitenTruss 0402Mihai RaducuNoch keine Bewertungen

- Cseb-Compressed Stabilized Earth Blocks: Building The Future With Earth Using A "Greener Material"Dokument7 SeitenCseb-Compressed Stabilized Earth Blocks: Building The Future With Earth Using A "Greener Material"Pradnya NaikNoch keine Bewertungen

- DMC Building With 2nd Floor TilesDokument3 SeitenDMC Building With 2nd Floor TilesOrnelAsperasNoch keine Bewertungen

- RECT - Uni-Axial Column Capacity ACI 318-08 R3Dokument3 SeitenRECT - Uni-Axial Column Capacity ACI 318-08 R3Glenn Enrico AmoloNoch keine Bewertungen

- Modificacion de Rotor Astuce 03092020 Rev 0Dokument1 SeiteModificacion de Rotor Astuce 03092020 Rev 0andresNoch keine Bewertungen

- Background To SANS10160Dokument256 SeitenBackground To SANS10160Darryl100% (1)

- Consol P200-R1 S: Consol P200-R1 S Consol P200-R1 S Consol P200-R1 S Consol P200-R1 S Consol P200-R1 S Consol P200-R1 SDokument2 SeitenConsol P200-R1 S: Consol P200-R1 S Consol P200-R1 S Consol P200-R1 S Consol P200-R1 S Consol P200-R1 S Consol P200-R1 SMa'rufNoch keine Bewertungen

- Sustainable Construction Material ReportDokument10 SeitenSustainable Construction Material ReportCik bintangNoch keine Bewertungen

- Introducing and Managing Quality Scheme For RMC inDokument9 SeitenIntroducing and Managing Quality Scheme For RMC inJerry AbebeNoch keine Bewertungen

- CS02 - BKF4812 - PEM - Nestle Lean ProductionDokument8 SeitenCS02 - BKF4812 - PEM - Nestle Lean Productionmustaf mohamedNoch keine Bewertungen

- Kingspan Quadcore ks1000rw Wall Panel Data Sheet en GB IeDokument9 SeitenKingspan Quadcore ks1000rw Wall Panel Data Sheet en GB IesfdfasNoch keine Bewertungen

- Test BankDokument42 SeitenTest Bankprins kyla Saboy100% (1)

- Lalbakiaya Bridge - 36, KaruniyaDokument133 SeitenLalbakiaya Bridge - 36, KaruniyaShiv MishraNoch keine Bewertungen

- Material SpecificationDokument12 SeitenMaterial SpecificationmehrNoch keine Bewertungen

- Finlandia Sauna Brochure-WEB PDFDokument24 SeitenFinlandia Sauna Brochure-WEB PDFNoemi FodorNoch keine Bewertungen

- Standards For Landscape Irrigation SystemDokument22 SeitenStandards For Landscape Irrigation SystemAlroukn MechanicalNoch keine Bewertungen

- 2 Specialization in CEDokument24 Seiten2 Specialization in CEChrizter Jim LumaadNoch keine Bewertungen

- 11 Flexure in Beams 03Dokument25 Seiten11 Flexure in Beams 03S. M. ZAHIDUR RAHMAN 1301129Noch keine Bewertungen

- Rotary Kiln Brick InstallationDokument71 SeitenRotary Kiln Brick Installationfachrizal cesarNoch keine Bewertungen

- Micro Homes: Mahira Jindal 19B0011Dokument24 SeitenMicro Homes: Mahira Jindal 19B0011mahira jindalNoch keine Bewertungen

- Drain Pipe Insulation BrochureDokument2 SeitenDrain Pipe Insulation BrochureTeoxNoch keine Bewertungen

- Senior Project ManagerDokument3 SeitenSenior Project Managerapi-121645513Noch keine Bewertungen

- PurlinDokument4 SeitenPurlinMohamed NkNoch keine Bewertungen

- Manpower Requirement ListDokument2 SeitenManpower Requirement ListJohn HenryNoch keine Bewertungen

- Welcome: All Faculty Members & All Participants of Integrated Course-10109Dokument39 SeitenWelcome: All Faculty Members & All Participants of Integrated Course-10109structure12367% (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesVon EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNoch keine Bewertungen

- A Place of My Own: The Architecture of DaydreamsVon EverandA Place of My Own: The Architecture of DaydreamsBewertung: 4 von 5 Sternen4/5 (242)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialVon EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNoch keine Bewertungen

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionVon EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Building Construction Technology: A Useful Guide - Part 1Von EverandBuilding Construction Technology: A Useful Guide - Part 1Bewertung: 4 von 5 Sternen4/5 (3)

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationVon EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettBewertung: 4 von 5 Sternen4/5 (1)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyVon EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyBewertung: 4 von 5 Sternen4/5 (1)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyVon EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyBewertung: 4 von 5 Sternen4/5 (1)

- Estimating Construction Profitably: Developing a System for Residential EstimatingVon EverandEstimating Construction Profitably: Developing a System for Residential EstimatingNoch keine Bewertungen

- Civil Engineer's Handbook of Professional PracticeVon EverandCivil Engineer's Handbook of Professional PracticeBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AVon EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANoch keine Bewertungen

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseVon EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseBewertung: 5 von 5 Sternen5/5 (3)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsVon EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsBewertung: 1 von 5 Sternen1/5 (4)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideVon Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideBewertung: 3.5 von 5 Sternen3.5/5 (7)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishVon EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishBewertung: 4 von 5 Sternen4/5 (3)

- History of Smart Textiles: A Comprehensive Guide To E-TextilesVon EverandHistory of Smart Textiles: A Comprehensive Guide To E-TextilesNoch keine Bewertungen

- Essential Building Science: Understanding Energy and Moisture in High Performance House DesignVon EverandEssential Building Science: Understanding Energy and Moisture in High Performance House DesignBewertung: 5 von 5 Sternen5/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsVon EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Field Guide for Construction Management: Management by Walking AroundVon EverandField Guide for Construction Management: Management by Walking AroundBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Power Electronics Diploma Interview Q&A: Career GuideVon EverandPower Electronics Diploma Interview Q&A: Career GuideNoch keine Bewertungen