Beruflich Dokumente

Kultur Dokumente

Benefits SigmaWeld

Hochgeladen von

Weld Bro SandeepCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Benefits SigmaWeld

Hochgeladen von

Weld Bro SandeepCopyright:

Verfügbare Formate

Sigma Weld is completely designed and developed at our R n D center in Mumbai, India.

We have

a strong RnD team to meet any specific requirements of our customers. Our technical support

team is well trained and equipped to support the service needs of our customers to maintain the

least down time.

Sigma Weld Welding Inverter Technology offers the following benefits :

1. Easier to Learn: Inbuilt features like Anti-Sticking, Adaptive Hot Start and Adaptive

Arc Force Control make Sigma Weld welding inverters most suitable for learners and

professionals alike. Adaptive features allow the operator to weld with a lot of ease and

control.

2. Easier to Weld: Advances feedback systems allow greater control over the welding

current. Sigma Weld welding inverters are CC (Constant Current) systems for MMA and

TIG applications and CC/CV (Constant Current/ Constant Voltage) for MIG and MAG

applications. This allows operators to achieve good quality weld joints with more ease ,

less skill and Spatterless Welding.

3. Energy Efficient: Sigma Weld are sophisticated IGBT based welding inverters which

consume 60% less energy compared to conventional transformer systems and

33% less energy compared to conventional rectifier systems. Another major

advantage is that the no load current is 0.2A compared to 2.1A in Welding Rectifiers and

8.0A in Welding Transformers. The more you use Sigma Weld the faster you recover

your investment.

4. Robust and Versatile: Sigma Weld can weld with all types of welding electrodes

including 6010(Cellulosic Electrode), 6013, 7018(Low Hydrogen) and SS 308.

Sigma Weld can work with cable lengths upto 50 meters.

5. Safety and Reliability: Inbuilt protections for IGBT Over Current, IGBT Short Circuit

Current, Welding Over Current, Thermal Overload and Prolonged Output Short ensure

longer working life for the equipment. Inbuilt VRD (Voltage Reduction Device) enable LOW

OCV when the inverter is not under use. This feature ensures safe working conditions for

the operators.

6. Portable and User Friendly: SigmaWeld are 70% lighter than equivalent Welding

Transformer or Rectifiers. They have a small footprint and have wheels for added

mobility. The user-friendly interface includes a Digital Display for setting weld current and

Ammeter for displaying welding current. Welding current can be set in increments of 1A

and each process has a memory recall so the operator has one touch process change

over.

7. Advanced Micro Controller Technology: Enables Sigma Weld to have reliable,

repeatable Up Slope, Down Slope and Pulsing capabilities for TIG welding with Lift Arc or

with High Frequency Initiation.

Environment Friendly: Sigma Weld Welding inverters helps reduce consumption of natural

resources like non-ferrous metals copper and aluminum which are to basics for Transformer and

Diode based Welding Systems. Any given 400A welding transformer would have minimum of

50kgs of copper / aluminium winding with a total weight of the System around 200Kgs. Sigma

Weld 400MT is only 45Kg in total system using transformers and chokes with a collective of less

than 5Kgs.

14

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Sandeep Kumar CV - Welding Engineer-Welding InspectorDokument4 SeitenSandeep Kumar CV - Welding Engineer-Welding InspectorWeld Bro Sandeep100% (1)

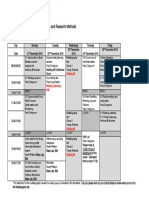

- Welding Systems and Research Methods 2016-17 v2Dokument1 SeiteWelding Systems and Research Methods 2016-17 v2Weld Bro SandeepNoch keine Bewertungen

- Closing The Gap Between Asic Custom Tools and TechniquesDokument431 SeitenClosing The Gap Between Asic Custom Tools and TechniquesAnonymous ZaO7fL4t100% (3)

- When The Weld Face Extends Beyond The Weld Toe PDFDokument1 SeiteWhen The Weld Face Extends Beyond The Weld Toe PDFWeld Bro SandeepNoch keine Bewertungen

- What Is Underwater Welding and How It Works?: 6. CraterDokument2 SeitenWhat Is Underwater Welding and How It Works?: 6. CraterWeld Bro SandeepNoch keine Bewertungen

- UndercutDokument1 SeiteUndercutWeld Bro SandeepNoch keine Bewertungen

- Record of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Dokument1 SeiteRecord of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Weld Bro SandeepNoch keine Bewertungen

- Welding DefectsDokument1 SeiteWelding DefectsWeld Bro SandeepNoch keine Bewertungen

- Lasposities Final Rev3 A3 Formaat PDFDokument1 SeiteLasposities Final Rev3 A3 Formaat PDFWeld Bro SandeepNoch keine Bewertungen

- Spot Weld Mech PropDokument57 SeitenSpot Weld Mech PropWeld Bro SandeepNoch keine Bewertungen

- Aws d1.1 WPS, PQR & WQTDokument4 SeitenAws d1.1 WPS, PQR & WQTWeld Bro SandeepNoch keine Bewertungen

- Kid ActivitiesDokument10 SeitenKid ActivitiesWeld Bro SandeepNoch keine Bewertungen

- NDT Methods NotesDokument1 SeiteNDT Methods NotesWeld Bro SandeepNoch keine Bewertungen

- CV FabricatorDokument2 SeitenCV FabricatorWeld Bro SandeepNoch keine Bewertungen

- General Familiarity With Other NDT Methods Module 4Dokument4 SeitenGeneral Familiarity With Other NDT Methods Module 4Weld Bro SandeepNoch keine Bewertungen

- Liquid Penetrant Testing Module 1Dokument6 SeitenLiquid Penetrant Testing Module 1Weld Bro SandeepNoch keine Bewertungen

- Pressure TestingDokument14 SeitenPressure TestingWeld Bro Sandeep100% (2)

- Level I AnswersDokument3 SeitenLevel I AnswersWeld Bro SandeepNoch keine Bewertungen

- GE T2100 Treadmill Service Manual Rev A.Dokument152 SeitenGE T2100 Treadmill Service Manual Rev A.Marckus Brody0% (1)

- 3 Space Sensor Users Manual Embedded 1 PDFDokument51 Seiten3 Space Sensor Users Manual Embedded 1 PDFmhasansharifiNoch keine Bewertungen

- MC770 / MC780 MPS3537mc / MPS4242mc Maintenance ManualDokument217 SeitenMC770 / MC780 MPS3537mc / MPS4242mc Maintenance ManualPon ThephavongNoch keine Bewertungen

- Bengkel Teknik Menjawab SPM 2016 PDFDokument59 SeitenBengkel Teknik Menjawab SPM 2016 PDFSuriyati Yusoff75% (4)

- V32Dokument2 SeitenV32Antonios A NikolaouNoch keine Bewertungen

- Exp 8 ArduinoDokument6 SeitenExp 8 ArduinoMohamed TalebNoch keine Bewertungen

- Ieee Base CT PT Sizing For Substation Excel Sheet - Google SearchDokument2 SeitenIeee Base CT PT Sizing For Substation Excel Sheet - Google SearchUjjal ChakmaNoch keine Bewertungen

- Uniconn Operation Manual Addendum Subject: Operation of Phoenix Select Gauge With Uniconn Firmware: 1.200R1 Wellview Version 2.400R1Dokument11 SeitenUniconn Operation Manual Addendum Subject: Operation of Phoenix Select Gauge With Uniconn Firmware: 1.200R1 Wellview Version 2.400R1ahmed elsheikhNoch keine Bewertungen

- VRV Ii Rsxy R22Dokument96 SeitenVRV Ii Rsxy R22Carlos Manriquez100% (2)

- UMTS Optimization Example Dr. Hatem MOKHTARIDokument35 SeitenUMTS Optimization Example Dr. Hatem MOKHTARIHatem MOKHTARINoch keine Bewertungen

- Ventilador Bear 1000 Especificaciones TecnicasDokument2 SeitenVentilador Bear 1000 Especificaciones TecnicasDaniel F. Guerrero P.Noch keine Bewertungen

- 2 Guide SSHV2Dokument3 Seiten2 Guide SSHV2Calsonic CMGNoch keine Bewertungen

- AQA AS Physics A Chapter 4 Textbook AnswersDokument4 SeitenAQA AS Physics A Chapter 4 Textbook AnswerscathylisterNoch keine Bewertungen

- 19-9-2014Dokument3 Seiten19-9-2014MANSA MARKETINGNoch keine Bewertungen

- Linux Kernel and Device DriversDokument492 SeitenLinux Kernel and Device DriversshankarnarendraNoch keine Bewertungen

- Electric Products: Contactors / MPCB / MCCB / ACBDokument29 SeitenElectric Products: Contactors / MPCB / MCCB / ACBZAHEER ABBASNoch keine Bewertungen

- Surface Vehicle InformationDokument7 SeitenSurface Vehicle InformationanupthattaNoch keine Bewertungen

- Infocus 930 920 900 PDFDokument85 SeitenInfocus 930 920 900 PDFspeedyeduNoch keine Bewertungen

- Mit Lab 01Dokument6 SeitenMit Lab 01api-247714257Noch keine Bewertungen

- Qualcomm Client Interview Question - Downlaod VLSI FOR ALLDokument18 SeitenQualcomm Client Interview Question - Downlaod VLSI FOR ALLPrajwal SNoch keine Bewertungen

- Huawei E560 User ManualDokument22 SeitenHuawei E560 User Manualgbhargav123100% (1)

- Wireless World 1995 09 S OCRDokument100 SeitenWireless World 1995 09 S OCRMilton NastNoch keine Bewertungen

- GSM User Manual 2017Dokument18 SeitenGSM User Manual 2017Cao NguyênNoch keine Bewertungen

- Man 41151 en 06 PDFDokument56 SeitenMan 41151 en 06 PDFPanneer Selvam100% (1)

- PLLDP BSCDokument6 SeitenPLLDP BSCmounhacNoch keine Bewertungen

- Claud D.: CationDokument3 SeitenClaud D.: CationSathvik S PrabhuNoch keine Bewertungen

- Akcesoria ABB Dla FFDokument8 SeitenAkcesoria ABB Dla FFjanusz_1025Noch keine Bewertungen

- G6 Electricity and Magnetism - Revision Booklet and ANSDokument21 SeitenG6 Electricity and Magnetism - Revision Booklet and ANSAhad AliNoch keine Bewertungen

- SAABO StiprintuvasDokument6 SeitenSAABO StiprintuvasTomasAleknaNoch keine Bewertungen