Beruflich Dokumente

Kultur Dokumente

Test Report Astm f1055 Daa 4ix1 2c 10-12

Hochgeladen von

Haseeb ZahidCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Test Report Astm f1055 Daa 4ix1 2c 10-12

Hochgeladen von

Haseeb ZahidCopyright:

Verfügbare Formate

Preliminary

..\Test_Report_ASTM_F1055_DAA_4Ix1_2C_10-12.doc

FRIALEN-Tapping Tee (DAA) 4IPS x 1/2CTS

made of PE4710

Dated: 26. July 2012

Introduction

This report describes the tests administered for the release of FRIALEN Electrofusion Tapping

Tee, part of the FRIALEN Safety Fittings product range, manufactured by

FRIATEC Aktiengesellschaft

Technical Plastics Division

Mannheim, Germany.

FRIALEN Electrofusion Tapping Tees are composed of Eltex TUB 121 Cell Class

PE345434C PE4710 and suitable in water service line up to 160 psig and Gas service pipeline

up to 125 psig.

General

The fusion procedure and the qualification test were administered at the Test Laboratories of

FRIATEC Aktiengesellschaft Technical Plastics Division, Mannheim, Germany with the pipes

documented in the result tables.

All tests are based on ASTM F1055 "Standard Specification for Electrofusion Type Polyethylene

Fittings for Outside Diameter Controlled Polyethylene Pipe and Tubing".

Fusion procedures based on the Assembly Instruction for FRIALEN Safety Fittings and were

executed at operating temperatures between 14F (-10C) to 120F (+49C).

Subsequently, the test samples were subject to the following tests (ASTM F1055)

- Sustained Pressure Test

ASTM F 1055 9.2 (ASTM D1598)

temperature

176 F (80 C)

hoop stress

670psi (4.6MPa)

min. Time-To-Failure 170h

- Minimum Hydraulic Burst Pressure Test

ASTM F 1055 9.1

- Impact Resistance Test

ASTM F 905

- Joint Crush Test (homogeneity of fusion)

ASTM F 1055 9.4

Proprietary Information

This report is the property of FRIATEC Aktiengesellschaft and is loaned subject to the conditions that it or any

information contained there in will not be used in any way detrimental to the interests of FRIATEC and that all copies

will be returned immediately on demand.

FRIATEC Aktiengesellschaft

Technical Plastics Division

Postbox 71 02 61 D-68222 Mannheim Germany

Tel. +49 621 - 486-0 Fax +49 621 486-1601

E-mail: info-frialen@friatec.de Internet: www.friatec.de

Quality Management

Technical Plastic Division

Test Report

Preliminary

Test Report

FRIALEN-Tapping Tee (DAA) 4IPS x 1/2CTS

made of PE4710

Dated: 26. July 2012

Results

Technical Characteristics/ Marking

Fusion Parameter: 41V 125sec

Marking:

FRIATEC Logo, Safety Fitting, 4IPS x 1/2CTS, ASTM D2513 F1055, AWWA C906,

CE, PE3408, SDR11, Batch-no., G, fusion barcode

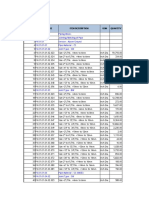

Sustained Pressure Test

according to ASTM F1055 9.2 (ASTM D1598)

Pressure

Minimum time to failure

Saddle / Outlet

133psig (9.3bar)

170 h (desired value)

Pipe

Assembly and

fusion ambient

Test

Time-to-Failure Result

temperature

temperature

DAA 4IPS x 1/2CTS

Drisco 8100

14F

176F

1000 h

no failure occurred

DAA 4IPS x 1/2CTS

Drisco 8100

14F

176F

1000 h

no failure occurred

DAA 4IPS x 1/2CTS

Drisco 8100

120F

176F

1000 h

no failure occurred

DAA 4IPS x 1/2CTS

Drisco 8100

120F

176F

1000 h

no failure occurred

Conclusion

All samples met the requirements. No leakages recorded.

Minimum Hydraulic Burst Pressure Test

according to ASTM F 1055 9.1

Minimum time to failure

Saddle / Outlet

60-70s (desired value)

Pipe

Assembly and

fusion ambient

Temperature

Test

Time-totemperature Failure

Burst

Result

pressure

DAA 4IPS x 1/2CTS

Drisco 8100

14F

73 F

66 s

767 psi

ductile pipe

failure

DAA 4IPS x 1/2CTS

Drisco 8100

14F

73 F

66 s

767 psi

ductile pipe

failure

DAA 4IPS x 1/2CTS

Drisco 8100

120F

73 F

65 s

770 psi

ductile pipe

failure

DAA 4IPS x 1/2CTS

Drisco 8100

120F

73 F

65 s

770 psi

ductile pipe

failure

Conclusion

All samples met the requirements. No leakages recorded

FRIATEC Aktiengesellschaft

Technical Plastics Division

Postbox 71 02 61 D-68222 Mannheim Germany

Tel. +49 621 - 486-0 Fax +49 621 486-1601

E-mail: info-frialen@friatec.de Internet: www.friatec.de

Quality Management

Technical Plastic Division

..\Test_Report_ASTM_F1055_DAA_4Ix1_2C_10-12.doc

Preliminary

Test Report

FRIALEN-Tapping Tee (DAA) 4IPS x 1/2CTS

made of PE4710

Dated: 26. July 2012

Impact Resistance Test

according to ASTM F 905

High

Weight

Saddle / Outlet

78.7 in.

11 lb

Pipe

Assembly and

fusion ambient

Temperature

Ambient

Result

temperature

DAA 4IPS x 1/2CTS

Drisco 8100

14F

73F

no break in the joint

DAA 4IPS x 1/2CTS

Drisco 8100

14F

73F

no break in the joint

DAA 4IPS x 1/2CTS

Drisco 8100

73F

73F

no break in the joint

DAA 4IPS x 1/2CTS

Drisco 8100

73F

73F

no break in the joint

Conclusion

All samples met the requirements. No leakages in the joint recorded

Joint Crush Test

according to ASTM F1055 9.4.1

Saddle / Outlet

Pipe

Assembly and

fusion ambient

Temperature

Test

Result

temperature

DAA 4IPS x 1/2CTS

Drisco 8100

14F

70-77F

Separation <15%

DAA 4IPS x 1/2CTS

Drisco 8100

14F

70-77F

Separation <15%

DAA 4IPS x 1/2CTS

Drisco 8100

120F

70-77F

Separation <15%

DAA 4IPS x 1/2CTS

Drisco 8100

120F

70-77F

Separation <15%

Conclusion

In all cases homogeneous fusion result were achieved. Only minor separations less then 15% of the

total fusion zone could be seen.

FRIATEC Aktiengesellschaft

Technical Plastics Division

Postbox 71 02 61 D-68222 Mannheim Germany

Tel. +49 621 - 486-0 Fax +49 621 486-1601

E-mail: info-frialen@friatec.de Internet: www.friatec.de

Quality Management

Technical Plastic Division

..\Test_Report_ASTM_F1055_DAA_4Ix1_2C_10-12.doc

Das könnte Ihnen auch gefallen

- Advanced Temperature Measurement and Control, Second EditionVon EverandAdvanced Temperature Measurement and Control, Second EditionNoch keine Bewertungen

- Panasonic Centrifugal Fan Performance GuideDokument210 SeitenPanasonic Centrifugal Fan Performance Guideออกแบบเครื่องแลกเปลี่ยนความร้อนNoch keine Bewertungen

- PD Cen-Tr 13931-2009Dokument32 SeitenPD Cen-Tr 13931-2009Meric100% (1)

- Astm 2466-15 PDFDokument6 SeitenAstm 2466-15 PDFDeisabel CrespoNoch keine Bewertungen

- Cb86nvl40m6ufrk0x8r3 PDFDokument22 SeitenCb86nvl40m6ufrk0x8r3 PDFvigneshNoch keine Bewertungen

- Saso Gso 1438 2003 e PDFDokument12 SeitenSaso Gso 1438 2003 e PDFshafeeqm3086Noch keine Bewertungen

- IGN 4-01-03 31 October 2015 PDFDokument35 SeitenIGN 4-01-03 31 October 2015 PDFGradinariu IonutNoch keine Bewertungen

- A A 58092Dokument5 SeitenA A 58092AbieNoch keine Bewertungen

- NSF Standard 14Dokument3 SeitenNSF Standard 14krisNoch keine Bewertungen

- Astm D3262-96Dokument8 SeitenAstm D3262-96anish_am2005Noch keine Bewertungen

- Astmf436 PDFDokument6 SeitenAstmf436 PDFMiguel Angel Oncoy TahuaNoch keine Bewertungen

- Chlorinated Poly (Vinyl Chloride) (CPVC) Pipe and Fittings For Chemical Waste Drainage SystemsDokument7 SeitenChlorinated Poly (Vinyl Chloride) (CPVC) Pipe and Fittings For Chemical Waste Drainage SystemsAhmad Zubair RasulyNoch keine Bewertungen

- Norma2 10226-1-2004Dokument13 SeitenNorma2 10226-1-2004Americo SantosNoch keine Bewertungen

- Iso 15874 3 2013 en PDFDokument11 SeitenIso 15874 3 2013 en PDFZakaria Chouli100% (3)

- C1071Dokument4 SeitenC1071dinhtung22100% (1)

- Standard Specification For Fiberglass, (Fibra de Vidrio)Dokument5 SeitenStandard Specification For Fiberglass, (Fibra de Vidrio)coltkidNoch keine Bewertungen

- F 876 - 01 - Rjg3ni0wmuuyDokument6 SeitenF 876 - 01 - Rjg3ni0wmuuyPrakash MakadiaNoch keine Bewertungen

- F1412 16Dokument7 SeitenF1412 16masoud132Noch keine Bewertungen

- PPI Handbook Above GroundDokument24 SeitenPPI Handbook Above GroundNeil MalottNoch keine Bewertungen

- Contact-Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Corrosion Resistant Pipe and FittingsDokument7 SeitenContact-Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Corrosion Resistant Pipe and Fittingshasan syukur100% (1)

- Sample 02 Declaration of ConformityDokument2 SeitenSample 02 Declaration of ConformitymamsikaNoch keine Bewertungen

- 1855 1Dokument2 Seiten1855 1hogoyoNoch keine Bewertungen

- Resilient Seated Wedge Gate Valve Data SheetDokument2 SeitenResilient Seated Wedge Gate Valve Data Sheetkbc404100% (1)

- Astm F439Dokument7 SeitenAstm F439Quat Le DinhNoch keine Bewertungen

- 13 14 Technical Literature and StandardsDokument8 Seiten13 14 Technical Literature and StandardsMohammad Rashad BarakatNoch keine Bewertungen

- Jeremias INSTALL DS-GOV PDFDokument28 SeitenJeremias INSTALL DS-GOV PDFjudi sierNoch keine Bewertungen

- Astm D1785 (2012) PDFDokument11 SeitenAstm D1785 (2012) PDFchairul anwarNoch keine Bewertungen

- ISCO HDPE Product Catalog-HDPE PipeDokument6 SeitenISCO HDPE Product Catalog-HDPE PipeJorge Santos RomeroNoch keine Bewertungen

- BS en 14692-2017 - TC - (2020-08-27 - 08-40-55 Am) PDFDokument28 SeitenBS en 14692-2017 - TC - (2020-08-27 - 08-40-55 Am) PDF梁山伯Noch keine Bewertungen

- Joints For Drain and Sewer Plastic Pipes Using Flexible Elastomeric SealsDokument3 SeitenJoints For Drain and Sewer Plastic Pipes Using Flexible Elastomeric SealsbetopagoadaNoch keine Bewertungen

- ASTM copyright document from 1999Dokument6 SeitenASTM copyright document from 1999Anonymous CT9vOyOjZk100% (1)

- Asme B36.10M-2004Dokument26 SeitenAsme B36.10M-2004Yen Piankin Wee Valencia100% (2)

- F439Dokument7 SeitenF439cenkunal100% (1)

- Astm C 97-2018Dokument4 SeitenAstm C 97-2018Mohammed AliNoch keine Bewertungen

- DIN 8075 - Polyethylene - Pipes PDFDokument11 SeitenDIN 8075 - Polyethylene - Pipes PDFvictoraghiNoch keine Bewertungen

- Astm F2159Dokument6 SeitenAstm F2159Hernando Andrés Ramírez GilNoch keine Bewertungen

- BS en 1796 - 2006Dokument68 SeitenBS en 1796 - 2006GermaSilamba100% (1)

- Astm F2561-16Dokument4 SeitenAstm F2561-16hugoNoch keine Bewertungen

- BS 5151Dokument18 SeitenBS 5151Steva76Noch keine Bewertungen

- En 13121-3 (2016) (E)Dokument10 SeitenEn 13121-3 (2016) (E)jasonNoch keine Bewertungen

- BF-PPS As Dismantling Joints - EngDokument3 SeitenBF-PPS As Dismantling Joints - EngbikarexpansionjointsNoch keine Bewertungen

- Iso 21809 2 2007 en FR PDFDokument11 SeitenIso 21809 2 2007 en FR PDFmsaremiNoch keine Bewertungen

- Epilux 200 Polyamide Cured Coaltar EpoxyDokument3 SeitenEpilux 200 Polyamide Cured Coaltar EpoxyIqra AngelsNoch keine Bewertungen

- 08 3 PDFDokument42 Seiten08 3 PDFmakoi100% (1)

- Non-Asbestos Gasket Material Data SheetDokument1 SeiteNon-Asbestos Gasket Material Data Sheetheena jainNoch keine Bewertungen

- Astm f442f442m 13 6943Dokument3 SeitenAstm f442f442m 13 6943Binodh DanielNoch keine Bewertungen

- Astm F714Dokument10 SeitenAstm F714santiago barrionuevoNoch keine Bewertungen

- E40000 Aquatherm Red Pipe 02Dokument74 SeitenE40000 Aquatherm Red Pipe 02Akram FerchichiNoch keine Bewertungen

- FRIALEN Product RangeDokument96 SeitenFRIALEN Product RangestavrarusNoch keine Bewertungen

- Diaphragm Ds 2 Post BDokument12 SeitenDiaphragm Ds 2 Post Bozzy75Noch keine Bewertungen

- Victaulic System Solution For HDPE Pipe Qualification Tests IPS and ISO High-Density Polyethylene (HDPE)Dokument6 SeitenVictaulic System Solution For HDPE Pipe Qualification Tests IPS and ISO High-Density Polyethylene (HDPE)محمد خميسNoch keine Bewertungen

- Hydro Plast - EngDokument36 SeitenHydro Plast - EngQuan TranNoch keine Bewertungen

- PE Water AbsorbtionDokument16 SeitenPE Water AbsorbtionMohamed ElarabiNoch keine Bewertungen

- Astm F2769Dokument10 SeitenAstm F2769Hernando Andrés Ramírez GilNoch keine Bewertungen

- Catalog WefatermDokument55 SeitenCatalog WefatermAlin NicolaeNoch keine Bewertungen

- Polyethylene (PE) Gas Pressure Pipe, Tubing, and Fittings: Standard Specification ForDokument18 SeitenPolyethylene (PE) Gas Pressure Pipe, Tubing, and Fittings: Standard Specification ForPatricio G. ArrienNoch keine Bewertungen

- Astm F876Dokument13 SeitenAstm F876Philip100% (1)

- EHEDG Position Paper 07 2017Dokument3 SeitenEHEDG Position Paper 07 2017Balaji MurugesanNoch keine Bewertungen

- Rhodia Tds Technyl C 548b v15 enDokument2 SeitenRhodia Tds Technyl C 548b v15 enDejan PekićNoch keine Bewertungen

- Rhodia - Tds - Technylstar S 218 v30 Black 31 N - enDokument5 SeitenRhodia - Tds - Technylstar S 218 v30 Black 31 N - ennimonhNoch keine Bewertungen

- Bridging Organization Theory and Supply Chain ManagementDokument8 SeitenBridging Organization Theory and Supply Chain ManagementHaseeb ZahidNoch keine Bewertungen

- Effect of Parameters On PP ProcessingDokument10 SeitenEffect of Parameters On PP ProcessingMohsin ShahNoch keine Bewertungen

- Dark Side of OCBDokument18 SeitenDark Side of OCBHaseeb ZahidNoch keine Bewertungen

- uPVC Pipes According to DIN StandardsDokument7 SeitenuPVC Pipes According to DIN Standardsしんちゃん ナカリンNoch keine Bewertungen

- ASTM D 2837 - Obtaining Hydro Static Design Basis For Thermoplastic Pipe MaterialsDokument14 SeitenASTM D 2837 - Obtaining Hydro Static Design Basis For Thermoplastic Pipe Materials이광춘Noch keine Bewertungen

- F 656 - 96 - Rjy1ni05nkeDokument3 SeitenF 656 - 96 - Rjy1ni05nkeMorched TounsiNoch keine Bewertungen

- Formulation of Field Databased Model A Case Study at PVC Pipe ManuDokument6 SeitenFormulation of Field Databased Model A Case Study at PVC Pipe ManuHaseeb ZahidNoch keine Bewertungen

- Long Term Hydrostatic StrenghtDokument11 SeitenLong Term Hydrostatic StrenghtHaseeb ZahidNoch keine Bewertungen

- D 2444 - 99 Rdi0ndqDokument8 SeitenD 2444 - 99 Rdi0ndqHumberto GutierrezNoch keine Bewertungen

- Specifications-PVC SDR SeriesDokument2 SeitenSpecifications-PVC SDR SerieskrishnaNoch keine Bewertungen

- Polymer DSCDokument8 SeitenPolymer DSCUmer HayatNoch keine Bewertungen

- ASTM D1785, D2665, D2241, F441 PVC and CPVC Pipe SpecsDokument6 SeitenASTM D1785, D2665, D2241, F441 PVC and CPVC Pipe SpecsFalak KhanNoch keine Bewertungen

- Specifications PVC Pipe Sch40Dokument2 SeitenSpecifications PVC Pipe Sch40Haseeb ZahidNoch keine Bewertungen

- Specifications CPVC PipeDokument2 SeitenSpecifications CPVC PipeHaseeb ZahidNoch keine Bewertungen

- Long Term Hydrostatic StrenghtDokument11 SeitenLong Term Hydrostatic StrenghtHaseeb ZahidNoch keine Bewertungen

- Tech ManualDokument128 SeitenTech ManualHaseeb ZahidNoch keine Bewertungen

- Astm F-441Dokument7 SeitenAstm F-441Haseeb ZahidNoch keine Bewertungen

- Wall Section AaDokument1 SeiteWall Section AaSHIVAM RAVALNoch keine Bewertungen

- IP (Power Plant Building)Dokument26 SeitenIP (Power Plant Building)Josue Carubio Ricalde Jr.Noch keine Bewertungen

- BXUV.P264 Fire Resistance Ratings - ANSI/UL 263Dokument5 SeitenBXUV.P264 Fire Resistance Ratings - ANSI/UL 263AlexNoch keine Bewertungen

- Finishes 2Dokument17 SeitenFinishes 2Aliea NasreenNoch keine Bewertungen

- Simplified Design Method For Slim Floor Beams Exposed To FireDokument22 SeitenSimplified Design Method For Slim Floor Beams Exposed To FireVirmantas JuoceviciusNoch keine Bewertungen

- Enclosures and Raceways GuideDokument31 SeitenEnclosures and Raceways GuideKean Havan PingoyNoch keine Bewertungen

- National Gypsum Construction GuideDokument164 SeitenNational Gypsum Construction Guidelglfan42Noch keine Bewertungen

- CCTV Project Price 2020!5!11Dokument10 SeitenCCTV Project Price 2020!5!11Salman FayyazNoch keine Bewertungen

- Antiquated Structural Systems - Part 1: Pdhonline Course S211 (6 PDH)Dokument53 SeitenAntiquated Structural Systems - Part 1: Pdhonline Course S211 (6 PDH)Vincent De GuzmanNoch keine Bewertungen

- Detailed Estimate For The Construction of A Residential BuildingDokument11 SeitenDetailed Estimate For The Construction of A Residential BuildingSukhendra SinghNoch keine Bewertungen

- Catalogue 2013-14 PDFDokument410 SeitenCatalogue 2013-14 PDFRAFID SUHAILNoch keine Bewertungen

- Anualized Geo SolarDokument6 SeitenAnualized Geo SolarMathieu LamaureNoch keine Bewertungen

- 07 Heater, Ventilation & A Ir Conditioning (Hvac) : 40 Control SystemDokument11 Seiten07 Heater, Ventilation & A Ir Conditioning (Hvac) : 40 Control SystemPhan VănNoch keine Bewertungen

- Vertical Vessel Circular Pattern Anchor Bolt DesignDokument4 SeitenVertical Vessel Circular Pattern Anchor Bolt DesignJem EripolNoch keine Bewertungen

- Electrical Bill of QuantityDokument1 SeiteElectrical Bill of QuantityRamadan Rashad100% (1)

- Slab On Ground (ACI360R)Dokument2 SeitenSlab On Ground (ACI360R)Roberto Catalani100% (2)

- PipingDokument57 SeitenPipingIshwar AltNoch keine Bewertungen

- ST5101-Advance Concrete StructuresDokument16 SeitenST5101-Advance Concrete Structuresraj25% (4)

- Road Estimate Cement Concrete RoadDokument15 SeitenRoad Estimate Cement Concrete RoadJAGANNoch keine Bewertungen

- NB Approved Architectural Plans 590 Myrtle AveDokument48 SeitenNB Approved Architectural Plans 590 Myrtle AveMaeNoch keine Bewertungen

- Mix Design - ACI 211.1-2002Dokument7 SeitenMix Design - ACI 211.1-2002Emut ManabungNoch keine Bewertungen

- Fit Out GuidelinesDokument46 SeitenFit Out GuidelinesAiswarya SreekumarNoch keine Bewertungen

- Method of Statement For Installation of Domestic Hot & Cold Water Supply Cop PDFDokument4 SeitenMethod of Statement For Installation of Domestic Hot & Cold Water Supply Cop PDFCool SharyNoch keine Bewertungen

- Canvass materials for RT3 Building plumbing projectDokument1 SeiteCanvass materials for RT3 Building plumbing projectTeddy AcedoNoch keine Bewertungen

- Jana Jagriti Basic SchoolDokument16 SeitenJana Jagriti Basic Schoolrajendra moktanNoch keine Bewertungen

- Preliminary design of structural elements for residential buildingDokument4 SeitenPreliminary design of structural elements for residential buildingSuson Dhital0% (1)

- ITP For BLOCKWORKDokument4 SeitenITP For BLOCKWORKimkashifsaleemNoch keine Bewertungen

- Brickwork, Masonry, Plastering & Painting WorksDokument8 SeitenBrickwork, Masonry, Plastering & Painting WorksGopal SudhirNoch keine Bewertungen

- Américas 1500Dokument48 SeitenAméricas 1500Ghina Revita SakinahNoch keine Bewertungen

- Folded Plate Structures FinalDokument27 SeitenFolded Plate Structures FinalJ 3 E100% (1)