Beruflich Dokumente

Kultur Dokumente

Key Points in Enquiry Specification Request For Quotation RFQ

Hochgeladen von

thuyenquyen_vtOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Key Points in Enquiry Specification Request For Quotation RFQ

Hochgeladen von

thuyenquyen_vtCopyright:

Verfügbare Formate

piping-engineering.

com

http://www.piping-engineering.com/enquiry-specification-request-for-quotation-rfq.html

Key Points in Enquiry Specification/ Request For Quotation

(RFQ)

While procuring the piping material, one needs to go through the request for quotation phase. And whenever we

prepare an enquiry specification/request for quotation (RFQ) there are many key points which needs to be

considered and included in the specification so that all the project requirements are followed and met by the

vendor/supplier during the delivery of the final product.

Before preparing the enquiry specification the engineer should read all the project specification and the applicable

codes and standards so that they are covered in the specification. If there is any requirement in the project which

is not a standard practice then that should be covered and highlighted to the vendor in the specification.

Specification engineer should always refer and follow the latest version of the code and standard available.

Key topics which need to be explicitly mentioned in an enquiry specification/Request for quotation (RFQ) are

mentioned below:

1. Product fabrication guidelines. (what can be done & what cannot be done, For ex.: cold work / hot work /

drawing etc)

2. Product chemical composition control. (For ex.: Codes applicable / Max % of elements etc)

3. Product Governing codes (For ex.: ASME / ASTM / NACE / Chapter IX etc)

4. Product heat treatment / stress relieving requirements. (For ex.: Tempering / Normalizing etc)

5. Product Surface treatment requirements (For ex.: Galvanizing / Pickling / Passivation etc)

6. Product production Quality assurance, quality control & quality management requirements (For ex.: ISO Quality

management system / Quality plans / Min. info. in Quality record manual etc)

7. Product inspection plan / inspection frequency / (For ex.: Inspection methods / frequency / Inspectors qualifying

procedures etc)

8. Product testing requirements (For ex.: Codes applicable / PMI / NDE / Hydrotest / sampling etc)

9. Product certification requirements (For ex.: EN10204 3.1 or 3.2 etc)

10. Product marking requirements (For ex.: Color code / tagging etc)

11. Product Preservation requirements (For ex.: preservation methods / Preservation requirements etc)

12. Products minimum documentation to be submitted for approval (For ex.: As per SDRL)

13. Product packing requirements (For ex.: Packing for sea / land / road transportation etc)

14. Product delivery information (For ex.: Final destination / Delivery period etc)

15. Product shipping information (For ex.: Weight & volume of product / Freight charges etc)

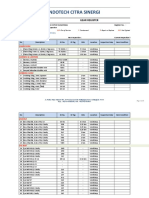

16. Size compatibility between Nominal sizes API 6A Sizes

Request for quotation

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Vendor Drawing Review VDR Valve Specific RequirementsDokument5 SeitenVendor Drawing Review VDR Valve Specific Requirementsthuyenquyen_vtNoch keine Bewertungen

- Vendor Drawing Review A Review of Valve DrawingsDokument3 SeitenVendor Drawing Review A Review of Valve Drawingsthuyenquyen_vt100% (1)

- Bolting Selection Guide For Bolting MaterialDokument5 SeitenBolting Selection Guide For Bolting Materialthuyenquyen_vtNoch keine Bewertungen

- TR-01Bonder Training Program (Main)Dokument198 SeitenTR-01Bonder Training Program (Main)thuyenquyen_vtNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- M 02 0001Dokument3 SeitenM 02 0001Miguel ruizNoch keine Bewertungen

- Lesson 2 - Reflection PaperDokument2 SeitenLesson 2 - Reflection PaperkristhelynNoch keine Bewertungen

- Headworks & Barrage: Chapter # 09 Santosh Kumar GargDokument29 SeitenHeadworks & Barrage: Chapter # 09 Santosh Kumar GargUmer WaheedNoch keine Bewertungen

- DP 900T00A ENU TrainerHandbookDokument288 SeitenDP 900T00A ENU TrainerHandbookAndré baungatnerNoch keine Bewertungen

- Integrated Curriculum For Secondary Schools: Mathematics Form 2Dokument139 SeitenIntegrated Curriculum For Secondary Schools: Mathematics Form 2Izawaty IsmailNoch keine Bewertungen

- Student Exploration: Electron Configuration: 8-27-2005 Joshua Perez-LunaDokument14 SeitenStudent Exploration: Electron Configuration: 8-27-2005 Joshua Perez-LunaJoshua Perez-Luna67% (3)

- SAGC Compliance Awareness-Grid UsersDokument66 SeitenSAGC Compliance Awareness-Grid Userskamal_khan85Noch keine Bewertungen

- Job No. 25800: Quebrada Blanca Fase 2Dokument1 SeiteJob No. 25800: Quebrada Blanca Fase 2Benjamín Muñoz MuñozNoch keine Bewertungen

- s145 Series HMM 201902 PDFDokument73 Seitens145 Series HMM 201902 PDFEuNoch keine Bewertungen

- Comparison of Plate Count Agar and R2A Medium For Enumeration of Heterotrophic Bacteria in Natural Mineral WaterDokument4 SeitenComparison of Plate Count Agar and R2A Medium For Enumeration of Heterotrophic Bacteria in Natural Mineral WaterSurendar KesavanNoch keine Bewertungen

- Module-2: SolidificationDokument16 SeitenModule-2: SolidificationSachin AgnihotriNoch keine Bewertungen

- Unit 8 - A Closer Look 2Dokument3 SeitenUnit 8 - A Closer Look 2Trần Linh TâmNoch keine Bewertungen

- Entrepreneurial BehaviourDokument16 SeitenEntrepreneurial Behaviournonalyn tomboconNoch keine Bewertungen

- Iphone 14 Pro Max Inspired Preset by Rey Dhen - XMPDokument3 SeitenIphone 14 Pro Max Inspired Preset by Rey Dhen - XMPRizkia Raisa SafitriNoch keine Bewertungen

- Cloudworx Pdms UsDokument2 SeitenCloudworx Pdms Usguru4lifegmailcomNoch keine Bewertungen

- Strain GaugeDokument7 SeitenStrain GaugefahadarizkiNoch keine Bewertungen

- FINAL Shivani Confined Space PermitDokument1 SeiteFINAL Shivani Confined Space PermitVimal SinghNoch keine Bewertungen

- Piramal Revanta - Tower 3Dokument13 SeitenPiramal Revanta - Tower 3bennymahaloNoch keine Bewertungen

- PQA824 ManualDokument100 SeitenPQA824 ManualElkin AguasNoch keine Bewertungen

- Civil & Structural Designer'S Data Pack: Section 7: MasonryDokument5 SeitenCivil & Structural Designer'S Data Pack: Section 7: MasonryMirea Florentin0% (1)

- Pism Pub Line Up - Jul-Dec - 2022Dokument1 SeitePism Pub Line Up - Jul-Dec - 2022Yus CeballosNoch keine Bewertungen

- Inspection List For Electrical PortableDokument25 SeitenInspection List For Electrical PortableArif FuadiantoNoch keine Bewertungen

- Normal DistributionDokument23 SeitenNormal Distributionlemuel sardualNoch keine Bewertungen

- En 10143-1993Dokument7 SeitenEn 10143-1993Eduardo TeixeiraNoch keine Bewertungen

- Floor DiaphragmDokument24 SeitenFloor DiaphragmChristian LeobreraNoch keine Bewertungen

- CHEM 111 Assignment 2024Dokument3 SeitenCHEM 111 Assignment 2024Ben Noah EuroNoch keine Bewertungen

- Sources of LawDokument27 SeitenSources of LawIshita AgarwalNoch keine Bewertungen

- Lesson 2 Principles of Cooperative ConversationDokument9 SeitenLesson 2 Principles of Cooperative Conversationdelilah o balladNoch keine Bewertungen

- Kelley DavisDokument3 SeitenKelley Davisapi-626701108Noch keine Bewertungen

- 65° Panel Antenna: General SpecificationsDokument2 Seiten65° Panel Antenna: General SpecificationsAnnBliss100% (2)