Beruflich Dokumente

Kultur Dokumente

Rev A. Magnetic Level Gauge With Level Transmitter Datasheet PDF

Hochgeladen von

NguyễnQuíTrọngOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Rev A. Magnetic Level Gauge With Level Transmitter Datasheet PDF

Hochgeladen von

NguyễnQuíTrọngCopyright:

Verfügbare Formate

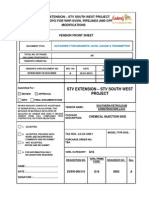

PETROVIETNAM LOW PRESSURE GAS DISTRIBUTION

JOINT STOCK COMPANY

PROJECT

TIEN HAI THAI BINH LOW PRESSURE GAS DISTRIBUTION

PIPELINE SYSTEM

PHASE

DEHYDRATION

MAGNETIC LEVEL GAUGE

WITH LEVEL TRANSMITTER

Rev

12/12/2014

Date

TVN

LDB

Prepared by

Checked by

Issued for Review

Description

Contractor:

ALPHA ECC

NHC

Alpha-ECC

Approved by Checked by Approved by

PVGAS D

Contractors Document Number:

KTA.TB-PAC03-J13-005

Total pages: 5

(Incl. this page)

CUSTOMER

: PVGAS D

ITEM/TAG No. LZT-0133

LOCATION

: VIETNAM

DATA SHEET No. KTA.TB-PAC03-J13-001.02

AREA

: BLOCK 102 & 106 - PHASE 1

PROJECT No.

PROJECT

: TB-HR LPGD PIPELINE SYSTEM

SHEET

1 OF 4

INSTRUMENT DATA SHEET

OTHER

TRANSMITTER

INDICATOR

FLOAT MATERIAL

PROCESS DETAILS

GENERAL

MAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER

NOTES :

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

Tag No.

Service

P&ID No.

Line/Vessel No.

Hazardous Area Classification

Quantity

Fluid

Phase

Operating pressure

Operating temperature

Design pressure

Design Temperature

Operating differential Pressure

Liquid (mixture) density

Body or Chamber Material

Magnetic Follower/Float Material

Flange Material

Flange Rating

Process Connection Type

Conn Size & Location : Upper

Conn Size & Location : Lower

Vent / Drain Conn. Type & Size

Visible Length

Center To Center Distance

Indicator Type

Indicator Scale

Indicator Scale Material

Manufacturer

Model No.

Service

Function

Range

Output

Supply Voltage

Accuracy

Output Action

Mounting

Enclosure: Material

Class

Contacts : No.

Form

Conduit Connection

Ex Certification

Mounting

Drain and Vent Valves:

NACE Compliant

1.

2.

3.

4.

5

LG-0133/LZT-0133

Flash Vessel

KTA.TB-PAC03-M07-003

V-101

ZONE 2 , GROUP IIA, T3

1 (One)

Barg

C

Barg

C

mBar

Kg/m3

TEG

Liquid

3.9

70

10

100

N/A

1079

316SS

316SS

316SS

ASME 150# RF WN

Flanged

DN50, Side

DN50, Side

Flanged 150# RF, DN 20

1500 mm

1500 mm

Magnetic flap

Magnetic flap

316 SS

VTA

VTA

Magnetic Level Gauge and Level Transmitter

Indicate/Transmit

0-100%

4-20 mA (2-wire), HART comm. Protocol.

24 V DC

0.1% of full span

Increase

Integral Low

Aluminium (Note 5)

IP65

M20x1.5

EEx:ia IIB T4

Direct Mounted (Bottom)

3/4" 150# WNRF FLAGNE

N/A

Insulation support/clip shall be provided by Vendor for insulation installed by Purchaser.

Refer to P&ID

Transmitter shall be supplied with 316 SS, Ex i, ATEX certified plugs for all spare cable entries

The rolling magnet type of indication with red and yellow follower.

Transmitter enclosure/ casing/ junction box shall be epoxy-coated low copper aluminium.

CUSTOMER

: PVGAS D

ITEM/TAG No. LZT-0142

LOCATION

: VIETNAM

DATA SHEET No. KTA.TB-PAC03-J13-005.02

AREA

: BLOCK 102 & 106 - PHASE 1

PROJECT No.

PROJECT

: TB-HR LPGD PIPELINE SYSTEM

SHEET

2 OF 4

INSTRUMENT DATA SHEET

OTHER

TRANSMITTER

INDICATOR

FLOAT MATERIAL

PROCESS DETAILS

GENERAL

MAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER

NOTES :

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

1.

2.

3.

4.

5

Tag No.

Service

P&ID No.

Line/Vessel No.

Hazardous Area Classification

Quantity

Fluid

Phase

Operating pressure

Operating temperature

Design pressure

Design Temperature

Operating differential Pressure

Liquid (mixture) density

Body or Chamber Material

Magnetic Follower/Float Material

Flange Material

Flange Rating

Process Connection Type

Conn Size & Location : Upper

Conn Size & Location : Lower

Vent / Drain Conn. Type & Size

Visible Length

Center To Center Distance

Indicator Type

Indicator Scale

Indicator Scale Material

Manufacturer

Model No.

Service

Function

Range

Output

Supply Voltage

Accuracy

Output Action

Mounting

Enclosure: Material

Class

Contacts : No.

Form

Conduit Connection

Ex Certification

Mounting

Drain and Vent Valves:

NACE Compliant

LZT-0142

Glycol Surge Drum

KTA.TB-PAC03-M07-004

V-103

ZONE 2 , GROUP IIA, T3

1 (One)

Barg

C

Barg

C

mBar

Kg/m3

TEG

Liquid

0.20

43-93.4

7.5

100

N/A

1066.1

316SS

316SS

316SS

ASME 150# RF WN

Flanged

DN50, Side

DN50, Side

Flanged 150# RF, DN 20

1900 mm

1900 mm

Magnetic flap

Magnetic flap

316 SS

VTA

VTA

Magnetic Level Gauge and Level Transmitter

Indicate/Transmit

0-100%

4-20 mA (2-wire), HART comm. Protocol.

24 V DC

0.1% of full span

Increase

Integral Low

Aluminium (Note 5)

IP65

M20x1.5

EEx:ia IIB T4

Direct Mounted (Bottom)

3/4" 150# WNRF FLAGNE

N/A

Insulation support/clip shall be provided by Vendor for insulation installed by Purchaser.

Refer to P&ID

Transmitter shall be supplied with 316 SS, Ex i, ATEX certified plugs for all spare cable entries

The rolling magnet type of indication with red and yellow follower.

Transmitter enclosure/ casing/ junction box shall be epoxy-coated low copper aluminium.

CUSTOMER

: PVGAS D

ITEM/TAG No. LZT-0172

LOCATION

: VIETNAM

DATA SHEET No. KTA.TB-PAC03-J13-005.02

AREA

: BLOCK 102 & 106 - PHASE 1

PROJECT No.

PROJECT

: TB-HR LPGD PIPELINE SYSTEM

SHEET

3 OF 4

INSTRUMENT DATA SHEET

OTHER

TRANSMITTER

INDICATOR

FLOAT MATERIAL

PROCESS DETAILS

GENERAL

MAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER

NOTES :

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

1.

2.

3.

4.

5

Tag No.

Service

P&ID No.

Line/Vessel No.

Hazardous Area Classification

Quantity

Fluid

Phase

Operating pressure

Operating temperature

Design pressure

Design Temperature

Operating differential Pressure

Liquid (mixture) density

Body or Chamber Material

Magnetic Follower/Float Material

Flange Material

Flange Rating

Process Connection Type

Conn Size & Location : Upper

Conn Size & Location : Lower

Vent / Drain Conn. Type & Size

Visible Length

Center To Center Distance

Indicator Type

Indicator Scale

Indicator Scale Material

Manufacturer

Model No.

Service

Function

Range

Output

Supply Voltage

Accuracy

Output Action

Mounting

Enclosure: Material

Class

Contacts : No.

Form

Conduit Connection

Ex Certification

Mounting

Drain and Vent Valves:

NACE Compliant

LZT-0172

Flash Vessel

KTA.TB-PAC03-M07-007

V-104

ZONE 2 , GROUP IIA, T3

1 (One)

Barg

C

Barg

C

mBar

Kg/m3

Water

Liquid

0.30

37

7.5

100

N/A

993.4

316SS

316SS

316SS

ASME 150# RF WN

Flanged

DN50, Side

DN50, Side

Flanged 150# RF, DN 20

800 mm

800 mm

Magnetic flap

Graduated in%

316 SS

VTA

VTA

Magnetic Level Gauge and Level Transmitter

Indicate/Transmit

0-100%

4-20 mA (2-wire), HART comm. Protocol.

24 V DC

0.1% of full span

Increase

Integral Low

Aluminium (Note 5)

IP65

M20x1.5

EEx:ia IIB T4

Direct Mounted (Bottom)

3/4" 150# WNRF FLAGNE

N/A

Insulation support/clip shall be provided by Vendor for insulation installed by Purchaser.

Refer to P&ID

Transmitter shall be supplied with 316 SS, Ex i, ATEX certified plugs for all spare cable entries

The rolling magnet type of indication with red and yellow follower.

Transmitter enclosure/ casing/ junction box shall be epoxy-coated low copper aluminium.

CUSTOMER

: PVGAS D

ITEM/TAG No.

LOCATION

: VIETNAM

DATA SHEET No. KTA.TB-PAC03-J13-005.02

AREA

: BLOCK 102 & 106 - PHASE 1

PROJECT No. AL-3098

PROJECT

: TBHR GAS DISTRIBUTION AND GATHERING

SHEET

VALVES

ATION

SPECIFICATION

SHEET

4 OF 4

INSTRUMENT DATA SHEET

MAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER- NOTES

GENERAL NOTES

1.

Documentation Required:

Hazardous Area Certificate - ATEX certification

Ingress Protection Certificate

Hydrotest Certificate

Calibration Certificate

Material Certificate, ISO-EN 10204, Type 3.1 (B) for pressure retaining parts.

Installation & Commissioning spare Parts List and 2 years Operational Spares List

Compliance/ Conformance Certificate

General Arrangement drawing with complete Model Numbers, Dimension and Hookup details

2.

All instruments shall be provided with a SS 316 name plate with tag no. pernamently inscribed

Level transmitters and accessories shall be able to sustain process design pressure, temperature and service fluid.

Level transmitters and accessories should meet the following specifications:

Elastomer used in the instrument / accessories are compatible with the service fluid specified

All tube fittings shall be SS316, of Swagelok make, imperial size, double compression type.

Field bus based transmitter/ devices must satisfy the requirements of the field bus registration laboratory with applicable checkmark of foundation field bus.

The field bus instruments in hazardous area shall be certified as per entity concept or shall be FISCO approved.

Internal software shall be configured by the vendor including the following information such as serial number, Device Tag (Tag Number) and Process description.

10

Bolts/nut ASTM A193 Gr.B7/A194-2H with xylan flourocarbon coated

Specification for instrumentation KTA.TB-PAC03-M65-007

at design conditions.

CUSTOMER

: PVGAS D

ITEM/TAG No. LIT-0111

LOCATION

: VIETNAM

DATA SHEET No. KTA.TB-PAC03-J13-005.02

AREA

: BLOCK 102 & 106 - PHASE 1

PROJECT No. AL-3098

PROJECT

: TB-HR LPGD PIPELINE SYSTEM

SHEET

VALVES SPECIFICATION

INSTRUMENT

1 OF 10

DATA SHEET

MAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER

OTHER

TRANSMITTER

INDICATOR

FLOAT MATERIAL

PROCESS DETAILS

GENERAL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

30

34

35

36

37

38

39

NOTES :

1.

2.

3.

4.

5

LG-0111/LIT-0111

Glycol Contactor C-101

KTA.TB-PAC03-M07-001

C-101

ZONE 2, GROUP IIA, T3

1 (One)

Tag No.

Service

P&ID No.

Line/Vessel No.

Hazardous Area Classification

Quantity

Fluid

Phase

Operating pressure

Operating temperature

Design pressure

Design Temperature

Operating differential Pressure

Liquid (mixture) density

Vapour density

Body or Chamber Material

Magnetic Follower/Float Material

Flange Material

Flange Rating

Process Connection Type

Conn Size & Location : Upper

Conn Size & Location : Lower

Vent / Drain Conn. Type & Size

Visible Length

Center To Center Distance

Indicator Type

Indicator Scale

Indicator Scale Material

Function

Manufacturer

Model No.

Service

Function

Range

Output

Supply Voltage

Accuracy

Output Action

Mounting

Enclosure: Material

Contacts : No.

Conduit Connection

Ex Certification

Mounting

Drain and Vent Valves:

NACE Compliant

TEG

Liquid

11.8 - 33.57

17.3 - 42.3

40

65

N/A

1093.5

9.41

Barg

C

Barg

C

mBar

Kg/m3

Kg/m3

316 SS

316 SS

316 SS

ASME 600# RF WN

Flanged

DN50, Side

DN50 Side

Flanged 600# RF, DN 20

1320mm

1320mm

Magnetic flap

Graduated in%

316 SS

Class

Form

VTA

VTA

Magnetic Level Gauge and Level Transmitter

Indicate/Transmit

0-100%

4-20 mA (2-wire), HART comm. Protocol.

24 V DC

0.1% of full span

Increase

Integral Low

Aluminium (Note 5) IP65

M20x1.5

EEx:ia IIB T4

Direct Mounted (Bottom )

3/4" 600# WNRF FLAGNE

N/A

Insulation support/clip shall be provided by Vendor for insulation installed by Purchaser.

Refer to P&ID

Transmitter shall be supplied with 316 SS, Ex i, ATEX certified plugs for all spare cable entries

The rolling magnet type of indication with red and yellow follower.

Transmitter enclosure/ casing/ junction box shall be epoxy-coated low copper aluminium.

CUSTOMER

: PVGAS D

ITEM/TAG No. LIT-0114

LOCATION

: VIETNAM

DATA SHEET No. KTA.TB-PAC03-J13-005.02

AREA

: BLOCK 102 & 106 - PHASE 1

PROJECT No. AL-3098

PROJECT

: TB-HR LPGD PIPELINE SYSTEM

VALVES SPECIFICATION

INSTRUMENT

SHEET

2 OF 10

DATA SHEET

MAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER

OTHER

TRANSMITTER

INDICATOR

FLOAT MATERIAL

PROCESS DETAILS

GENERAL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

NOTES :

1.

2.

3.

4.

5

LG-0114/LIT-0114

Glycol Contactor C-101

KTA.TB-PAC03-M07-001

C-101

ZONE 2, GROUP IIA, T3

1 (One)

Tag No.

Service

P&ID No.

Line/Vessel No.

Hazardous Area Classification

Quantity

Fluid

Phase

Operating pressure

Operating temperature

Design pressure

Design Temperature

Operating differential Pressure

Liquid (mixture) density

Vapour density

Body or Chamber Material

Magnetic Follower/Float Material

Flange Material

Flange Rating

Process Connection Type

Conn Size & Location : Upper

Conn Size & Location : Lower

Vent / Drain Conn. Type & Size

Visible Length

Center To Center Distance

Indicator Type

Indicator Scale

Indicator Scale Material

Manufacturer

Model No.

Service

Function

Range

Output

Supply Voltage

Accuracy

Output Action

Mounting

Enclosure: Material

Contacts : No.

Conduit Connection

Ex Certification

Mounting

Drain and Vent Valves:

NACE Compliant

Class

Form

Barg

C

Barg

C

mBar

Kg/m3

Kg/m3

Hydrocarbon

Liquid

13.7

34.6 - 36.4

40

65

N/A

716.1 - 994.9

9.41

316 SS

316 SS

316 SS

ASME 600# RF WN

Flanged

DN50, Side

DN50 Side

Flanged 600# RF, DN 20

1000mm(Estimate)

1000mm(Estimate)

Magnetic flap

Graduated in%

316 SS

VTA

VTA

Magnetic Level Gauge and Level Transmitter

Indicate/Transmit

0-100%

4-20 mA (2-wire), HART comm. Protocol.

24 V DC

0.1% of full span

Increase

Integral Low

Aluminium (Note 5) IP65

M20x1.5

EEx:ia IIB T4

Direct Mounted (Bottom / Top)

3/4" 600# WNRF FLAGNEe

N/A

Insulation support/clip shall be provided by Vendor for insulation installed by Purchaser.

Refer to P&ID

Transmitter shall be supplied with 316 SS, Ex i, ATEX certified plugs for all spare cable entries

The rolling magnet type of indication with red and yellow follower.

Transmitter enclosure/ casing/ junction box shall be epoxy-coated low copper aluminium.

CUSTOMER

: PVGAS D

ITEM/TAG No. LZT-0113

LOCATION

: VIETNAM

DATA SHEET No. KTA.TB-PAC03-J13-005.02

AREA

: BLOCK 102 & 106 - PHASE 1

PROJECT No. AL-3098

PROJECT

: TB-HR LPGD PIPELINE SYSTEM

SHEET

VALVES SPECIFICATION

INSTRUMENT

3 OF 10

DATA SHEET

MAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER

OTHER

TRANSMITTER

INDICATOR

FLOAT MATERIAL

PROCESS DETAILS

GENERAL

1

2

3

4

5

6

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

NOTES :

1.

2.

3.

4.

5

Tag No.

Service

P&ID No.

Line/Vessel No.

Hazardous Area Classification

Quantity

Fluid

Phase

Operating pressure

Operating temperature

Design pressure

Design Temperature

Operating differential Pressure

Liquid (mixture) density

Vapour density

Body or Chamber Material

Magnetic Follower/Float Material

Flange Material

Flange Rating

Process Connection Type

Conn Size & Location : Upper

Conn Size & Location : Lower

Vent / Drain Conn. Type & Size

Visible Length

Center To Center Distance

Indicator Type

Indicator Scale

Indicator Scale Material

Manufacturer

Model No.

Service

Function

Range

Output

Supply Voltage

Accuracy

Output Action

Mounting

Enclosure: Material

Contacts : No.

Conduit Connection

Ex Certification

Mounting

Drain and Vent Valves:

NACE Compliant

Class

Form

Barg

C

Barg

C

mBar

Kg/m3

Kg/m3

LG-0113/LZT-0113

Glycol Contactor C-101

KTA.TB-PAC03-M07-001

C-101

ZONE 2, GROUP IIA, T3

1 (One)

TEG

Liquid

11.8 - 33.57

17.3 - 42.3

40

65

N/A

1093.5

9.41

316 SS

316 SS

316 SS

ASME 600# RF WN

Flanged

DN50, Side

DN50 Side

Flanged 600# RF, DN 20

1320mm

1320mm

Magnetic flap

Graduated in%

316 SS

VTA

VTA

Magnetic Level Gauge and Level Transmitter

Indicate/Transmit

0-100%

4-20 mA (2-wire), HART comm. Protocol.

24 V DC

0.1% of full span

Increase

Integral Low

Aluminium (Note 5) IP65

M20x1.5

EEx:ia IIB T4

Direct Mounted (Bottom )

3/4" 600# WNRF FLAGNE

N/A

Insulation support/clip shall be provided by Vendor for insulation installed by Purchaser.

Refer to P&ID

Transmitter shall be supplied with 316 SS, Ex i, ATEX certified plugs for all spare cable entries

The rolling magnet type of indication with red and yellow follower.

Transmitter enclosure/ casing/ junction box shall be epoxy-coated low copper aluminium.

CUSTOMER

: PVGAS D

ITEM/TAG No. LZT-0114

LOCATION

: VIETNAM

DATA SHEET No. KTA.TB-PAC03-J13-005.02

AREA

: BLOCK 102 & 106 - PHASE 1

PROJECT No. AL-3098

PROJECT

: TB-HR LPGD PIPELINE SYSTEM

VALVES SPECIFICATION

INSTRUMENT

SHEET

4 OF 10

DATA SHEET

MAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER

OTHER

TRANSMITTER

INDICATOR

FLOAT MATERIAL

PROCESS DETAILS

GENERAL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

NOTES :

1.

2.

3.

4.

5

LG-0114/LZT-0114

Glycol Contactor C-101

KTA.TB-PAC03-M07-001

C-101

ZONE 2, GROUP IIA, T3

1 (One)

Tag No.

Service

P&ID No.

Line/Vessel No.

Hazardous Area Classification

Quantity

Fluid

Phase

Operating pressure

Operating temperature

Design pressure

Design Temperature

Operating differential Pressure

Liquid (mixture) density

Vapour density

Body or Chamber Material

Magnetic Follower/Float Material

Flange Material

Flange Rating

Process Connection Type

Conn Size & Location : Upper

Conn Size & Location : Lower

Vent / Drain Conn. Type & Size

Visible Length

Center To Center Distance

Indicator Type

Indicator Scale

Indicator Scale Material

Manufacturer

Model No.

Service

Function

Range

Output

Supply Voltage

Accuracy

Output Action

Mounting

Enclosure: Material

Class

Contacts : No.

Form

Conduit Connection

Ex Certification

Mounting

Drain and Vent Valves:

NACE Compliant

Barg

C

Barg

C

mBar

Kg/m3

Kg/m3

Hydrocarbon

Liquid

13.7

34.6 - 36.4

40

65

N/A

716.1 - 994.9

9.41

316 SS

316 SS

316 SS

ASME 600# RF WN

Flanged

DN50, Side

DN50 Side

Flanged 600# RF, DN 20

800mm

800mm

Magnetic flap

Graduated in%

316 SS

VTA

VTA

Magnetic Level Gauge and Level Transmitter

Indicate/Transmit

0-100%

4-20 mA (2-wire), HART comm. Protocol.

24 V DC

0.1% of full span

Increase

Integral Low

Aluminium (Note 5) IP65

M20x1.5

EEx:ia IIB T4

Direct Mounted (Bottom)

3/4" 600# WNRF FLAGNE

N/A

Insulation support/clip shall be provided by Vendor for insulation installed by Purchaser.

Refer to P&ID

Transmitter shall be supplied with 316 SS, Ex i, ATEX certified plugs for all spare cable entries

The rolling magnet type of indication with red and yellow follower.

Transmitter enclosure/ casing/ junction box shall be epoxy-coated low copper aluminium.

CUSTOMER

: PVGAS D

ITEM/TAG No. LIT-0131

LOCATION

: VIETNAM

DATA SHEET No. KTA.TB-PAC03-J13-005.02

AREA

: BLOCK 102 & 106 - PHASE 1

PROJECT No. AL-3098

PROJECT

: TB-HR LPGD PIPELINE SYSTEM

SHEET

VALVES SPECIFICATION

INSTRUMENT

5 OF 10

DATA SHEET

FLOAT MATERIAL

PROCESS DETAILS

GENERAL

MAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Tag No.

Service

P&ID No.

Line/Vessel No.

Hazardous Area Classification

Quantity

LG-0131/LIT-0131

Flash Vessel

KTA.TB-PAC03-M07-003

V-101

ZONE 2, GROUP IIA, T3

1 (One)

Fluid

Phase

Operating pressure

Operating temperature

Design pressure

Design Temperature

Operating differential Pressure

Liquid (mixture) density

Vapour density

Hydrocarbon

Liquid

3.9

70

10

100

N/A

700

4.75

17

18

19

20

21

22

23

24

Body or Chamber Material

Magnetic Follower/Float Material

Flange Material

Flange Rating

Process Connection Type

Conn Size & Location : Upper

Conn Size & Location : Lower

Vent / Drain Conn. Type & Size

OTHER

TRANSMITTER

INDICATOR

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

45

46

47

48

49

NOTES :

1.

2.

3.

4.

5

Visible Length

Center To Center Distance

Indicator Type

Indicator Scale

Indicator Scale Material

Manufacturer

Model No.

Service

Function

Range

Output

Supply Voltage

Accuracy

Output Action

Mounting

Enclosure: Material

Contacts : No.

Conduit Connection

Ex Certification

Mounting

Drain and Vent Valves:

NACE Compliant

Barg

C

Barg

C

mBar

Kg/m3

Kg/m3

Class

Form

316 SS

316 SS

316 SS

ASME 150# RF WN

Flanged

DN50, Side

DN50 Side

Flanged 150# RF, DN 20

850mm

850mm

Magnetic flap

Graduated in%

316 SS

VTA

VTA

Magnetic Level Gauge and Level Transmitter

Indicate/Transmit

0-100%

4-20 mA (2-wire), HART comm. Protocol.

24 V DC

0.1% of full span

Increase

Integral Low

Aluminium (Note 5) IP65

M20x1.5

EEx:ia IIB T4

Direct Mounted (Bottom / Top)

3/4" 600# WNRF FLAGNE

N/A

Insulation support/clip shall be provided by Vendor for insulation installed by Purchaser.

Refer to P&ID

Transmitter shall be supplied with 316 SS, Ex i, ATEX certified plugs for all spare cable entries

The rolling magnet type of indication with red and yellow follower.

Transmitter enclosure/ casing/ junction box shall be epoxy-coated low copper aluminium.

CUSTOMER

: PVGAS D

ITEM/TAG No. LIT-0132

LOCATION

: VIETNAM

DATA SHEET No. KTA.TB-PAC03-J13-005.02

AREA

: BLOCK 102 & 106 - PHASE 1

PROJECT No. AL-3098

PROJECT

: TB-HR LPGD PIPELINE SYSTEM

SHEET

VALVES SPECIFICATION

INSTRUMENT

6 OF 10

DATA SHEET

MAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER

OTHER

TRANSMITTER

INDICATOR

FLOAT MATERIAL

PROCESS DETAILS

GENERAL

1

2

3

4

5

6

8

9

10

11

12

13

14

15

16

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

NOTES :

1.

2.

3.

4.

5

Tag No.

Service

P&ID No.

Line/Vessel No.

Hazardous Area Classification

Quantity

Fluid

Phase

Operating pressure

Operating temperature

Design pressure

Design Temperature

Operating differential Pressure

Liquid (mixture) density

Vapour density

Body or Chamber Material

Magnetic Follower/Float Material

Flange Material

Flange Rating

Process Connection Type

Conn Size & Location : Upper

Conn Size & Location : Lower

Vent / Drain Conn. Type & Size

Visible Length

Center To Center Distance

Indicator Type

Indicator Scale

Indicator Scale Material

Manufacturer

Model No.

Service

Function

Range

Output

Supply Voltage

Accuracy

Output Action

Mounting

Enclosure: Material

Class

Contacts : No.

Form

Conduit Connection

Ex Certification

Mounting

Drain and Vent Valves:

NACE Compliant

Barg

C

Barg

C

mBar

Kg/m3

Kg/m3

LG-0132/LIT-0132

Flash Vessel

KTA.TB-PAC03-M07-003

V-101

ZONE 2, GROUP IIA, T3

1 (One)

TEG

Liquid

3.9

70

10

100

N/A

1079

4.75

316 SS

316 SS

316 SS

ASME 150# RF WN

Flanged

DN50, Side

DN50 Side

Flanged 150# RF, DN 20

1500mm

1500mm

Magnetic flap

Graduated in%

316 SS

VTA

VTA

Magnetic Level Gauge and Level Transmitter

Indicate/Transmit

0-100%

4-20 mA (2-wire), HART comm. Protocol.

24 V DC

0.1% of full span

Increase

Integral Low

Aluminium (Note 5) IP65

M20x1.5

EEx:ia IIB T4

Direct Mounted (Bottom)

3/4" 600# WNRF FLAGNE

N/A

Insulation support/clip shall be provided by Vendor for insulation installed by Purchaser.

Refer to P&ID

Transmitter shall be supplied with 316 SS, Ex i, ATEX certified plugs for all spare cable entries

The rolling magnet type of indication with red and yellow follower.

Transmitter enclosure/ casing/ junction box shall be epoxy-coated low copper aluminium.

CUSTOMER

: PVGAS D

ITEM/TAG No. LIT-0141

LOCATION

: VIETNAM

DATA SHEET No. KTA.TB-PAC03-J13-005.02

AREA

: BLOCK 102 & 106 - PHASE 1

PROJECT No. AL-3098

PROJECT

: TB-HR LPGD PIPELINE SYSTEM

SHEET

VALVES SPECIFICATION

INSTRUMENT

7 OF 10

DATA SHEET

MAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER

OTHER

TRANSMITTER

INDICATOR

FLOAT MATERIAL

PROCESS DETAILS

GENERAL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

NOTES :

1.

2.

3.

4.

5

LG-0141/LIT-0141

Glycol Surge Drum

KTA.TB-PAC03-M07-004

V-103

ZONE 2, GROUP IIA, T3

1 (One)

Tag No.

Service

P&ID No.

Line/Vessel No.

Hazardous Area Classification

Quantity

Fluid

Phase

Operating pressure

Operating temperature

Design pressure

Design Temperature

Operating differential Pressure

Liquid (mixture) density

Body or Chamber Material

Magnetic Follower/Float Material

Flange Material

Flange Rating

Process Connection Type

Conn Size & Location : Upper

Conn Size & Location : Lower

Vent / Drain Conn. Type & Size

Visible Length

Center To Center Distance

Indicator Type

Indicator Scale

Indicator Scale Material

Manufacturer

Model No.

Service

Function

Range

Output

Supply Voltage

Accuracy

Output Action

Mounting

Class

Enclosure: Material

Form

Contacts : No.

Conduit Connection

Ex Certification

Mounting

Drain and Vent Valves:

NACE Compliant

TEG

Liquid

0.25

82.4 - 94

7.5

100

N/A

1066.1

Barg

C

Barg

C

mBar

Kg/m3

316 SS

316 SS

316 SS

ASME 150# RF WN

Flanged

DN50, Side

DN50 Side

Flanged 150# RF, DN 20

900mm

900mm

Magnetic flap

Graduated in%

316 SS

VTA

VTA

Magnetic Level Gauge and Level Transmitter

Indicate/Transmit

0-100%

4-20 mA (2-wire), HART comm. Protocol.

24 V DC

0.1% of full span

Increase

Integral Low

Aluminium (Note 5) IP65

M20x1.5

EEx:ia IIB T4

Direct Mounted (Bottom)

3/4" 600# WNRF FLAGNE

N/A

Insulation support/clip shall be provided by Vendor for insulation installed by Purchaser.

Refer to P&ID

Transmitter shall be supplied with 316 SS, Ex i, ATEX certified plugs for all spare cable entries

The rolling magnet type of indication with red and yellow follower.

Transmitter enclosure/ casing/ junction box shall be epoxy-coated low copper aluminium.

CUSTOMER

: PVGAS D

ITEM/TAG No. LZT-0151

LOCATION

: VIETNAM

DATA SHEET No. KTA.TB-PAC03-J13-005.02

AREA

: BLOCK 102 & 106 - PHASE 1

PROJECT No. AL-3098

PROJECT

: TB-HR LPGD PIPELINE SYSTEM

SHEET

VALVES SPECIFICATION

INSTRUMENT

8 OF 10

DATA SHEET

MAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER

OTHER

TRANSMITTER

INDICATOR

FLOAT MATERIAL

PROCESS DETAILS

GENERAL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

47

48

49

50

NOTES : 1.

2.

3.

4.

5

LG-0151/LZT-0151

Tag No.

Service

P&ID No.

Line/Vessel No.

Hazardous Area Classification

Quantity

Fluid

Phase

Operating pressure

Operating temperature

Design pressure

Design Temperature

Operating differential Pressure

Liquid (mixture) density

Body or Chamber Material

Magnetic Follower/Float Material

Flange Material

Flange Rating

Process Connection Type

Conn Size & Location : Upper

Conn Size & Location : Lower

Vent / Drain Conn. Type & Size

Visible Length

Center To Center Distance

Indicator Type

Indicator Scale

Indicator Scale Material

Manufacturer

Model No.

Service

Function

Range

Output

Supply Voltage

Accuracy

Output Action

Mounting

Class

Enclosure: Material

Form

Contacts : No.

Conduit Connection

Ex Certification

Mounting

Drain and Vent Valves:

NACE Compliant

Glycol Reboiler

KTA.TB-PAC03-M07-005

V-102

ZONE 2, GROUP IIA, T3

1 (One)

Barg

C

Barg

C

mBar

3

Kg/m

TEG

Liquid

0.30

204

7.5

235

N/A

969.9

316 SS

316 SS

316 SS

ASME 150# RF WN

Flanged

DN50, Side

DN50 Side

Flanged 150# RF, DN 20

600mm

600mm

Magnetic flap

Graduated in%

316 SS

VTA

VTA

Magnetic Level Gauge and Level Transmitter

Indicate/Transmit

0-100%

4-20 mA (2-wire), HART comm. Protocol.

24 V DC

0.1% of full span

Increase

Integral Low

Aluminium (Note 5) IP65

M20x1.5

EEx:ia IIB T4

Direct Mounted (Bottom )

3/4" 600# WNRF FLAGNE

N/A

Insulation support/clip shall be provided by Vendor for insulation installed by Purchaser.

Refer to P&ID

Transmitter shall be supplied with 316 SS, Ex i, ATEX certified plugs for all spare cable entries

The rolling magnet type of indication with red and yellow follower.

Transmitter enclosure/ casing/ junction box shall be epoxy-coated low copper aluminium.

ITEM/TAG No. LIT-0171

CUSTOMER

: PVGAS D

LOCATION

: VIETNAM

DATA SHEET No. KTA.TB-PAC03-J13-005.02

AREA

: BLOCK 102 & 106 - PHASE 1

PROJECT No. AL-3098

PROJECT

: TB-HR LPGD PIPELINE SYSTEM

SHEET

VALVES SPECIFICATION

INSTRUMENT

9 OF 10

DATA SHEET

MAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER

OTHER

TRANSMITTER

INDICATOR

FLOAT MATERIAL

PROCESS DETAILS

GENERAL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

NOTES :

1.

2.

3.

4.

5

LG-0171/LIT-0171

Reflux Drum

KTA.TB-PAC03-M07-007

V-104

ZONE 2, GROUP IIA, T3

1 (One)

Tag No.

Service

P&ID No.

Line/Vessel No.

Hazardous Area Classification

Quantity

Fluid

Phase

Operating pressure

Operating temperature

Design pressure

Design Temperature

Operating differential Pressure

Liquid (mixture) density

Body or Chamber Material

Magnetic Follower/Float Material

Flange Material

Flange Rating

Process Connection Type

Conn Size & Location : Upper

Conn Size & Location : Lower

Vent / Drain Conn. Type & Size

Visible Length

Center To Center Distance

Indicator Type

Indicator Scale

Indicator Scale Material

Manufacturer

Model No.

Service

Function

Range

Output

Supply Voltage

Accuracy

Output Action

Mounting

Class

Enclosure: Material

Form

Contacts : No.

Conduit Connection

Ex Certification

Mounting

Drain and Vent Valves:

NACE Compliant

Water

Liquid

0.20

37

7.5

100

N/A

993.4

Barg

C

Barg

C

mBar

Kg/m3

316 SS

316 SS

316 SS

ASME 150# RF WN

Flanged

DN50, Side

DN50 Side

Flanged 150# RF, DN 20

800mm

800mm

Magnetic flap

Graduated in%

316 SS

VTA

VTA

Magnetic Level Gauge and Level Transmitter

Indicate/Transmit

0-100%

4-20 mA (2-wire), HART comm. Protocol.

24 V DC

0.1% of full span

Increase

Integral Low

Aluminium (Note 5) IP65

M20x1.5

EEx:ia IIB T4

Direct Mounted (Bottom)

3/4" 600# WNRF FLAGNE

N/A

Insulation support/clip shall be provided by Vendor for insulation installed by Purchaser.

Refer to P&ID

Transmitter shall be supplied with 316 SS, Ex i, ATEX certified plugs for all spare cable entries

The rolling magnet type of indication with red and yellow follower.

Transmitter enclosure/ casing/ junction box shall be epoxy-coated low copper aluminium.

CUSTOMER

: PVGAS D

ITEM/TAG No.

LOCATION

: VIETNAM

DATA SHEET No. KTA.TB-PAC03-J13-005.02

AREA

: BLOCK 102 & 106 - PHASE 1

PROJECT No. AL-3098

PROJECT

: TB-HR LPGD PIPELINE SYSTEM

SHEET

VALVES

ATION

SPECIFICATION

SHEET

10 OF 10

INSTRUMENT DATA SHEET

MAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER- NOTES

GENERAL NOTES

1.

Documentation Required:

Hazardous Area Certificate - ATEX certification

Ingress Protection Certificate

Hydrotest Certificate

Calibration Certificate (5 points) issued by manufacturer

Material Certificate, ISO-EN 10204, Type 3.1 (B) for pressure retaining parts.

Installation & Commissioning spare Parts List and 2 years Operational Spares List

Compliance/ Conformance Certificate

General Arrangement drawing with complete Model Numbers, Dimension and Hookup details

2.

All instruments shall be provided with a SS 316 name plate with tag no. pernamently inscribed

Level transmitters and accessories shall be able to sustain process design pressure, temperature and service fluid.

Level transmitters and accessories should meet the following specifications:

Elastomer used in the instrument / accessories are compatible with the service fluid specified

All tube fittings shall be SS316, of Swagelok make, imperial size, double compression type.

Field bus based transmitter/ devices must satisfy the requirements of the field bus registration laboratory with applicable checkmark of foundation field bus.

The field bus instruments in hazardous area shall be certified as per entity concept or shall be FISCO approved.

Internal software shall be configured by the vendor including the following information such as serial number, Device Tag (Tag Number) and Process description.

10

Bolts/nut ASTM A193 Gr.B7/A194-2H with xylan flourocarbon coated

Specification for instrumentation KTA.TB-PAC03-M65-007

at design conditions.

Das könnte Ihnen auch gefallen

- Alesco User GuideDokument20 SeitenAlesco User GuideXHo D. King Jr.90% (10)

- Fusible Plug Loop Panel1Dokument5 SeitenFusible Plug Loop Panel1caigithe85245650% (2)

- Control Valve Data SheetDokument3 SeitenControl Valve Data SheetgrabettyNoch keine Bewertungen

- Epd-Lca Meranti Plywood-Final ReportDokument29 SeitenEpd-Lca Meranti Plywood-Final ReporttangNoch keine Bewertungen

- Court Document SummaryDokument15 SeitenCourt Document SummaryAkAsh prAkhAr vErmA100% (1)

- Con Law I - Case Cheat SheetDokument22 SeitenCon Law I - Case Cheat SheetPriscilla Quansah100% (1)

- Coriolis Mass Flow MeterDokument2 SeitenCoriolis Mass Flow MeterSreejesh SundaresanNoch keine Bewertungen

- Comments Response SheetDokument8 SeitenComments Response Sheetcherif yahyaoui67% (3)

- DatasheetDokument17 SeitenDatasheetHimawan Sigit NugrohoNoch keine Bewertungen

- Control Valve DatasheetDokument1 SeiteControl Valve DatasheetshamoojeeNoch keine Bewertungen

- NCR - SampleDokument7 SeitenNCR - SamplecamycaxNoch keine Bewertungen

- Control Valve Data SheetDokument22 SeitenControl Valve Data Sheetnileshana100% (1)

- LGDD ZZ ITTDSXS 00 45671233 0 Instrument DatasheetDokument37 SeitenLGDD ZZ ITTDSXS 00 45671233 0 Instrument DatasheetuyaiekanemNoch keine Bewertungen

- Flow Meter Data SheetDokument2 SeitenFlow Meter Data SheetAnonymous S0Dyd1FsXNoch keine Bewertungen

- On OFF ValveDokument30 SeitenOn OFF ValveAjay TiwariNoch keine Bewertungen

- Datasheet For Flow ComputerDokument2 SeitenDatasheet For Flow ComputerAngela BarberNoch keine Bewertungen

- WPI-KE-1104-SP141-QM5433 (Datasheet)Dokument4 SeitenWPI-KE-1104-SP141-QM5433 (Datasheet)Jèfrì PìnémNoch keine Bewertungen

- Datasheet Level GaugeDokument9 SeitenDatasheet Level GaugeedcielNoch keine Bewertungen

- Pressure Differential Transmitter Datasheet for LNG Terminal ProjectDokument3 SeitenPressure Differential Transmitter Datasheet for LNG Terminal ProjectsswahyudiNoch keine Bewertungen

- BE-WI-248-01-F07 Datasheet Turbine FlowmeterDokument3 SeitenBE-WI-248-01-F07 Datasheet Turbine Flowmetermika cabelloNoch keine Bewertungen

- Example Instrument IndexDokument1 SeiteExample Instrument Indexsvnaik14Noch keine Bewertungen

- 2.1.1.5 Instrument IndexDokument18 Seiten2.1.1.5 Instrument IndexpeckonetNoch keine Bewertungen

- Datasheet PSV PDPDEDokument8 SeitenDatasheet PSV PDPDERicardo NapitupuluNoch keine Bewertungen

- Positioner SpecsDokument1 SeitePositioner Specsbiswasdipankar05Noch keine Bewertungen

- Thermowell Temperature Gauge Tag: TUNG1-27-TGDokument1 SeiteThermowell Temperature Gauge Tag: TUNG1-27-TGKenneth EmbeleNoch keine Bewertungen

- HSSDDokument3 SeitenHSSDamijetomar08Noch keine Bewertungen

- Ku-Twk-41-Ic-Lst-0200 A Instrument Index Io List-Peshkbir PDFDokument28 SeitenKu-Twk-41-Ic-Lst-0200 A Instrument Index Io List-Peshkbir PDFLienu PrinceNoch keine Bewertungen

- Data SheetDokument12 SeitenData SheetHimawan Sigit NugrohoNoch keine Bewertungen

- BE-WI-248-01-F12 Datasheet Level Instrument Displacer or FloatDokument3 SeitenBE-WI-248-01-F12 Datasheet Level Instrument Displacer or Floatmika cabelloNoch keine Bewertungen

- Orifice Plate Flow Meter Data SheetDokument4 SeitenOrifice Plate Flow Meter Data SheetTaimoor KhanNoch keine Bewertungen

- Detail Engineering SummaryDokument15 SeitenDetail Engineering SummaryDattatray Nikam100% (6)

- Va1-Lici-00eg-I-m4d-Das-0009 RTD & ThermowellDokument17 SeitenVa1-Lici-00eg-I-m4d-Das-0009 RTD & ThermowellKhang TrangNoch keine Bewertungen

- Datasheet For Level TransmitterDokument9 SeitenDatasheet For Level TransmitterVenkatesan ManikandanNoch keine Bewertungen

- IO List Document EngineeringDokument3 SeitenIO List Document EngineeringEphraem KalisNoch keine Bewertungen

- RTD Temperature Transmitter Datasheet: TAG Number ServiceDokument1 SeiteRTD Temperature Transmitter Datasheet: TAG Number ServiceEyu100% (1)

- Hydraulic Power Unit Cum Control Panel: Sheet No. 1 of 1Dokument1 SeiteHydraulic Power Unit Cum Control Panel: Sheet No. 1 of 1rakeshsundaramurthyNoch keine Bewertungen

- Temperature Measuring Instruments Selection & ApplicationDokument70 SeitenTemperature Measuring Instruments Selection & ApplicationIrfan AliNoch keine Bewertungen

- 3103 - Level TransmitterDokument10 Seiten3103 - Level Transmittersudhiryadav99Noch keine Bewertungen

- General: Instrument SpecificationDokument4 SeitenGeneral: Instrument SpecificationAJAY1381Noch keine Bewertungen

- Control ValveDokument1 SeiteControl ValveAjay TiwariNoch keine Bewertungen

- Flow Measurement Selection and ApplicationDokument84 SeitenFlow Measurement Selection and ApplicationArunan MNoch keine Bewertungen

- Table of Contents for Valve Actuator SpecificationDokument10 SeitenTable of Contents for Valve Actuator SpecificationzazaNoch keine Bewertungen

- 10 IN 00 IWD 009 - Rev.1 - 180611Dokument867 Seiten10 IN 00 IWD 009 - Rev.1 - 180611irfanNoch keine Bewertungen

- Conduit and Instrumentation Fittings LayoutDokument221 SeitenConduit and Instrumentation Fittings LayoutMr.thawatchai100% (1)

- Ip Pressure Transmitter Data SheetDokument4 SeitenIp Pressure Transmitter Data SheetMohammad BabazadehNoch keine Bewertungen

- Datasheet For Pressure Gauge - Process DataDokument8 SeitenDatasheet For Pressure Gauge - Process DataLai HuynhNoch keine Bewertungen

- Data Sheet Control ValveDokument1 SeiteData Sheet Control Valvearchanakalyan0% (1)

- Calibrate DP Level TransmitterDokument4 SeitenCalibrate DP Level TransmitterSijo Joy100% (2)

- Thermowell and Immersion Probe Installation GuideDokument7 SeitenThermowell and Immersion Probe Installation GuideBEN ADEGBULUNoch keine Bewertungen

- Engineering Standard for Control ValvesDokument11 SeitenEngineering Standard for Control Valvesrahul.ril1660Noch keine Bewertungen

- Intools Handbook Index Module GuideDokument23 SeitenIntools Handbook Index Module GuideseenubalaNoch keine Bewertungen

- Instrument Index Platform: Domain: Finalproject Plant: AreaDokument3 SeitenInstrument Index Platform: Domain: Finalproject Plant: AreaJasJusNoch keine Bewertungen

- Control Valves Datasheet PDFDokument7 SeitenControl Valves Datasheet PDFAlvin SmithNoch keine Bewertungen

- Instrument Cable SizingDokument2 SeitenInstrument Cable Sizingsv_verma100% (1)

- Control & Safety System SpecificationDokument38 SeitenControl & Safety System Specificationsugeng wahyudi100% (1)

- IDokument78 SeitenIrathnam.pmNoch keine Bewertungen

- RFQ For Level TransmitterDokument22 SeitenRFQ For Level Transmittersugeng wahyudi100% (1)

- Level Measuring Instruments Selection ApplicationsDokument87 SeitenLevel Measuring Instruments Selection ApplicationsArunan M100% (1)

- MAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER DATA SHEET-Rev.C PDFDokument14 SeitenMAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER DATA SHEET-Rev.C PDFNguyễnQuíTrọngNoch keine Bewertungen

- STV SW Project Level Gauge DatasheetDokument4 SeitenSTV SW Project Level Gauge Datasheetnguyenquoc1988Noch keine Bewertungen

- Pressure Transmitter Data SheetDokument2 SeitenPressure Transmitter Data Sheetneurolepsia3790Noch keine Bewertungen

- Product Drawing: Customer Project Tag No. Unit Description of Service Location PID No./Line NumberDokument6 SeitenProduct Drawing: Customer Project Tag No. Unit Description of Service Location PID No./Line NumberMWBABARNoch keine Bewertungen

- LSHH-7300 Rev ADokument1 SeiteLSHH-7300 Rev AmorlsNoch keine Bewertungen

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Von EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Bewertung: 3.5 von 5 Sternen3.5/5 (3)

- MAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER DATA SHEET-Rev.C PDFDokument14 SeitenMAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER DATA SHEET-Rev.C PDFNguyễnQuíTrọngNoch keine Bewertungen

- OPC Redundancy PDFDokument6 SeitenOPC Redundancy PDFNguyễnQuíTrọngNoch keine Bewertungen

- Response Sheet No.: Rs-Kta - Tb-Pac03-045.2: No Document No. Document Title Rev CM Next 1. 2. 3Dokument3 SeitenResponse Sheet No.: Rs-Kta - Tb-Pac03-045.2: No Document No. Document Title Rev CM Next 1. 2. 3NguyễnQuíTrọngNoch keine Bewertungen

- Response Sheet No.: Rs-Kta - Tb-Pac03-045.2: No Document No. Document Title Rev CM Next 1. 2. 3Dokument3 SeitenResponse Sheet No.: Rs-Kta - Tb-Pac03-045.2: No Document No. Document Title Rev CM Next 1. 2. 3NguyễnQuíTrọngNoch keine Bewertungen

- Opc FaqDokument19 SeitenOpc FaqNguyễnQuíTrọngNoch keine Bewertungen

- Centum CS 3000 PDFDokument270 SeitenCentum CS 3000 PDFBrendan Stack75% (4)

- ISATR84Dokument6 SeitenISATR84checito49100% (1)

- Viscous Damped Movement PDFDokument1 SeiteViscous Damped Movement PDFNguyễnQuíTrọngNoch keine Bewertungen

- Accessories 1 PDFDokument1 SeiteAccessories 1 PDFNguyễnQuíTrọngNoch keine Bewertungen

- Dcspresentation 13005437501565 Phpapp01Dokument77 SeitenDcspresentation 13005437501565 Phpapp01edorablesatishNoch keine Bewertungen

- Dcs Yokogwa EngineeringDokument263 SeitenDcs Yokogwa EngineeringMilton Michael100% (1)

- Control wellhead & gathering system flows and pressuresDokument3 SeitenControl wellhead & gathering system flows and pressuresAhmedAmer1Noch keine Bewertungen

- Combustible Gas Detector DatasheetDokument4 SeitenCombustible Gas Detector DatasheetNguyễnQuíTrọngNoch keine Bewertungen

- Dcs Yokogwa EngineeringDokument263 SeitenDcs Yokogwa EngineeringMilton Michael100% (1)

- Yokogawa Centum CS3000 OverviewDokument71 SeitenYokogawa Centum CS3000 OverviewMHafidzAliNoch keine Bewertungen

- Centum Cs3000 System ConfigurationDokument10 SeitenCentum Cs3000 System Configurationbullfire100% (1)

- Safety SystemDokument81 SeitenSafety SystemNguyễnQuíTrọngNoch keine Bewertungen

- Instrumentation TextbookDokument166 SeitenInstrumentation TextbookGerman ToledoNoch keine Bewertungen

- Safety Instrumented System (Sis) For Process Operation Based On Real - Time MonitoringDokument56 SeitenSafety Instrumented System (Sis) For Process Operation Based On Real - Time MonitoringGCNoch keine Bewertungen

- Safety SystemDokument81 SeitenSafety SystemNguyễnQuíTrọngNoch keine Bewertungen

- Opc Overview - Emerson Very GoodDokument12 SeitenOpc Overview - Emerson Very GoodNguyễnQuíTrọngNoch keine Bewertungen

- Steam Turbine TheoryDokument16 SeitenSteam Turbine Theoryvik03223Noch keine Bewertungen

- Safety Instrumented System (Sis) For Process Operation Based On Real - Time MonitoringDokument56 SeitenSafety Instrumented System (Sis) For Process Operation Based On Real - Time MonitoringGCNoch keine Bewertungen

- Safety SystemDokument81 SeitenSafety SystemNguyễnQuíTrọngNoch keine Bewertungen

- Which Professional Design AnemometerDokument1 SeiteWhich Professional Design AnemometerNguyễnQuíTrọngNoch keine Bewertungen

- What's The Difference Between Pipe, Tube and Impulse TubeDokument1 SeiteWhat's The Difference Between Pipe, Tube and Impulse TubeNguyễnQuíTrọngNoch keine Bewertungen

- What Type of Flowmeter Should I Use To Measure Fluid That Consists of 15-37% Solid ContentDokument1 SeiteWhat Type of Flowmeter Should I Use To Measure Fluid That Consists of 15-37% Solid ContentNguyễnQuíTrọngNoch keine Bewertungen

- Vibration SwitchtransmitterDokument1 SeiteVibration SwitchtransmitterNguyễnQuíTrọngNoch keine Bewertungen

- What Is The Difference Between SIS and ESDDokument6 SeitenWhat Is The Difference Between SIS and ESDNguyễnQuíTrọngNoch keine Bewertungen

- File 1599385749210Dokument21 SeitenFile 1599385749210adel madanyNoch keine Bewertungen

- Reflection Paper - InternshipDokument7 SeitenReflection Paper - Internshipapi-549362324Noch keine Bewertungen

- Factors Affecting Customer Loyalty to Indosat OoredooDokument13 SeitenFactors Affecting Customer Loyalty to Indosat OoredooDede BhubaraNoch keine Bewertungen

- People v. Sandiganbayan (Evidence)Dokument2 SeitenPeople v. Sandiganbayan (Evidence)donnamariebollosNoch keine Bewertungen

- Reactions of Hydrocarbons and HaloalkanesDokument6 SeitenReactions of Hydrocarbons and HaloalkanesGwynethAdrienneLeighVillapandoNoch keine Bewertungen

- Understanding ICT Through 4 PIC 1 WORD PUZZLESDokument43 SeitenUnderstanding ICT Through 4 PIC 1 WORD PUZZLESMishel Macaraeg0% (1)

- One, Two and Three PerspectiveDokument10 SeitenOne, Two and Three PerspectiveNikko Bait-itNoch keine Bewertungen

- The Oikos in Athenian LawDokument13 SeitenThe Oikos in Athenian LawTúlio CarvalhoNoch keine Bewertungen

- SSC 146G Summer 2016 Human Sexuality SyllabusDokument1 SeiteSSC 146G Summer 2016 Human Sexuality SyllabusJames SmithNoch keine Bewertungen

- How To Download Cosmetic Injection Techniques A Text and Video Guide To Neurotoxins Fillers Ebook PDF Docx Kindle Full ChapterDokument36 SeitenHow To Download Cosmetic Injection Techniques A Text and Video Guide To Neurotoxins Fillers Ebook PDF Docx Kindle Full Chapterkerri.kite140100% (23)

- CMT 565:waste and Wastewater Technology: Experiment No: 5 Title: Biochemical Oxygen Demand (Bod)Dokument4 SeitenCMT 565:waste and Wastewater Technology: Experiment No: 5 Title: Biochemical Oxygen Demand (Bod)kuekNoch keine Bewertungen

- Transportasi Kelembagaan PengantarDokument26 SeitenTransportasi Kelembagaan Pengantarade wiraNoch keine Bewertungen

- Health Grade 9 1st QuarterDokument1 SeiteHealth Grade 9 1st QuarterCapila Ron100% (1)

- Narrative Techniques To Kill A MockingbirdDokument4 SeitenNarrative Techniques To Kill A MockingbirdJoshua LawrenceNoch keine Bewertungen

- 800m Training Plan For Mando EmployeDokument7 Seiten800m Training Plan For Mando EmployeSunder Veera Karthikeyan100% (1)

- MedicineDokument19 SeitenMedicineSarah100% (1)

- ĐỀ CHUẨN MINH HỌA SỐ 03Dokument17 SeitenĐỀ CHUẨN MINH HỌA SỐ 03Lê Thị Ngọc ÁnhNoch keine Bewertungen

- CBSE Class 10 Maths Sample Paper 2019-20Dokument33 SeitenCBSE Class 10 Maths Sample Paper 2019-20omvrat singhNoch keine Bewertungen

- Daily Aspirin Therapy Understand The Benefits and RisksDokument5 SeitenDaily Aspirin Therapy Understand The Benefits and RisksNicholas OwensNoch keine Bewertungen

- English 7 1st Lesson Plan For 2nd QuarterDokument4 SeitenEnglish 7 1st Lesson Plan For 2nd QuarterDiane LeonesNoch keine Bewertungen

- Holy Trinity University: Puerto Princesa City Basic Education DepartmentDokument2 SeitenHoly Trinity University: Puerto Princesa City Basic Education DepartmentBrian Reyes GangcaNoch keine Bewertungen

- Chisholm - Referring To Things That No Longer ExistDokument13 SeitenChisholm - Referring To Things That No Longer ExistMichele Paolini PaolettiNoch keine Bewertungen

- Dilo SpaDokument2 SeitenDilo SpajosefNoch keine Bewertungen

- Pope Francis' Call to Protect Human Dignity and the EnvironmentDokument5 SeitenPope Francis' Call to Protect Human Dignity and the EnvironmentJulie Ann BorneoNoch keine Bewertungen

- General Physics Mass, Weight, DensityDokument37 SeitenGeneral Physics Mass, Weight, DensityMat MinNoch keine Bewertungen

- Corporal Lesson PDFDokument6 SeitenCorporal Lesson PDFCarmeli VillavicencioNoch keine Bewertungen