Beruflich Dokumente

Kultur Dokumente

Design of Reinforced Plastic Pips 1004 Rev.02

Hochgeladen von

kbrozzzOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design of Reinforced Plastic Pips 1004 Rev.02

Hochgeladen von

kbrozzzCopyright:

Verfügbare Formate

PAGE :

of 42

FIBERPIPE

BANDIRMA CCPP - TURKEY

COOLING WATER PIPING

ISSUED FOR INFORMATION

31/07/09

GG

LT

LS

ISSUED FOR INFORMATION

05/05/09

GG

LT

LS

ISSUED FOR INFORMATION

10/04/09

GG

LT

LS

REV.NO

REASON FOR ISSUE

CLIENT:

DATE OF

ISSUE

PREPARED BY CHECKED

BY

APPROVED BY APPR. BY

CLIENT

DOCUMENT TITLE:

DESIGN OF REINFORCED PLASTIC PIPES

according BS7159 & AWWA M45

ORIGINATOR:

CLIENT

PROJECT NO.:

SDRL CODE:

SUPPLIER PROJECT

NUMBER:

09/004

SUPPLIER DOCUMENT

NUMBER:

09/004-CI-0001

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

TABLE OF CONTENTS

1.

2.

3.

4.

5.

6.

7.

Design Basis

Item List

Tested Modulus of Elasticity for Filament Wound Pipes

Resin Characteristics

Minimum Mechanical Properties of Reinforced Laminate Layers

Unit Thickness

General

7.1

7.2

7.3

7.4

7.5

7.6

7.7

Factors for Design

Conditions for Design

Fluid Characteristics

Resin Characteristics

Glass Characteristics

Construction of Chemical Barrier

Construction of Top Coat

8. Pipe

8.1

8.2

8.3

Pipe Input Data

Pipe Output Data

Construction of Mechanical Reinforcement

8.4

8.5

8.6

8.7

Design Calculation for Pipes subjected to Internal Pressure and Bending Moments

Design Calculation for Pipe subjected to Vacuum

Design Calculation for Pipe with Specified Stiffness

Buried Pipe

9. Butt Joint

9.1

9.2

9.3

9.4

9.5

Butt Joint Input Data

Butt Joint Output Data

Construction of Mechanical Reinforcement

Design Calculation

Mechanical Properties

10. Flange

10.1

10.2

10.3

10.4

10.5

10.6

Flange Input Data

Flange Output Data

Calculation Parameters

Operating conditions

Bolting up conditions

Results

11. Elbow

11.1

11.2

11.3

11.4

11.5

11.6

11.7

Elbow Input Data

Elbow Output Data

Construction of Mechanical Reinforcement

Design Calculation for Elbows subjected to Internal Pressure and Bending Moments

Mechanical Properties

Design Calculation for Elbows subjected to Vacuum

Design Calculation for Elbows with Specified Stiffness

12. Tee

12.1

12.2

12.3

12.4

12.5

12.6

Tee Input Data

Tee Output Data

Construction of Mechanical Reinforcement

Design Calculation for Tee subjected to Internal Pressure

Mechanical Properties

Compensation Design

09-004_CI0001-02 .xls

2/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

13. Reducer

13.1

13.2

13.3

13.4

13.5

13.6

13.7

Reducer Input Data

Reducer Output Data

Construction of Mechanical Reinforcement

Design Calculation for Reducer subjected to Internal Pressure

Mechanical Properties

Design Calculation for Reducer subjected to Vacuum

Design Calculation for Reducer with Specified Stiffness

14. Cap

14.1

14.2

14.3

14.4

14.5

14.6

Cap Input Data

Cap Output Data

Construction of Mechanical Reinforcement

Design Calculation for Caps subjected to Internal Pressure

Mechanical Properties

Design Calculation for Caps subjected to Vacuum

09-004_CI0001-02 .xls

3/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

1. Design Basis

The design of pipes and fittings is basec on rules according to BS7159 and BS6464.

This standards includes a method of calculation for an appropriate laminate construction

based on the allowable unit loading and unit modulus for the type of composite concerned.

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

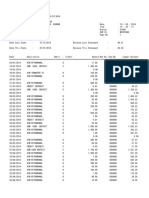

2. Item List

ITEM

T2400

T2000

T1600

T500

T400

T350

T300

T250

T200

T150

T100

T80

T600

T300

Nominal Diameter

[mm]

2400

2000

1600

500

400

350

300

250

200

150

100

80

600

300

Design Pressure

[bar]

6,2

6,2

6,2

7,5

7,5

7,5

7,5

7,5

7,5

7,5

7,5

7,5

7,5

7,5

pW

Operating pressure

[bar]

4,3

4,3

4,3

5,5

5,5

5,5

5,5

5,5

5,5

5,5

5,5

5,5

5,5

5,5

Maximum Design

Temperature

[C]

60

60

60

60

60

60

60

60

60

60

60

60

60

60

pe

Design Vacuum

[bar]

0,4

0,9

0,4

0,6

0,6

0,6

0,6

0,6

0,6

0,6

0,6

0,6

0,4

0,4

Content Specific Gravity

[kg/dm3]

tl

Liner Thickness

[mm]

1,65

1,65

1,65

1,65

1,65

1,65

1,65

1,65

1,65

1,65

1,65

1,65

1,65

1,65

ttc

Top Coat Thickness

[mm]

0,2

0,2

0,2

0,2

0,2

0,2

0,2

0,2

0,2

0,2

0,2

0,2

0,2

0,2

Reinforc

ement

Reinforc

ement

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

ND

Proposed resin

Choosen resin

isopthalic

isopthalic

isopthalic

isopthalic

isopthalic

isopthalic

polyester

polyester

polyester

polyester

polyester

polyester

isopthalic

isopthalic

isopthalic

isopthalic

isopthalic

isopthalic

vinyleser LT vinyleser LT vinyleser LT vinyleser LT vinyleser LT vinyleser LT

isopthalic

isopthalic

isopthalic

isopthalic

isopthalic

isopthalic

polyester

polyester

polyester

polyester

polyester

polyester

isopthalic

isopthalic

isopthalic

isopthalic

isopthalic

isopthalic

vinyleser LT vinyleser LT vinyleser LT vinyleser LT vinyleser LT vinyleser LT

Proposed resin

liner

Choosen resin

liner

Allowable Design strain

[mm/mm

]

0,002

0,002

0,002

0,002

0,002

0,002

0,002

0,002

0,002

0,002

0,002

0,002

0,002

0,002

Short Term Failure Stress

[Mpa]

240

240

240

240

240

240

240

240

240

240

240

240

240

240

Short Term Failure Strain

[mm/mm

]

0,013

0,013

0,013

0,013

0,013

0,013

0,013

0,013

0,013

0,013

0,013

0,013

0,013

0,013

SFST

Short Term Safety Factor

6,3

6,3

6,3

6,3

6,3

6,3

6,3

6,3

6,3

6,3

6,3

6,3

6,3

6,3

09-004_CI0001-02 .xls

5/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

3. Tested Modulus of Elasticity for Filament Wound Pipes

Winding angle

ELAM ta

ELAM tc

G12

v12

v21

N/mm2

N/mm2

N/mm2

55

65

70

75

12500

9000

24000

27000

10730

0,3

0,55

10730

ww

0,3

0,5

4. Resin Characteristics

HDT

Relative density

kg/dm3

isopthalic

polyester

105

1,12

vinylester MTvinylester MHT vinylester HT

125

145

180

1,15

1,15

1,15

5. Minimum Mechanical Properties of Reinforced Laminate Layers

(Table 2 BS6464:1984)

Lap

shear

strenght

Specific gravity

(see B.5

of

BS6464:

Chopped Strand Mat

Woven Roving

Continuous Rovings

Unit modulus X

Ultimate tensile

(see B.4 of

unit strenght u

BS6464:1984)

(see B.3 of

BS6464:1984)

N/mm

N/mm

N/mm2

(width per kg/m2

glass)

(width per kg/m2 glass)

200

15898

5

250

17278

5

500

28000

5

Unidirectional Roving

Mortar

3500

Poisson's

Modulus

Poisson's

Modulus

kg/dm3

v12

v21

1,5

1,7

1,9

1,7

1,12

0,3

0,3

0,3

0,3

0,3

0,3

0,3

0,01

0,01

0,3

6. Unit Thickness

(fig.2 BS6464:1984)

CSM Percentage Glass Content by Mass

WR & UR Percentage Glass Content by Mass

CR Percentage Glass Content by Mass

mgcsm

mgwr

mgcs

35

56

75

CSM Thickness

tcsm

(100 mg CSM )

1

+

2,56

(mg CSM d R ) 2,05

WR & UR Thickness

twr

1

(100 mgWR )

+

(mgWR d R ) 1,10

2,56

CR Thickness

tcr

1 (100 mgCR)

+

2,56 (mgCRdR )

09-004_CI0001-02 .xls

0,69

%

%

%

mm per

kg/m2 glass

mm per

kg/m2 glass

mm per

kg/m2 glass

6/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

T2400

T2000

T1600

T500

T400

T350

T300

T250

T200

T150

6,3

6,3

6,3

6,3

6,3

6,3

6,3

6,3

mm/mm

mm/mm

mm/mm

mm/mm

mm/mm

mm/mm

1,5

1,2

1,0

1,1

1,1

0,035

0,0020

0,0020

0,0023

0,0028

0,002

1,5

1,2

1,0

1,1

1,1

0,035

0,0020

0,0020

0,0023

0,0028

0,002

1,5

1,2

1,0

1,1

1,1

0,035

0,0020

0,0020

0,0023

0,0028

0,002

1,5

1,2

1,0

1,1

1,1

0,035

0,0020

0,0020

0,0023

0,0028

0,002

1,5

1,2

1,0

1,1

1,1

0,035

0,0020

0,0020

0,0023

0,0028

0,002

1,5

1,2

1,0

1,1

1,1

0,035

0,0020

0,0020

0,0023

0,0028

0,002

1,5

1,2

1,0

1,1

1,1

0,035

0,0020

0,0020

0,0023

0,0028

0,002

1,5

1,2

1,0

1,1

1,1

0,035

0,0020

0,0020

0,0023

0,0028

0,002

1,5

1,2

1,0

1,1

1,1

0,035

0,0020

0,0020

0,0023

0,0028

0,0020

1,5

1,2

1,0

1,1

1,1

0,035

0,0020

0,0020

0,0023

0,0028

0,0020

C

MPa

MPa

MPa

cycles

60

0,62

0,43

0,04

1000

60

0,62

0,43

0,09

1000

60

0,62

0,43

0,04

1000

60

0,75

0,55

0,06

1000

60

0,75

0,55

0,06

1000

60

0,75

0,55

0,06

1000

60

0,75

0,55

0,06

1000

60

0,75

0,55

0,06

1000

60

0,75

0,55

0,06

1000

60

0,75

0,55

0,06

1000

m/s

Pa

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

as

0,00

0,00

0,00

0,00

0,00

0,00

0,00

0,00

0,00

0,00

kg/dm3

water

1

water

1

water

1

water

1

water

1

water

1

water

1

water

1

water

1

water

1

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

polyester

isopthalic

vinyleser LT

isopthalic

vinyleser LT

105

1,12

isopthalic

polyester

105

105

1,12

isopthalic

polyester

105

105

1,12

isopthalic

polyester

105

105

1,12

isopthalic

polyester

105

105

1,12

isopthalic

polyester

105

105

1,12

isopthalic

polyester

105

105

1,12

isopthalic

polyester

105

105

1,12

isopthalic

polyester

105

105

1,12

isopthalic

vinyleser LT

105

105

1,12

isopthalic

vinyleser LT

105

1,12

1,12

1,12

1,12

1,12

1,12

1,12

1,12

1,12

1,12

7. General

7.1. Factors for Design

(par. 14.4.1 BS6464:1984)

Design Factor

Factor relating to Method of Manufacture

Factor Relating to Long Term Behaviour

Factor relating to Temperature

Factor relating to Cyclic Loading

Factor relating to Curing Procedure

Resin Strain Failure

Allowable Resin Strain

Chopped Strand Mat Allowable Strain

Woven Roving Allowable Strain

Continuous Roving

Allowable Design Strain

K

k1

k2

k3

k4

k5

R

=3k1k2k3k4k5

=min(Rx0,1;0,0020)

=uCSM/(XCSMK)

=uWR/(XWRK)

=uCR/(XCRK)

=min(;CSM;WR;CR)

CSM

WR

CS

d

7.2. Conditions for Design

Design Temperature

Design Pressure

Operating Pressure

Design Vacuum

Number of cycles expected in lifetime

Wind Conditions

Wind Speed

Wind Dynamic Pressure

Seismic Conditions

Equivalent Acceleration

T

p

pW

pe

N

VS

qs

=0,613VS2

7.3. Fluid Characteristics

Fluid

Specific Gravity

7.4. Resin Characteristics

Liner Resin

HDT Liner Resin

Relative Density of Liner Resin

C

dl

Mechanical Reinforcement Resin

HDT Mechanical Reinforcement Resin

Relative Density of Mechanical Reinforcement

Resin

C

dmr

7.5. Glass Characteristics

Surface Veil

Chopped Strand Mat (CSM)

09-004_CI0001-02 .xls

7/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

Roving (CR)

Woven Roving (WR)

Unidirectional Roving (UR)

T2400

T2000

T1600

T500

T400

T350

T300

T250

T200

T150

7.6. Construction of Chemical Barrier

Adivised Chemical Barrier

Thickness

mm

[C veil tissue /

800 kg/m2

1,65

mm

[C veil tissue]

0,2

[C veil tissue /

[C veil tissue /

[C veil tissue /

[C veil tissue /

[C veil tissue /

[C veil tissue /

[C veil tissue /

[C veil tissue /

[C veil tissue /

800 kg/m2 CSM] 800 kg/m2 CSM] 800 kg/m2 CSM] 800 kg/m2 CSM] 800 kg/m2 CSM] 800 kg/m2 CSM] 800 kg/m2 CSM] 800 kg/m2 CSM] 800 kg/m2 CSM]

1,65

1,65

1,65

1,65

1,65

1,65

1,65

1,65

1,65

7.7. Construction of Top Coat

Used Top Coat Barrier

Thickness

09-004_CI0001-02 .xls

[C veil tissue]

0,2

[C veil tissue]

0,2

[C veil tissue]

0,2

[C veil tissue]

0,2

[C veil tissue]

0,2

[C veil tissue]

0,2

[C veil tissue]

0,2

[C veil tissue]

0,2

[C veil tissue]

0,2

8/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

T100

T80

T600

T300

7. General

7.1. Factors for Design

(par. 14.4.1 BS6464:1984)

Design Factor

Factor relating to Method of Manufacture

Factor Relating to Long Term Behaviour

Factor relating to Temperature

Factor relating to Cyclic Loading

Factor relating to Curing Procedure

Resin Strain Failure

Allowable Resin Strain

Chopped Strand Mat Allowable Strain

Woven Roving Allowable Strain

Continuous Roving

Allowable Design Strain

1,5

1,2

1,0

1,1

1,1

0,035

0,0020

0,0020

0,0023

0,0028

0,0020

1,5

1,2

1,0

1,1

1,1

0,035

0,0020

0,0020

0,0023

0,0028

0,0020

1,5

1,2

1,0

1,1

1,1

0,035

0,0020

0,0020

0,0023

0,0028

0,0020

1,5

1,2

1,0

1,1

1,1

0,035

0,0020

0,0020

0,0023

0,0028

0,0020

60

0,75

0,55

0,06

1000

60

0,75

0,55

0,06

1000

60

0,75

0,55

0,04

1000

60

0,75

0,55

0,04

1000

33

680

33

680

33

680

33

680

as

0,00

0,00

0,00

0,00

water

1

water

1

water

1

water

1

isopthalic

vinyleser LT

isopthalic

vinyleser LT

isopthalic

vinyleser LT

isopthalic

vinyleser LT

105

1,12

isopthalic

vinyleser LT

105

105

1,12

isopthalic

vinyleser LT

105

105

1,12

isopthalic

vinyleser LT

105

105

1,12

isopthalic

vinyleser LT

105

1,12

1,12

1,12

1,12

K

k1

k2

k3

k4

k5

R

CSM

WR

CS

d

=3k1k2k3k4k5

=min(Rx0,1;0,0020)

=uCSM/(XCSMK)

=uWR/(XWRK)

=uCR/(XCRK)

=min(;CSM;WR;CR)

7.2. Conditions for Design

Design Temperature

Design Pressure

Operating Pressure

Design Vacuum

Number of cycles expected in lifetime

Wind Conditions

Wind Speed

Wind Dynamic Pressure

Seismic Conditions

Equivalent Acceleration

T

p

pW

pe

N

VS

qs

=0,613VS2

7.3. Fluid Characteristics

Fluid

Specific Gravity

7.4. Resin Characteristics

Liner Resin

HDT Liner Resin

Relative Density of Liner Resin

dl

Mechanical Reinforcement Resin

HDT Mechanical Reinforcement Resin

Relative Density of Mechanical Reinforcement

Resin

dmr

7.5. Glass Characteristics

Surface Veil

Chopped Strand Mat (CSM)

09-004_CI0001-02 .xls

9/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

Roving (CR)

Woven Roving (WR)

Unidirectional Roving (UR)

T100

T80

T600

T300

7.6. Construction of Chemical Barrier

Adivised Chemical Barrier

Thickness

[C veil tissue /

[C veil tissue /

[C veil tissue /

[C veil tissue /

800 kg/m2 CSM] 800 kg/m2 CSM] 800 kg/m2 CSM] 800 kg/m2 CSM]

1,65

1,65

1,65

1,65

7.7. Construction of Top Coat

Used Top Coat Barrier

Thickness

09-004_CI0001-02 .xls

[C veil tissue]

0,2

[C veil tissue]

0,2

[C veil tissue]

0,2

[C veil tissue]

0,2

10/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

T2400

T2000

T1600

T500

T400

T350

T300

T250

T200

T150

T100

Horizontal

Horizontal

Simply

Supported

Horizontal

Simply

Supported

Horizontal

Horizontal

Horizontal

Horizontal

Horizontal

Horizontal

Horizontal

Horizontal

Buried

Buried

Buried

Buried

Buried

Buried

Buried

Buried

8. Pipe

8.1 Pipe Input Data

Geometrical Input

Configuration

Type of Support

Nominal Bore

Buried

ND

mm

2400

2000

1600

500

400

350

300

250

200

150

100

mm

11200

11200

11200

11200

11200

11200

11200

11200

11200

11200

11200

Lmax

mm

15430

13117

Maximum Deflection

mm

0,00

0,00

0,00

Assumed Distance between Supports / Pipe Lenght

mm

Distance between Joints

Maximum Distance between Supports to limite deflection to

1/300 of the span

Minimum Width of Support

mm

268

245

219

122

110

102

95

87

77

67

55

Coefficient of thermal expansion

1/C

1,8E-05

1,8E-05

1,8E-05

1,8E-05

1,8E-05

1,8E-05

1,8E-05

1,8E-05

1,8E-05

1,8E-05

1,8E-05

Internal Loads

p

N/mm2

0,62

0,62

0,62

0,75

0,75

0,75

0,75

0,75

0,75

0,75

0,75

Design Vacuum

pe

N/mm

0,04

0,09

0,04

0,06

0,06

0,06

0,06

0,06

0,06

0,06

0,06

Operating pressure

pW

N/mm2

0,43

0,43

0,43

0,55

0,55

0,55

0,55

0,55

0,55

0,55

0,55

Design Pressure

8.2 Pipe Output Data

Pipe Thickness

Pipe Mechanical Reinforcement Thickness

tr

mm

19,3

16,9

13,3

7,0

7,0

5,6

5,6

4,2

4,2

2,8

2,8

Internal Liner Thickness

tl

mm

1,7

1,7

1,7

1,7

1,7

1,7

1,7

1,7

1,7

1,7

1,7

Top Coat Thickness

ttc

mm

0,2

0,2

0,2

0,2

0,2

0,2

0,2

0,2

0,2

0,2

0,2

Pipe Total Thickness

tt

=tr+tl+ttc

mm

21,1

18,8

15,1

8,8

8,8

7,4

7,4

6,0

6,0

4,6

4,6

Pipe Structural Diameter

=ND+2tl

mm

2403,3

2003,3

1603,3

503,3

403,3

353,3

303,3

253,3

203,3

153,3

103,3

Pipe Outside Diameter

Do

=ND+2tt

mm

2442,2

2037,6

1630,3

517,6

417,6

364,8

314,8

262,1

212,1

159,3

109,3

Mean Pipe Diameter

Dm

=ND+tt

mm

2421,1

2018,8

1615,1

508,8

408,8

357,4

307,4

256,0

206,0

154,6

104,6

Pipe mechanical reinforcement specific gravity

SGP

=SGiti/tr

kg/dm3

1,9

1,9

1,9

1,9

1,9

1,9

1,9

1,9

1,9

1,9

1,9

Weights

Stiffener Ring Weight

W SR

72,9

81,1

38,4

0,0

0,0

0,0

0,0

0,0

0,0

0,0

0,0

Pipe Diameters

Pipe Specific Gravity

Pipe Mechanical Reinforcement Weight

Pipe Mechanical Reinforcement + Stiffeners Rings Weight

O+d3+d4)(2A22+2A33+Akg/m

WR

=Dtrr

kg/m

276,2

202,6

127,1

20,9

16,8

11,8

10,1

6,3

5,1

2,5

1,7

W R+SR

=W SR+W R

kg/m

349,0

283,6

165,5

20,9

16,8

11,8

10,1

6,3

5,1

2,5

1,7

0,8

Pipe Liner Weight

WL

=NDtll

kg/m

18,7

15,6

12,4

3,9

3,1

2,7

2,3

1,9

1,6

1,2

Pipe Top Coat Weight

W TC

=(DO-2ttc)ttctc

kg/m

1,7

1,4

1,1

0,4

0,3

0,3

0,2

0,2

0,1

0,1

0,1

Pipe Total Weight

WT

WC

=W R+SR+W L+W TC

kg/m

369,4

300,6

179,1

25,2

20,2

14,7

12,6

8,4

6,8

3,8

2,6

=((ND2)tll)/4

kg/m

4523,9

3141,6

2010,6

196,3

125,7

96,2

70,7

49,1

31,4

17,7

7,9

2051

2051

2051

2024

2024

2024

2024

2024

2024

2024

2024

Weight of Contents

8.3 Construction of Mechanical Reinforcement

Continuous Cross Roving Grammature

09-004_CI0001-02 .xls

g/m2

11/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

T2400

T2000

T1600

T500

T400

T350

T300

T250

T200

T150

T100

Continuous Cross Roving Angle

Longitudinal Unit Modulus

XLAMa

N/mm

55

8603

55

8603

55

8603

55

8603

55

8603

55

8603

55

8603

55

8603

55

8603

55

8603

55

8603

Circumferential Unit Modulus

XLAMc

N/mm

16518

16518

16518

16518

16518

16518

16518

16518

16518

16518

16518

Poisson Modulus for Continuous Cross Roving

vac

0,30

0,30

0,30

0,30

0,30

0,30

0,30

0,30

0,30

0,30

0,30

Poisson Modulus for Continuous Cross Roving

vca

0,55

0,55

0,55

0,55

0,55

0,55

0,55

0,55

0,55

0,55

0,55

g/m2

840

840

4

2,3

0

0,0

1

0,6

0

0,0

0

0,0

0

0,0

0

0,0

0

0,0

0

0,0

0

0,0

0

0,0

CSM-Chopped Strand Mat

UR-Unidirectional Roving

WR-Woven Roving

CPR-Continuous Parallel Roving

CCR-Continuous Cross Roving

CPR Grammature

CPR Layers

CPR Thickness

mm

CPR Neutral Axis

mm

8,47

0,00

6,35

0,00

0,00

0,00

0,00

0,00

0,00

0,00

0,00

CPR Momet of Inertia

mm3

215,2967625

25,51469998

g/m

2051

2051

2051

2024

2024

2024

2024

2024

2024

2024

2024

12

16,939

9

12,7

5

7,0

5

7,0

4

5,6

4

5,6

3

4,2

3

4,2

2

2,8

2

2,8

-0,29

0,00

0,00

0,00

0,00

0,00

0,00

0,00

0,00

CRR Grammature

CRR Layers

CRR Thickness

mm

12

16,9

CRR Neutral Axis

mm

-1,16

0,00

CRR Momet of Inertia

mm

405,0296953

405,0296953

Total Mechanical Reinforcement thickness

mm

19,3

16,9

13,3

7,0

7,0

5,6

5,6

4,2

4,2

2,8

2,8

Mechanical Reinforcement Neutral Axis

mm

-1,1563

0,0000

-0,2891

0,0000

0,0000

0,0000

0,0000

0,0000

0,0000

0,0000

0,0000

170,8719027 28,15708446 28,15708446 14,41642724 14,41642724 6,081930243 6,081930243 1,802053405 1,802053405

OK!>2 mm

OK!>2 mm

OK!>2 mm

OK!>2 mm

OK!>2 mm

OK!>2 mm

OK!>2 mm

OK!>2 mm

OK!>2 mm

OK!>2 mm

OK!>2 mm

[//

[///

[///

[///

[///

[///

[///

[///

[///

[//

[///

/1xcpr840/9xc

/5xccr2024/ / / /5xccr2024/ / / /4xccr2024/ / / /4xccr2024/ / / /3xccr2024/ / / /3xccr2024/ / / /2xccr2024/ / / /2xccr2024/ / /

/4xcpr840/12xc /12xccr2051/ /

cr2051/ / / / / /

cr2051/ / / / / / ]

////]

///]

///]

///]

///]

///]

///]

///]

///]

]

Mechanical Reinforcement Laminate Sequence

8.4 Design Calculation for Pipes subjected to Internal Pressure and Bending Moments

Loads on pipe

Axial Unit Load(pressure)

Qap

Axial Unit Load(moments)

Qam

Axial Unit Load (pressure and bending moments)

Qa

Circumferential Unit Load (pressure)

Qcp

Circumferential Unit Load (deflection)

Qcm

Circumferential Unit Load (pressure and deflection)

Qc

=Qcp+Qcm

Qac

=FC/(ND)

=Dp/4

N/mm

=MD/(D2)+Ft/(D) N/mm

=Qap+Qam

N/mm

=Dp/2

311

249

94

76

66

57

47

38

29

19

0,0

0,0

0,0

0,0

0,0

0,0

0,0

0,0

0,0

0,0

0,0

373

311

249

94

76

66

57

47

38

29

19

745,0

621,0

497,0

188,7

151,2

132,5

113,7

95,0

76,2

57,5

38,7

N/mm

298,1

0,0

0,0

130,8

120,3

89,1

77,6

74,1

68,2

51,1

50,0

N/mm

1043,1

621,0

497,0

319,5

271,5

221,6

191,4

169,0

144,4

108,6

88,8

N/mm

0,0

0,0

0,0

0,0

0,0

0,0

0,0

0,0

0,0

0,0

0,0

N/mm

0,0

0,0

0,0

0,0

0,0

0,0

0,0

0,0

0,0

0,0

0,0

=0,6trXLAMa/(SF*ND) N/mm

=1,3QP

N/mm

256

260

194

176

220

161

188

127

158

94

141

332

338

252

229

286

209

244

165

206

122

183

2389293716

2248501179

1489774314

861020966

1017879192

680993031

764456468

458803304

542386719

270276176

366333142

Shear

Compressive Load

N/mm

373

Buckling

Permissibile Axial Compressive Load to prevent buckling

Qp

Permissibile Bending Load to prevent buckling

Qm

Permissibile Shear Load to prevent buckling

Qs

Safety Factor for Buckling

SF

09-004_CI0001-02 .xls

=1,169trXLAMa(tr/ND5)1/

4

(ND/L)1/2/SF

N/mm

12/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

T2400

T2000

T1600

T500

T400

T350

T300

T250

T200

T150

T100

=abs(Qac/Qp)+abs(Qam

Interaction Criterion for Buckling

/Qm)+(S/Qs)2

0,00

0,00

0,00

0,00

0,00

0,00

0,00

0,00

0,00

0,00

0,00

OK!<1

OK!<1

OK!<1

OK!<1

OK!<1

OK!<1

OK!<1

OK!<1

OK!<1

OK!<1

OK!<1

211738

160827

87063

87063

69650

69650

52238

52238

34825

34825

Mechanical Properties

Longitudinal Unit Modulus

XLAMa

=(Ximini)a

N/mm

219832

OK!

OK!

OK!

OK!

OK!

OK!

OK!

OK!

OK!

OK!

OK!

Circumferential Unit Modulus

XLAMc

=(Ximini)c

N/mm

500618

406538

328423

167161

167161

133729

133729

100296

100296

66864

66864

Longitudinal Tensile Modulus of the Laminate

ELAMta

=XLAMa/tr

N/mm2

11419

12500

12108

12500

12500

12500

12500

12500

12500

12500

12500

Circumferential Tensile Modulus of the Laminate

ELAMtc

=XLAMc/tr

N/mm2

26004

24000

24726

24000

24000

24000

24000

24000

24000

24000

24000

Longitudinal Flexural Modulus of the Laminate

ELAMfa

=(EiIi/Ii)a

N/mm

9376

12500

11331

12500

12500

12500

12500

12500

12500

12500

12500

Circumferential Flexural Modulus of the Laminate

ELAMfc

=(EiIi/Ii)c

N/mm2

29790

24000

26167

24000

24000

24000

24000

24000

24000

24000

24000

Laminate Design Longitudinal Unit Loading

ULAMa

=XLAMad

N/mm

439,2

423,1

321,3

174,0

174,0

139,2

139,2

104,4

104,4

69,6

69,6

OK!>Qa

OK!>Qa

OK!>Qa

OK!>Qa

OK!>Qa

OK!>Qa

OK!>Qa

OK!>Qa

OK!>Qa

OK!>Qa

OK!>Qa

Laminate Design Circumferential Unit Loading

ULAMc

=XLAMcd

N/mm

1000,2

812,3

656,2

334,0

334,0

267,2

267,2

200,4

200,4

133,6

133,6

OK!>Qc

OK!>Qc

OK!>Qc

OK!>Qc

OK!>Qc

OK!>Qc

OK!>Qc

OK!>Qc

OK!>Qc

OK!>Qc

OK!>Qc

ca

=ULAMa / tr

N/mm2

23

25

24

25

25

25

25

25

25

25

25

Axial Stress Capacity

Axial Stress (pressure)

Axial Stress (moments)

ap

am

=(pWD/4) / tr

=Qastr

Residual Axial Stress (thermal effects)

ar

=ca-ap-am

Circumferential Stress Capacity

cc

=ULAMc / tr

Circumferential Stress (pressure)

Circumferential Stress (deflection)

Residual Circumferential Stress

cp

=(pWD/2) / tr

N/mm

N/mm2

N/mm2

2

N/mm

N/mm

N/mm2

cm

cr

=cc-cp-cm

N/mm2

13

13

13

10

59%

51%

54%

40%

32%

35%

30%

33%

27%

30%

20%

0%

0%

0%

0%

0%

0%

0%

0%

0%

0%

0%

12

11

15

17

16

17

17

18

17

20

41%

49%

46%

60%

68%

65%

70%

67%

73%

70%

80%

52

48

49

48

48

48

48

48

48

48

48

27

25

26

20

16

17

15

17

13

15

10

52%

53%

53%

41%

33%

36%

31%

35%

28%

32%

21%

15,5

0,0

0,0

18,8

17,3

16,0

13,9

17,7

16,3

18,3

18,0

30%

0%

0%

39%

36%

33%

29%

37%

34%

38%

37%

9,6

22,5

23,5

9,3

14,8

14,5

19,0

13,6

18,3

14,5

19,8

19%

47%

47%

19%

31%

30%

40%

28%

38%

30%

41%

Poisson Modulus

vac

=(miniXivi/nimiXi)ac

0,3

0,3

0,3

0,3

0,3

0,3

0,3

0,3

0,30

0,30

0,30

Poisson Modulus

vca

=(miniXivi/nimiXi)ca

0,45

0,55

0,51

0,55

0,55

0,55

0,55

0,55

0,550

0,550

0,550

Axial Strain (pressure)

ap

=ap/ELAMta-vcacp/ELAMtc mm/mm

0,00071

0,00043

0,00054

0,00034

0,00027

0,00030

0,00026

0,00028

0,00023

0,00026

0,00017

Axial Strain (moments)

am

=am/ELAMfa-vcacm/ELAMfc mm/mm

-0,00023

0,00000

0,00000

-0,00043

-0,00040

-0,00037

-0,00032

-0,00041

-0,00037

-0,00042

-0,00041

Circumferential Strain (pressure)

cp

=cp/ELAMtc-vacap/ELAMta mm/mm

0,00068

0,00075

0,00073

0,00059

0,00047

0,00052

0,00044

0,00049

0,00040

0,00045

0,00030

Circumferential Strain (deflection)

cm

=cm/ELAMfc-vacam/ELAMfa mm/mm

0,00052

0,00000

0,00000

0,00078

0,00072

0,00067

0,00058

0,00074

0,00068

0,00076

0,00075

2,5

2,5

2,5

2,5

2,5

2,5

2,5

2,5

2,5

2,5

2,5

8.5 Design Calculation for Pipe subjected to Vacuum

Pipe without Stiffening Rings

Safety Factor

SF

Minimum Wall Thickness

tm

Minimum Stiffeness

09-004_CI0001-02 .xls

=(ND+2tr)(SFpet/2ELAMt

c)

0,33

mm

=ELAMfc(tm3/12)/(ND+tr)3 Pa

30,3

35,5

21,1

7,8

6,3

5,5

4,7

3,9

3,2

2,4

1,6

Buckling,

increase t or

use ribs

Buckling,

increase t or

use ribs

Buckling,

increase t or

use ribs

Buckling,

increase t or

use ribs

OK!

OK!

OK!

OK!

OK!

OK!

OK!

4808

10574

4801

7353

7501

7437

7551

7471

7651

7551

8063

13/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

T2400

T2000

T1600

T500

T400

T350

T300

T250

T200

T150

T100

8779

3433

6059

4396

6081

4271

5341

3439

4748

2671

4713

2240

2000

2000

1000

1000

1000

1000

1000

1000

1000

1000

Pipe with Stiffening Rings - Fixed Distance between Rings

Maximum Distance between Stiffening Rings

Jmax

=(250Xlamc/(SFpet))(td/(ND+2tmm

Choosen Distance between Stiffening Rings

mm

Outside Sructural Diameter

Do

mm

2439

2034

1627

514

414

361

311

258

208

156

106

Minimum Wall Thickness

tm=Do(0,4SFpetJ/(ElamtcDo))^0,4

mm

11,15

13,65

8,53

3,85

3,38

3,12

2,85

2,55

2,24

1,88

1,50

OK!<tr

OK!<tr

OK!<tr

OK!<tr

OK!<tr

OK!<tr

OK!<tr

OK!<tr

OK!<tr

OK!<tr

OK!<tr

=ND+2tr

Shell with Stiffening Rings - Fixed Laminated Thickness

Stiffness factor of the Stiffening Ring

Diameter of Neutral Axis of Stiffening Ring

EI

=0,18(ND+2tt)JDs2pet mm4

1,48735E+11

1,76369E+11 39610468650 883154784,4 458371862,6 305289894,3 194251990,7 111603590,9 58077682,13 24281498,84

7558891,9

Increase t,

Increase t,

Increase t,

Increase t,

Increase t,

Increase t,

Increase t,

Increase t,

ridesign rib or ridesign rib or ridesign rib or ridesign rib or ridesign rib or ridesign rib or ridesign rib or ridesign rib or

approach ribs approach ribs approach ribs approach ribs approach ribs approach ribs approach ribs approach ribs

OK!<EiIi

OK!<EiIi

OK!<EiIi

mm

2471,6

2079,2

1652,8

Ei

N/mm2

40683

40683

40683

bi

mm

250

250

250

Ds

=ND+2y

507,0

407,0

355,6

305,6

254,2

204,2

152,8

102,8

Construction of Stiffening Ring

Section 4 Hoop Modulus of Elasticity

Dimension (see fig.)

Dimension (see fig.)

di

Section Area

Ai

Section Neutral Axis

yi

Section Moment of Inertia

Ii

Section Stiffness Factor

Rib Hoop Modulus of Elasticity

Dimension (see fig.)

mm

44

52

31

mm2

11000

13000

7750

mm

41

43

29

5,57202381

5,57202381

mm4

2,102E+06

3,074E+06

6,653E+05

EiIi

Nmm

8,550E+10

1,250E+11

2,706E+10

EiAi

4,475E+08

5,289E+08

3,153E+08

Nmm

1,846E+10

2,271E+10

9,075E+09

=bidi3/12+Ai(y-yi)2

EiAiyi

Ei

di

Section Area

Ai

Section Neutral Axis

yi

Section Moment of Inertia

Ii

6,965029762 6,965029762

4,179017857 4,179017857 2,786011905 2,786011905

N/mm2

mm

bi

Dimension (see fig.)

Section Stiffness Factor

=bidi

40683,24324 40683,24324 40683,24324 40683,24324 40683,24324 40683,24324 40683,24324 40683,24324

mm

=bidi

mm2

mm

36

40

26

3,482514881 3,482514881 2,786011905 2,786011905 2,089508929 2,089508929 1,393005952 1,393005952

mm4

4,341E+06

5,416E+06

1,257E+06

1263,462758 1133,897814 485,0266707 450,2006712 149,8824552 134,5999625 28,13754195 23,17900709

EiIi

Nmm

1,522E+11

1,813E+11

4,256E+10

30323106,2

EiAi

5,407E+08

5,855E+08

3,536E+08

7500824,081 6731633,342 4499167,698 4176117,398 2471694,735 2219672,864 1044029,349

860045,406

Nmm

1,936E+10

2,319E+10

9,329E+09

26121731,48 23443013,29 12534734,77 11634712,79 5164628,217 4638026,268 1454339,098

1198048,37

EiAiyi

=bidi3/12+Ai(y-yi)2

27213547,54

11640640,1

10804816,11 3597178,924 3230399,099 675301,0069 556296,1702

Fig.1 - General Stiffening Rib Configuration

09-004_CI0001-02 .xls

14/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

T2400

T2000

T1600

T500

T400

T350

T300

T250

T200

T150

T100

8.6 Design Calculation for Pipe with Specified Stiffness

Pipe without Stiffening Rings

Pipe without Stiffening Rings Stiffness

=ELAMfc(tt3/12)/Dm3

Pipe without Stiffening Rings Stiffness Factor

EI

=ELAMfc(tt3/12)

Stiffening Ring Stiffness

SR

=EiIi/(Ds3BR)

Stiffening Ring Cooperating Lenght

BR

=b1+2b2+1,73d3+b4

Pa

1251

1185

1217

5186

10026

7696

12126

8889

17148

12126

39827

17712951

9720713

5109905

675770

675770

345994

345994

145966

145966

43249

43249

Pa

24441

51814

26169

5186

10026

7696

12126

8889

17148

12126

39827

mm

413

389

360

45

40

34

31

25

22

16

13

mm

2240

2000

2000

1000

1000

1000

1000

1000

1000

1000

1000

Pa

5522

11037

5711

5186

10026

7696

12126

8889

17148

12126

39827

78181345

90561620

23981211

675770

675770

345994

345994

145966

145966

43249

43249

18

22

14

Nmm

Stiffening Rings

Distance between Stiffening Rings

Pipe with Stiffening Rings

Pipe with Stiffening Rings Mean Stiffness

=S(J-BR)/J+SRBR/J

Pipe with Stiffening Rings Stiffness Factor

EI

=SDm3

Neutrl Axis of pipe with Stiffening Rings

Nmm

mm

OK! Rib close

Rib is too

Rib is too

OK! Rib close OK! Rib close OK! Rib close OK! Rib close OK! Rib close OK! Rib close OK! Rib close OK! Rib close

to External

high, Increase high, Increase to External

to External

to External

to External

to External

to External

to External

to External

8.7 Buried Pipe

(according AWWA M45)

Geometrical Input

Height of Solil above Top of the Pipe

Height of Water above top of Pipe

Minimum Trench Width

Trench Width

Specific Weight of the Soil

Specific Weight of the Water

mm

1200

1200

1200

1200

1200

1200

1200

1200

1200

1200

1200

HW

mm

1200

1200

1200

1200

1200

1200

1200

1200

1200

1200

1200

mm

3358

2852

2343

952

827

761

699

633

570

504

442

mm

3500

4000

4000

1000

1000

1000

1000

1000

1000

1000

1000

1,8

1,8

1,8

1,8

1,8

1,8

1,8

1,8

1,9

1,9

1,9

None

None

None

None

None

None

None

None

None

None

None

Cohesive

Cohesive

Cohesive

Cohesive

Cohesive

Cohesive

Cohesive

Cohesive

Cohesive

Cohesive

Cohesive

blows/ft

>0-1

>0-1

>0-1

>0-1

>0-1

>0-1

>0-1

>0-1

>0-1

>0-1

>0-1

kg/cm2

N/mm2

>1-2

>1-2

>1-2

>1-2

>1-2

>1-2

>1-2

>1-2

>1-2

>1-2

>1-2

20,68

20,68

20,68

20,68

20,68

20,68

20,68

20,68

20,68

20,68

20,68

Stiff

Stiff

Stiff

Stiff

Stiff

Stiff

Stiff

Stiff

Stiff

Stiff

Stiff

SM

SM

SM

SM

SM

SM

SM

SM

SM

SM

SM

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

BdMIN

=1,25Do+305

Bd

kg/dm3

SGS

kg/dm

SGW

Special Installation Case

Native Soil

see table 5-6 pag.51

Type of Soil

Granular Soil Standard Penetration Resistance

Unconfined Compression Strenght

Native Modulus of Soil Reaction

UCS

E'n

Soil Description

Foundation Bedding

Soil Classification Group Name

see table 5-5 pag.49

Soil Type

Pipe Zone Embedment Soil Stiffness Category

Equivalent Bedding Angle

Proctor

Bedding Coefficient (Degree of Support Provided by the Soil)

Pipe Zone Embedment

Soil Classification Group Name

09-004_CI0001-02 .xls

KX

SC3

SC3

SC3

SC3

SC3

SC3

SC3

SC3

SC3

SC3

SC3

180

180

180

180

180

180

180

180

180

180

180

>95%

>95%

>95%

>95%

>95%

>95%

>95%

>95%

>95%

>95%

>95%

0,083

0,083

0,083

0,083

0,083

0,083

0,083

0,083

0,083

0,083

0,083

SM

SM

SM

SM

SM

SM

SM

SM

SM

SM

SM

see table 5-5 pag.49

15/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

Soil Type

Pipe Zone Embedment Soil Stiffness Category

Proctor

Backfill soil modulus

E'b

Modulus of Soil Reaction

E'

WC

T2400

T2000

T1600

T500

T400

T350

T300

T250

T200

T150

T100

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

Silty sand,

fines>12%

SC3

SC3

SC3

SC3

SC3

SC3

SC3

SC3

SC3

SC3

SC3

85%

85%

85%

85%

85%

85-95%

85-95%

85-95%

85-95%

85-95%

85-95%

2

see table 5-4 pag.48 N/mm

6,9

2,8

2,8

6,9

6,9

6,9

6,9

6,9

6,9

6,9

6,9

=ScE'b

N/mm2

6,9

4,8

4,8

6,9

6,9

6,9

6,9

6,9

6,9

6,9

6,9

=H*SGS

N/mm2

0,022

0,022

0,022

0,022

0,022

0,022

0,022

0,022

0,023

0,023

0,023

0,01

0,02

0,01

0,00

0,00

0,00

0,00

0,00

0,00

0,00

0,00

External Loads

Vertical Soil Load on Pipe

Live Load on Pipe

WL

N/mm

Axles Number

na

Wheels per Axle

nw

Distance between axles

La

mm

1500

1500

1500

1500

1500

1500

1500

1500

1500

1500

1500

Distance between wheels in an axle

Lw

mm

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

Pipe Cover depth

mm

1200

1200

1200

1200

1200

1200

1200

1200

1200

1200

1200

Trench width

Bd

mm

3500

4000

4000

1000

1000

1000

1000

1000

1000

1000

1000

35

35

35

35

35

35

35

35

35

35

35

mm

1680

1680

1680

1000

1000

1000

1000

1000

1000

1000

1000

Backfill Soil Slip Angle

Acting Transversal Lenght

sigma

X

Acting Axles

naa

Acting Wheels per Axle

nwa

Total Acting Wheels

Nwa

Total Acting Area

Awa

mm2

Maximum Live Load on Pipe

WL

N/mm2

Total Acting Force

Pt

Wheel Acting Force

Pw

tons

Axle Acting Force

Pa

tons

09-004_CI0001-02 .xls

5344821

5344821

5344821

2824074

2824074

2824074

2824074

2824074

2824074

2824074

2824074

0,01

0,02

0,01

0,00

0,00

0,00

0,00

0,00

0,00

0,00

0,00

62311

103544

74928

31155

51772

37464

0,0

0,0

0,0

0,0

0,0

10

0,0

0,0

0,0

0,0

0,0

16/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

T2400

T2000

T1600

T500

T400

T350

T300

T250

T200

T150

T100

Fig.2 - General truck Configuration and Distribution of Live Loads on Pipe

09-004_CI0001-02 .xls

17/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

T2400

T2000

T1600

T500

T400

T350

T300

T250

T200

T150

T100

1,5

1,5

1,5

1,5

1,5

1,5

Pipe Deflection

Deflection Lag Factor to compensate for the time-consolidation

rate of the soil

DL

Installation Conditions

Ka

Initial Conditions

Da

Vertical Deflection

Dy/Dm

mm/mm

0,75

0,75

0,75

0,75

0,75

0,75

0,75

0,75

0,75

0,75

0,75

0,000

0,000

0,000

0,000

0,000

0,000

0,000

0,000

0,000

0,000

0,000

0,017

0,018

0,010

0,009

0,007

0,007

0,007

0,006

0,007

0,005

( D LW C + W L ) k X ( D m / 2) 3

mm/mm + D a0,013

EI + 0 .061k a E ' ( D m / 2) 3

OK! Less than OK! Less than OK! Less than OK! Less than

5%

5%

5%

5%

OK! Less

than 5%

OK! Less than OK! Less than OK! Less than OK! Less than OK! Less than OK! Less than

5%

5%

5%

5%

5%

5%

Strain due to Deflection

Shape Factor relate Pipe Deflection to Bending Strain

Df

see table 5-1 pag.42

Rerounding coefficient

rC

cm

(1-pW)/3

=Dfrc(Dy/Dm)(tt/Dm)

0,86

0,86

0,86

0,82

0,82

0,82

0,82

0,82

0,82

0,82

0,82

Strain

mm/mm

0,00052

0,00061

0,00080

0,00078

0,00072

0,00067

0,00058

0,00074

0,00068

0,00076

0,00075

Stress

cs

=cmELAMfc

N/mm2

15,5

14,6

20,8

18,8

17,3

16,0

13,9

17,7

16,3

18,3

18,0

Allowable Buckling pressure

5,5

4,5

5,5

5,5

4,5

5,5

4,5

5,5

4,5

4,5

4,5

see par. 5.7.5 pag.52

Water Buoyancy Factor

RW

0,67

0,67

0,67

0,67

0,67

0,67

0,67

0,67

0,67

0,67

0,67

Empirical Coefficient of Elastic Support

B'

0,24

0,24

0,24

0,24

0,24

0,24

0,24

0,24

0,24

0,24

0,24

Design Factor

FS

Allowable Buckling Pressure

qa

Number of Lobes formed at Buckling

N/mm2

2,5

2,5

2,5

2,5

2,5

2,5

2,5

2,5

2,5

2,5

2,5

30,43

22,24

13,51

0,15

0,29

0,22

0,35

0,26

0,49

0,35

1,14

2,5

785,5

1216,8

1591,8

2151,7

3102,3

4790,7

8504,2

18573,5

1,4

1,6

Typical Pipe Installation Conditions

N/mm2

0,07

OK! Less than

qa

0,12

OK! Less

than0 qa

0,07

0,09

OK! Less than OK! Less than

qa

qa

0,09

OK! Less

than qa

0,09

0,09

0,09

0,09

0,09

0,09

OK! Less than OK! Less than OK! Less than OK! Less than OK! Less than OK! Less than

qa

qa

qa

qa

qa

qa

Live Load Conditions

N/mm2

0,04

0,05

0,04

0,03

OK! Less than OK! Less than OK! Less than OK! Less than

qa

qa

qa

qa

0,03

OK! Less

than qa

0,03

0,03

0,03

0,03

0,03

0,03

OK! Less than OK! Less than OK! Less than OK! Less than OK! Less than OK! Less than

qa

qa

qa

qa

qa

qa

Buoyancy

Uplift Force

FUP

=(Do2/4)SGW

N/mm

46,8

32,6

20,9

2,1

1,4

1,0

0,8

0,5

0,4

0,2

0,1

Soil Weight above the Pipe

WS

=DOSGSRWH

N/mm

35,3

29,5

23,6

7,5

6,0

5,3

4,6

3,8

3,2

2,4

1,7

Water Weight inside the Pipe

WW

N/mm

45,2

31,4

20,1

2,0

1,3

1,0

0,7

0,5

0,3

0,2

0,1

Pipe Weight

WP

N/mm

3,7

3,0

1,8

0,3

0,2

0,1

0,1

0,1

0,1

0,0

0,0

1,5

1,5

1,5

1,5

1,5

1,5

1,5

1,5

1,5

1,5

1,5

N/mm

84,3

63,9

45,5

9,7

7,5

6,4

5,4

4,4

3,6

2,6

1,8

OK! No

Buoyancy of

Fill in Pipe

OK! No

Buoyancy of

Fill in Pipe

OK! No

Buoyancy of

Fill in Pipe

OK! No

Buoyancy of

Fill in Pipe

OK! No

Buoyancy of

Fill in Pipe

OK! No

Buoyancy of

Fill in Pipe

OK! No

Buoyancy of

Fill in Pipe

OK! No

Buoyancy of

Fill in Pipe

OK! No

Buoyancy of

Fill in Pipe

OK! No

Buoyancy of

Fill in Pipe

OK! No

Buoyancy of

Fill in Pipe

39,0

32,5

25,4

7,7

6,2

5,4

4,7

3,9

3,3

2,5

1,7

OK! No

Buoyancy of

Empty Pipe

OK! No

Buoyancy of

Empty Pipe

OK! No

Buoyancy of

Empty Pipe

OK! No

Buoyancy of

Empty Pipe

OK! No

Buoyancy of

Empty Pipe

OK! No

Buoyancy of

Empty Pipe

OK! No

Buoyancy of

Empty Pipe

OK! No

Buoyancy of

Empty Pipe

OK! No

Buoyancy of

Empty Pipe

OK! No

Buoyancy of

Empty Pipe

OK! No

Buoyancy of

Empty Pipe

Safety Factor

SF

W P+W W+W S

W P+W S

09-004_CI0001-02 .xls

=(ND /4)C

N/mm

18/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

T80

T600

T300

Horizontal

Horizontal

Horizontal

Buried

Encastr

Encastr

8. Pipe

8.1 Pipe Input Data

Geometrical Input

Configuration

Type of Support

Nominal Bore

ND

80

600

300

11200

11200

11200

Lmax

13131

7701

Maximum Deflection

0,00

0,00

0,00

Assumed Distance between Supports / Pipe Lenght

Distance between Joints

Maximum Distance between Supports to limite deflection to

1/300 of the span

Minimum Width of Support

Coefficient of thermal expansion

49

134

95

1,8E-05

1,8E-05

2,5E-05

Internal Loads

Design Pressure

0,75

0,75

0,75

Design Vacuum

pe

0,06

0,04

0,04

Operating pressure

pW

0,55

0,55

0,55

Pipe Mechanical Reinforcement Thickness

tr

2,8

7,5

3,4

Internal Liner Thickness

tl

1,7

1,7

1,7

Top Coat Thickness

ttc

0,2

0,2

0,2

Pipe Total Thickness

tt

=tr+tl+ttc

4,6

9,4

5,2

Pipe Structural Diameter

=ND+2tl

83

603

303

Pipe Outside Diameter

Do

=ND+2tt

89

619

310

Mean Pipe Diameter

Dm

=ND+tt

85

609

305

Pipe mechanical reinforcement specific gravity

SGP

=SGiti/tr

1,9

1,9

1,9

Weights

Stiffener Ring Weight

W SR

O+d3+d4)(2A22+2A33+A

0,0

0,0

0,0

WR

=Dtrr

27

W R+SR

=W SR+W R

27

8.2 Pipe Output Data

Pipe Thickness

Pipe Diameters

Pipe Specific Gravity

Pipe Mechanical Reinforcement Weight

Pipe Mechanical Reinforcement + Stiffeners Rings Weight

Pipe Liner Weight

WL

=NDtll

Pipe Top Coat Weight

W TC

=(DO-2ttc)ttctc

0,1

Pipe Total Weight

WT

WC

=W R+SR+W L+W TC

2,1

32

5,0

283

71

2024

2024

2024

Weight of Contents

=((ND )tll)/4

8.3 Construction of Mechanical Reinforcement

Continuous Cross Roving Grammature

09-004_CI0001-02 .xls

19/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

T80

T600

T300

Continuous Cross Roving Angle

Longitudinal Unit Modulus

XLAMa

55

8603

55

8603

55

8603

Circumferential Unit Modulus

XLAMc

16518

16518

16518

Poisson Modulus for Continuous Cross Roving

vac

0,30

0,30

0,30

Poisson Modulus for Continuous Cross Roving

vca

0,55

0,55

0,55

829

829

CPR Thickness

0

0,0

1

0,6

1

0,6

CPR Neutral Axis

0,00

3,48

1,39

CPR Momet of Inertia

CSM-Chopped Strand Mat

UR-Unidirectional Roving

WR-Woven Roving

CPR-Continuous Parallel Roving

CCR-Continuous Cross Roving

CPR Grammature

CPR Layers

CRR Grammature

CRR Layers

8,11521343 1,62252061

2024

2024

2024

5

7,0

2

2,8

-0,29

-0,29

CRR Thickness

2

2,8

CRR Neutral Axis

0,00

CRR Momet of Inertia

Total Mechanical Reinforcement thickness

2,8

7,5

3,4

Mechanical Reinforcement Neutral Axis

0,0000

-0,2853

-0,2853

1,802053405 28,1570845 1,80205341

OK!>2 mm OK!>2 mm OK!>2 mm

[//

[//

[///

/1xcpr829/5x /1xcpr829/2x

/2xccr2024/ /

ccr2024/ / / / ccr2024/ / / /

////]

//]

//]

Mechanical Reinforcement Laminate Sequence

8.4 Design Calculation for Pipes subjected to Internal Pressure and Bending Moments

Loads on pipe

Axial Unit Load(pressure)

Qap

=Dp/4

16

113

57

Axial Unit Load(moments)

Qam

=MD/(D2)+Ft/(D)

0,0

0,0

0,0

Axial Unit Load (pressure and bending moments)

Qa

=Qap+Qam

16

113

57

Circumferential Unit Load (pressure)

Qcp

=Dp/2

31,2

226,2

113,7

Circumferential Unit Load (deflection)

Qcm

Circumferential Unit Load (pressure and deflection)

Qc

=Qcp+Qcm

Qac

=FC/(ND)

Permissibile Axial Compressive Load to prevent buckling

Qp

Permissibile Bending Load to prevent buckling

Qm

46,7

0,0

0,0

77,9

226,2

113,7

0,0

0,0

0,0

0,0

0,0

0,0

=0,6trXLAMa/(SF*ND)

176

162

60

=1,3QP

229

211

78

433070619

847654763

214482086

Shear

Compressive Load

Buckling

Permissibile Shear Load to prevent buckling

Qs

Safety Factor for Buckling

SF

09-004_CI0001-02 .xls

=1,169trXLAMa(tr/ND5)1/

4

(ND/L)1/2/SF

20/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

T80

T600

T300

=abs(Qac/Qp)+abs(Qam

Interaction Criterion for Buckling

/Qm)+(S/Qs)2

0,00

0,00

0,00

OK!<1

OK!<1

OK!<1

89060

36822

Mechanical Properties

Longitudinal Unit Modulus

XLAMa

=(Ximini)a

34825

OK!

OK!

OK!

Circumferential Unit Modulus

XLAMc

=(Ximini)c

66864

190373

90076

Longitudinal Tensile Modulus of the Laminate

ELAMta

=XLAMa/tr

12500

11819

10970

Circumferential Tensile Modulus of the Laminate

ELAMtc

=XLAMc/tr

24000

25263

26836

Longitudinal Flexural Modulus of the Laminate

ELAMfa

=(EiIi/Ii)a

12500

10486

8236

Circumferential Flexural Modulus of the Laminate

ELAMfc

=(EiIi/Ii)c

24000

27733

31904

Laminate Design Longitudinal Unit Loading

ULAMa

=XLAMad

69,6

177,9

73,6

OK!>Qa

OK!>Qa

OK!>Qa

Laminate Design Circumferential Unit Loading

ULAMc

=XLAMcd

133,6

380,4

180,0

OK!>Qc

OK!>Qc

OK!>Qc

Axial Stress Capacity

ca

=ULAMa / tr

25

24

22

Axial Stress (pressure)

ap

=(pWD/4) / tr

Axial Stress (moments)

am

=Qastr

Residual Axial Stress (thermal effects)

ar

=ca-ap-am

Circumferential Stress Capacity

cc

=ULAMc / tr

Circumferential Stress (pressure)

cp

=(pWD/2) / tr

Circumferential Stress (deflection)

Residual Circumferential Stress

cm

cr

=cc-cp-cm

11

12

16%

47%

57%

0%

0%

0%

21

13

84%

53%

43%

48

50

54

22

25

17%

44%

46%

16,8

0,0

0,0

35%

0%

0%

23,0

28,5

28,8

48%

56%

54%

Poisson Modulus

vac

=(miniXivi/nimiXi)ac

0,30

0,30

0,30

Poisson Modulus

vca

=(miniXivi/nimiXi)ca

0,550

0,484

0,410

Axial Strain (pressure)

ap

=ap/ELAMta-vcacp/ELAMtc

0,00014

0,00051

0,00075

Axial Strain (moments)

am

=am/ELAMfa-vcacm/ELAMfc

-0,00038

0,00000

0,00000

Circumferential Strain (pressure)

cp

=cp/ELAMtc-vacap/ELAMta

0,00024

0,00059

0,00059

Circumferential Strain (deflection)

cm

=cm/ELAMfc-vacam/ELAMfa

0,00070

0,00000

0,00000

2,5

2,5

2,5

7,9

3,7

8.5 Design Calculation for Pipe subjected to Vacuum

Pipe without Stiffening Rings

Safety Factor

SF

Minimum Wall Thickness

tm

=(ND+2tr)(SFpet/2ELAMt

c)

0,33

1,3

OK!

Minimum Stiffeness

09-004_CI0001-02 .xls

=ELAMfc(tm3/12)/(ND+tr)3

8381

Buckling,

Buckling,

increase t or increase t or

use ribs

use ribs

5026

5002

21/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

T80

T600

T300

Pipe with Stiffening Rings - Fixed Distance between Rings

Maximum Distance between Stiffening Rings

Jmax

=(250Xlamc/(SFpet))(td/(ND+2t

6459

6325

2527

1000

1000

1000

Choosen Distance between Stiffening Rings

Outside Sructural Diameter

Do

Minimum Wall Thickness

tm=Do(0,4SFpetJ/(ElamtcDo))^0,4 1,31

=ND+2tr

86

OK!<tr

615

307

3,60

2,32

OK!<tr

OK!<tr

Shell with Stiffening Rings - Fixed Laminated Thickness

Stiffness factor of the Stiffening Ring

EI

=0,18(ND+2tt)JDs2pet

Diameter of Neutral Axis of Stiffening Ring

Ds

=ND+2y

3974541,01 1032574994

Increase t,

Increase t,

ridesign rib

ridesign rib or

or approach

approach ribs

ribs

128378402

Increase t,

ridesign rib

or approach

ribs

82,8

607,5

303,4

Ei

40683

40683

40683

bi

Construction of Stiffening Ring

Section 4 Hoop Modulus of Elasticity

Dimension (see fig.)

Dimension (see fig.)

di

Section Area

Ai

Section Neutral Axis

yi

Section Moment of Inertia

Ii

Section Stiffness Factor

Rib Hoop Modulus of Elasticity

Dimension (see fig.)

=bidi3/12+Ai(y-yi)2

0,000E+00

0,000E+00

0,000E+00

EiIi

0,000E+00

0,000E+00

0,000E+00

EiAi

0,000E+00

0,000E+00

0,000E+00

EiAiyi

Ei

0,000E+00

0,000E+00

0,000E+00

bi

Dimension (see fig.)

di

Section Area

Ai

Section Neutral Axis

yi

Section Moment of Inertia

Ii

Section Stiffness Factor

0

=bidi

=bidi

=bidi3/12+Ai(y-yi)2

2,087E+01

1,821E+03

7,584E+01

EiIi

5,008E+05

5,049E+07

2,420E+06

EiAi

7,743E+05

1,067E+07

2,577E+06

EiAiyi

1,079E+06

4,020E+07

4,325E+06

Fig.1 - General Stiffening Rib Configuration

09-004_CI0001-02 .xls

22/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

T80

T600

T300

8.6 Design Calculation for Pipe with Specified Stiffness

Pipe without Stiffening Rings

Pipe without Stiffening Rings Stiffness

=ELAMfc(tt3/12)/Dm3

76227

4410

3602

Pipe without Stiffening Rings Stiffness Factor

EI

=ELAMfc(tt3/12)

43249

988916

100543

Stiffening Ring Stiffness

SR

=EiIi/(Ds3BR)

76227

4410

3602

Stiffening Ring Cooperating Lenght

BR

=b1+2b2+1,73d3+b4

12

51

24

Distance between Stiffening Rings

Pipe with Stiffening Rings

1000

1000

1000

Pipe with Stiffening Rings Mean Stiffness

=S(J-BR)/J+SRBR/J

76227

4410

3602

Pipe with Stiffening Rings Stiffness Factor

EI

=SDm3

43249

988916

100543

Neutrl Axis of pipe with Stiffening Rings

Stiffening Rings

OK! Rib close

OK! Rib closeOK!

to External

Rib close

Surface

to External

of Pipe

Surface of Pipe

to External

8.7 Buried Pipe

(according AWWA M45)

Geometrical Input

Height of Solil above Top of the Pipe

Height of Water above top of Pipe

Minimum Trench Width

1300

1300

1300

HW

1300

1300

1300

417

1078

693

Bd

1000

1500

1000

Specific Weight of the Soil

SGS

1,9

1,9

1,9

Specific Weight of the Water

SGW

Trench Width

BdMIN

=1,25Do+305

Special Installation Case

None

Native Soil

Type of Soil

Granular Soil Standard Penetration Resistance

Unconfined Compression Strenght

Native Modulus of Soil Reaction

Embankment Embankment

see table 5-6 pag.51

Cohesive

Cohesive

Cohesive

>0-1

30-50

30-50

UCS

>1-2

>1-2

>1-2

E'n

20,68

20,68

20,68

Stiff

Stiff

Stiff

SM

GW

GW

Soil Description

Foundation Bedding

Soil Classification Group Name

see table 5-5 pag.49

Silty sand,

fines>12%

Well graded gravel,

Well graded

fines <5%

gravel, fines <5%

Soil Type

Pipe Zone Embedment Soil Stiffness Category

SC3

SC2

SC2

Equivalent Bedding Angle

180

180

180

>95%

>95%

>95%

0,083

0,083

0,083

SM

GW

GW

Proctor

Bedding Coefficient (Degree of Support Provided by the Soil)

Pipe Zone Embedment

Soil Classification Group Name

09-004_CI0001-02 .xls

KX

see table 5-5 pag.49

23/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

T80

T600

T300

Silty sand,

fines>12%

Well graded gravel,

Well graded

fines <5%

gravel, fines <5%

Soil Type

Pipe Zone Embedment Soil Stiffness Category

Proctor

SC3

SC2

SC2

85-95%

85-95%

85-95%

Backfill soil modulus

E'b

see table 5-4 pag.48

6,9

13,8

13,8

Modulus of Soil Reaction

E'

=ScE'b

6,9

20,7

20,7

Vertical Soil Load on Pipe

WC

=H*SGS

0,025

0,025

0,025

Live Load on Pipe

WL

0,00

0,10

0,10

Axles Number

na

Wheels per Axle

nw

Distance between axles

La

1500

1500

1500

Distance between wheels in an axle

Lw

2000

2000

2000

Pipe Cover depth

1300

1300

1300

Trench width

Bd

1000

1500

1000

External Loads

Backfill Soil Slip Angle

sigma

35

35

35

1000

1500

1000

Acting Axles

naa

Acting Wheels per Axle

nwa

Total Acting Wheels

Nwa

Total Acting Area

Awa

3314364

6045174

3314364

Maximum Live Load on Pipe

WL

0,00

0,10

0,10

Total Acting Force

Pt

604517

331436

Wheel Acting Force

Pw

302259

331436

0,0

30,2

33,1

Axle Acting Force

Pa

0,0

60,5

66,3

Acting Transversal Lenght

09-004_CI0001-02 .xls

24/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

T80

T600

T300

Fig.2 - General truck Configuration and Distribution of Live Loads on Pipe

09-004_CI0001-02 .xls

25/42

Societ a Socio Unico

VETRORESINA ENGINIA GROUP

T80

T600

T300

1,5

1,5

1,5

Pipe Deflection

Deflection Lag Factor to compensate for the time-consolidation

rate of the soil

DL

Installation Conditions

Ka

0,75

0,75

0,75

Initial Conditions

Da

0,000

0,000

0,000

0,003

0,012

0,012

Vertical Deflection

Dy/Dm

( D LW C + W L ) k X

EI + 0 .061k a E ' (

OK! Less

OK! Less thanOK!

5%Less than 5%

than 5%

Strain due to Deflection

Shape Factor relate Pipe Deflection to Bending Strain

Df

see table 5-1 pag.42

4,5

Rerounding coefficient

rC

cm

(1-pW)/3

=Dfrc(Dy/Dm)(tt/Dm)

0,82

0,82

0,82

Strain