Beruflich Dokumente

Kultur Dokumente

Adsorcion Gas

Hochgeladen von

Olvis GuillenCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Adsorcion Gas

Hochgeladen von

Olvis GuillenCopyright:

Verfügbare Formate

ESL-IE-84-04-88

GAS-ADSORPTION PROCESSES - AN UPDATE

George E. Keller II

Union Carbide Corporation

South Charleston. West Virginia

ABSTRACT

Gas-adsorption processes are commonly used

in the petroleum. natural-gas, petrochemical and

other industries. It is important to be aware

of those process situations which favor the use

of adsorption, and although no hard and fast

rules can be given. some generalizations can be.

and the first part of the paper is devoted to a

discussion of these generalizations. Adsorption

processes come in a wide range of physical

embodiments. These embodiments are first

discussed as idealizations, and their strong

points and weak points are delineated. Next,

several specific process flowsheets which have

been commercialized rather recently and which

may be extrapolable to other separations are

discussed. Finally, the issue of where

gas-adsorption technology is headed is

confronted. Suggestions are made as to possible

new and expanded applications.

which have been commercialized will be

discussed. and. finally. some suggestions will

be made as to directions in which the technology

is moving and opportunities for expanded

applications for gas adsorption.

WHEN CAN ADSORPTION COMPETE?

Gas adsorption's chief competitors are

obviously the vapor-liquid separations and. more

recently, membrane-based processes.

Vapor-liquid processes are formidable

competitors because of their simple flowsheets;

this translates into relatively low capital

costs per unit of feed processed. Given the

importance of capital costs in overall process

economics, vapor-liquid separations will usually

be a first choice if the energy costs are

tolerable. And in fact, systems of distillation

columns can often be heat-integrated to reduce

energy costs, further increasing their economic

viability in competition with other separations.

INTRODUCTION

Distillation and related vapor-liquid-based

separations (absorption and azeotropic and

extractive distillation) are by far the most

widely used separation processes in the

natural-gas, petroleum, petrochemical and

related industries. In addition, vapor-liquid

based separations have been practiced for

several hundred years. and they are probably

approaching a technological asymptote. By

contrast, adsorption has been practiced, except

for a few instances such as solution

clarification and for air purification in

hospitals and on battlefields, for only about 60

years. But in this relatively short time, and

having approached much less closely its

technological asymptote, adsorption now ranks

second to vapor-liquid-based separations in

frequency of use in the above-named industries.

Nevertheless, there clearly are situations

for which adsorption is the proper choice.

Although we cannot cite precise criteria, we can

enumerate several rough criteria. In the

following list, distillation is assumed to be

the chief competitor, and it is also assumed

that an adsorbent with proper selectivity

(greater than two for the adsorbate over

less-adsorbing components) is available.

1. The relative volatility for distillation is

low - 1.2-1.5 or less.

2. Several components must be separated from

other components boiling in among the components

to be separated.

3. Pressures greater than about 40 to 60

atmospheres (and especially if the feed gas is

substantially lower in pressure than the column

pressure) and/or cryogenic temperatures must be

used.

In this paper we will first describe those

process conditions which favor the use of gas

adsorption. We will then describe several

archetype processes and delineate their strong

and weak points. Next some specific variations

519

Proceedings from the Sixth Annual Industrial Energy Technology Conference Volume II, Houston, TX, April 15-18, 1984

ESL-IE-84-04-88

Pressure-Swing Adsorption (PSA~ - In this cyle,

shown in its simplest form in igure 2, the!

adsorbate is desorbed by lowering its partial

pressure, partly by reducing total pressure and

partly by using some of the non-adsorbate as a

partial-pressure-reducing purge gas. Usually

PSA processes employ at least three beds in '

parallel, with several purging and

.

blowdown/repressurization steps to minimize feed

compression costs and maximize less-adsorbed

product recovery.

4. Thermal damage to the products or rapid

column fouling occurs at practical distillation

conditions.

Criteria for selecting between adsorption

and membrane-based processes are not yet

available, and the proper choice must be made on

a case-by-case analysis.

ARCHETYPE PROCESSES

Four archetype processes will be briefly

discussed here. These processes differ

primarily in the means by which desorption is

effected. In a following section we will show

some recent process modifications.

Less-Adsorbed

Product

Temperature-Swing Adsorption - A schematic

diagram is shown in Figure 1. Once a bed is

loaded with adsorbate, it is taken off-line and

regenerated by heating and (almost always)

purging with an inert gas. Increasing the

adsorbent temperature reduces the tenacity of

the adsorbate-adsorbent bonds, and the inert gas

reduces the partial pressure of adsorbate; both

effects serve to facilitate desorption.

rn

D

The advantages of this process are that high

degrees of separation are possible and that

investments are usually reasonable. The

disadvantages are that the energy usage is very

high per unit of adsorbate and that regeneration

times are long - several hours to a day or

more. As a result, this cycle is economical

only for removing small amounts (generally a few

weight percent or less) of materials from feed

streams.

Less-Adsorbed

Product

rn

D

Adsorba1e

Plus Le~s

Adsorbed

Product

Purge Gas

Pressurized

Feed

Purge Gas

Figure 2.

PSA Cycle

Heater

The advantages of PSA are that it can

perform bulk separations (those for which t~e

adsorbate concentration is greater than about 10

weight percent) and that investments are

competitive with alternative processes. The

chief disadvantage is that only the

less-adsorbed product can be recovered in h~gh

purity; the adsorbed product inevitably con~ains

some of the less-adsorbed product used as a I

purge. Desorption under vacuum can reduce

adsorbed-product contamination, however.

Inert-Purge Adsorption - This cycle, shown in

Figure 3, operates adiabatically and uses an

inert gas to lower the partial pressure of ~he

adsorbate and desorption. Occasionally total

pressure will be reduced.

Vent

Cooler

Possible

Recycle

The chief advantages are process simplicity,

leading to low investment, and the ability to

perform bulk separations in some cases. Th~

disadvantages are the large exotherms, which

limit the adsorbate loading, the fact that very

large amounts of inert gas must be used if the

adsorbate is tightly held, and the problem of

recovery of the adsorbate from the inert gas.

Adsorbate

Feed

Figure 1.

Temperature-Swing Cycle

520

Proceedings from the Sixth Annual Industrial Energy Technology Conference Volume II, Houston, TX, April 15-18, 1984

ESL-IE-84-04-88

Less-Adsorbed

rroduct

The chief advantages are elimination of the

exotherm, which makes higher loadings possible,

and the ability to perform bulk separations.

The disadvantages are process complexity, which

leads to high investment, and the energy

requirement to operate the stills.

Purge

Gas

Conclusion - Compared to distillation,

gas-adsorption technology is substantially more

varied, and clearly one flowsheet cannot be used

for all separations. One must therefore be

prepared to deal with both adsorbent development

and flowsheet selection and development to

effect a successful process development.

NEW DEVELOPMENTS

In this section we will highlight some

recent developments - variations on the

archetype processes - which either increase the

number of separations amenable to adsorption or

improve the economics of the archetype processes.

Adsorbate

Plus

Purge Gas

Feed

Figure 3.

Continuous Temperature-Swing Adsorption - All of

the archetype processes are discontinuous:

adsorbate is first loaded and then desorbed in a

fixed bed. The idea of performing continuous

adsorptions by moving the adsorbent between

adsorption and desorption zones is far from new

and extends at least back to the 1930s. In 1950

the Hypersorption process was developed by Union

Oil Company [1,2]. This process foundered

because of excessive attrition of the

activated-carbon adsorbent. Recently Kureha

Chemical Company, Ltd., of Japan has developed a

hard, microspherical activated carbon called

bead activated carbon (SAC). This development

has made possible a fluidized-bed/moving-bed

process, shown in Figure 5, for removin9 small

amounts (less than a few weight percent) of

adsorbates from feed streams. The process,

called GASTAK in Japan [3] is marketed in the

United States under the name PURASIV HR [4,5] by

Union Carbide. There are presently 12 operating

units in the United States and over 40 in

Japan. The units in the United States treat

from 300 thousand to 5.5 million cubic feet per

hour of feed, removing such materials as

hydrocarbons and oxygenated and chlorinated

hydrocarbons.

Inert-Purge Cycle

~lacement-Purge Adsorption - This final

archetype cycle, shown in Figure 4, is similar

in concept to inert~purge adsorption except that

the displacement medium competitively adsorbs

with adsorbate and effects desorption both by

partial-pressure reduction and by mass action.

The displacement medium boils outside the range

of the products and is recovered from the

products by distillation.

A = Adsorbates

B = Less-adsorbed components

C = Displacement agent

D

B+D

Nitrogen Recovery - Bergbau Forschung GmbH has

developed a process for recovering nitrogen from

air in up to 99.9 percent purity using a

PSA-type cycle with vacuum desorption [6,7].

The adsorbent is a unique carbon molecular sieve

which separates on the basis of differing

diffusion rates in the adsorbent pores rather

than on inherent equilibrium selectivity; the

carbon is virtually non-selective at

equilibrium. Under diffusion control, however,

oxygen penetrates into the particles much faster

than nitrogen, leaving a nitrogen-enriched,

gas-phase product. Nitrogen production using

carbon molecular sieves is the only known

commercial process using diffusion-selectivity

as the basis for separation.

~

~

~

~

~

~

Feed

A+B

A+D

D

Figure 4.

Displacement-Purge Cycle

521

Proceedings from the Sixth Annual Industrial Energy Technology Conference Volume II, Houston, TX, April 15-18, 1984

ESL-IE-84-04-88

"POLYBEO" PSA - Usually in the design of a

process, the simpler the flowsheet, the better

the economics. An exception to this generality

is the POLYBED PSA process for hydrogen recovery,

commercialized by Union Carbide [10-12J.

Normally P5A processes will consist of four or

fewer beds in parallel; POLYBEO PSA USes five

and in some cases even over 10 beds in parallel.

In addition, the process involves extensive gas

interchanges and pressure eQuiliz tions between

the beds. The net result is a process which can

treat very large feed streams (up to about two

million standard cubic feet per hour in a single

train), recover higher percentages of hydrogen

in the feed (about 86 percent vs. 70 to 75

percent for more conventional PSAs), and produce

astoniShingly pure hydrogen (e.g., 99.999

percent) .

Less-Adsorbed Gas

Feed

.~

Steam

~.

Azeotrope Breaking - Some of the more cos ly

mixtures for separation by vapor-liquid means

are azeotrope-forming solutions. Extractive or

azeotropic distillation must be used, and

several columns must be used. Quite recently a

new adsorption-based process has surfaced which

is especially suited for separating aQueous

organic mixtures containing up to 20 or more

weight percent water [13J. An inert-purge cycle

is used, and in the example discussed, carbo~

dioxide or nitrogen is used as the purge gas for

separating the ethanol-water azeotrope using

molecular sieves. The important feature of the

process is that most of the heat of adsorption

is stored in the bed during the adsorption p~rt

of the cycle, and that heat is then available

for the subsequent desorption of the water. The

net result is tha , along with an investment

lower than that of azeotropic distillation, ohe

energy requirement is less than 2000 Btu/gal.

The process is being commercialized.

Recovered

Solvents

1 - - - ...

Condensa te

Li ft

Gas

Figure 5.

PURASTV HR Process

H20/C0 2

Separation Section

,.-______

Removal

,------.---...,. - - -

Other methods of using PSA for obtaining

nitrogen from air have been revealed by Toray

Industries, Inc. [8J and Air Products Corp. [9J.

These processes, by adjusting feed and purge

flows, produce a relatively pure adsorbate

(nitrogen) stream and a relatively impure less

adsorbed (oxygen) stream, using more traditional

moleculat" sieve adsorbents. A diagram of the

Toray process is shown in Figure 6. Dried air

is passed through the absorber at super

atmospheric pr ssure, and nitrogen is

preferentially adsorbed. Part of the nitrogen

product from previous cycles is then passed into

the bed to desorb small amounts of oxygen, after

which the bed is reduced to atmospheric pressure

to desorb nitrogen. Finally more nitrogen is

recovered by vacuum desorption. The adsorbent

used in this process is apparently the same

zeolite molecular sieves - as that used in

oxygen PSA processes.

--'A.~

,-

.,

I

I

I

rn

c

Ol

Ol

C

Ol

>-

::;)

0..

.D

.n

>-

Vl

>

Vl

C1)

OJ

0

1--

I

I - - - -_ _ .....

I

L..... -

..A

------~R-e~fl:-u-x---..6

Pressurized Ai r

This process has been demonstrated in

pilot-scale. Its commercial status is unknown.

The Air Products process has been commercialized.

Figure 6.

Toray Nitrogen Process

522

Proceedings from the Sixth Annual Industrial Energy Technology Conference Volume II, Houston, TX, April 15-18, 1984

ESL-IE-84-04-88

"TIP" Total Isomerization Process - Isomerization

reactions often have equilibrium limitations

which prevent attainment of one pure isomer.

This problem can be obviated if a separation

process can be coupled with the isomerization

step to remove selectively the isomer(s) of

interest. This has been done for paraffin

isomerization by combining the Hysomer paraffin

isomerization process. developed by Shell

Research BV, with Union Carbide's IsoSiv normal/

isoparaffin separation process [14J. The overall

process, known as the TIP Total Isomerization

Process, is shown in Figure 7. The Hysomer

reactor reacts the feed to a near-equilibrium

mixture of isomers, which is fed to the

adsorption unit. Normal paraffins are

preferentially adsorbed, and the isoparaffins

are recovered as a high-octane stream while the

adsorbed normal paraffins are desorbed by a

hydrogen purge and returned to the Hysomer unit.

Product from a TIP unit has a Research Octane

Number of 88 to 92, compared to a RON of 79 to

82 for the product from a Hysomer unit alone.

adsorption and suggest some technological

innovations which could stimulate this growth.

Bulk Gas Separations - Adsorption for oxygen and

nitrogen purification has been limited until

recently primarily to applications requiring a

few pounds to a few tons per day. Oxygen is now

produced via PSA for small steel mills,

waste-treatment plants, welding shops, and for

in-house care of patients with various types of

lung disease. On-board oxygen generation for

aircraft will soon be a reality. But as process

improvements continue, PSA oxygen will be able

to compete economically with cryogenically

produced oxygen in much larger plants - 100 tons

per day or more - in situations in which the

higher argon level in the PSA oxygen is not a

problem.

Nitrogen production via PSA is growing

rapidly, for such uses as inerting of storage

tanks and other vessels and areas, purging of

process lines and vessels, creating modified

atmospheres to prolong storage life in food

storage areas, etc. And if grain-storage

fumigants uch as ethylene dibromide come under

increasing environmental pressure, nitrogen

inerting may prove to be an ideal replacement

for use in enclosed areas.

Light

Pa ra Hi ns

H2 + Recycle

Normal Paraffins

Feed

PSA hydrogen recovery will also grow in

popularity in comparison to cryogenic methods.

It will be possible to process feed streams of

1.5 to three million standard cubic feet per

hour at pressures up to about 1000 psi. P A

will also be favored in cases in which the

virtual absence of inerts in the hydrogen

product would minimize purge stream losses in

other parts of the process.

C7\

.D

<..

Octane

Isomer

Produc t

Vl

-0

The major challenge for PSA is to produce

two nearly pure products at once in a simple

fashion; such a capability would allow PSA to

compete head-on with distillation for an

increasing number of separations. Increasing

the feed-to-purge pressure ratio is the primary

means for improving the purity of the adsorbed

product. Desorption under vacuum is one means

though not without added costs - for increasing

this ratio. Other PSA cycles not involving the

need for high ratios would constitute a true

breakthrough.

Heater

Figure 7.

TIP Total Isomerizc.tion Process

Inert-purge cycles, given the

recently-demonstrated success in drying of

azeotropes, would seem to be poised for use in

several new separations. Prime candidates

include those systems now separated by

azeotropic and extractive distillation, many of

which contain water as one constituent. The use

of inert-purge cycles for isomer and other

close-boiler separations should also grow for

those systems whose components can be easily

separated from the purge gas.

NEW DIRECTIONS FOR GAS ADSORPTION

It is unlikely that gas adsorption will ever

rival the vapor-liquid separations in frequency

of use in the natural-gas, petroleum,

petrochemical and related industries.

Nevertheless, gas adsorption will continue to

make inroads as its technological limits are

more closely approached. Gas adsorption's

serious competition for the separations where it

is now used will come chiefly from

fixed-membrane processes. The extent of the

inroad cannot yet be discerned. Below we will

point out the likely areas of growth for gas

Displacement-purge cycles will not find many

new uses, primarily because of the inherent

complexity of these cycles.

523

Proceedings from the Sixth Annual Industrial Energy Technology Conference Volume II, Houston, TX, April 15-18, 1984

ESL-IE-84-04-88

[3] Sak aguch i, Y., Chemica 1 Economy and

Fixed-bed, temperature-swing processes

rarely turn out to be economical for bulk

separations. Moving-bed and fluidized-bed

processes based on thermal regeneration may

prove to be much more economical because of

lower heat requirements per unit of feed. The

key to the success of these processes lies in

the development of highly-attrition-resistant

adsorbent particles.

Engineering Review

(December, 1976).

~,

No. 12, 36

[4] Anon., Chemical Engineering, 39

(August 29, 1977).

[5] "PURASIV HR for Hydrocarbon Recovery",

Union Carbide Corporation, Danbury, CT.

[6J Knoblauch, K., Chemical Engineering, 87

(November 6, 1978).

Some other areas of new or expanded use for

gas adsorption include synthesis gas ratio

adjustment, carbon dioxide recovery from oil

and gas-field streams. ammonia process

vent-recovery, and purging of inerts from

chemical-process streams.

[7] "Pure Nitrogen Generator", Gas Services

International, Ltd., Enfield, Middlesex,

England.

[ 8J Miwa, K., and T. Inoue, Chemical Economy

and Engineering Review 12, No. 11, 40

(November, 1980).

I

[9J Sircar, S., and J. W. Zondlo, U. S. Patent

4.013,429, March 22, 1977.

I

[lOJ Heck, J. L., and T. Johansen, Hydrocarbon

Processing. 175 (January, 1978).

Gas Purification - It is not likely that many

process innovations will be needed for these

separations. Fixed-bed, temperature-swing

processes will continue to predominate, although

moving-bed and fluidized-bed processes such as

PURASIV HR should become more popular. Air

pollution concerns should bring about increased

applications for recovery of organics from

various process vent streams, storage-tank

vents. and air streams from solvent-pointing and

other operations involving vaporization of

organics. Major-use areas such as gas

dehydration, removal of sulfur compounds and

carbon dioxide and various specialty separations

will grow about in proportion to the growth of

those industries in which these separations are

found.

[11 ] Corr, F., Dropp, F., and E. Rudelstorferr,

Hydrocarbon Processing. 119 (March,

197~).

[12J Cassidy, R. 1., "POLYBED Pressure-Swing I

Adsorption Hydrogen Processing", in

Flank, W. H. (ed.), Adsorption and Ion

Exchange with Synthetic Zeolites, Ameridan

Chemical Society Symposium Series 135

(1980) .

References

[1] Berg, C., Petroleum Refiner 30, No.9, 241

(September,1951).

[13J Garg, D. R., and J. P. Ausikaitis, Chem4

Eng. Progress, 60 (Apri 1, 1983).

[2] Treybal, R. E., "Mass Transfer Operations",

McGraw-Hill (1955).

[14J Symoniak, Hydrocarbon Processing, 110 n-lay,

1980) .

524

Proceedings from the Sixth Annual Industrial Energy Technology Conference Volume II, Houston, TX, April 15-18, 1984

Das könnte Ihnen auch gefallen

- Hazard and Operability (HAZOP) & Hazard Analysis TrainingDokument106 SeitenHazard and Operability (HAZOP) & Hazard Analysis TrainingShainu Govindankutty100% (8)

- Pneumatic Control ValvesDokument59 SeitenPneumatic Control ValvesArvind97Noch keine Bewertungen

- McCabe Thiele DiagramDokument8 SeitenMcCabe Thiele DiagramDaniel Ippolito PelufoNoch keine Bewertungen

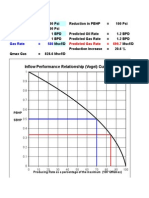

- IPR For Gas WellsDokument2 SeitenIPR For Gas WellsOlvis GuillenNoch keine Bewertungen

- Netopt UGDokument105 SeitenNetopt UGMarcosGonzalezNoch keine Bewertungen

- ION7300 Instl Guide 70002-0198-08Dokument28 SeitenION7300 Instl Guide 70002-0198-08Olvis GuillenNoch keine Bewertungen

- LOPADokument125 SeitenLOPAOlvis Guillen100% (1)

- Brill Beggs ZDokument3 SeitenBrill Beggs ZtechbhaskarNoch keine Bewertungen

- Pump - Efficiency For CentrifugalDokument10 SeitenPump - Efficiency For CentrifugalFrankhil ContrerasNoch keine Bewertungen

- Project Component Type Item Information ValueDokument14 SeitenProject Component Type Item Information ValueOlvis GuillenNoch keine Bewertungen

- Flare System OptimizationDokument4 SeitenFlare System OptimizationOlvis GuillenNoch keine Bewertungen

- Pump With Connection Streams, Matl&Manhouradjustments, and Pipe Item DetailsDokument16 SeitenPump With Connection Streams, Matl&Manhouradjustments, and Pipe Item DetailsOlvis GuillenNoch keine Bewertungen

- Vessel - Vertical Sizing - IPunitsDokument25 SeitenVessel - Vertical Sizing - IPunitsAnders FTNoch keine Bewertungen

- Student Registry ListingDokument1 SeiteStudent Registry ListingOlvis GuillenNoch keine Bewertungen

- Flare System OptimizationDokument4 SeitenFlare System OptimizationOlvis GuillenNoch keine Bewertungen

- Pump - Efficiency For CentrifugalDokument10 SeitenPump - Efficiency For CentrifugalFrankhil ContrerasNoch keine Bewertungen

- Basic Anti-Surge Control System ReferenceDokument6 SeitenBasic Anti-Surge Control System ReferenceOlvis GuillenNoch keine Bewertungen

- Determination of Permeability Using Well Test AnalysisDokument216 SeitenDetermination of Permeability Using Well Test AnalysisAditya AriewijayaNoch keine Bewertungen

- Well Testing SpeDokument5 SeitenWell Testing Speiqbalpec12345Noch keine Bewertungen

- Floating Roof Tank - Design PDFDokument2 SeitenFloating Roof Tank - Design PDFlinustec100% (5)

- A Snapshot of A TripDokument2 SeitenA Snapshot of A TripOlvis GuillenNoch keine Bewertungen

- Spreadsheet Line PackDokument3 SeitenSpreadsheet Line PackOlvis GuillenNoch keine Bewertungen

- AdvancesNaturalGasTechnologyITO12 PDFDokument553 SeitenAdvancesNaturalGasTechnologyITO12 PDFgion_ro401Noch keine Bewertungen

- Pipeline Design and ConstructionDokument47 SeitenPipeline Design and ConstructionSaber Abdel Moreid100% (5)

- PWC - Financial Reporting in The Oil and Gas IndustryDokument156 SeitenPWC - Financial Reporting in The Oil and Gas Industryahsan57100% (2)

- Oil and Gas Pipeline Pigging OperationsDokument60 SeitenOil and Gas Pipeline Pigging OperationsOlvis Guillen100% (1)

- Thin Walled Pressure Vessels 1Dokument21 SeitenThin Walled Pressure Vessels 1shangovinna_10781090Noch keine Bewertungen

- Pneumatic Valves: For Precision and ControlDokument45 SeitenPneumatic Valves: For Precision and Controlm_alodat6144Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Australian Wood Review December 2018Dokument100 SeitenAustralian Wood Review December 2018Maicon MorandiniNoch keine Bewertungen

- Isorod Guide SpecDokument8 SeitenIsorod Guide SpecmarkicivanNoch keine Bewertungen

- Prueba de Alternador CaterpillarDokument2 SeitenPrueba de Alternador CaterpillarRamón José Aponte FrancoNoch keine Bewertungen

- Timbercrete Structural Design-2Dokument30 SeitenTimbercrete Structural Design-2kevin_au18Noch keine Bewertungen

- Machine Tool Structure Design and AnalysisDokument40 SeitenMachine Tool Structure Design and AnalysisPrakash RajNoch keine Bewertungen

- Multi-point fastening system for bottom-hung windowsDokument8 SeitenMulti-point fastening system for bottom-hung windowsna1111Noch keine Bewertungen

- A Lucas Alternator and Zener Charging CircuitDokument8 SeitenA Lucas Alternator and Zener Charging CircuitderryukNoch keine Bewertungen

- Compact Repeater 972-0RB12 3Dokument16 SeitenCompact Repeater 972-0RB12 3Kelly Perez LopezNoch keine Bewertungen

- Tecumseh Guidelines For Utilization of R134aDokument7 SeitenTecumseh Guidelines For Utilization of R134aAnibal RiosNoch keine Bewertungen

- Pig SigDokument6 SeitenPig SigdmitosNoch keine Bewertungen

- Volume Ii: Specifications (Exterior Painting) : Issue: FINAL, 14th FEB 2013Dokument4 SeitenVolume Ii: Specifications (Exterior Painting) : Issue: FINAL, 14th FEB 2013Ahmad SaadeldinNoch keine Bewertungen

- 50 Chemical Injection System Access Fitting Assemblies - 50-DS Revc PDFDokument19 Seiten50 Chemical Injection System Access Fitting Assemblies - 50-DS Revc PDFChemkhiNoch keine Bewertungen

- Brochure - Type 546 Manual and Actuated Ball Valves DN10 To DN100Dokument12 SeitenBrochure - Type 546 Manual and Actuated Ball Valves DN10 To DN100Ahuntzakozidor AhuntzakozidorNoch keine Bewertungen

- High Rate Solids Contact Clarifier HRSCCDokument4 SeitenHigh Rate Solids Contact Clarifier HRSCCshambhurajesurywanshi1Noch keine Bewertungen

- Natural Fiber Reinforced Polymer Composite Material-A ReviewDokument6 SeitenNatural Fiber Reinforced Polymer Composite Material-A ReviewWelly TobingNoch keine Bewertungen

- Cold Storage Design GuideDokument5 SeitenCold Storage Design GuideMihuler Yordy Romero RojasNoch keine Bewertungen

- Exhaust Emission Reduction Technologies For Diesel Engines: Pankaj Gupta 142116517 Stress and VibrationDokument25 SeitenExhaust Emission Reduction Technologies For Diesel Engines: Pankaj Gupta 142116517 Stress and VibrationTushar RadkarNoch keine Bewertungen

- ADAPT TN388 Vibration Footfall ExampleDokument11 SeitenADAPT TN388 Vibration Footfall ExampleMohammadreza MollaeiNoch keine Bewertungen

- Saes B 008Dokument5 SeitenSaes B 008Anonymous a4Jwz14WNoch keine Bewertungen

- Leather Burnishing & Polishing: Existing ProcedureDokument6 SeitenLeather Burnishing & Polishing: Existing ProcedurevinothjohnnashNoch keine Bewertungen

- UK SP MB Kingspan Multibeam Brochure PDFDokument144 SeitenUK SP MB Kingspan Multibeam Brochure PDFhemendraengNoch keine Bewertungen

- Garlock Blue Gard 3000 Data SheetDokument1 SeiteGarlock Blue Gard 3000 Data SheetMatheus TorresNoch keine Bewertungen

- Uni Interface ZündDokument3 SeitenUni Interface Zündmaxime100% (1)

- Machine Operation: Sort Laundry According To Care SymbolsDokument4 SeitenMachine Operation: Sort Laundry According To Care SymbolsRafael RukNoch keine Bewertungen

- PO format-ACCDokument17 SeitenPO format-ACCSpace designNoch keine Bewertungen

- Web in Ar Meth Lab Presentation Second Half 083011Dokument38 SeitenWeb in Ar Meth Lab Presentation Second Half 083011jeffk_6580% (15)

- Separation TechniquesDokument4 SeitenSeparation TechniquesNicola Faye BronNoch keine Bewertungen

- Logitech G27 C-Clamps ReplacementDokument20 SeitenLogitech G27 C-Clamps Replacementfadli_nugraha6109Noch keine Bewertungen

- BOOKSDokument19 SeitenBOOKSAsif AhmedNoch keine Bewertungen

- Answers To Unit - Test Papers 2Dokument2 SeitenAnswers To Unit - Test Papers 2geetaNoch keine Bewertungen