Beruflich Dokumente

Kultur Dokumente

61SNC01 - 06 - Engine Mechanical - Cylinder Head

Hochgeladen von

angelvalladaresOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

61SNC01 - 06 - Engine Mechanical - Cylinder Head

Hochgeladen von

angelvalladaresCopyright:

Verfügbare Formate

06/09/19 10:40:47 61SNC010_060_0001

Engine Mechanical

Cylinder Head

Special Tools .................................................................

Component Location Index .........................................

Engine Compression Inspection .................................

VTEC Rocker Arm Test .................................................

Valve Clearance Adjustment .......................................

Crankshaft Pulley Removal and Installation ..............

Cam Chain Removal .....................................................

Cam Chain Installation .................................................

Chain Case Oil Seal Installation ..................................

CKP Pulse Plate Replacement .....................................

Cylinder Head Cover Removal ....................................

Cylinder Head Cover Installation ................................

Cylinder Head Removal ...............................................

Camshaft Sprocket Removal .......................................

Camshaft Sprocket Installation ...................................

CMP Pulse Plate Removal and Installation ................

Cylinder Head Inspection for Warpage ......................

Rocker Arm Assembly and Camshaft Removal .........

Rocker Arm and Shaft

Disassembly/Reassembly ........................................

Rocker Arm and Shaft Inspection ...............................

Camshaft Inspection ....................................................

Valve, Spring, and Valve Seal Removal .....................

Valve Inspection ...........................................................

Valve Stem-to-Guide Clearance Inspection ...............

Valve Guide Replacement ...........................................

Valve Seat Reconditioning ..........................................

Valve, Spring, and Valve Seal Installation .................

Rocker Arm Assembly and Camshaft Installation .....

Cylinder Head Installation ...........................................

6-2

6-3

6-6

6-7

6-10

6-12

6-14

6-16

6-20

6-21

6-22

6-22

6-24

6-27

6-28

6-30

6-31

6-32

6-33

6-34

6-36

6-38

6-39

6-39

6-40

6-42

6-44

6-45

6-45

06/09/19 10:40:49 61SNC010_060_0002

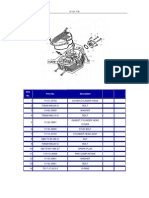

Cylinder Head

Special Tools

Ref. No.

Tool Number

07AAJ-PNAA101

07HAH-PJ7A100

07JAA-001020A

07JAB-001020A

07NAB-001040A

07PAD-0010000

07757-PJ1010A

07742-0010100

07746-0010400

07749-0010000

07VAJ-P8A010A

6-2

Description

Air Pressure Regulator

Valve Guide Reamer, 5.5 mm

Socket, 19 mm

Holder Handle

Holder Attachment, 50 mm

Stem Seal Driver

Valve Spring Compressor Attachment

Valve Guide Driver, 5.5 mm

Attachment, 52 x 55 mm

Driver

VTEC Air Adapter

Qty

1

1

1

1

1

1

1

1

1

1

1

06/09/19 10:40:52 61SNC010_060_0003

Component Location Index

CYLINDER HEAD COVER

Removal, page 6-22

Installation, page 6-22

HEAD COVER GASKET

CAM CHAIN

TENSIONER SLIDER

CRANKSHAFT POSITION

(CKP) SENSOR

CHAIN CASE

O-RING

CYLINDER HEAD PLUG

CAMSHAFT SPROCKET

Removal, page 6-27

Installation, page 6-28

CAM CHAIN GUIDE

CAM CHAIN

Removal, page 6-14

Installation, page 6-16

CAM CHAIN TENSIONER

CRANKSHAFT POSITION (CKP)

PULSE PLATE

Replacement, page 6-21

CRANKSHAFT PULLEY

Removal and Installation, page 6-12

CRANKSHAFT PULLEY BOLT

Removal and Installation, page 6-12

(contd)

6-3

06/09/19 10:40:53 61SNC010_060_0004

Cylinder Head

Component Location Index (contd)

CYLINDER HEAD BOLTS

THERMOSTAT HOUSING

THERMOSTAT

O-RING

ROCKER ARM OIL CONTROL

SOLENOID

CYLINDER HEAD

GASKET

DOWEL PINS

6-4

ROCKER ARM OIL CONTROL

SOLENOID FILTER

06/09/19 10:40:57 61SNC010_060_0005

LOST MOTION HOLDER

Removal, page 6-32

Inspection, page 6-45

LOST MOTION ASSEMBLY

VALVE COTTERS

ROCKER ARM ASSEMBLY

VTEC Rocker Arm Test, page 6-7

Rocker Arm Assembly Removal,

page 6-32

Rocker Arm and Shaft Disassembly/

Reassembly, page 6-33

Rocker Arm and Shaft Inspection,

page 6-34

SPRING RETAINER

EXHAUST VALVE

SPRING

O-RING

CYLINDER HEAD PLUG

EXHAUST VALVE

SEAL

CAMSHAFT POSITION (CMP)

PULSE PLATE

Replacement, page 6-30

VALVE SPRING

SEAT

EXHAUST VALVE

GUIDE

O-RING

CAMSHAFT POSITION

(CMP) SENSOR

CAMSHAFT

Inspection, page 6-36

INTAKE VALVE SPRING

INTAKE VALVE SEAL

Removal, page 6-38

Installation, page 6-44

INTAKE VALVE GUIDE

Replacement, page 6-40

CYLINDER HEAD

Removal, page 6-24

Inspection, page 6-31

Installation, page 6-45

INTAKE VALVE

EXHAUST VALVE

Removal, page 6-38

Installation, page 6-44

6-5

06/09/19 10:40:58 61SNC010_060_0006

Cylinder Head

Engine Compression Inspection

NOTE: After the inspection, you must reset the

powertrain control module (PCM). Otherwise, the PCM

will continue to stop the fuel injectors from functioning.

1. Warm up the engine to normal operating

temperature (cooling fan comes on).

2. Turn the ignition switch OFF.

3. Connect the Honda Diagnostic System (HDS) to the

data link connector (DLC) (see step 2 on page 11-3).

4. Turn the ignition switch ON (II).

5. Make sure the HDS communicates with the vehicle

and the PCM. If it doesnt communicate,

troubleshoot the DLC circuit (see page 11-218).

6. Select PGM-FI, INSPECTION, then AII INJECTORS

OFF on the HDS.

7. Turn the ignition switch OFF.

8. Remove the four intake side ignition coils (see page

4-19).

9. Remove the four intake side spark plugs.

10. Attach the compression gauge to a spark plug hole.

NOTE: Use a compression gauge with a connecting

length (between the edge and the flange) of less

than 23 mm (0.9 in.).

11. Remove the No. 61 B IMA 2 (10 A) fuse in the

auxiliary under-hood fuse/relay box.

12. Open the throttle fully, then crank the engine with

the starter motor and measure the compression.

Compression Pressure:

Above 980 kPa (10.0 kgf/cm2, 142 psi)

13. Measure the compression on the remaining

cylinders.

Maximum Variation:

Within 200 kPa (2.0 kgf/cm2, 29 psi)

14. If the compression is not within specifications,

check the following items, then remeasure the

compression.

Looseness exhaust side spark plug

Damaged or worn valves and seats

Damaged cylinder head gasket

Damaged or worn piston rings

Damaged or worn piston and cylinder bore

15. Remove the compression gauge from the spark

plug hole.

16. Install the four intake side spark plugs.

17. Install the four intake side ignition coils (see page

4-19).

18. Select PCM reset (see page 11-4) to cancel the ALL

INJECTORS OFF function on the HDS.

19. Do the start clutch pressure control calibration

procedures (see page 14-204).

20. Install the No. 61 B IMA 2 (10 A) fuse in the

auxiliary under-hood fuse/relay box.

21. Clear any IMA DTCs that may have been set while

doing this inspection procedure.

22. If the IMA battery level gauge (BAT) displays no

segment, start the engine, and hold it between

3,500 rpm and 4,000 rpm without load (in Park or

neutral) until the BAT displays at least three

segments.

6-6

06/09/19 10:40:59 61SNC010_060_0007

VTEC Rocker Arm Test

Special Tools Required

Air pressure regulator 07AAJ-PNAA101

VTEC air adapter 07VAJ-P8A010A

1. Start the engine and let it run for 5 minutes, then

turn the ignition switch OFF.

2. Remove the cylinder head cover (see page 6-22).

3. Set the No. 1 piston at top dead center (TDC) (see

step 2 on page 6-10).

4. Push on the intake 1st rocker arm (A) for the No. 1

cylinder. Make sure that the intake 1st rocker arm

and the intake 2nd rocker arm (B) are mechanically

connected by the rocker arm pistons and that the

intake 2nd rocker arm does not move when pushed

manually. Then move the intake 3rd rocker arm (C)

for the No. 1 cylinder. The intake 3rd rocker arm

should move independently of the intake 1st rocker

arm.

If the intake 2nd rocker arm does not move

independently and the intake 3rd rocker arm

moves independently, go to step 5.

If the intake 2nd rocker arm moves

independently, remove and disassemble the

rocker arm assembly, and check that the rocker

arm pistons between the intake 1st and 2nd

rocker arms move smoothly. If any rocker arm or

rocker arm piston needs replacing, replace the

rocker arms for the cylinder as an assembly.

If the intake 3rd rocker arm does not moves

independently, remove and disassemble the

rocker arm assembly, and check that the rocker

arm pistons between the intake 2nd and 3rd

rocker arms move smoothly. If any rocker arm or

rocker arm piston needs replacing, replace the

rocker arms for the cylinder as an assembly.

5. Push on the exhaust 1st rocker arm (A) for the No. 1

cylinder. Make sure that the exhaust 1st rocker arm

and the exhaust 2nd rocker arm (B) are

mechanically connected by the rocker arm pistons

and that the exhaust 2nd rocker arm does not move

when pushed manually.

If the exhaust 2nd rocker arm does not move

independently, go to step 6.

If the exhaust 2nd rocker arm moves

independently, remove and disassemble the

rocker arm assembly, and check that the rocker

arm pistons between the exhaust 1st and 2nd

rocker arms move smoothly. If any rocker arm or

rocker arm piston needs replacing, replace the

rocker arms for the cylinder as an assembly.

6. Check that the air pressure on the shop air

compressor gauge indicates over 400 kPa

(4.0 kgf/cm2, 47 psi).

7. Inspect the valve clearance (see page 6-10).

8. Install the special tool (A) to the cam chain side

inspection hole, then connect the air pressure

regulator (B).

B

07AAJ-PNAA101

A

07VAJ-P8A010A

(contd)

6-7

06/09/19 10:41:00 61SNC010_060_0008

Cylinder Head

VTEC Rocker Arm Test (contd)

9. Loosen the valve on the regulator, and apply the

specified air pressure.

12. Install the special tool (A) to the transmission side

inspection hole, then connect the air pressure

regulator (B).

Specified Air Pressure:

200 kPa (2.0 kgf/cm2, 28 psi)

B

07AAJ-PNAA101

A

07VAJ-P8A010A

10. Push on the intake 1st rocker arm (A) for the No. 1

cylinder. Make sure that the intake 1st rocker arm

and the intake 3rd rocker arm (B) are mechanically

connected by the rocker arm pistons and that the

intake 3rd rocker arm does not move when pushed

manually.

If the intake 3rd rocker arm does not move

independently, go to step 11.

If the intake 3rd rocker arm moves independently,

remove and disassemble the rocker arm

assembly, and check that the rocker arm pistons

between the intake 1st and 3rd rocker arms move

smoothly. If any rocker arm or rocker arm piston

needs replacing, replace the rocker arms for the

cylinder as an assembly.

13. Move the intake 2nd rocker arm (A) and intake 3rd

rocker arm (B) for the No. 1 cylinder. The intake 2nd

and intake 3rd rocker arm should move

independently of the intake 1st rocker arm (C).

If the intake 2nd and 3rd rocker arms move

independently, go to step 14.

If the intake 2nd or intake 3rd rocker arm does

not move independently, remove and

disassemble the rocker arm assembly, and check

that the rocker arm pistons between the intake

1st and 2nd rocker arms move or intake 1st and

3rd smoothly. If any rocker arm or rocker arm

piston needs replacing, replace the rocker arms

for the cylinder as an assembly.

B

11. Tighten the valve on the regulator, then remove the

special tools.

6-8

06/09/19 10:41:00 61SNC010_060_0009

14. Move the exhaust 2nd rocker arm (A) for the No. 1

cylinder. The exhaust 2nd rocker arm should move

independently of the exhaust 1st rocker arm (B).

If the exhaust 2nd rocker arm moves

independently, go to step 15.

If the exhaust 2nd rocker arm does not move

independently, remove and disassemble the

rocker arm assembly, and check that the rocker

arm pistons between the exhaust 1st and 2nd

rocker arms move smoothly. If any rocker arm or

rocker arm piston needs replacing, replace the

rocker arms for the cylinder as an assembly.

15. Tighten the valve on the regulator, then remove the

special tools.

16. Repeat step 4 to 15 on the remaining cylinders

rocker arms with each piston at TDC. When all the

rocker arms pass the test, go to step 17.

17. Install the cylinder head cover (see page 6-22).

6-9

06/09/19 10:41:02 61SNC010_060_0010

Cylinder Head

Valve Clearance Adjustment

NOTE: Adjust the valves only when the cylinder head

temperature is less than 100 F (38 C).

1. Remove the cylinder head cover (see page 6-22).

4. Insert the feeler gauge (A) between the adjusting

screw and the end of the valve stem on No. 1

cylinder and slide it back and forth; you should feel

a slight amount of drag.

2. Set the No. 1 piston at top dead center (TDC). The

UP mark (A) on the camshaft sprocket should be

at the top, and the TDC grooves (B) on the camshaft

sprocket should line up with the top edge of the

chain case.

5. If you feel too much or too little drag, loosen the

locknut (A), and turn the adjusting screw (B) until

the drag on the feeler gauge is correct.

3. Select the correct thickness feeler gauge for the

valves youre going to check.

B

20 Nm

(2.0 kgfm,

15 lbfft)

Valve Clearance

Intake:

0.150.19 mm (0.0060.007 in.)

Exhaust: 0.240.28 mm (0.0090.011 in.)

EXHAUST

No. 1

No. 2

No. 3

No. 4

A

6. Tighten the locknut and recheck the clearance.

Repeat the adjustment if necessary.

Specified Torque

20 Nm (2.0 kgfm, 14 lbfft)

Apply new engine oil to the nut threads.

No. 1

No. 2

No. 3

No. 4

INTAKE

6-10

06/09/19 10:41:03 61SNC010_060_0011

7. Rotate the crankshaft clockwise. Align the No. 3

piston TDC groove (A) on the camshaft sprocket

with the top edge of the chain case.

11. Rotate the crankshaft clockwise. Align the No. 2

piston TDC groove (A) on the camshaft sprocket

with the top edge of the head.

8. Check the valve clearance on the No. 3 cylinder;

adjust it if necessary

12. Check the valve clearance on the No. 2 cylinder;

adjust it if necessary.

9. Rotate the crankshaft clockwise. Align the No. 4

piston TDC groove (A) on the camshaft sprocket

with the top edge of the chain.

13. Install the cylinder head cover (see page 6-22).

10. Check the valve clearance on the No. 4 cylinder;

adjust it if necessary.

6-11

06/09/19 10:41:03 61SNC010_060_0012

Cylinder Head

Crankshaft Pulley Removal and Installation

Special Tools Required

Holder handle 07JAB-001020A

Holder attachment, 50 mm 07NAB-001040A

Socket, 19 mm 07JAA-001020A

or a commercially available 19 mm socket

Removal

Installation

1. Clean the crankshaft pulley (A), crankshaft (B), bolt

(C), and washer (D). Lubricate with new engine oil

as shown.

: Clean

: Lubricate with new engine oil

1. Remove the front wheels.

2. Remove the splash shield and the engine

undercover (see step 22 on page 5-5).

3. Remove the drive belt (see page 10-10).

4. Hold the pulley with the holder handle (A) and the

holder attachment (B).

C

A

2. Install the crankshaft pulley while moving the

engine forward and loosely install the crankshaft

pulley.

3. Install the lower torque rod mounting bolts (see

step 15 on page 5-15).

B

07NAB-001040A

A

07JAB-001020A

C

07JAA-001020A

(or commercially

available)

4. Remove the jack and the wood block.

5. Install the under-floor TWC (see step 26 on page

5-16).

5. Remove the crankshaft pulley bolt with a 19 mm

socket (C) and a breaker bar.

6. Remove the under-floor three way catalytic

converter (TWC) (see step 40 on page 5-8).

7. Support the engine with a jack and a wood block

under the oil pan.

8. Remove the lower torque rod mounting bolts (see

step 49 on page 5-9).

9. Remove the crankshaft pulley while moving the

engine forward.

6-12

06/09/19 10:41:04 61SNC010_060_0013

6. Tighten the crankshaft pulley bolt. Do not use an

impact wrench.

1 Hold the pulley with the holder handle (A) and

pulley holder attachment (B), then tighten the

bolt to 37 Nm (3.8 kgfm, 27 lbfft) with a

torque wrench and a heavy duty 19 mm socket

(C). If the pulley bolt or crankshaft are new,

tighten the bolt to 177 Nm (18.0 kgfm,

130 lbfft), then remove the bolt and tighten it

to 37 Nm (3.8 kgfm, 27 lbfft).

7. Install the drive belt (see page 10-10).

8. Install the splash shield and the engine undercover

(see step 42 on page 5-19).

9. Install the front wheels.

2 Mark the bolt head (D) and the crankshaft

pulley (E) as shown, then tighten the bolt an

additional 90 (The mark on the bolt head lines

up with the mark on the crankshaft pulley).

B

07NAB-001040A

C

07JAA-001020A

(or commercially

available)

A

07JAB-001020A

D

90

6-13

06/09/19 10:41:05 61SNC010_060_0014

Cylinder Head

Cam Chain Removal

NOTE: Keep the cam chain away from magnetic fields.

1. Remove the front wheels.

10. Remove the ground cable (A), then remove the side

engine mount bracket (B).

2. Remove the splash shield and the engine

undercover (see step 22 on page 5-5).

3. Remove the drive belt (see page 10-10).

4. Turn the crankshaft pulley so its top dead center

(TDC) mark (A) lines up with the pointer (B).

11. Disconnect the crankshaft position (CKP) sensor

connector (A), then remove the dipstick tube

mounting bolt (B) and the harness clamps (C).

5. Remove the water pump pulley (see step 4 on page

10-5).

6. Remove the cylinder head cover (see page 6-22).

7. Remove the crankshaft pulley (see page 6-12).

8. Remove the oil pan (see page 7-11).

9. Support the engine with a jack and a wood block

under the engine block.

B

C

A

6-14

06/09/19 10:41:06 61SNC010_060_0015

12. Remove the chain case (A), then remove the

crankshaft position (CKP) pulse plate (B).

14. Apply new engine oil to the sliding surface of the

cam chain tensioner slider (A).

B

B

13. Measure the cam chain separation. If the distance

is less than the service limit, replace the cam chain

and the cam chain tensioner.

Standard Distance:

Service Limit:

19 mm (0.75 in.)

15 mm (0.59 in.)

15. Hold the cam chain tensioner slider with a

screwdriver, then remove the bolt (B), and loosen

the bolt (C).

16. Remove the cam chain tensioner slider.

(contd)

6-15

06/09/19 10:41:07 61SNC010_060_0016

Cylinder Head

Cam Chain Removal (contd)

Cam Chain Installation

17. Remove the cam chain tensioner (A) and the cam

chain guide (B).

NOTE: Keep the cam chain away from magnetic fields.

1. Set the crankshaft to top dead center (TDC). Align

the TDC mark (A) on the crankshaft sprocket with

the pointer (B) on the oil pump.

B

A

18. Remove the cam chain.

2. Set the No. 1 piston at TDC. The UP mark (A) on

the camshaft sprocket should be at the top, and the

TDC grooves (B) on the camshaft sprocket should

line up with the top edge of the cylinder head.

B

6-16

06/09/19 10:41:08 61SNC010_060_0017

3. Install the cam chain on the crankshaft sprocket

with the colored piece (A) aligned with the TDC

mark (B) on the crankshaft sprocket.

5. Apply new engine oil to the threads of the cam

chain tensioner mounting bolt (A).

B

B

4. Install the cam chain on the camshaft sprocket with

the pointer (A) aligned with the center of the two

colored pieces (B).

B

A

A

8 x 1.25 mm

22 Nm

(2.2 kgfm, 16 lbfft)

6 x 1.0 mm

12 Nm

(1.2 kgfm, 8.7 lbfft)

6. Install the cam chain tensioner (B) and the cam

chain guide (C).

7. Install the cam chain tensioner slider, and tighten

the lower side bolt loosely.

(contd)

6-17

06/09/19 10:41:09 61SNC010_060_0018

Cylinder Head

Cam Chain Installation (contd)

8. Apply new engine oil to the sliding surface of the

cam chain tensioner slider (A).

6 x 1.0 mm

12 Nm

(1.2 kgfm, 8.7 lbfft)

13. Apply liquid gasket, P/N 08717-0004, 08718-0001,

08718-0003, or 08718-0009, evenly to the cylinder

head and engine block mating surface of the chain

case. Install the component within 5 minutes of

applying the liquid gasket.

NOTE:

Apply a 1.5 mm wide bead of liquid gasket along

the broken lines (A).

Apply a 3.0 mm wide bead of liquid gasket to the

engine block upper surface contact areas (B) on

the chain case.

If you apply liquid gasket P/N 08718-0012, the

component must be installed with 4 minutes.

If too much time has passed after applying the

liquid gasket, remove the old liquid gasket and

residue, then reapply new liquid gasket.

9. Turn the cam chain tensioner clockwise to

compress the cam chain tensioner slider. Install the

remaining bolt, then tighten the two bolts.

10. Check the chain case oil seal for damage. If the oil

seal is damaged, replace the chain case oil seal

(see page 6-20).

11. Remove any old liquid gasket from the chain case

mating surfaces, bolts, and bolt holes.

12. Clean and dry the chain case mating surfaces.

6-18

06/09/19 10:41:11 61SNC010_060_0019

14. Install the crankshaft position (CKP) pulse plate (A)

and the chain case (B).

NOTE:

Wait at least 30 minutes before filling the engine

with oil.

Do not run the engine for at least 3 hours after

installing the chain case.

16. Install the side engine mount bracket (A), then

tighten the mounting bolts and nut in the

numbered sequence shown.

B

12 x 1.25 mm

72 Nm

(7.3 kgfm,

53 lbfft)

6 x 1.0 mm

9.8 Nm (1.0 kgfm, 7.2 lbfft)

12 x 1.25 mm

54 Nm

(5.5 kgfm, 40 lbfft)

Replace.

12 x 1.25 mm

54 Nm

(5.5 kgfm,

A

40 lbfft)

Replace.

17. Install the ground cable (B).

8 x 1.25 mm

31 Nm

(3.2 kgfm, 23 lbfft)

6 x 1.0 mm

12 Nm

(1.2 kgfm, 8.7 lbfft)

18. Remove the jack and the wood block.

19. Install the oil pan (see page 7-27).

15. Install the harness clamps (A) and the dipstick tube

mounting bolt (B), then connect the CKP sensor

connector (C).

20. Install the crankshaft pulley (see page 6-12).

21. Install the cylinder head cover (see page 6-22).

22. Install the water pump pulley (see page 10-5).

23. Install the drive belt (see page 10-10).

24. Install the splash shield and the engine undercover

(see step 42 on page 5-19).

A

B

6 x 1.0 mm

9.8 Nm

(1.0 kgfm,

7.2 lbfft)

25. Install the front wheels.

26. Do the crankshaft position (CKP) pattern clear/CKP

pattern learn procedure (see page 11-4).

A

C

6-19

06/09/19 10:41:11 61SNC010_060_0020

Cylinder Head

Chain Case Oil Seal Installation

Special Tools Required

Driver 07749-0010000

Attachment, 52 x 55 mm 07746-0010400

1. Use the special tools to drive a new oil seal

squarely into the chain case to the specified

installed height.

07749-0010000

07746-0010400

2. Measure the distance between the chain case

surface and the oil seal.

Oil Seal Installed Height:

34.535.2 mm (1.361.39 in.)

34.535.2 mm

(1.361.39 in.)

6-20

06/09/19 10:41:58 61SNC010_060_0021

CKP Pulse Plate Replacement

1. Remove the front wheels.

14. Install the CKP pulse plate.

2. Remove the splash shield and the engine

undercover (see step 22 on page 5-5).

15. Check the chain case oil seal for damage. If the oil

seal is damaged, replace the chain case oil seal

(see page 6-20).

3. Remove the drive belt (see page 10-10).

4. Turn the crankshaft pulley so its top dead center

(TDC) mark lines up with the pointer (see step 2 on

page 6-10).

5. Remove the water pump pulley (see step 4 on page

10-5).

6. Remove the cylinder head cover (see page 6-22).

16. Remove all of the old liquid gasket from the chain

case mating surfaces, bolt, and bolt holes.

17. Clean and dry the chain case mating surfaces.

18. Apply liquid gasket, P/N 08717-0004, 08718-0001,

08718-0003 or 08718-0009, evenly to the engine

block mating surface of the chain case. Install the

component within 5 minutes of applying the liquid

gasket (see step 13 on page 6-18).

7. Remove the crankshaft pulley (see page 6-12).

8. Remove the oil pan (see page 7-11).

9. Support the engine with a jack and a wood block

under the engine block.

10. Remove the ground cable, then remove the side

engine mount bracket (see step 59 on page 5-11).

NOTE:

If you apply liquid gasket P/N 08718-0012, the

component must be installed with 4 minutes.

If too much time has passed after applying the

liquid gasket, remove the old liquid gasket and

residue, then reapply new liquid gasket.

19. Install the chain case (see step 14 on page 6-19).

11. Disconnect the crankshaft position (CKP) sensor

connector, then remove the harness clamp and the

dipstick tube mounting bolt (see step 11 on page

6-14).

20. Install the side engine mount bracket, then install

the ground cable (see step 16 on page 6-19).

12. Remove the chain case (see step 12 on page 6-15).

22. Install the oil pan (see page 7-27).

13. Remove the CKP pulse plate (A).

23. Install the crankshaft pulley (see page 6-12).

21. Remove the jack and the wood block.

24. Install the cylinder head cover (see page 6-22).

25. Install the water pump pulley (see step 4 on page

10-5).

26. Install the drive belt. (see page 10-10).

27. Install the splash shield and the engine undercover

(see step 42 on page 5-19).

28. Install the front wheels.

29. Do the crankshaft (CKP) pattern clear/CKP pattern

learn procedure (see page 11-4).

6-21

06/09/19 10:41:59 61SNC010_060_0022

Cylinder Head

Cylinder Head Cover Removal

Cylinder Head Cover Installation

1. Remove the engine cover (see step 7 on page 5-3).

1. Check the spark plug seals (A) for damage. If the

seal is damaged, replace the spark plug seals.

2. Remove the eight ignition coils (see page 4-19).

3. Remove the harness holder (A) and the breather

hose (B).

2. Thoroughly clean the head cover gasket and the

groove.

3. Install the head cover gasket (B) in the groove of

the cylinder head cover (C).

4. Remove the cylinder head cover.

4. Check that the mating surfaces are clean and dry.

5. Apply a 3.0 mm wide bead of the liquid gasket, P/N

08717-0004, 08718-0001, 08718-0003, or 087180009, on the chain case mating areas (A). Install the

component within 5 minutes of applying the liquid

gasket.

NOTE:

If you apply liquid gasket P/N 08718-0012, the

component must be installed with 4 minutes.

If too much time has passed after applying the

liquid gasket, remove the old liquid gasket and

residue, then reapply new liquid gasket.

A

6-22

06/09/19 10:42:00 61SNC010_060_0023

6. Once the cylinder head cover (A) is on the cylinder

head, slide the cover slightly back and forth to seat

the head cover gasket.

9. Install the breather hose (A) and the harness holder

(B).

6 x 1.0 mm

12 Nm

(1.2 kgfm, 8.7 lbfft)

B

6 x 1.0 mm

9.8 Nm

(1.0 kgfm,

7.2 lbfft)

A

A

7. Inspect the cover washer (B). Replace any washer

that is damaged or deteriorated.

8. Tighten the bolts in two or three steps. In the final

step, tighten all bolts in sequence shown to 12 Nm

(1.2 kgfm, 8.7 lbfft).

10. Install the eight ignition coils (see page 4-19).

11. Install the engine cover (see step 55 on page 5-21).

12. After assembly, wait at least 30 minutes before

filling the engine with oil.

6-23

06/09/20 16:08:14 61SNC010_060_0024

Cylinder Head

Cylinder Head Removal

NOTE:

Use fender covers to avoid damaging painted

surfaces.

To avoid damaging the wire and terminals, unplug

the wiring connectors carefully while holding the

connector portion.

To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100 F

(38 C) before loosening the cylinder head bolts.

Mark all wiring and hoses to avoid misconnection.

Also, be sure that they do not contact other wiring or

hoses, or interfere with other parts.

Keep the cam chain away from magnetic fields.

8. Remove the eight ignition coils (see page 4-19).

9. Remove the harness holder and the breather hose

(see step 3 on page 6-22).

10. Disconnect the purge control solenoid valve

connector (A), then remove the clip (B).

D

A

B

C

1. Relieve the fuel pressure (see page 11-356).

2. Remove the engine cover (see step 7 on page 5-3).

3. Drain the engine coolant (see page 10-6).

4. Remove the air cleaner assembly (see page 11-381).

5. Remove the intake manifold (see page 9-3).

6. Disconnect the knock sensor connector (A), then

remove the harness clamp (B) and the connecting

pipe (C).

11. Disconnect the purge joint from the clamp stay (C),

then remove the fuel pipe nut (D) and remove the

purge control solenoid stay bolts (E).

12. Remove the upper radiator hose (A), lower radiator

hose (B), water bypass hose (C), and heater hoses

(D).

A

D

C

B

7. Disconnect the camshaft position (CMP) sensor (A)

and the engine coolant temperature (ECT) sensor 1

connector (B), then remove the harness clamp (C).

6-24

06/09/19 10:42:03 61SNC010_060_0025

23. Make a reference mark (A) across the camshaft

sprocket and the cam chain.

13. Remove the drive belt (see page 10-10).

14. Turn the crankshaft pulley so its top dead center

(TDC) mark lines up with the pointer (see step 4 on

page 6-14).

15. Remove the water pump (see page 10-5).

16. Remove the cylinder head cover (see page 6-22).

17. Remove the under floor three way catalytic

converter (TWC) and the warm-up three way

catalytic converter (WU-TWC) (see step 40 on page

5-8).

18. Remove the crankshaft pulley (see page 6-12).

24. Loosely install the crankshaft pulley.

19. Support the engine with a jack and a wood block

under the oil pan.

25. Apply new engine oil to the sliding surface of the

cam chain tensioner through the oil return hole in

the cylinder head.

20. Remove the ground cable, then remove the side

engine mount bracket (see step 10 on page 6-14).

21. Disconnect the crankshaft position (CKP) sensor (A)

and the harness clamp (B), then remove the

dipstick tube (C).

22. Remove the chain case.

(contd)

6-25

06/09/19 10:42:05 61SNC010_060_0026

Cylinder Head

Cylinder Head Removal (contd)

26. Hold the crankshaft pulley and set the socket

wrench (A) on the camshaft sprocket bolt.

29. Remove the top bolt that secures the cam chain

guide.

A

C

D

27. Turn the camshaft clockwise to compress the cam

chain tensioner, then install the 6 x 1.0 mm bolt (B)

in the bolt hole (C) in the engine block through the

cam chain tensioner (D).

30. Remove the cylinder head bolts. To prevent

warpage, loosen the bolts in sequence 1/3 turn at a

time; repeat the sequence until all bolts are

loosened.

NOTE:

Turning torque should not exceed 44 Nm

(4.5 kgfm, 33 lbfft) when turning the camshaft.

Do not turn the camshaft counterclockwise.

28. Hold the camshaft with a 27 mm open-end wrench,

then remove the camshaft sprocket.

31. Remove the cylinder head.

6-26

06/09/19 10:42:06 61SNC010_060_0027

Camshaft Sprocket Removal

NOTE: Keep the cam chain away from magnetic fields.

4. Remove the cylinder head plug.

1. Remove the cylinder head cover (see page 6-22).

2. Make a reference mark (A) across the camshaft

sprocket and the cam chain.

5. Hold the crankshaft pulley and set the socket

wrench (A) on the camshaft sprocket bolt.

3. Apply new engine oil to the sliding surface of the

cam chain tensioner through the oil return hole in

the cylinder head.

6. Remove the maintenance bolt (B), and turn the

camshaft clockwise to compress the cam chain

tensioner, then install the 6 x 1.0 mm bolt (C) in the

bolt hole (D) in the engine block through the

maintenance hole and the cam chain tensioner (E).

NOTE:

Turning torque should not exceed 44 Nm

(4.5 kgfm, 33 lbfft) when turning the camshaft.

Do not turn the camshaft counterclockwise.

(contd)

6-27

06/09/19 10:42:07 61SNC010_060_0028

Cylinder Head

Camshaft Sprocket Removal

(contd)

Camshaft Sprocket Installation

NOTE: Keep the cam chain away from magnetic fields.

7. Hold the camshaft with a 27 mm open-end wrench,

then loosen the camshaft sprocket bolt.

1. Install the cam chain around the camshaft sprocket

aligned with the reference mark (A), then install the

camshaft sprocket on the camshaft.

A

2. Hold the camshaft with a 27 mm open-end wrench,

then tighten the bolt.

8. Remove the camshaft sprocket bolt, then remove

the camshaft sprocket.

NOTE: Apply new engine oil to the bolt threads and

flange.

Specified Torque: 56 Nm (5.7 kgfm, 41 lbfft)

NOTE: Hang the cam chain with a wire.

6-28

06/09/19 10:42:08 61SNC010_060_0029

3. Apply new engine oil to the sliding surface of the

cam chain tensioner through the oil return hole in

the cylinder head.

7. Install the new cylinder head plug.

8. Install the cylinder head cover (see page 6-22).

4. Hold the crankshaft pulley and set the socket

wrench (A) on the camshaft sprocket bolt.

D

C

14 x 1.25 mm

20 Nm (2.0 kgfm, 15 lbfft)

5. Turn the camshaft clockwise to compress the cam

chain tensioner, then remove the 6 x 1.0 mm bolt

(B).

NOTE:

Turning torque should not exceed 44 Nm

(4.5 kgfm, 33 lbfft) when turning the camshaft.

Do not turn the camshaft counterclockwise.

6. Install the maintenance bolt (C) with a new washer

(D).

6-29

06/09/19 10:42:09 61SNC010_060_0030

Cylinder Head

CMP Pulse Plate Removal and Installation

Removal

6. Remove the camshaft position (CMP) pulse plate.

1. Remove the air cleaner assembly (see page 11-381).

2. Remove the cylinder head cover (see page 6-22).

3. Remove the purge control solenoid valve stay (see

step 16 on page 5-5).

4. Remove the cylinder head plug.

5. Hold the camshaft with a 27 mm open-end wrench,

then loosen the bolt.

6-30

06/09/19 10:42:10 61SNC010_060_0031

Cylinder Head Inspection for

Warpage

Installation

1. Install the CMP pulse plate (A). Hold the camshaft

with an open-end wrench (B), then tighten the bolt

(C).

1. Remove the cylinder head (see page 6-24).

2. Inspect the camshaft (see page 6-36).

3. Check the cylinder head for warpage. Measure

along the edges, and three ways across the center.

Warpage

Standard (New):

Service Limit:

0.07 mm (0.0028 in.)

0.08 mm (0.0031 in.)

If warpage is less than 0.08 mm (0.0031 in.)

cylinder head resurfacing is not required.

If warpage is between 0.08 mm (0.0031 in.) and

0.2 mm (0.008 in.), resurface the cylinder head.

Maximum resurface limit is 0.2 mm (0.008 in.)

based on a height of 120 mm (4.72 in.).

C

14 x 1.5 mm

34 Nm (3.5 kgfm, 25 lbfft)

Cylinder Head Height

Standard (New): 119.9120.1 mm

(4.7204.728 in.)

PRECISION STRAIGHT EDGE

2. Install the new cylinder head plug.

3. Install the purge control solenoid valve stay (see

step 45 on page 5-19).

4. Install the cylinder head cover (see page 6-22).

5. Install the air cleaner assembly (see page 11-381).

6-31

06/09/19 10:42:12 61SNC010_060_0032

Cylinder Head

Rocker Arm Assembly and Camshaft Removal

1. Remove the camshaft sprocket (see page 6-27).

2. Loosen the rocker arm adjusting screws (A).

4. Remove the lost motion holder (A), the lost motion

assembly (B), and the rocker arm assembly (C),

then remove the camshaft (D).

B

C

3. Remove the lost motion holder bolts and the

camshaft holder bolts. To prevent damaging the

camshaft, loosen the bolts two turns at a time, in a

crisscross pattern.

6-32

06/09/19 10:42:13 61SNC010_060_0033

Rocker Arm and Shaft Disassembly/Reassembly

NOTE:

Identify parts as they are removed so they can be reinstalled in their original location.

Remove the rocker shaft bolts before disassembling the rocker arms.

Inspect the rocker shaft and rocker arms (see page 6-34).

If reused, the rocker arms must be installed in their original location.

Prior to reassembling, clean all the parts in solvent, dry them, and apply new engine oil to any contact points.

Apply new engine oil to the threads of the rocker shaft bolts when installing them.

When replacing the rocker arm assembly, remove the fastening hardware from the new rocker arm assembly.

LOST MOTION HOLDER BOLT

8 x 1.25 mm

22 Nm (2.2 kgfm, 16 lbfft)

LOST MOTION HOLDER

LOST MOTION

ASSEMBLY

ROCKER SHAFT

ROCKER SHAFT BOLT

8 x 1.25 mm

20 Nm (2.0 kgfm, 15 lbfft)

LOST MOTION

ASSEMBLY

ROCKER SHAFT BOLT

8 x 1.25 mm

20 Nm (2.0 kgfm, 15 lbfft)

NO.5

CAMSHAFT

HOLDER

NO. 1

CAMSHAFT

HOLDER

NO. 2

CAMSHAFT

HOLDER

NO.3

CAMSHAFT

HOLDER

NO.4

CAMSHAFT

EXHAUST

HOLDER

1st and 2nd

ROCKER ARM

ASSEMBLY

INTAKE

1st, 2nd and 3rd

ROCKER ARM

ASSEMBLY

6-33

06/09/19 10:42:13 61SNC010_060_0034

Cylinder Head

Rocker Arm and Shaft Inspection

1. Remove the rocker arm assembly (see page 6-32).

2. Disassemble the rocker arm assembly (see page

6-33).

3. Measure the diameter of the shaft at the first rocker

location.

5. Measure the inside diameter of the rocker arm, and

check it for an out-of-round condition.

Rocker Arm-to-Shaft Clearance

Standard (New): 0.0170.045 mm

(0.00030.0018 in.)

Service Limit:

0.067 mm (0.0026 in.)

4. Zero the gauge (A) to the shaft diameter.

6. Repeat for all the rockers and both shafts. If the

clearance is over the limit, replace the rocker shaft

and all over-tolerance rocker arms. If any intake

rocker arm needs replacement, replace all five

rocker arms in that set (intake 1st, 2nd, 3rd, exhaust

1st and 2nd).

6-34

06/09/19 10:42:14 61SNC010_060_0035

Rocker Arms

7. Inspect the rocker arm synchronizing pistons (A).

Push them manually. If they do not move smoothly,

replace the rocker arm set.

NOTE:

Apply new engine oil to the pistons when

reassembling.

When reassembling the intake 1st and exhaust

1st rocker arms (B), carefully apply air pressure

to the oil passage of the rocker arm.

A

B

8. Reassemble the rocker arm assembly (see page

6-33).

9. Install the rocker arm assembly (see page 6-45).

6-35

06/09/19 10:42:14 61SNC010_060_0036

Cylinder Head

Camshaft Inspection

NOTE: Do not rotate the camshaft during inspection.

3. Seat the camshaft by pushing it away from the

camshaft pulley end of the cylinder head.

1. Remove the rocker arm assembly (see page 6-32).

2. Put the camshaft, the camshaft holders, and the

lost motion holder on the cylinder head, then

tighten the bolts to the specified torque.

Specified Torque

8 mm Bolts:

22 Nm (2.2 kgfm, 16 lbfft)

Apply new engine oil to the bolt threads and flange.

6 mm Bolt:

12 Nm (1.2 kgfm, 8.7 lbfft)

Apply new engine oil to the bolt threads and flange.

4. Zero the dial indicator against the end of the

camshaft, then push the camshaft back and forth

and read the end play. If the end play is beyond the

service limit, replace the cylinder head and recheck.

If it is still beyond the service limit, replace the

camshaft.

Camshaft End Play

Standard (New): 0.050.15 mm (0.0020.006 in.)

Service Limit:

0.3 mm (0.01 in.)

6-36

06/09/19 10:42:15 61SNC010_060_0037

5. Loosen the lost motion holder bolts and the

camshaft holder bolts two turns at a time, in a

crisscross pattern. Then remove the lost motion

holder and the camshaft holders from the cylinder

head.

10. Check the total runout with the camshaft supported

on V-blocks.

6. Lift the camshaft out of the cylinder head, wipe it

clean, then inspect the lift ramps. Replace the

camshaft if any lobes are pitted, scored, or

excessively worn.

If the total runout of the camshaft is within the

service limit, replace the cylinder head.

If the total runout is beyond the service limit,

replace the camshaft and recheck the camshaftto-holder oil clearance. If the oil clearance is still

beyond the service limit, replace the cylinder

head.

7. Clean the camshaft journal surfaces in the cylinder

head, then set the camshaft back in place. Place a

plastigage strip across each journal.

Camshaft Total Runout

Standard (New): 0.03 mm (0.001 in.) max.

Service Limit:

0.04 mm (0.002 in.)

8. Install the camshaft holders, then tighten the bolts

to the specified torque as shown in step 2.

9. Remove the camshaft holders. Measure the widest

part of plastigage on each journal.

If the camshaft-to-holder clearance is within

limits, go to step 11.

If the camshaft-to-holder clearance is beyond the

service limit and the camshaft has been replaced,

replace the cylinder head.

If the camshaft-to-holder clearance is beyond the

service limit and the camshaft has not been

replaced, go to step 10.

Camshaft-to-Holder Oil Clearance

Standard (New): 0.0500.089 mm

(0.00200.0035 in.)

Service Limit:

0.15 mm (0.006 in.)

11. Measure cam lobe height.

Cam Lobe Height Standard (New):

INTAKE

EXHAUST

2nd

35.568 mm

35.699 mm

(1.4003 in.)

(1.4054 in.)

3rd

36.060 mm

(1.4196 in.)

1st

29.700 mm

29.900 mm

(1.1692 in.)

(1.1771 in.)

2nd

1st

3rd

1st

2nd

C/C

EXHAUST

INTAKE

6-37

06/09/19 10:42:17 61SNC010_060_0038

Cylinder Head

Valve, Spring, and Valve Seal Removal

Special Tools Required

Valve spring compressor attachment 07757-PJ1010A

6. Install the valve guide seal remover.

Identify the valves and valve springs as they are

removed so that each item can be reinstalled in its

original position.

1. Remove the cylinder head (see page 6-24).

2. Remove the rocker arm assembly and the camshaft

(see page 6-32).

3. Using an appropriate-sized socket (A) and a plastic

mallet (B), lightly tap the valve retainer to loosen

the valve cotters.

B

A

7. Remove the valve seal.

4. Install the valve spring compressor attachment and

the valve spring compressor. Compress the spring

and remove the valve cotters.

07757-PJ1010A

8. Remove the valve spring seat and the valve.

5. Remove the valve spring compressor, the valve

spring compressor attachment, the spring retainer,

and the spring.

6-38

06/09/19 10:42:17 61SNC010_060_0039

Valve Inspection

Valve Stem-to-Guide Clearance

Inspection

1. Remove the valves (see page 6-38).

2. Measure the valve in these areas.

Intake Valve Dimensions

A Standard (New): 34.8535.15 mm

(1.3721.383 in.)

B Standard (New): 117.65118.15 mm

(4.6324.652 in.)

C Standard (New): 5.485.49 mm

(0.21570.2161 in.)

C Service Limit:

5.45 mm (0.215 in.)

Exhaust Valve Dimensions

A Standard (New): 29.8530.15 mm

(1.1751.187 in.)

B Standard (New): 117.75118.25 mm

(4.6354.659 in.)

C Standard (New): 5.455.46 mm

(0.21460.2150 in.)

C Service Limit:

5.42 mm (0.213 in.)

1. Remove the valves (see page 6-38).

2. Slide the valve out of its guide about 10 mm

(0.39 in.), then measure the guide-to-stem

clearance with a dial indicator while rocking the

stem in the direction of normal thrust (wobble

method).

If the measurement exceeds the service limit,

recheck it using a new valve.

If the measurement is now within the service

limit, reassemble using a new valve.

If the measurement with a new valve still

exceeds the service limit, go to step 3.

Intake Valve Stem-to-Guide Clearance

Standard (New): 0.040.10 mm

(0.0020.004 in.)

Service Limit:

0.16 mm (0.006 in.)

B

C

Exhaust Valve Stem-to-Guide Clearance

Standard (New): 0.100.16 mm

(0.0040.006 in.)

Service Limit:

0.22 mm (0.009 in.)

3. Subtract the O.D. of the valve stem, measured with

a micrometer, from the I.D. of the valve guide,

measured with an inside micrometer or ball gauge.

Take the measurements in three places along the

valve stem and three places inside the valve guide.

The difference between the largest guide

measurement and the smallest stem measurement

should not exceed the service limit.

Intake Valve Stem-to-Guide Clearance

Standard (New): 0.0200.050 mm

(0.00080.0020 in.)

Service Limit:

0.08 mm (0.003 in.)

Exhaust Valve Stem-to-Guide Clearance

Standard (New): 0.0500.080 mm

(0.00200.0031 in.)

Service Limit:

0.11 mm (0.004 in.)

6-39

06/09/19 10:42:19 61SNC010_060_0040

Cylinder Head

Valve Guide Replacement

Special Tools Required

Valve guide driver, 5.5 mm 07742-0010100

Valve guide reamer, 5.5 mm 07HAH-PJ7A100

1. Inspect valve stem-to-guide clearance (see page

6-39).

2. As illustrated, use a commercially available airimpact valve guide driver (A) modified to fit the

diameter of the valve guides. In most cases, the

same procedure can be done using the special tool

and a conventional hammer.

87 mm

(3.43 in.)

5. Working from the camshaft side, use the driver and

an air hammer to drive the guide about 2 mm

(0.1 in.) towards the combustion chamber. This will

knock off some of the carbon and make removal

easier. Hold the air hammer directly in line with the

valve guide to prevent damaging the driver. Wear

safety goggles or a face shield.

6. Turn the head over, and drive the guide out toward

the camshaft side of the head.

5.3 mm

(0.21 in.)

57 mm

(2.24 in.)

10.8 mm

(0.42 in.)

3. Select the proper replacement guides, and chill

them in the freezer section of a refrigerator for

about an hour.

4. Use a hot plate or oven to evenly heat the cylinder

head to 300 F (150 C). Monitor the temperature

with a cooking thermometer. Do not get the head

hotter than 300 F (150 C); excessive heat may

loosen the valve seats.

07742-0010100

7. If a valve guide wont move, drill it out with a 8 mm

(5/16 in.) bit, then try again.

NOTE: Drill guides only in extreme cases; you

could damage the cylinder head if the guide breaks.

8. Take out the new guide(s) from the freezer, one at a

time, as you need them.

6-40

06/09/19 10:42:42 61SNC010_060_0041

9. Apply a thin coat of new engine oil to the outside of

the new valve guide. Install the guide from the

camshaft side of the head; use the valve guide

driver to drive the guide into the specified installed

height (A) of the guide (B). If you have all eight

guides to do, you may have to reheat the head.

10. Coat both the reamer and the valve guide with

cutting oil.

11. Rotate the reamer clockwise the full length of the

valve guide bore.

Valve Guide Installed Height:

16.2516.75 mm (0.6400.659 in.)

07742-0010100

07HAH-PJ7A100

12. Continue to rotate the reamer clockwise while

drawing it from the bore.

B

A

13. Thoroughly wash the guide in detergent and water

to remove any cutting residue.

14. Check the clearances with a valve (see page 6-39).

Verify that a valve slides in the intake and exhaust

valve guides without being stuck.

15. Inspect the valve seating, if necessary renew the

valve seat using a valve seat cutter (see page 6-42).

6-41

06/09/19 10:42:43 61SNC010_060_0042

Cylinder Head

Valve Seat Reconditioning

1. Inspect valve stem-to-guide clearance (see page

6-39). If the valve guides are worn, replace them

(see page 6-40) before cutting the valve seats.

2. Renew the valve seats in the cylinder head using a

valve seat cutter.

5. Make one more very light pass with the 45 cutter

to remove any possible burrs caused by the other

cutters.

Valve Seat Width

Intake:

Standard (New): 0.8501.150 mm

(0.03350.0453 in.)

Service Limit:

1.60 mm (0.063 in.)

Exhaust:

Standard (New): 1.2501.550 mm

(0.04920.0610 in.)

Service Limit:

2.00 mm (0.079 in.)

6. After resurfacing the seat, inspect for even valve

seating: Apply Prussian Blue compound (A) to the

valve face. Insert the valve in its original location in

the head, then lift it and snap it closed against the

seat several times.

3. Carefully cut a 45 seat, removing only enough

material to ensure a smooth and concentric seat.

4. Bevel the upper edge of the seat with the 30 cutter

and the lower edge of the seat with the 60 cutter.

Check the width of the seat and adjust accordingly.

30

45

A

60

7. The actual valve seating surface (B), as shown by

the blue compound, should be centered on the seat.

If it is too high (closer to the valve stem), you

must make a second cut with the 60 cutter to

move it down, then one more cut with the 45

cutter to restore seat width.

If it is too low (close to the valve edge), you must

make a second cut with the 30 cutter to move it

up, then make one more cut with the 45 cutter

to restore seat width.

NOTE: The final cut should always be made with

the 45 cutter.

6-42

06/09/19 10:42:43 61SNC010_060_0043

8. Insert the intake and exhaust valves in the head,

and measure the valve stem installed height (A).

Intake Valve Stem Installed Height

Standard (New): 47.748.1 mm

(1.8781.894 in.)

Service Limit:

48.4 mm (1.906 in.)

Exhaust Valve Stem Installed Height

Standard (New): 47.648.0 mm

(1.8741.890 in.)

Service Limit:

48.3 mm (1.902 in.)

9. If the valve stem installed height is over the service

limit, replace the valve and recheck. If it is still over

the service limit, replace the cylinder head; the

valve seat in the head is too deep.

6-43

06/09/19 10:42:44 61SNC010_060_0044

Cylinder Head

Valve, Spring, and Valve Seal Installation

Special Tools Required

Stem seal driver 07PAD-0010000

Valve spring compressor attachment 07757-PJ1010A

1. Coat the valve stems with new engine oil. Install

the valves in the valve guides.

2. Check that the valves move up and down smoothly.

3. Install the spring seats on the cylinder head.

5. Install the valve spring. Place the end of the valve

spring with closely wound coils toward the cylinder

head.

6. Install the spring retainer.

7. Install the valve spring compressor attachment and

the valve spring compressor. Compress the spring

and install the valve cotters.

07757-PJ1010A

4. Install the new valve seals (A) using the stem seal

driver (B).

NOTE: The exhaust valve seal (C) has a black spring

(D), and the intake valve seal (E) has a white spring

(F). They are not interchangeable.

B

07PAD-0010000

NOTE: Use 5.5 mm side.

8. Remove the valve spring compressor and the valve

spring compressor attachment.

9. Lightly tap the end of each valve stem two or three

times with a plastic mallet (A) to ensure proper

seating of the valve and the valve cotters. Tap the

valve stem only along its axis so you do not bend

the stem.

A

6-44

06/09/19 10:42:46 61SNC010_060_0045

Rocker Arm Assembly and

Camshaft Installation

Cylinder Head Installation

Install the cylinder head in the reverse order of

removal:

1. Reassemble the rocker arm assembly (see page

6-33).

2. Apply new engine oil to the camshaft lobes and

journals.

3. Install the camshaft (A) rocker arm assembly (B),

then install the lost motion assembly (C) and the

lost motion holder (D).

1. Clean the cylinder head and the engine block

surface.

2. Install the new cylinder head gasket (A) and the

dowel pins (B) on the engine block. Always use a

new cylinder head gasket.

C

B

B

A

3. Check that the crankshaft keyway is facing up.

4. Install the cylinder head on the engine block.

5. Measure the diameter of each cylinder head bolt at

point A and point B.

B 50 mm (2.0 in.)

4. Apply new engine oil to the bolt threads and flange.

Tighten each bolt two turns at a time in sequence.

A 45 mm (1.8 in.)

Specified Torque

8 mm Bolts: 22 Nm (2.2 kgfm, 16 lbfft)

6 mm Bolt: 12 Nm (1.2 kgfm, 8.7 lbfft)

6 mm Bolt:

6. If either diameter is less than 10.6 mm (0.42 in.),

replace the cylinder head bolt.

5. Install the camshaft sprocket (see page 6-28).

6. Adjust the valve clearance (see page 6-10).

(contd)

6-45

06/09/19 10:42:47 61SNC010_060_0046

Cylinder Head

Cylinder Head Installation (contd)

7. Apply new engine oil to the threads and flange of

all cylinder head bolts. Be sure to install the

165 mm long head bolt (A) in the location shown.

10. Install the cam chain guide mounting top bolt.

8. Tighten the cylinder head bolts in sequence to

29 Nm (3.0 kgfm, 22 lbfft), use a beam-type

torque wrench. When using a preset-type torque

wrench, be sure to tighten slowly and do not

overtighten. If a bolt makes any noise while you are

torquing it, loosen the bolt and retighten it from the

first step.

9. Tighten all cylinder head bolts an additional 130 .

NOTE: Remove the cylinder head bolt if you

tightened it beyond the specified angle, and go

back to step 5 of the procedure.

130

6-46

6 x 1.0 mm

12 Nm (1.2 kgfm, 8.7 lbfft)

11. Install the cam chain around the camshaft sprocket

aligned with the reference mark (A), then install the

camshaft sprocket on the camshaft.

A

06/09/19 10:42:48 61SNC010_060_0047

12. Hold the camshaft with an open-end wrench, then

tighten the bolt.

15. Hold the crankshaft pulley and set the socket

wrench (A) on the camshaft sprocket bolt.

Specified Torque: 56 Nm (5.7 kgfm, 41 lbfft)

13. Loosely install the crankshaft pulley.

14. Apply new engine oil to the sliding surface of the

cam chain tensioner through the oil return hole in

the cylinder head.

16. Turn the camshaft clockwise to compress the cam

chain tensioner, then remove the 6 x 1.0 mm bolt

(B).

NOTE:

Turning torque should not exceed 44 Nm

(4.5 kgfm, 33 lbfft), when turning the camshaft.

Do not turn the camshaft counterclockwise.

17. Check the chain case oil seal for damage. If the oil

seal is damaged, replace the chain case oil seal

(see page 6-20).

18. Remove any old liquid gasket from the chain case

mating surfaces, bolts, and bolt holes.

19. Clean and dry the chain case mating surfaces.

(contd)

6-47

06/09/19 10:42:49 61SNC010_060_0048

Cylinder Head

Cylinder Head Installation (contd)

20. Apply liquid gasket, P/N 08717-0004, 08718-0001,

08718-0003, or 08718-0009, evenly to the cylinder

head and engine block mating surface of the chain

case. Install the component within 5 minutes of

applying the liquid gasket (see step 13 on page

6-18).

22. Set the edge of the chain case (A) to the edge of the

oil pan (B), then install the chain case on the engine

block (C). Wipe off the excess liquid gasket on the

oil pan and chain case mating area.

NOTE: When installing the chain case, do not slide

the bottom surface on the oil pan mounting surface.

NOTE:

Apply a 1.5 mm wide bead of liquid gasket along

the broken lines (A).

Apply a 3.0 mm wide bead of liquid gasket to the

engine block upper surface contact areas (B) on

the chain case.

If you apply liquid gasket P/N 08718-0012, the

component must be installed with 4 minutes.

If too much time has passed after applying the

liquid gasket, remove the old liquid gasket and

residue, then reapply new liquid gasket.

21. Apply liquid gasket, P/N 08718-0001, or 08718-0009

evenly to the oil pan mating surface of the chain

case. Install the component within 5 minutes of

applying the liquid gasket.

NOTE:

Apply a 1.5 mm wide bead of liquid gasket along

the broken lines (A).

Apply a 5.0 mm wide bead of liquid gasket to the

shaded area (B).

If you apply liquid gasket P/N 08718-0012, the

component must be installed with 4 minutes.

If too much time has passed after applying the

liquid gasket, remove the old liquid gasket and

residue, then reapply new liquid gasket.

8 x 1.25 mm

31 Nm

(3.2 kgfm, 23 lbfft)

C

A

B

B

6-48

6 x 1.0 mm

12 Nm

(1.2 kgfm, 8.7 lbfft)

06/09/19 10:42:51 61SNC010_060_0049

23. Install the dipstick tube (A) with a new O-ring (B).

Connect the crankshaft position (CKP) sensor

connector (C) and the harness clamps (D).

31. Install the upper radiator hose (A), the lower

radiator hose (B), the water bypass hose (C), and

the heater hoses (D).

D

B

6 x 1.0 mm

9.8 Nm

(1.0 kgfm, 7.2 lbfft)

24. Install the side engine mount bracket, then tighten

the mounting nuts in the numbered sequence

shown (see step 16 on page 6-19).

25. Install the ground cable (see step 17 on page 6-19).

32. Install the purge control solenoid stay bolts (A) and

the fuel pipe nut (B), then connect the purge joint to

the clamp stay (C).

B

6 x 1.0 mm

12 Nm (1.2 kgfm, 8.7 lbfft)

E

26. Install the crankshaft pulley (see page 6-12).

27. Install the warm-up three way catalytic converter

(WU-TWC) and the under-floor three way catalytic

converter (TWC) (see step 26 on page 5-16).

D

C

28. Install the cylinder head cover (see page 6-22).

29. Install the water pump (see page 10-5).

30. Install the drive belt (see page 10-10).

A

6 x 1.0 mm

9.8 Nm (1.0 kgfm, 7.2 lbfft)

33. Install the clip (D), then connect the purge control

solenoid valve connector (E).

(contd)

6-49

06/09/19 10:42:51 61SNC010_060_0050

Cylinder Head

Cylinder Head Installation (contd)

34. Install the harness clamp (A), then connect the

camshaft position (CMP) sensor (B) and the engine

coolant temperature (ECT) sensor 1 connector (C).

36. Install the intake manifold (see page 9-5).

37. Install the air cleaner assembly (see page 11-381).

38. After installation, check that all tubes, hoses, and

connectors are installed correctly.

39. Inspect for fuel leaks. Turn the ignition switch

ON (II) (do not operate the starter) so the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat this operation two or three times, then

check for fuel leakage at any point in the fuel line.

40. Refill the radiator with engine coolant, and bleed

the air from the cooling system with the heater

valve open (see step 8 on page 10-7).

35. Install the connecting pipe (A) with a new O-ring (B).

Install the harness clamp (C), then connect the

knock sensor connector (D).

41. Do the CKP pattern clear/CKP pattern learn

procedure (see page 11-4).

42. Inspect the idle speed (see page 11-342).

43. Inspect the ignition timing (see page 4-18).

B

Replace.

A

C

6-50

6 x 1.0 mm

12 Nm

(1.2 kgfm, 8.7 lbfft)

Das könnte Ihnen auch gefallen

- 61SNC01 - 05 - Engine Mechanical - AssemblyDokument23 Seiten61SNC01 - 05 - Engine Mechanical - AssemblyangelvalladaresNoch keine Bewertungen

- 61SNC01 - 07 - Engine Mechanical - BlockDokument30 Seiten61SNC01 - 07 - Engine Mechanical - BlockangelvalladaresNoch keine Bewertungen

- Ryobi Mower Parts-ListDokument5 SeitenRyobi Mower Parts-Listdepeters3183Noch keine Bewertungen

- Homelite String Trimmer Parts Manual Trim N' Edge String Trimmer UT 20772Dokument12 SeitenHomelite String Trimmer Parts Manual Trim N' Edge String Trimmer UT 20772Jerry HNoch keine Bewertungen

- Sturmey-Archer AWC-SRC3-MANUAL PDFDokument5 SeitenSturmey-Archer AWC-SRC3-MANUAL PDFtudorbusuiocNoch keine Bewertungen

- 22. FUEL INJECTION SYSTEMDokument43 Seiten22. FUEL INJECTION SYSTEMIvan Escudero Bedmar50% (4)

- 4 Bar Linkage Calculator v3.0: Vehicle Specifications: Suspension Geometry: Geometry SummaryDokument16 Seiten4 Bar Linkage Calculator v3.0: Vehicle Specifications: Suspension Geometry: Geometry SummaryWagner MenezesNoch keine Bewertungen

- Sturmey Archer 8speedDokument2 SeitenSturmey Archer 8speedLuvikas Maybe KscNoch keine Bewertungen

- Batidora HL 600Dokument24 SeitenBatidora HL 600Abel G. CantonNoch keine Bewertungen

- AC Pressure Chart R-134a Temperature Pressure ChartDokument3 SeitenAC Pressure Chart R-134a Temperature Pressure ChartJoseph Tchagou PoumoNoch keine Bewertungen

- Seleccion y Diseño GerotorDokument28 SeitenSeleccion y Diseño GerotoremersonNoch keine Bewertungen

- Power Steering Ecu Assy: ReplacementDokument22 SeitenPower Steering Ecu Assy: ReplacementMusat Catalin-MarianNoch keine Bewertungen

- SM - Kymco Vitality 50 - Chapter 11 (Crankcase - Crankshaft)Dokument14 SeitenSM - Kymco Vitality 50 - Chapter 11 (Crankcase - Crankshaft)jose sousa oliveiraNoch keine Bewertungen

- RY30002ADokument6 SeitenRY30002ACool CatNoch keine Bewertungen

- TIS - Scion 2006 Xa RepairDokument5 SeitenTIS - Scion 2006 Xa RepairJuan Antonio Ochoa PadronNoch keine Bewertungen

- Transmission Removal and Installation atDokument8 SeitenTransmission Removal and Installation atJeferson SilvaNoch keine Bewertungen

- Scott Bonnar 45 Owners Manual S1942892-IDokument12 SeitenScott Bonnar 45 Owners Manual S1942892-IAndrew Wilson0% (1)

- Manitou Tower ServiceDokument35 SeitenManitou Tower ServiceKélio Wolfrane Santos MachadoNoch keine Bewertungen

- Whirlpool Awt 5088 4Dokument14 SeitenWhirlpool Awt 5088 4Gabriel BogasieruNoch keine Bewertungen

- Induction Module Assembly 9.5: GeneralDokument10 SeitenInduction Module Assembly 9.5: Generalvette512Noch keine Bewertungen

- Suzuki Samourai Repair Guides - Electronic Engine Controls - Idle Speed Control Solenoid (Iscs) ValveDokument1 SeiteSuzuki Samourai Repair Guides - Electronic Engine Controls - Idle Speed Control Solenoid (Iscs) ValveAymzNoch keine Bewertungen

- F-15097HtrCoreRepairF150 Exp 002Dokument20 SeitenF-15097HtrCoreRepairF150 Exp 002a76xlchNoch keine Bewertungen

- Shimano SLX HG81 Cassette Service ManualDokument1 SeiteShimano SLX HG81 Cassette Service ManualJose Luis GutierrezNoch keine Bewertungen

- JC125 17BDokument46 SeitenJC125 17BcomandoppNoch keine Bewertungen

- Axitec Ac260p-265p-270p PDFDokument2 SeitenAxitec Ac260p-265p-270p PDFJorge MonteiroNoch keine Bewertungen

- Illustrated Parts List 126400: Model SeriesDokument17 SeitenIllustrated Parts List 126400: Model SeriesAnonymous 3yaErv6XNoch keine Bewertungen

- Electro Magnetic Brakes for Heavy Duty ApplicationsDokument4 SeitenElectro Magnetic Brakes for Heavy Duty ApplicationsSumit SharmaNoch keine Bewertungen

- Engine Removal and Reassembly GuideDokument60 SeitenEngine Removal and Reassembly GuideVincent RoyNoch keine Bewertungen

- Briggs & Stratton Elite Portable Generator Parts List Model # 030241Dokument6 SeitenBriggs & Stratton Elite Portable Generator Parts List Model # 030241MarkNoch keine Bewertungen

- Tools ListDokument7 SeitenTools ListSantiago CamargoNoch keine Bewertungen

- Water Pump 8212 5 0l Removal and Installation PDFDokument4 SeitenWater Pump 8212 5 0l Removal and Installation PDFMichael HernandezNoch keine Bewertungen

- 07 - Timing Chain - RemovalDokument4 Seiten07 - Timing Chain - Removal08088338Noch keine Bewertungen

- Dodge Nitro KA - 2007 - ClutchDokument29 SeitenDodge Nitro KA - 2007 - ClutcheephantomNoch keine Bewertungen

- Alineadora 650 660 Lista de PartesDokument24 SeitenAlineadora 650 660 Lista de PartesHenry AlvaxNoch keine Bewertungen

- Articulated Dump TruckDokument2 SeitenArticulated Dump TruckFavorSea Industrial Channel Limited100% (1)

- SM - Kymco Vitality 50 - Chapter 05 (Engine Installation)Dokument11 SeitenSM - Kymco Vitality 50 - Chapter 05 (Engine Installation)jose sousa oliveiraNoch keine Bewertungen

- Graco Part ManualDokument22 SeitenGraco Part ManualandraNoch keine Bewertungen

- 03 Big River v1Dokument1 Seite03 Big River v1api-295593579Noch keine Bewertungen

- Condition:: MODELS: Musso (Y158), Korando (K116)Dokument1 SeiteCondition:: MODELS: Musso (Y158), Korando (K116)francisca19100% (1)

- Tecumseh Model Hm80 155128e Parts ListDokument11 SeitenTecumseh Model Hm80 155128e Parts ListAndy TuranskyNoch keine Bewertungen

- Tune-Up Guide For Geo Metro 1.0 Liter CarsDokument8 SeitenTune-Up Guide For Geo Metro 1.0 Liter CarsDerek JewettNoch keine Bewertungen

- Champion NGK Bosch NGK Denso NGK: RHT June 2009Dokument10 SeitenChampion NGK Bosch NGK Denso NGK: RHT June 2009ludlanNoch keine Bewertungen

- Sturmey-Archer SRF3 User ManualDokument4 SeitenSturmey-Archer SRF3 User Manualksjack100% (1)

- Ariel Leader Sheetmetal1Dokument20 SeitenAriel Leader Sheetmetal1Thunderbird3Noch keine Bewertungen

- 850BDokument0 Seiten850BAjay AjayNoch keine Bewertungen

- 2002 Peugeot 307 SWDokument137 Seiten2002 Peugeot 307 SWClaude SefakoNoch keine Bewertungen

- IPL, Partner, Colibri Plus, 1997-01, TrimmerDokument3 SeitenIPL, Partner, Colibri Plus, 1997-01, TrimmerEduard VečenajNoch keine Bewertungen

- Schema Generator Curent Kipor KGE6500XDokument1 SeiteSchema Generator Curent Kipor KGE6500XGeneratoare de Curent ElectricNoch keine Bewertungen

- Valve Lash Adjustment 8L 22L4 PDFDokument12 SeitenValve Lash Adjustment 8L 22L4 PDFMindo.silitongaNoch keine Bewertungen

- Interior: SectionDokument26 SeitenInterior: SectionJUAN CARLOS PAZNoch keine Bewertungen

- Installation, Start-Up, and Service InstructionsDokument44 SeitenInstallation, Start-Up, and Service InstructionsLau AlvarezNoch keine Bewertungen

- Marzocchi 2015 MTB CatalogueDokument40 SeitenMarzocchi 2015 MTB CatalogueEzequiel Acosta GarcíaNoch keine Bewertungen

- Tuff Support Product CatalogDokument113 SeitenTuff Support Product CatalogRula SiuNoch keine Bewertungen

- SM - Kymco Vitality 50 - Chapter 12 Carburetor)Dokument29 SeitenSM - Kymco Vitality 50 - Chapter 12 Carburetor)jose sousa oliveiraNoch keine Bewertungen

- Procedimietos CulataDokument15 SeitenProcedimietos CulataSERVICIO TECNICO AUTOMOTRIZ TONATONoch keine Bewertungen

- Transmission and Transfer Gear (Power Shift)Dokument8 SeitenTransmission and Transfer Gear (Power Shift)ariel rubioNoch keine Bewertungen

- Acura 3.5RL V6-3.5L 2001: Timing Belt: Service and Repair Removal and InstallationDokument28 SeitenAcura 3.5RL V6-3.5L 2001: Timing Belt: Service and Repair Removal and InstallationCarlos Gunter Tamayo MoralesNoch keine Bewertungen

- Clutch: SectionDokument22 SeitenClutch: SectionMatea Virgil SorinNoch keine Bewertungen

- Toyota Celica l4 2.2l Dohc 5s Fe 1990Dokument16 SeitenToyota Celica l4 2.2l Dohc 5s Fe 1990ORLANDO0301Noch keine Bewertungen

- Desmonte de Bomba de Inyeccion 3406cDokument5 SeitenDesmonte de Bomba de Inyeccion 3406cAnderson CamachoNoch keine Bewertungen

- Radiator Cooling Fan Motor Relay: Diagnostic AidsDokument5 SeitenRadiator Cooling Fan Motor Relay: Diagnostic AidsangelvalladaresNoch keine Bewertungen

- 151 Quick Ideas For Delegating and Decision MakingDokument192 Seiten151 Quick Ideas For Delegating and Decision MakingDjordje MarkovicNoch keine Bewertungen

- P0011 - DTC 2006 Kia SpectraDokument5 SeitenP0011 - DTC 2006 Kia Spectraangelvalladares100% (1)

- Timing Belt Adjustments - 2006 Kia SpectraDokument5 SeitenTiming Belt Adjustments - 2006 Kia Spectraangelvalladares100% (1)

- 2007 Honda Civic Hybrid - Engine CoolingDokument19 Seiten2007 Honda Civic Hybrid - Engine Coolingangelvalladares100% (1)

- Honda Civic Hybrid - SuspensionDokument43 SeitenHonda Civic Hybrid - SuspensionangelvalladaresNoch keine Bewertungen

- 2007 Civic Hybrid SystemDokument188 Seiten2007 Civic Hybrid SystemAngel Valladares67% (3)

- Civic Transeje Aut CVTDokument300 SeitenCivic Transeje Aut CVTCarlos Mendoza CambrónNoch keine Bewertungen

- 61SNC01 - 06 - Engine Mechanical - Cylinder HeadDokument50 Seiten61SNC01 - 06 - Engine Mechanical - Cylinder HeadangelvalladaresNoch keine Bewertungen

- Patient in The Institute of Therapy and Rehabilitation of Pondok Pesantren Ibadurrahman Tenggarong Seberang)Dokument10 SeitenPatient in The Institute of Therapy and Rehabilitation of Pondok Pesantren Ibadurrahman Tenggarong Seberang)Fitri AzizaNoch keine Bewertungen

- Field Technician UPS and Inverte - Question Bank.Dokument35 SeitenField Technician UPS and Inverte - Question Bank.shruti borkarNoch keine Bewertungen

- SIP Trunking Turnup GuideDokument8 SeitenSIP Trunking Turnup Guideashok7Noch keine Bewertungen

- Cylinder Head Valve Guide and Seat Inspection and RepairDokument1 SeiteCylinder Head Valve Guide and Seat Inspection and Repairnetifig352Noch keine Bewertungen

- TCDC Corporate IdentityDokument90 SeitenTCDC Corporate Identityชั่วคราว ธรรมดาNoch keine Bewertungen

- 23 - Eave StrutsDokument2 Seiten23 - Eave StrutsTuanQuachNoch keine Bewertungen

- 431510nt PDFDokument14 Seiten431510nt PDFkbryantperez2012Noch keine Bewertungen

- Dyefix-CF - Dye Fixing Agent With Excellent Fastness To Chlorine.Dokument10 SeitenDyefix-CF - Dye Fixing Agent With Excellent Fastness To Chlorine.L.N.CHEMICAL INDUSTRYNoch keine Bewertungen

- MS 2400 1 2010 P-TocDokument7 SeitenMS 2400 1 2010 P-Tocfauzirohani0% (1)

- Data FNC BatteriesDokument20 SeitenData FNC BatteriessalmanahmedmemonNoch keine Bewertungen

- Basic Education Research AgendaDokument41 SeitenBasic Education Research AgendaKristine Barredo100% (1)

- Amu Resume by KKMDokument2 SeitenAmu Resume by KKMapi-457874888Noch keine Bewertungen

- Indian Institute of Management Calcutta: Master of Business Administration For ExecutivesDokument9 SeitenIndian Institute of Management Calcutta: Master of Business Administration For ExecutivesBapun Mishra100% (1)

- Schematic Diagrams: Compact Component SystemDokument12 SeitenSchematic Diagrams: Compact Component SystemGustavo DestruelNoch keine Bewertungen

- Canadair Regional Jet 100/200 - Automatic Flight Control SystemDokument28 SeitenCanadair Regional Jet 100/200 - Automatic Flight Control Systemmamon113Noch keine Bewertungen

- Atheros Valkyrie BT Soc BriefDokument2 SeitenAtheros Valkyrie BT Soc BriefZimmy ZizakeNoch keine Bewertungen

- 81/253/INF For IEC Use Only 2004-08-27 International Electrotechnical Commission Technical Committee No. 81: Lightning ProtectionDokument3 Seiten81/253/INF For IEC Use Only 2004-08-27 International Electrotechnical Commission Technical Committee No. 81: Lightning ProtectionAndres Felipe Muñoz ANoch keine Bewertungen

- ResumeDokument3 SeitenResumeAadil AhmadNoch keine Bewertungen

- MFXi MPMi User Guide 02122010 DraggedDokument1 SeiteMFXi MPMi User Guide 02122010 DraggedDani BalanNoch keine Bewertungen

- DiMaggio Et Al 2001 Social Implication of The InternetDokument30 SeitenDiMaggio Et Al 2001 Social Implication of The InternetDon CorneliousNoch keine Bewertungen

- Warning Chime System: SectionDokument77 SeitenWarning Chime System: SectionmanualNoch keine Bewertungen

- Manual de ServicioDokument196 SeitenManual de ServicioJuan P. Ibanez CorreaNoch keine Bewertungen

- AST F2033 Hip JointDokument5 SeitenAST F2033 Hip Jointdeepdreamx6400Noch keine Bewertungen

- Star Burst EffectDokument22 SeitenStar Burst EffectDexter AlcantaraNoch keine Bewertungen

- مساهمة البرمجيات المدمجة في تحسين جودة خدمات الإدارة الجبائية (عرض برمجية جباية -تيك نموذجا) PDFDokument18 Seitenمساهمة البرمجيات المدمجة في تحسين جودة خدمات الإدارة الجبائية (عرض برمجية جباية -تيك نموذجا) PDFAnis AnisNoch keine Bewertungen

- Creative Photography Lab 52 Fun Exercises For Developing Self-Expression With Your CameraDokument146 SeitenCreative Photography Lab 52 Fun Exercises For Developing Self-Expression With Your Camerajwestmister100% (2)

- 2011 PG Parts CatalogDokument181 Seiten2011 PG Parts CatalogHaitem FarganiNoch keine Bewertungen

- 9829d23b-6e45-4cbd-b732-f870faff49a0Dokument6 Seiten9829d23b-6e45-4cbd-b732-f870faff49a0Swamy Dhas DhasNoch keine Bewertungen