Beruflich Dokumente

Kultur Dokumente

b1gd r2 (Goulds)

Hochgeladen von

Bagus Arief WibowoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

b1gd r2 (Goulds)

Hochgeladen von

Bagus Arief WibowoCopyright:

Verfügbare Formate

TECHNICAL BROCHURE

B1GD R2

FEATURES

Single phase pumps now have built-in overload protection. See control panel

note on page 3.

Impeller: Silicon bronze, multi-vane semi-open, with pump-out vanes for

mechanical seal protection. Balanced for smooth operation.

Grinder Cutter System: The anti-roping design, hardened cutter is keyed to the

motor shaft for positive drive. The cutter ring is specially designed to be reversed

when the first side wears out thus doubling its life and reducing maintenance

costs. The cutter system is designed and tested to pass items found in normal

wastewater.

Casing: Heavy duty cast iron, volute type for maximum efficiency. Use with

A10-12 guide rail system for ease of installation and maintenance.

Dual Mechanical Seals: Silicon carbide vs. silicon carbide outer seal and ceramic

vs. carbon inner seal, stainless steel metal parts, BUNA-N elastomers. Upper and

lower shaft seals are positioned independently and are separated by an oil-filled

chamber. Optional Silicon/Tungsten Carbide outer seal available.

Optional Seal Sensor Probe: Located in oil-filled chamber. If pumpage should

begin to leak past lower seal it indicates to pump control panel a fault has

occurred. Requires optional Seal Fail Circuit in the control panel.

Fasteners and Pipe Plugs: 300 series stainless steel.

AGENCY LISTINGS

1GD

SUBMERSIBLE GRINDER PUMP

DUAL SEAL WITH OPTIONAL SEAL SENSOR PROBE

US

Tested to UL 778 and CSA 22.2 108 Standards

By Canadian Standards Association

File #LR38549

Goulds Water Technology

Wastewater

APPLICATIONS

MOTORS

Designed for high head sewage applications where a

gravity system is not practical. Ideal for pressure sewage systems.

Fully submerged in oil-filled chamber. High grade

turbine oil surrounds motor for more efficient heat

dissipation, permanent lubrication of bearings and

mechanical seal for complete protection against

outside environment.

Class F insulation

Single Phase: 2 HP, 208 or 230 volt, 60 Hertz,

3450 RPM, 14/4 power cord. Motor has built-in

overload with automatic reset. Start capacitor,

run capacitor and starting relay are required and

will be located in the control panel. See Recommended Control Panels in chart on this bulletin.

Three Phase: 2 HP, 200, 230, 460 or 575 V, 60 Hz,

3450 RPM. 14/4 STOW. Overload protection must

be provided in starter unit.

Designed for Continuous Operation: Pump ratings

are within the motor manufacturers recommended

working limits and can be operated continuously

without damage when fully submerged.

Bearings: Upper and lower heavy duty ball bearing

construction for precision positioning of parts and

to carry thrust loads.

Power (Sensor) Cables: Severe duty rated, oil and

water resistant. Epoxy seal on motor end provides

secondary moisture barrier in case of outer jacket

damage and to prevent oil wicking. 20 foot standard

with optional lengths available.

O-ring: Assures positive sealing against contaminants and oil leakage.

Shaft: 300 series stainless steel, keyed design, short

overhang for minimum shaft deflection.

Pump is capable of running dry without damage to

mechanical components.

SPECIFICATIONS

Pump:

Solids handling capabilities: 3" maximum

Discharge: 114" NPT removable flange

Capacities: up to 46 GPM

Total heads: up to 106 feet TDH

Motor:

2 HP, 3450 RPM, 60 Hz

Class "F" insulation

Rated for continuous duty fully submerged

Maximum Fluid Temperature:

104 F continuous duty, 140 F intermittent duty

Single Phase:

208 or 230 volt

Built-in, auto reset, on-winding motor overload

Three Phase:

200, 230, 460 or 575 volt

Class 10 ambient compensated, overload protection

required in control panel.

NOMENCLATURE DESCRIPTION

1st, 2nd and 3rd Characters Discharge Size and Type

1GD = 1" discharge, grinder, dual seal

4th Character Mechanical Seals

5 = silicon carbide/silicon carbide/BUNA lower seal

and carbon/ceramic/BUNA upper seal (standard)

3 = silicon carbide/tungsten carbide/BUNA lower

seal and carbon/ceramic/BUNA upper seal (optional)

5th Character Cycle/RPM

1 = 60 Hz/3500 RPM

5 = 50 Hz/2900 RPM

6th Character Horsepower

G = 2 HP

7th Character Phase/Voltage

1 = single phase, 230 V 5 = three phase, 575 V

2 = three phase, 200 V 6 = three phase, 380 V

3 = three phase, 230 V 8 = single phase, 208 V

4 = three phase, 460 V

PAGE 2

8th Character Impeller Diameter

A = 558", Standard

C = 4"

B = 5"

D = 4"

9th Character Cord Length (Power and Sensor)

A = 20' (standard) F = 50'

D = 30'

J = 100'

10th Character Options

S = Seal fail, moisture sensing circuit1

E = Epoxy paint

Last Character Option

H = Pilot duty thermal sensors1 (3 phase only!!)

These options add a 2-wire or 4-wire sensor cord to the

pump and require optional control panel circuits to operate. See panel options on control panel bulletin BCP5.

Goulds Water Technology

Wastewater

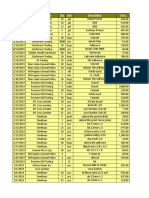

MODEL AND MOTOR INFORMATION

Order No.

HP Phase Volts RPM

1GD51G1AA

1GD51G8AA

1GD51G2AA

1GD51G3AA

230

15.5

208

17.5

1GD51G4AA

1GD51G5AA

Locked

KVA

Rotor

Code

Amps

Full Load

Efficiency

Start

Line-Line

1.37

0.62

79.0

14.0

44.8

81.0

12.0

37.4

460

6.0

18.7

81.4

575

4.8

14.0

83.2

230

3450

FEATURES (continued)

Effective with December 2005 (M05) Date Codes Single-Phase 1GD Pumps Contain a

Built-in, Auto Reset Overload.

Important Control Panel Requirements and Notes:

1) See panel bulletin BCP5 for other available options.

2) These pumps require a magnetic contactor, start and run

capacitors and a starting relay in the control panel.

Resistance

96.0

200

Maximum

Amps

1.8

NA

2.8

11.1

Power Weight

Cord

lbs.

110

14/4

STOW

20'

LONG

105

18.0

Pump

Order No.

Pump

Seal Fail

Circuit

1GD51G1A_

1GD51G8A_

No

1GD51G1A_S

1GD51G8A_S

Yes

Voltage /

Phase

Recommended

Control Panel

Simplex

Duplex

230 / 1

S1GD2

D1GD2

208 / 1

S1GD2

D1GD2

230 / 1

S1GD2H

D1GD2J

208 / 1

S1GD2H

D1GD2J

3) CP-1GDB Capacitor packs with starting relays are available on product bulletin BCPCAP. They are for certified

panel shops to build into a custom panel. Field installing

capacitor packs into a S10020 or D10020 will negate the

UL listing on that panel and is therefore not permissible.

MATERIALS OF CONSTRUCTION

Item

No.

Part Name

1

2

Impeller, multi-vane

Castings

3

4

5

6

7

Shaft-Keyed

Fasteners

Ball bearings

Power cable

O-ring

Outer

Mech. No.

Seal

6

Material

Standard

1179

1003

300 Series SS

300 Series SS

Steel

STOW, 20 feet

BUNA-N

Service

5

3

Rotary Stationary

Elastomers

Metal

Parts

OPT

10K22

Heavy

duty

Silicon Tungsten

Carbide Carbide

BUNA-N

300

Series SS

STD

10K28

Mild

abrasives

Silicon Carbide

BUNA-N

300

Series SS

Material Code

1003

Engineering Standard

Cast iron ASTM A48 Class 30

1179

Silicon bronze ASTM C87600

PAGE 3

APPLICATION DATA

DIMENSIONS

Maximum Solid Size

N/A

Minimum Casing Thickness

Casing Corrosion Allowance

Maximum Working Pressure

50 PSI

Maximum Submergence

50 feet

(All dimensions are in inches. Do not use for construction purposes.)

16"

ROTATION

8"

Fully submerged for continuous

operation

Minimum Submergence

6" below top of motor for intermittent

operation

812

22

40C (104F) continuous operation

Maximum Environmental

Temperature

60C (140F) intermittent operation

CONSTRUCTION DETAILS

14/3, type SJTOW: single phase

Power Cable Type

1112

14/4, type STOW: single phase

KICKBACK

14/4, type STOW: all three phase

Sensor Cable Type

16/2, type SJTOW: heat sensor or seal fail only

18/4, type SJTOW: seal/heat

sensor

ROTATION

Motor Cover

Gray Cast Iron ASTM A48 Class 30

Bearing Housing

Gray Cast Iron ASTM A48 Class 30

Seal Housing

Gray Cast Iron ASTM A48 Class 30

Casing

Gray Cast Iron ASTM A48 Class 30

Impeller

Motor Shaft

Cast Bronze ASTM B584 C87600

12

AISI 300 Series8Stainless

Steel

Motor Design

NEMA 56 Frame, oil filled with Class F Insulation

Optional: Motor Seal

Fail (Moisture) Detection

Seal fail sensor in an oil-filled seal chamber.

Connect to an optional relay in control panel.

Optional: Motor

Thermal Protection

1 and 3

Normally closed on-winding thermostats open

534

12

at 275 F (135 C) and close at 11211

F (78

C).

Require terminal connection in the control panel.

KICKBACK

Single Phase: Built-in, auto reset overload

Three Phase: require ambient compensated

Class 10 protection in the control panel.

Motor Overload

Protection

534

22

External Hardware

300 Series Stainless Steel

Impeller Type

Semi-open with pump out vanes on back shroud

Cutter

Two blades; type 440C stainless steel

Oil Capacity

Seal Chamber

1.5 quarts

Oil Capacity

Motor Chamber

4.5 quarts

114 NPT

DISCHARGE

612

3

STANDARD PARTS

Ball Bearing Upper

Single row ball SKF 6203-2Z

Ball Bearing Lower

Single row ball SKF 6206-2Z

Mechanical Seals Standard

Carbon/Ceramic; Upper

Silicon Carbide/Silicon Carbide - Lower

Mechanical Seals Optional

Silicon Carbide/Tungsten Carbide Lower

O-Ring Stuffing Box

BUNA-N, AS 568A-256

O-Ring Motor Cover

BUNA-N, AS 568A-166

Standard

Foot

Xylem Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (866) 325-4210

Fax: (888) 322-5877

www.gouldswatertechnology.com

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

2014 Xylem Inc.

B1GD R2

November 2014

Optional Pump Legs

Order No. 4K639

(Set of 3)

Das könnte Ihnen auch gefallen

- Standarisasi Surgical Room Menurut AHSRAE - A07 - 07SI - TABELDokument1 SeiteStandarisasi Surgical Room Menurut AHSRAE - A07 - 07SI - TABELBagus Arief WibowoNoch keine Bewertungen

- TRAFODokument1 SeiteTRAFOBagus Arief WibowoNoch keine Bewertungen

- Cable Tray Catalogue - Three Star v3.3 (Low Quality)Dokument27 SeitenCable Tray Catalogue - Three Star v3.3 (Low Quality)Bagus Arief WibowoNoch keine Bewertungen

- Cable Trench Installation GuideDokument12 SeitenCable Trench Installation GuideTimothy LeonardNoch keine Bewertungen

- Completion of Professional Security 19" LED MonitorDokument2 SeitenCompletion of Professional Security 19" LED MonitorBagus Arief WibowoNoch keine Bewertungen

- Air Change RatesDokument3 SeitenAir Change RatesErick QuintoNoch keine Bewertungen

- nx-100 ImDokument113 Seitennx-100 ImBagus Arief WibowoNoch keine Bewertungen

- DuctDokument60 SeitenDuctdenizkund100% (5)

- Air Conditioning Duct Design-Lecture 38Dokument20 SeitenAir Conditioning Duct Design-Lecture 38Mrityunjay TiwariNoch keine Bewertungen

- SilabusELKA (ITS)Dokument37 SeitenSilabusELKA (ITS)keputihutaraNoch keine Bewertungen

- Air Conditioning Duct Design-Lecture 38Dokument20 SeitenAir Conditioning Duct Design-Lecture 38Mrityunjay TiwariNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Schedule Change ManagementDokument10 SeitenSchedule Change ManagementFreydell A BarretoNoch keine Bewertungen

- PricesDokument16 SeitenPricesMingVitugNoch keine Bewertungen

- Flans ASME B16.5 PDFDokument47 SeitenFlans ASME B16.5 PDFMircea Dan StanciuNoch keine Bewertungen

- Catálogo Transair LegrisDokument32 SeitenCatálogo Transair LegrisJeisson HinostrozaNoch keine Bewertungen

- Utica PEG-C Gas Fired Steam Boilers BrochureDokument4 SeitenUtica PEG-C Gas Fired Steam Boilers Brochuree-ComfortUSA100% (1)

- Job Pile Design-450 (R1)Dokument58 SeitenJob Pile Design-450 (R1)Deren p. JacobeNoch keine Bewertungen

- Ansys - VM ListDokument6 SeitenAnsys - VM ListRUDHRA DHANASEKARNoch keine Bewertungen

- HighRise Building Construction ProfileDokument161 SeitenHighRise Building Construction ProfileHamayet Rasel86% (7)

- Fire Standpipe System Basic Course BNBC & NFPADokument28 SeitenFire Standpipe System Basic Course BNBC & NFPAMRZ100% (2)

- Fire Test Methods: Astm Nfpa UL ISO IEC Astm E05Dokument13 SeitenFire Test Methods: Astm Nfpa UL ISO IEC Astm E05Aloka KarunarathneNoch keine Bewertungen

- LunaCel VBX H13 FilterDokument1 SeiteLunaCel VBX H13 FilterKurkuma PlusNoch keine Bewertungen

- Is 883 - 2016 - Reff2021 Design of TimberDokument29 SeitenIs 883 - 2016 - Reff2021 Design of Timbermano chandranNoch keine Bewertungen

- Cost Control and Cost PlanningDokument3 SeitenCost Control and Cost PlanningMariam Mustafa0% (1)

- PlanholdersDokument9 SeitenPlanholdersAdam AbrahamNoch keine Bewertungen

- USTP Reinforced Concrete Design CourseDokument18 SeitenUSTP Reinforced Concrete Design CourseKatherine Shayne Yee100% (1)

- Utility Duct Drawings From BCL Joydebpur-Mymensing 4 Lane Project - OptDokument1 SeiteUtility Duct Drawings From BCL Joydebpur-Mymensing 4 Lane Project - OptParvez Syed RafiNoch keine Bewertungen

- Benefits and Design Tipsfor ChillersDokument4 SeitenBenefits and Design Tipsfor ChillersSharon LambertNoch keine Bewertungen

- Lab Tests in ConstructionDokument17 SeitenLab Tests in Constructionsridhar k.l50% (4)

- FM Should Be A Master of Building's All Tecnnical SystemsDokument61 SeitenFM Should Be A Master of Building's All Tecnnical SystemsmohammadNoch keine Bewertungen

- Construction Stage Report PDFDokument5 SeitenConstruction Stage Report PDFAnonymous KRVmsq5BZBNoch keine Bewertungen

- Types of DrawingsDokument25 SeitenTypes of DrawingsRajesh Prabtani100% (1)

- Case Study 1 - C.E.P.T. Ahmedabad: Planning, Circulation & FunctionDokument7 SeitenCase Study 1 - C.E.P.T. Ahmedabad: Planning, Circulation & FunctionHasan NedariyaNoch keine Bewertungen

- Moderate Mary Ma ThewDokument4 SeitenModerate Mary Ma ThewShyam Kumar0% (2)

- 80043-846-01 Standard ResolutionDokument24 Seiten80043-846-01 Standard ResolutionAlejandro Hernandez GarciaNoch keine Bewertungen

- Layher Speedyscaf: Technical BrochureDokument60 SeitenLayher Speedyscaf: Technical BrochureMarco Antonio NaranjoNoch keine Bewertungen

- Approved Hydraulic Fluids For Putzmeister Concrete PumpsDokument1 SeiteApproved Hydraulic Fluids For Putzmeister Concrete PumpsNazeeh Abdulrhman AlbokaryNoch keine Bewertungen

- 6 Lege Guide SS17 Property RightsDokument2 Seiten6 Lege Guide SS17 Property RightsTPPFNoch keine Bewertungen

- Architecture Project Garment Factory.Dokument13 SeitenArchitecture Project Garment Factory.Veè Vêk JåyswãlNoch keine Bewertungen

- Iron Wafer Type Check Valve: Kitz Cast Iron ValvesDokument1 SeiteIron Wafer Type Check Valve: Kitz Cast Iron ValvesAndy SetyawanNoch keine Bewertungen

- Tappi Tip 0402-18Dokument19 SeitenTappi Tip 0402-18pedroNoch keine Bewertungen