Beruflich Dokumente

Kultur Dokumente

Mercedes Benz M102 Engine Control With EZL Characteristics

Hochgeladen von

Stephenson100%(2)100% fanden dieses Dokument nützlich (2 Abstimmungen)

3K Ansichten20 SeitenMercedes Benz M102/103 Continous Injection System - Electronic (CIS-E) with EZL

Originaltitel

Mercedes Benz M102 Engine Control with EZL characteristics

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenMercedes Benz M102/103 Continous Injection System - Electronic (CIS-E) with EZL

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

100%(2)100% fanden dieses Dokument nützlich (2 Abstimmungen)

3K Ansichten20 SeitenMercedes Benz M102 Engine Control With EZL Characteristics

Hochgeladen von

StephensonMercedes Benz M102/103 Continous Injection System - Electronic (CIS-E) with EZL

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 20

15-1250 Testing electronic ignition system with variable characteristics EZL

‘Operation no. of operation texts and work units or standard texts

‘and fat rales:

15-1250.

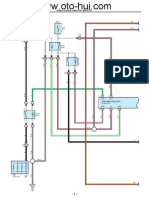

Connection diagram for engine tester with oscilloscope

arve

a

rey

Nw

Rt

ris.

S50

=_-

Coolant temperature sensor (EZUIKE,LH),4-pin S20/2

Battery

Crankshaft positon sensor "

ZL igniton contd unit xt

‘Spark plugs 10

EZL resistance vimming phig 2

High voltage distributor 030

RA 18.1132-1260"

on fi

Throtte valve switch, ful loadidle spo0d

recognition

gato cov

Diagnoste sockevtorminal Block, terminal TD

Seaman on toate pte

Engine ster with osciloscope

Special tools

Commercially available tools and testers

Se

201 589 00 99 00.

15 54

Designation

€.g. Make, order no.

Multimeter ‘Sun, DMM-5

Fluke, Multimeter 23,

Hermann, Avometer 2003

Engine tester Hermann, Datascope 9800

Aa

Pay attention to the safety regulations when

working on the ignition system (15-0505).

‘Switch off ignition when plugging in and

unplugging the connectors at the EZL ignition

contro! unit

Note

If dealing with faults regarding handling, first of

all test the ignition. Then, continue fault finding

at the KE injection system,

‘The test is divided into two sections:

a) Engine not running

In this section the basic functions of the ignition

system are tested.

W the fault cannot be rectified, continue trouble-

shooting in section b), "Engine running,”

ee PAIS 1132-12502

Bosch, MOT 301/400

‘Sun, 2110

BEAR, D ACE

b) Engine running

Faults in the ignition timing or at the

corresponding components can affect vehicle

handling,

Test data

Resistances (test data from 0 - 100 °C)

Ignition coil primary (terminals 1 and 15) 9 [03-06

Ignition coit secondary (terminals 1 and 4) ko [13

Position indicator coil resistance

(terminals 7 and 31¢) 9 | 680-1200

insulation (terminal 7 and ground) _k@ | > 200

Distributor cap per terminal, @ | 700-1300

distributor rotor,

spark plug connector

Voltages, engine not running, ignition switched on

Battery voltage v [> 115

Terminals 15 and 31 (contacts § and 2 diagnostic socket) V [> 11

Between terminals 15 and 1

(contacts § and 4 diagnostic socket) vo

4-pin round connector, terminals 15 and 31 vie

4-pin round connector, terminals 16 and 31 v[>1

Voltages at starting speed

Battery voltage v]= 10

Ignition coil terminal 15 v [= 10

Ignition coil terminal 1 v [85-105

Voltages at idle speed

Battery voltage v [13-445

Ignition coil terminal 15 v [13-145

Ignition coil terminal 1 v [rasa

Dwell angle

At starting speed 1-30"

‘At 8200 rpm 24 - 53°

Ignition timing point at starting speed in ° KW [TOC +2°

te 15.1192-125083

EZL ignition timing point

Engine

EZL ignition

control unit

Engine speed

Amin

Ignition timing point in * CA before TOC.

Resistance

trimming plug

position or

type of fuel

without

vacuum

with vacuum

Basic version KAT/RUF and G)

KAT, © KAT

103.940

103.941

103.942

103.943

003 645 95 32

003 545 96 32

005 545 84 32

005 545 86 32

006 545 73 32

006 545 75 32

008 545 61 32,

008 545 63 32

011 545 88 32

011 545 89 32

3200

25-29

19-23

40-44

Idle speed

‘Sand N

TAY

TA

103.980

003 645 1432

003 545 15 32

3200

1 leaded

23-27

39-43

Idle speed

Premium

e413

e413

3200

3! unleaded

19-23

39-43

Idle speed

premim

8-13

813

103.981

103.983

103.985

004 545 44 32

004 545 46 32

005 545 85 32,

005 545 87 32

006 545 74 32,

006 545 76 32,

007 545 86 32

007 545 87 32

008 545 62 32

008 645 64 32

3200

27-31

40-44

21-25,

40-44

Idle speed

103.982

004 545 44 32

004 545 46 32

005 545 85 32

005 545 87 32

006 545 74 32

006 545 76 32

103.984

007 545 86 32

007 545 87 32

Sand N

National versi

ion GD 1986, GS) 198

6")

103.981

103.983

004 $45 69 32

005 545 49 32

005 545 88 32

3200

29-33

23-27

40-44

Idle speod

Sand N

TOC +2

TOC +2

') For GH) KAT, CS) KAT, same values as basic version KAT.

Se FA 15192-12504

EZL ignition timing point

Engine

EZL ignition’

control unit

Engine speed

timin

Ignition timing point in * CA betore TOC.

Resistance

trimming plug

position or

type of fuel

without

vacuum

with vacuum

National version @

103.940

103.942

005 545 84 32

005 545 86 32

006 $45 73 32

006 545 75 32

008 545 61 32,

008 545 63 32

3200

Reference

19-23

40-44

{dle speed

resistor 220 0

7A

7A

103.981

103.983

004 545 44 32

004 545 46 32

005 545 85 32,

005 £45 87 32,

006 545 74 32,

006 545 76 32

008 545 62 32,

008 545 64 32

3200

Reference

21-25,

40-44

Idle speed

resistor 220 0

ear

er

National version

103.940,

103.942

005 545 84 32,

005 545 86 32

006 545 73 32

006 545 75 32

008 545 61 32

008 545 63 32

3200

Reference

25-29

40-44

Idle speed

resistor 750 @

TA

m1

103.981

103.983,

103.985

004 545 44 32

004 545 46 32

005 545 85 32

005 545 87 32,

006 545 74 32,

006 545 76 32

008 545 62 32

008 545 64 32

3200

Reference

27-31

40-44

Idle speed

resistor 750 0

en

en

National version @

103.940

103.942

005 545 84 32

005 545 86 32

006 545 73 32

006 545 75 32,

008 $45 61 32

008 545 63 32

008 545 95 32

009 545 79 32

3200

Reference

25-29

40-44

Idle speed

resistor 750 0

ma

ma

103.981

103.983,

004 $45 44 32

004 545 46 32

005 545 85 32

005 545 87 32

006 545 74 32

006 545 76 32

008 545 96 32

009 545 80 32

3200

Reference

27-31

49-44

Idle speed

resistor 750 9

et

eA 15.1192-125015

Resistances of EZL resistance trimming plug (R16)

Position Resistance

EZL resistance trimming plug

ka "EZL-ECE”

"EZL-KAT™ "EZL"

1 1

2.4

1.3

0.75

0.47

0.22,

O/T) Mo] al m)>

sTelelsl2[slo

STzlefojels

a) Engine not running

‘Symbols for testers

~

Contact

Connector

‘© Spark plugs, ignition cables, distributor rotor

and distributor cap in proper mechanical and

electronic order.

Test e.g. by visual inspection, measuring

resistance and ignition oscilloscope.

© Battery voltage 11 - 14 V

ee 15.1132-12506

Symbols for test mode with multimeter

=O Multimeter

DC voltage mode

=@> Multimeter

Resistance mode

+@+ Oscilloscope

Note

If the specification of a main test step, e.g. test

step 1.0, is in order, continue with the next main

test step, 0.9. test step 2.0.

It the specification of a main test step, 0.9. test

step 1.0, is not achieved, continue test with

sub-test step, ¢.9. test step 1.1

‘See appropriate wiring diagram volume for

wiring diagrams.

Test | Test scope [Test connection [Operation’ | Specifi-._| Possible cause/Remedy

step Requirement | cation

10 | Voltage Nia Unplug pin [11-14 V | Test voltage supply via

supply < =O >-|round ignition lock,

tml.31 tml 18 | connector at Test ground cable,

EZL conteol Test wiring and contacts

unit. according to wiring

Ignition: ON diagram, replace if

necessary

44 Ground Ne Ignition: OFF <1 | Open circuit in wiring

cable + Oe

tm. 31

2.0 | Crankshart us Ignition: OFF |680- | Replace crankshaft position

position |—< =@"= >—|Unplug 1200.2 | sensor (L5)

sensor (LS) |tmi.31d tml. 7 | crankshaft

Position sensor

‘connector (LS)

at EZL control

unit

at us ‘Unplug Us 21°V | Signal too small or no

— =@+ >~| crankshaft see signal + replace position

tml. 31d tml. 7| position sensor | "diagram | sensor,

connector (L5) |crank- | different voltage levels -+

atEZL control | shaft | test segments on

unit. position | fywheeldriven plate (visual

Engine: start |sensor | check)

Starting speed. | signal | Signal in order -» replace

(5 | EZL control unit

22 | Insulation at L5 | ignition: OFF | 2200 k@ | Visual check of control

sensor col |1 =@"+ >| Unplug cable,

imi. 7 | crankshaft Replace crankshaft position

position sensor

‘connector (L5)

at EZL control

unit

sensor (L5)

-_

RA 15.1192-12507

Test [Test scope [Test connection [Operation | Specifi-_ | Possible cause/Remedy

step Requirement _| cation

3.0 | Dwell angle | Engine tester Engine: start [1-30 | Dwell angle not to tolerance

at starting or = replace EZL control unit

speed 1-50 % |No dwell angle + test no-

toad current cutott

3.1 |Nodload x1 lgnition: ON [OV Replace EZL control unit

cure [5 —¢ =@"= > 4 and ignition coil

cutott

40 [Ignition 1 Ignition: OFF | <1 | Replace ignition coil

coll (T1) | tm, 1 =@'tmi.as | Disconnect

primary cables at

ignition coil

5.0 [Ignition 11 Ignition: OFF [8-13 k2 | Replace ignition coil

coil (T1) tml, 1 =*@"*= imi, 4 | Disconnect

secondary cables at

ignition coil

6.0 | Primary | Engine tester Engine: start |200- | Replace EZL control unit

voltage 350 V

Oscilloscope image

Parade primary

7.0 [Primary | Engine teste Engine: start |See | Replace EZL control unit

current * diagram

limiting | Oscilloscope image: good

Superposition image

secondary super-

position”

(iagno-

sis

Manual

Engine,

Vol. +,

Register

°)

me a5. 1192-12500

Test | Test scope |Test connection [Operation’ | Speciti- | Possible cause/Remedy

step Requirement _| cation

8.0 ignition Engine tester Engine: start [8 - Soe test stops 8.1-8.5

voltage 20 kV

Oscilloscope image:

Parade secondary

8.1 | Distributor Distributor cap | Ignition: OFF |700- | Replace distributor rotor

cap (each . Remove 1300 0

terminal —_ | inside outside | distributor cap. | per

individually) Disconnect | terminal

ignition cables.

8.2 | Distributor Distributor | Ignition: OFF |700- | Replace distributor rotor

rotor rotor Remove 1300 2

o> distributor cap. | and

Middle Peak visual

check

8.3 | Ignition af 5/3] Ignition: OFF [<1 — | Replace ignition cable

cable tml. 4 =@"= tml. 4 | Disconnect terminal 4

terminal 4 at ignition cable

igntion coil terminal 4 at

1) ignition coil

(71) and at

distributor cap.

8.4 [Ignition Ignition ‘Spark | Ignition: OFF | 700- | Replace ignition cable with

cables with | cable plug| Disconnect |1300 2 | spark plug connector

spark plug connector |igntion cable | per

connector ~O- at HT ignition

distributor | cable

($513) and

spark plug

connector

85 |Spark plugs | Visual inspection ignition: OFF | Electrode | Replace according to

Remove all | gap condition

spark plugs. | 0.8 mm

3.0 Ignition —_ | Engine tester Engine: start [TDC | Test ignition coll and HT

timing Starting speed | +2° | distributor

point at

starting

speed

=e FA 18 1122-12509

b) Engine running

‘Symbols for testers

< Contact

= Connector

Preconditions for test

© Engine at operating temperature.

© Coolant temperature <95 °C.

‘* Test ignition timing point at idle speed.

‘© Test ignition timing point at 3200/min with

and without vacuum (detach vacuum tine at

EZL control unit).

Pay attention to resistance trimming plug

position.

‘Switch off engine during test only if stated.

AA 15.1192-1250710

‘Symbols for test mode with multimeter

=@*- Multimeter

Resistance mode

-@-~ Oscilloscope

Pay attention to notes for work on breakerless

transistorized ignition system (15-0505).

Note

If the specification of a main test step, e.g. test

step 2.0, is in order, continue with the next

main test step, @.g. test step 3.0.

IF the specification of a main test step, e.g. test

step 2.0, is not achieved, continue test with

sub-tost stop, 0.9. test step 2.1

‘See appropriate wiring diagram volume for

wiring diagrams.

Test |Test scope |Test connection |Operation’ | Specifi- | Possible cause/Remedy

step Requirement _| cation

1.0 ignition | Engine tester Engine: start | See table | Test EZL resistance

timing ldle speed — | of trimming plug (R16),

point ignition | Test EZL reference resistor

timing | (R16/1) (Pay attention to

points | national version and Part

o.),

Test throttle valve switch,

tull oadidle speed

recognition (S29/2),

Test pressure sensor,

Test coolant temperature

sensor (81/2),

Coolant temperature

>95 °C

20 0 [ez R16 | ignition: OFF | See table | Test @ values in resistance

resistance |1 ~@*+ > 3|Compare of resis- | trimming plug,

trimming ‘engine version | tances of | Replace resistance

plug and resistance |EZL | trimming plug

(R16) ") ‘timing plug | trimming

inscription. | plug

Unplug 4-pin | (R16)

‘coupling at

EZL control

unit.

1 Excont GS GD GD

> PAS 192-1250"

Test [Test scope |Test connection Operation’ | Specifi- | Possible cause/Remedy

step Requirement _| cation

a1 few Ignition: OFF [A = | Replace EZL resistance

resistance Compare 8 2.4k2 | trimming plug

trimming engine version |. 1.3k2

plug (R16) and resistance }D 750 2

4) trimming plug JE 470 0

inscription |F 220 0

(see table G oa

resistances

EZL trimming

plug (R16).

Unplug 4-pin

coupling at

EZL control

unit. Test

clockwise

between

middle and

‘outer connec-

tor pins.

22 lez 16/1 | Ignition: OFF | Replace EZL resistance

reference |. ~@"+ >— 3| Pay attention trimming plug

resistor to national

(r6/1) 2) version and

Part no., see

table. Unplug

4-pin coupling

at EZL control

unit.

23 fea Rigi Ignition: OFF [Part no. | Replace EZL resistance

reference |2.— =@*+ — 1] Unplug EZL and @ | trimming plug

resistor reference | value

(Rieit) *) resistor. see table

EZL

reference

resistor

(ri6/)

» ceo @ © @

4 n¥@O@

Se A 15.1132-1250N2

Test Test scope |Test connection Operation” | Speciti- | Possible cause/Remedy

step Requirement _| cation

30 | Throttle Nuva Ignition: OFF | idle ‘Adjust or replace throttle

valve LL @>>2 position | valve switch,

switch, full approx. | Rectify open circuit in

load/die 02 wiring according to wiring

speed Full load | diagram

recognition approx.

(s2972) 09.

Part load

position

See also

table "re-

sistances

at throttle

vaive

switch

full load’

idle

speed re-

‘cognition

(s292)"

40 [Pressure | Engine tester Vacum fine at |When — | Check vacuum line from

sensor Ez contro! | vacuum | intake manifold to EZL

unit dis- fine con- | control unit for leaks.

connected. nected, | if no fault found, replace

Coupling ignition | EZL contro! unit.

disconnected | timing

from throttle | point

valve switch, | must

Engine: start | advance.

Engine speed’

gear lever

position: idling.

ee AIS 1192-125019

Test [Test scope |Test connection | Operation’ —_| Specifi- | Possible cause/Remedy

step Requirement | cation

5.0 Coolant N1/2| Ignition: OFF | Q values, | Replace cable according to

tempera- | 1 =@'+ >~1]Unplug 4-pin | see aia- | wirng diagram.

ture sensor coupling at. | grammed | Replace cootant tempera-

(6112) EZL control | coolant | ture sensor (81/2)

unit, test 2 | tempera-

values at two | ture

temperatures | sensor

(2/4-pin)

Example:

+ 20°C

2.28-

272k

+ 80°C

290-

3640

6.0 — [ignition | Engine tester Detach’ ‘See table | Replace EZL ignition

timing vacuum fine at }ignition | control unit

point EZL contro! | timing

unit. points

Engine: start

7.0 | Dwell angle | Engine tester Vacuum tine |24-59° | Replace EZL ignition

‘at 3200 rpm and 4-pin control unit

coupling EZL

control unit

connected.

Engine: start

ee 84 15.1132-1250716

Test [Test scope [Test connection [Operation | Specifi- | Possible cause/Remedy

step Requirement _| cation

ao [HT Visual check Ignition: OFF Distributor cap, mechanical

distributor Remove damage in HT distributor,

(S53) distributor cap. replace HT distributor i

A necessary.

Pay close

attention to

satety notes

(15-0508).

2.0 — | interter- =O* Ignition: OFF |1kQ — | Replace faulty parts

ence Remove

supression distributor cap.

resistors, Measure

distributor resistances

cap, distri- individually.

butor rotor,

spark plug

connector

10.0 Ignition —_| Engine tester Ignition: ON [Good | Replace ignition coil

coil Engine: start | poor, see

Oscitloscop image: idle speed —_| analyzing

Parade oscillo-

scope

image

(Biagno-

sis

Manual,

Engine,

Vol. 1

Register

©).

y

Ignition voltage: (average value) 6 ~ 16 KV. Diference of cylinders to each other 3 kV

Ignition voltage rise: the gnton voltage measured at dle speed must rise by not ore than 6 KV when engine speed is

increased up o 3000 rom by blppng the vote

‘Combustion curve starting point: 0.6 ~ 1.2 KV. Dilorence of the cylinders to each othor 0.3 KV.

‘Combustion time: 1.9 - 2.5 ms. Dilerence of the cylinders to each other <0.3 ms.

ee FA 15.1132-1250115

Location of components

Round power supply connector at EZL ignition

control unit (N1/2)

EZL ignition contro! unit (N1/2)

‘Arrow 4:pin connector sonsor

EZL ignition control unit (N1/2)

Avrow Vacuum line

eA 15 1992-125016

EZL resistance trimming plug (R16)

ry

B 24 Ko

c 13 ka

D 075 = ka

E 047 ka

F 022 4k

G@ oo ka

Bottom part of connector, EZL resistance

trimming plug (R16)

EZL reference resistor (R16/1)

Part no. Resistance | National

version

000 5402281 | 220 2 ®

000 502401 17500 [O@

Diagnostic socketterminal block (X11)

“Torminal TN

A 15.1132-1250017

EZLKE, LH) coolant temperature sensor, 4-pin

(8112)

Connect 4-pin connector, coolant temperature

sensor (B11/2)

Pin assignment (positions

stamped in connector)

2

3

4

EZUAKR tomporature

KE tomporature sonsor

(Ground, EZUAKR ignition

contr nit

(Ground, KE conal unt

Coolant temperature sensor (81172), 2-pin

—_

RA 15.1192-125018

EZL KE

Biz

KE

Diagram, coolant temperature sensor

(2'4-pin)

High voltage distributor (S5/3)

Igition coil (T1)

Terminal 1

> Terminal 15

era 5.1192-1250719

#8

ve sessed genesd GUG0HE DEE

ai

tll ape

i |, e

eS

Connector, crankshatt position sensor (L5)

Diagram, crankshaft position sensor (LS) signal

Plug connection, throttle valve switch full

loadidle speed recognition (S29/2x1)

Resistances at throttle valve switch full load/idle

‘speed recognition (S29/2)

Idle speed approx. 0 Q

Full load approx. ©

—3id

P15-0240-13

fro: Lens

1:

oO

> aH 15.1192-1250/20

$20/2

ae contact

Ful load

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Wiring Diagram ECU 2KD-FTVDokument13 SeitenWiring Diagram ECU 2KD-FTVDam Nguyen87% (95)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Man Edc7 c32Dokument12 SeitenMan Edc7 c32Adam92% (13)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Service Manual Common Rail System (CRS) - DensoDokument134 SeitenService Manual Common Rail System (CRS) - DensoThang Tong86% (7)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Softing DTS Monaco Data SheetDokument4 SeitenSofting DTS Monaco Data SheetStephensonNoch keine Bewertungen

- Euro4 vehicle diesel engines 199 - 397 kW (270 - 540 hpDokument6 SeitenEuro4 vehicle diesel engines 199 - 397 kW (270 - 540 hpBranislava Savic63% (16)

- S60me C8 - 2 Gi PDFDokument413 SeitenS60me C8 - 2 Gi PDFStephenson100% (2)

- TCUDokument9 SeitenTCUStephensonNoch keine Bewertungen

- Heavy Vehicle Technology (381) : Editor R BrooksDokument7 SeitenHeavy Vehicle Technology (381) : Editor R Brooksnz578427Noch keine Bewertungen

- CAESAR HW Implementers Guide v1.1Dokument42 SeitenCAESAR HW Implementers Guide v1.1StephensonNoch keine Bewertungen

- Double Coin Dual Spacing InfoSheetDokument2 SeitenDouble Coin Dual Spacing InfoSheetStephensonNoch keine Bewertungen

- Commercial Vehicle Regulations 2018Dokument15 SeitenCommercial Vehicle Regulations 2018StephensonNoch keine Bewertungen

- 16SP (En) PDFDokument139 Seiten16SP (En) PDFSomda valentinNoch keine Bewertungen

- Irf9530, Sihf9530: Vishay SiliconixDokument8 SeitenIrf9530, Sihf9530: Vishay SiliconixKrista TranNoch keine Bewertungen

- 16speed P (EN)Dokument3 Seiten16speed P (EN)StephensonNoch keine Bewertungen

- EAHCV DDI 1 Basic TrainingDokument1 SeiteEAHCV DDI 1 Basic TrainingStephensonNoch keine Bewertungen

- ASTronic Product BrochureDokument8 SeitenASTronic Product BrochureRajib BiswasNoch keine Bewertungen

- SD Connect MultiplexerDokument7 SeitenSD Connect MultiplexerStephenson100% (2)

- VCX Plus PicturesDokument2 SeitenVCX Plus PicturesStephenson100% (1)

- TSL Pro Install T InfoDokument12 SeitenTSL Pro Install T InfoStephensonNoch keine Bewertungen

- Manual VAS5054Dokument41 SeitenManual VAS5054Tony MedranoNoch keine Bewertungen

- EPA2010ElectricalModels M2106 M2112 108SD 114SDDokument10 SeitenEPA2010ElectricalModels M2106 M2112 108SD 114SDDavid FuentesNoch keine Bewertungen

- SIAUT Fuel Injection Systems-DieselDokument39 SeitenSIAUT Fuel Injection Systems-DieselAbhishek KohliNoch keine Bewertungen

- VVDI Prog Programmer V4.5.8 User ManualDokument52 SeitenVVDI Prog Programmer V4.5.8 User Manualobd365Noch keine Bewertungen

- Iecex Ul 14 0012x Issue 0Dokument3 SeitenIecex Ul 14 0012x Issue 0StephensonNoch keine Bewertungen

- High Pressure System PumpDokument2 SeitenHigh Pressure System PumpStephensonNoch keine Bewertungen

- CANoe - Diva FactSheet enDokument2 SeitenCANoe - Diva FactSheet enStephensonNoch keine Bewertungen

- 8K/16K 5.0V Microwire Serial EEPROM: FeaturesDokument12 Seiten8K/16K 5.0V Microwire Serial EEPROM: FeaturesStephensonNoch keine Bewertungen

- V2I816218Dokument5 SeitenV2I816218StephensonNoch keine Bewertungen

- Wirelesss TelematicsDokument2 SeitenWirelesss TelematicsStephensonNoch keine Bewertungen

- OnRoad Bus en 10132 Doppelseiten Web ScreenDokument19 SeitenOnRoad Bus en 10132 Doppelseiten Web ScreenmilivojNoch keine Bewertungen