Beruflich Dokumente

Kultur Dokumente

SPE 145987 Ten Year Evolution and Field History of Design Changes For A Torque and Drag Reduction Performance Drilling Sub

Hochgeladen von

lulalala8888Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SPE 145987 Ten Year Evolution and Field History of Design Changes For A Torque and Drag Reduction Performance Drilling Sub

Hochgeladen von

lulalala8888Copyright:

Verfügbare Formate

SPE 145987

Ten Year Evolution and Field History of Design Changes for a Torque and

Drag Reduction Performance Drilling Sub

John E. McCormick and Chad D. Evans, SPE, Weatherford International, and Cameron Kirkpatrick, SPE, The

University of Texas at Austin

Copyright 2011, Society of Petroleum Engineers

This paper was prepared for presentation at the SPE Asia Pacific Oil and Gas Conference and Exhibition held in Jakarta, Indonesia, 20 22 September 2011.

This paper was selected for presentation by an SPE program committee following review of information contained in an abstract submitted by the author(s). Contents of the paper have not been

reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material does not necessarily reflect any position of the Society of Petroleum Engineers, its

officers, or members. Electronic reproduction, distribution, or storage of any part of this paper without the written consent of the Society of Petroleum Engineers is prohibited. Permission to

reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of SPE copyright .

Introduction

The need for advances in the robustness and versatility of downhole tools is increasing as well geometries

become more complex. With more challenging wells being drilled everyday even the most advanced tools need

to be improved upon. This is typically where research and development (R&D) engineers play a vital role. They

work closely with operations personnel to create and constantly improve downhole tools. As service companies

typically are the R&D arm of the oilfield, tools and improved designs are primarily market driven. This paper will

explore the development of a mechanical friction reduction tool (MFRT), which is sometimes necessary in ERD

and complex geometry wells to overcome torque and drag limitations.

A tool starts as a concept that will overcome an obstacle when drilling or completing a well or ensure the safety

and cost effectiveness of an operation. The R&D engineers take this idea and develop it into a first generation

tool. They then meet with their managers, fellow engineers and operations managers to discuss the concept, the

functionality, and the technical and financial viability of the tool. The engineers then go back and refine the

design of the tool, after which is scheduled another design review meeting. This process undergoes several

iterations, with more technical and managerial personnel involved each meeting, until a final design is agreed

upon. This design review process is intended to manage the progress of the design, keeping check on the

financial, functional, and implementation aspects of the tool.

Once the first articles have been manufactured and field trials run, these tools are run commercially. Close watch

is kept on the use of the tools and any issue and need for improvement are addressed by the design team.

Constant assessments of the tools performance are carried out. This paper describes the development of a tool

over a ten year period using the MFRT as a case study. We look at specific changes made to the tool, why these

changes were implemented, and field trial results for the different modifications.

Overview of the Mechanical Friction Reduction Tool (MFRT)

The MFRT design was acquired from a start-up company. This concept for the drilling tool to reduce torque and

drag was good, but the drilling tool was designed from a cementing perspective by a company that specialized in

casing accessories. A series of immediate changes were needed. Other modifications came as a result of using

the tools in more strenuous environments andinput from operations personnel.

The MFRT is a sub based tool consisting of a 4 ft long mandrel with a clamp-on casting. The casting consists of 6

pods offset at 60 degrees each, which contain 2 rollers per pod. The rollers are used to reduce axial drag.

Between the casting and the mandrel, or sub body, is a bearing sleeve which reduces rotational friction, or

SPE 145987

torque. The sub rotates with the string while the casting and sleeve remain stationary. Figure 1 illustrates the

design.

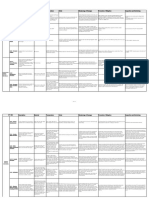

Fig 1. Design of the Torque and Drag Reduction Sub

The MFRT is designed to be a very versatile tool. It can be used in almost any downhole operation when jointed

drill pipe is used and is particularly helpful in drilling and liner hanging operations where torque or lack of string

weight is the limiting factor. The tools can be run in cased and open hole. Generally tools are run 1 per stand,

though applications with exceptionally severe side loads may necessitate 3 per 2 stands.

Because the MFRTs are sub based and 4 feet long, they can often be racked back in the derrick without removing

the tools from the string. Where torque or drag is a limiting factor in a well, these tools are a very effective way

for operators to achieve drilling goals. The next section describes several of the changes made from field

experience that the MFRT has undergone over the past 10 years.

Design History and Changes

The tool was originally designed by a company specializing in casing accessory tools and based on the idea that it

would be primarily used in cased hole. This presented a problem in many applications; in these applications the

MFRT tools would become the weak link in the string. In order to increase the integrity of the tools within the drill

string the material processing steps were changed in order to produce a tool that has a minimum yield strength

of 120,000 psi.

Other material changes included varying the alloying elements in the carbon steel used to manufacture the sub.

This change was made to increase the strength of the material. Initially, the material being used for the mandrels

had acceptable yield strength; however, this strength existed primarily at the original outer surface of the

material. The strength decreased as the distance from the OD of the material decreased in the radial direction.

Thus the internal strength deteriorated the further away from the outer-most portion the material was located.

Any machining of the material was necessary during or after manufacture would remove the higher strength

material.

The jar grade material still has a drop off in strength when moving into the material from the outer diameter, but

the drop off is linear instead of exponential, and has a very small slope. Thus the strength is virtually the same

and does not depend on the type or amount of machining work performed. These changes were made after

obtaining the original IP from the start-up company in order to bring the tools material up to par with their other

downhole tools such as drilling jars.

SPE 145987

Another immediate and the most readily apparent change made to the MFRT was the switch from a casting

design of 4 roller pods to a design with 6 roller pods. Each pod became smaller in size when the change from 4 to

6 occurred (Fig. 2), however, the number and size of the rollers remained the same. In the 4 pod design tool each

pod contained 3 rollers and were spaced 90 out of phase. The hinge pin was also redesigned to be made more

robust.

Fig 2. Six Pod Casting Design of the Torque and Drag Redcution Tool

The functionality of the tool was improved because the pods are now staggered (every other pod is on the

opposite end of the casting from the other (Fig. 2) and spaced at only 60 out of phase. This means that the

contact area between the rollers and the wellbore is now more evenly dispersed, thus the load that the tool must

take is moved away from the center and dissipated more evenly across the mandrel. This improvement not only

increased the functionality of the tool in cased hole scenarios but also allowed the MFRT to be run in open hole

conditions.

Another important modification that involves the MFRTs drag reducing rollers came after the pod design change

took place. Originally, both in the 4 and 6 pod tools, the rollers were manufactured with either a circular or a flat

shape. With this design the rollers were mainly loaded on their edges, this was especially the case with the flat

rollers, which caused excessive roller wear and could even lead to casting damage as the rollers tended to

mushroom and bite into the pods (Fig. 3 and Fig. 4). This lessens the drag reduction effect of the tool and

decreases the life of the casting. Figure 3 shows a roller that has deformed by developing a lip around the edge.

Figure 4 shows an undamaged roller security slot on the left and a slot on the right that has been worn by a

deformed roller.

Fig 3 & 4. Mushrooming and Casting Wear

The severity of this damage was very dependent on the size of hole that the tools were placed in. The use of each

size of tool is limited to a certain range of hole sizes. Even within this range of sizes the amount of contact

between the flat or circular rollers and the wellbore varies with size. This variation can either increase or decrease

the severity of the wear experienced with this design. One might think that the rational design change would be

to design a tool where the rollers have the same radius of curvature as the casing. The problem is that this would

require a specific tool for each combination of drill pipe and casing/hole sizes, which is impractical.

For this reason the rollers are now designed with a radius of curvature which allows one size of MFRT to be run in

several casing or open hole sizes without the severe side loading and wear experienced previously. Figure 5

SPE 145987

shows the same size casting in multiple casing sizes. As the casing size increases, the rollers have less contact

area with the wellbore. However, with the elliptically shaped rollers the contact area is still maintained away

from the edge of the roller, reducing the risk for roller wear and deformation.

Fig 5. Multiple Casing Sizes for the Same Sized MFRT Casting

Normal, or acceptable, wear to the rollers can be seen below in Figure 6. Under the loading commonly

experienced by these tools, a wear line may develop in the middle of the roller, but this does not affect the

performance or maintenance of the tool. The rollers are simply replaced post-job.

Fig 6. Acceptable Wear on the Sub

A recent improvement made with regard to the rollers dealt with their position in the pods. The rollers were

moved up, radialy away from the mandrel, and above the inner diameter of the casting. This change prevents the

rollers from contacting the mandrel even if the bearing sleeve is allowed to wear beyond its acceptable limit. This

reduces both the cost and likelyhood of repairs to the coating significantly when the MFRTs are run in

environments with loading near their published limits.

The Equivanlent Circulating Densities (ECDs) caused by the MFRT are low with the offset, out of phase six pod

design. The smaller and more efficiently spaced pods improve the flow paths of the drilling fluids. This is

illustrated in the CFD image in Fig. 7.

SPE 145987

Fig 7. Flow Test on the Torque and Drag Reduction Sub

Another material change involves the hardfacing material applied to the OD of the journal area of the mandrel.

This change has been one of the most significant made to the MFRT in recent years. In order to protect the

journal area from significant wear due to high side loads, debris, cuttings and coarse mud particles being caught

between the journal and bearing sleeve, a hardfacing must be applied. This material needs to be strong, hard (i.e.

abrasion resistant) as well as ductile. Also, the material must have a very strong bond to the steel material of the

sub and have very low porosity.

Over the years, numerous amounts of test have been conducted on various hardfacing solutions, these tests

include bond strength tests, fatigue tests as well as others. Overall the tests showed that some of the initial

hardfacings used on the tools were adequate but could be improved upon. This is where a new application

process, using a higher velocity than previously used, was introduced to mechanically coat the journal area. The

type of coating has also changed, a special alloy tungsten carbide has been chosen as the best coating for the

MFRTs. This coating and application process has proven to provide the best combination of ductility, strength,

abrasion resistance and porosity of any other processes tested. Reworking of tools due to wear can be a costly

process where hardfacing is concerned and many steps have been taken to produce a coating that will last the

lifetime of the tool.

More abrasion resistant coatings are necessary for operation in extremely abrasive formations or for use during

casing exits. As deep, horizontal casing exits become more common, achieving the weight to set single-trip

mechanical systems becomes difficult, necessitating the use of additional T&D reduction methods to ensure a

successful operation. Since the MFRT is mud lubricated, cuttings travel into and out of the space between the

sleeve and the sub body. Metal shavings from the casing exit, however, become embedded in the sleeve, causing

wear to the sub bodies (Fig.8 and Fig. 9).

Fig 8 & Fig 9. Wear on the Sub Bodies

SPE 145987

A significant factor in fatigue failure is stress concentrations. Fatigue cracks can result in a parted drill string,

which is a catastrophic mode of failure for a drill string. These tools are asked to go into very severe drilling

conditions and not only survive, but make the operation achievable. MFRTs are placed in the most severe

sections of wells when T&D forces threaten the ability of the rig to reach TD or complete the well.

As with every downhole string component used in deviated wells, stress concentrations in often severe doglegs

are unavoidable. However, the stress concentrations can be designed to impart a minimal negative effect. At the

very beginning of the MFRT the mandrel had a 90 transition; this type of transition causes the highest stress

concentration possible. This was quickly changed to a different transition, decreasing the stress concentration

and providing a more stable transition.

With the initial transition design of the tool, an issue was encountered on a drilling run and a design review was

conducted where the tranisiton was redesigned. A series of FEA models of the MFRT mandrel body were

produced and various changes were tested. The FEA models revealed that a specific type of transition produced

the smallest stress concentration. For this reason the tools now feature this modification.

An MFRT sub with a journal area that supports the casting and rollers is shown in Figure 10 and 11 bent under

stress in a dogleg. The maximum allowable dogleg for tools can be determined by thorough testing to ten million

cycles, or revolutions, without generating fatigue cracks. If a tool can withstand ten million cycles with no fatigue

cracks, it is considered to be able to rotate infinitely at that dogleg with the loading paramaters used.

Fig 10. Stress Concentration Locally

Fig 11. Stress Concentration for the Entire TooThe bearing sleeve is one of the most important pieces of the

MFRT. It is designed to withstand the abrasion generated by rotating the sub within the non-rotating casting

while the tool is under extreme torsional, axial and radial forces associated with ER wells. As such, their design is

critical to the success of the tool. Many iterations of the bearing sleeves have been used during the existence of

the tools, from the relatively simple early designs to the highly engineered sleeves the tools feature

today.Operators require a sleeve that performs under the extremely harsh conditions the tools are exposed to as

well as a sleeve that will last for several hundred hours of drilling. Material testing for the sleeves has been

extensive, with many different materials, including PEEK, being tested. The end results of these test has landed

SPE 145987

on a carbon-composite material which has been found to provide the best wear resistance and reliability of

manufacturing. However, the trade off to using this material is its increased abrasiveness; this is where the

increased attention to the hardfacing already mentioned becomes increasingly important.

The bearing sleeves are designed to be the sacrificial member for wear. This keeps both the cost of the tools and

repair costs low enough to keep the tools commercially viable. In the past there have been several instances of

tools being run beyond the capabilities of the bearing sleeves. When this happens the sleeves wear thin and the

tools cannot perform at their highest level. This also causes an increase in repair cost and may necessitate

changing the sleeves during a bit trip. The sleeves can be manufactured with a wear indicator on their ID. Once

this indicator is no longer visible the sleeves need to be replaced. The wear indicator grooves serve a dual

purpose; they are also radial and thrust lubrication grooves (Fig. 12). Another design highlight of the sleeves

include protrusions into the roller pod areas (Fig. 13), which help to keep the castings and the bearing sleeves as

one non-rotating part once installed on the mandrel. This helps to reduce unnecessary wear on the OD of the

sleeves and maintains the torque reduction capability of the tools.

Fig 12. Radial and Thrust Lubrication Grooves

Fig 13. Protrustion Areas

Conclusion

Both with initial design and the redesign of a tool, there is a significant amount of engineering required to

produce a tool that is capable of operating in the types of downhole environements that exist in todays oilfield.

Even with the intelligent concepts and thorough designs of drilling and completion tools, modifications are

needed either to correct problems with the design or to enable those tools to perform better and operate in even

more severe environments.

A set of standard running limitations for the MFRTs has been developed based on both engineering calculations

and field experience. Hole size, side loads, and dogleg severities (DLS) are restricted to insure safe use. There are

a range of hole sizes that each tool can be run in. These sizes are determined by the elliptical shape of the rollers.

SPE 145987

If the hole size is not within the appropriate size range, the rollers will be point loaded and risk deformation. The

side loading and DLS both contribute to cumulative fatigue in the sub. The fatigue tests run for the tools

determine the maximum DLS the tools can handle. Each run the tools are modeled by an applications engineers

and a decision is made based on the results of the model to determine the benefits of running the tools.

Standards for the tools have been developed over time, but because each run has its own unique complications,

an engineer is consulted before each use.

ACKNOWLEDGEMENTS

The authors wish to thank Weatherford for their support and permission to publish this paper.

REFERENCES

1.

Long, T.P., McCormick, J.E. and Frilot, M.A., Inaccessible Drilling Targets and Completions Operation Made

Possible by the Alleviation of Excessive Torque and Drag, IADC/SPE 125991, IADC/SPE Middle East

Drilling Technology Conference & Exhibition, Manama, October 2009.

2.

Mason, C.J., Williams, L.G., and Murray, G.N., Reinventing the Wheel Reducing Friction in High-Angle

Wells, SPE 63270, SPE Annual Technical Conference and Exhibition, Dallas, October 2000.

Das könnte Ihnen auch gefallen

- Great Health Direct: A Medical Plan To Protect You Against Life's UncertaintiesDokument9 SeitenGreat Health Direct: A Medical Plan To Protect You Against Life's Uncertaintieslulalala8888Noch keine Bewertungen

- Mto - F.Dokument36 SeitenMto - F.lulalala8888Noch keine Bewertungen

- SPE-174567-MS A Novel Technique For Enhanced Oil Recovery: In-Situ CO - Emulsion GenerationDokument13 SeitenSPE-174567-MS A Novel Technique For Enhanced Oil Recovery: In-Situ CO - Emulsion Generationlulalala8888Noch keine Bewertungen

- Streaming Potentials at Hydrocarbon Reservoir ConditionsDokument14 SeitenStreaming Potentials at Hydrocarbon Reservoir Conditionslulalala8888Noch keine Bewertungen

- SPMSDokument7 SeitenSPMSlulalala8888Noch keine Bewertungen

- Rent.: Emulsion. DemulsifirsDokument3 SeitenRent.: Emulsion. Demulsifirslulalala8888Noch keine Bewertungen

- Numerical Simulation of Emulsion Flow Through Porous Media M.R. Islam S.M. Farouq AliDokument12 SeitenNumerical Simulation of Emulsion Flow Through Porous Media M.R. Islam S.M. Farouq Alilulalala8888Noch keine Bewertungen

- Simulation of O/W Emulsion Flow in Alkaline/Surfactant Flood For Heavy Oil RecoveryDokument13 SeitenSimulation of O/W Emulsion Flow in Alkaline/Surfactant Flood For Heavy Oil Recoverylulalala8888Noch keine Bewertungen

- OTCbservationDokument9 SeitenOTCbservationlulalala8888Noch keine Bewertungen

- Eor/Ior Additional Reading Available at TheDokument1 SeiteEor/Ior Additional Reading Available at Thelulalala8888Noch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Unit 4 Study Guide Solutions - Kinetics & ThermoDokument3 SeitenUnit 4 Study Guide Solutions - Kinetics & ThermoPenguin/CatNoch keine Bewertungen

- Estimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnsDokument10 SeitenEstimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnssdddNoch keine Bewertungen

- KLEN 2207 Cream CleanerDokument3 SeitenKLEN 2207 Cream CleanerSneha Nagaokar100% (1)

- SPE-10489-PA PVT y Scal PDFDokument9 SeitenSPE-10489-PA PVT y Scal PDF'Andres TorregrosaNoch keine Bewertungen

- Section A: Multiple Choice Questions (Compulsory)Dokument19 SeitenSection A: Multiple Choice Questions (Compulsory)ivyNoch keine Bewertungen

- Asahi KaseiDokument24 SeitenAsahi KaseiRitam GhoshNoch keine Bewertungen

- Thordon Material Selection Guide General Pumps Rev 201307Dokument1 SeiteThordon Material Selection Guide General Pumps Rev 201307NuM NaNoch keine Bewertungen

- Crystal Structure Refinement and Hydration Behaviour of Doped Tricalcium AluminateDokument10 SeitenCrystal Structure Refinement and Hydration Behaviour of Doped Tricalcium AluminateJuliano. PQMNoch keine Bewertungen

- Doc316 53 01223Dokument6 SeitenDoc316 53 01223Abdul GhafoorNoch keine Bewertungen

- Low Power CMOS VLSI Circuit Design (LPVD) : Dr. Veena S ChakravarthiDokument43 SeitenLow Power CMOS VLSI Circuit Design (LPVD) : Dr. Veena S ChakravarthiVeena SridharNoch keine Bewertungen

- Manual de Parte Bomba Gorman RuppDokument38 SeitenManual de Parte Bomba Gorman RuppLuis Fernando Arias FlorezNoch keine Bewertungen

- HILTI ExBar Rebar Design Soft WareDokument30 SeitenHILTI ExBar Rebar Design Soft WareAline Tabet Abi SaadNoch keine Bewertungen

- 99ebook Com Msg00388 PDFDokument15 Seiten99ebook Com Msg00388 PDFM Sarmad KhanNoch keine Bewertungen

- Practice Exam 2.4Dokument6 SeitenPractice Exam 2.4jamalNoch keine Bewertungen

- HFM Vatell SpecsDokument3 SeitenHFM Vatell SpecsPro_td_Vivimos_9063Noch keine Bewertungen

- A Sustainable Bioplastic Obtained From Rice StrawDokument12 SeitenA Sustainable Bioplastic Obtained From Rice StrawNovrynda Eko SatriawanNoch keine Bewertungen

- Compozitia Smaltului Si DemineralizareaDokument10 SeitenCompozitia Smaltului Si DemineralizareaMadalina Elena TapeleaNoch keine Bewertungen

- Planck's Law - WikipediaDokument88 SeitenPlanck's Law - Wikipedia朱岳宸Noch keine Bewertungen

- eArt-Calculating Overpressure From BLEVE ExplosionsDokument6 SeiteneArt-Calculating Overpressure From BLEVE ExplosionsJurizal Julian LuthanNoch keine Bewertungen

- XII PhysicsDokument55 SeitenXII PhysicsCharu BhanotNoch keine Bewertungen

- Ball Valve SeatDokument2 SeitenBall Valve Seatmrkadu_61Noch keine Bewertungen

- 19 Heat of Combustion MGDokument5 Seiten19 Heat of Combustion MGmanuelscribdgonzalesNoch keine Bewertungen

- Ch. 15 Review AnswersDokument2 SeitenCh. 15 Review AnswersJose PopoffNoch keine Bewertungen

- WEDECO LBXSeriesDokument8 SeitenWEDECO LBXSeriesÁrpád VassNoch keine Bewertungen

- Engineering Piping Design Guide Fiberglass Reinforced Piping SystemsDokument36 SeitenEngineering Piping Design Guide Fiberglass Reinforced Piping Systemsoscarhdef100% (1)

- Improved Procedures For The Genetic Transformation of Rhodobacter CapsulatusDokument1 SeiteImproved Procedures For The Genetic Transformation of Rhodobacter CapsulatusSerena XuNoch keine Bewertungen

- EccentricDokument3 SeitenEccentricChypraNoch keine Bewertungen

- 571 SummaryDokument3 Seiten571 SummarySimbu Arasan100% (1)

- Silver Clusters in Zeolites: Structure, Stability and PhotoactivityDokument1 SeiteSilver Clusters in Zeolites: Structure, Stability and PhotoactivityJan HermannNoch keine Bewertungen

- Flow Simulation and Static Structural Analysis On Pelton TurbineDokument7 SeitenFlow Simulation and Static Structural Analysis On Pelton TurbineRahul ReddyNoch keine Bewertungen