Beruflich Dokumente

Kultur Dokumente

Maxxforce 11 y 13

Hochgeladen von

Ruju RujuCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Maxxforce 11 y 13

Hochgeladen von

Ruju RujuCopyright:

Verfügbare Formate

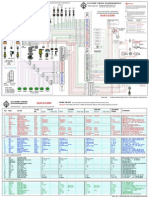

ENGINE WIRING DIAGRAM (Side 1)

Engine

Coolant

Temp.

(ECT

Sensor)

Retarder

Control

Air-Charge System

Cooling System

Engine Retarder

1

2

EGR

Control

Valve

Fuel System

Timing System

Fuel Rail Engine

Pressure

Fuel

(FRP)

Pressure

Sensor

(EFP)

Sensor

Camshaft Crankshaft

Position

Position

Sensor

Sensor

(CMP)

(CKP)

Lube System

Manifold

Manifold Absolute

Air Temp. Pressure/

Intake Air

(MAT)

Temp 2

Sensor

(MAP/IAT2)

Sensor

Engine

Coolant

Temp. 2

(ECT2

Sensor)

Engine

Oil

Temp.

(EOT)

Sensor

Engine

Oil

Pressure

(EOP)

Sensor

Coolant Mixer

Valve (CMV)

Boost

Exhaust

Control

Gas

Recirculation Solenoid

(BCS)

Position

Valve

(EGRP)

Sensor

A Navistar Company

E1-55

E1-73

E1-72

E1-54

E1-40

E1-20

E1-37

E1-43

E1-80

E1-61

E1-24

E1-21

E1-38

E1-85

E1-83

E1-25

E1-81

E1-62

E1-70

E1-76

E1-57

E1-84

E1-65

E1-77

E1-58

E1-46

E1-67

E1-49

EGR VREF

EGRP

EGR GND

BCS GND

BCS

ITVC GND

ITVC

E1-32

E1-87

E1-39

E1-4

E1-2

E1-36

E1-18

FPCV

FPC GND

EGR GND

EGRC

GND

GND

B+

B+

Intake

Throttle

Valve

(ITV)

1 Fuel

Pressure

Control Valve

(FPCV)

Breather

Heater

Air System

Fuel System

ITVD

Exhaust Lambda Sensor

(ELS)

RC

RC GND

ELS

ELS VGND

ELSTRIM

ELSPCUR

ELSHTR

ELSHTR GND

BB2-8

BB2-5

BB2-3

BB2-2

BB2-1

BB2-6

BB2-7

BB1-7

BB1-5

BB1-6

BB1-2

BB1-3

BB1-4

BB2-4

BB1-1

Ignition

For detailed vehicle circuit information, refer to the following

Truck documents:

Chassis Electrical Circuit Manual

Electrical System Troubleshooting Guide

Schematic Lines

Color Code

Description

Body

Builder

Connectors

Red

Blue

Green

Brown

Black

+12 VDC

+5 VDC

Signal Circuit

Data Communication

Ground Circuit

Battery

Ground

Cold Start Assist System

CSS

IAT

Cold Start

Solenoid

(CSS)

Value

36-pin

Connector E2

ECL1

ECL2

EFANS

EFAN

DDS

VSS-L

VSS-H

ATA-H

ATA-L

X3-4

X3-2

X2-2

X1-18

X3-8

X4-9

X4-10

X4-20

X4-21

X3-12

X3-13

CAN-H

CAN-L

Chassis

Harness

Connector C

VIGN

CAN-H

CAN-L

K-Line

8

10

9

13

Vehicles have

EITHER a single speed,

two-speed, or

variable speed fan.

Fuselink

B+

Single or Two-Speed

Electronic Fan Control

B

A

X2-6

X2-13

11

17

28

23

22

30

APS

SIG GND

VBREF

IVS 1150

DIAG 1150

GND

EIM PWR

MPR

VIGN

VIGN

ACM PWR

24

34

18

35

36

1

42

37

15

38

Trans

Conn

120

85

A

B

30

86

20A

20A

30

AC

Ignition

Switch

10A

5A

Engine Coolant

Level (ECL)

EIM/ACM

Relay

85

86

87

OTHER CAN

CONNECTIONS

EIM/ACM

Relay

Connector

MPH

RPM

Instrument

Cluster

ESC

10A

Continued

Side 2

A

Note on Fuses:

This document is for

reference only concerning

physical fuse placement in the

vehicle wiring.

Fuses labeled in blue are

included in the vehicle wiring.

25A

10A

Horton

Fan

APS/IVS

87

Public CAN-H

Public CAN-L

VIGN

Continued

Side 2

B

CAN-H

CAN- L

X4-18

X4-24

X4-4

X4-23

X4-15

X3-6 & 7

X4-1 & 2

X3-5

X3-3

Horton

Fan

Variable

Electronic Fan Control

Cab

Interface

Connector

Private

Private

Note on Electronic Fan:

OUT1

E1-8

E1-10

E1-11

E1-17

E1-3; 9

E1-14; 15

E1-1; 7

E1-12; 13

E2-13

E2-4

E2-7

E2-3

E2-36

E2-22

E2-21

E2-35

E2-17

E2-6

E2-2

E2-12

E2-19

E2-30

E2-23

E2-31

E2-24

E2-8

E2-5

9 Relay

OUT2

CSRD

CSRC

CSRE

X1-13

X4-14

X2-18

BAP

IAT

Sensor

Cold Start

(CSR)

Internal

Sensor

B+ 15, 16, 17, 18

GND

1, 2, 3, 4

21

VIGN

7

GND

CMV

CMV GND

CFV

CFV GND

Information on this form was current at the time of publication.

Updates may have been made to introduce product

improvements and technical advancements. See correct

vehicle service publication for chassis wiring.

Glow

Plug

Coolant Flow

Valve (CFV)

(optional)

AES

OWL

SIG GND

VREF

REMP

WTS

XCS

TACH

RAS

VSS_CAL

RPRE

RVAR

SCS

WEL

X1-17

X1-7

EGR System

X1-16

X1-5

X1-6

X1-14

X1-20

X2-10

X4-6

X3- 11

X3-14

X3-17

X3-19

X3-20

X3-21

X4-17

Engine

Control

Module ECM

98-pin

Connector E1

CKP-L

CKP-H

CMP-H

CMP-L

EFP VREF

EFP

EFP GND

FRP VREF

FRP

FRP GND

EOP VREF

EOP

EOP GND

EOT

EOT GND

MAP VREF

MAP

MAP GND

IAT2

MAT

MAT GND

ECT2

ECT2 GND

ECT

ECT GND

EBP VREF

EBP

EBP GND

To prevent personal injury or death, read all safety instructions

in the "Safety Information" section of Engine Diagnostics

Manual EGES-420 before doing any diagnostic procedures.

EIM Connectors

X1-X4

WARNING

International MAXXFORCE 11 and 13

2008 Model Year

Megafuse

E

F

G

H

BATTERIES

D

C

A

Vehicle Diagnostic Connector

EGED-430-2 2009 Navistar, Inc.

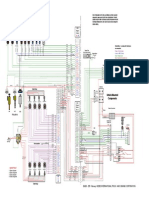

ENGINE WIRING DIAGRAM (Side 2)

International MAXXFORCE 11 and 13

2008 Model Year

R

A Navistar Company

Engine Mounted Components

Chassis Mounted Components

Aftertreatment Exhaust

Sensors

Front

Exhaust

Gas

Temperature 1

(EGT1)

Sensor

Exhaust

Gas

Temperature 2

(EGT2)

Sensor

(DOC In)

(DPF In)

Aftertreatment Fuel

Sensors and Actuators

Exhaust Exhaust

Gas

Gas

Aftertreat- Aftertreat- AftertreatTemper- Differential ment Fuel ment Fuel ment Fuel

ature 3 Pressure Pressure Supply

Drain

(EGDP)

(EGT3)

(AFP)

(AFS)

(AFD)

Sensor

Sensor

Sensor

Valve

Valve

(DPF Out)

Connector Locations

Engine Control Module

(ECM)

Aftertreatment Fuel

Injector

(AFI)

(Across DPF)

2

3

4

5

6

Flywheel

FIRING ORDER:

Aftertreatment

Control Module

Connectors A B

Private CAN

Communication Bus

ECM

16 pin

Connector D

D-4

D-13

D-11

D-6

D-5

D-12

D-3

D-14

D-1

D-16

D-2

D-15

Cylinder

Cylinder

Cylinder

#2

#4

#6

Cylinder

Cylinder

#3

#5

FUEL INJECTORS

CAN-H

CAN-L

AFI-A

AFI-B

AFS

AFD

B-20

B-21

A-17

A-18

A-2

A-1

VREF

SIG GND

AFP

EGDP

EGT3

EGT2

EGT1

ACM PWR

ACM PWR

ACM PWR

GND

GND

B-24

B-1

B-23

B-18

B-14

B-15

B-12

B-8

B-22

A-23

A-16

B-17

Engine Interface Module

(EIM)

Cylinder

#1

Continued

Side 1

A

Continued

Side 1

B

Power and Ground

Private CAN

Communication Bus

Aftertreatment Control Module

(ACM)

NOTE:

The private CAN

trunk line should be

connected as shown

below

:

ACM

ECM

EIM

CAN terminating

resistor resides

inside ECM

CAN terminating

resistor resides

inside EIM

EGED-430-2 2009 Navistar, Inc.

Das könnte Ihnen auch gefallen

- Diagrama Electronico DT466Dokument2 SeitenDiagrama Electronico DT466Aldo Fran Vargas82% (22)

- 2013 Maxxforce DT, 9, 10 Wiring DiagramsDokument2 Seiten2013 Maxxforce DT, 9, 10 Wiring DiagramsJhon Constantine90% (10)

- Maxxforce 13Dokument3 SeitenMaxxforce 13Pablo Cervantes100% (1)

- Diagrama Maxxforce 15Dokument2 SeitenDiagrama Maxxforce 15alejandro sanchez100% (7)

- Engine Wiring Diagram Form: ECM 96-Pin E1 ConnectorDokument2 SeitenEngine Wiring Diagram Form: ECM 96-Pin E1 Connectorjuan carlos rojas cadena100% (3)

- Forma VT-275Dokument2 SeitenForma VT-275Mari Karmen Lopez100% (6)

- Diag Maxxforce 9 10Dokument2 SeitenDiag Maxxforce 9 10Fernando Garcia Cortes100% (2)

- Chassis Electrical Circuit Diagram Manual Electrical System Troubleshooting GuideDokument2 SeitenChassis Electrical Circuit Diagram Manual Electrical System Troubleshooting GuideMartinez Andryj100% (3)

- EPA10 Maxxforce 11, 13 Engine Service ManualDokument591 SeitenEPA10 Maxxforce 11, 13 Engine Service ManualRod Ramos92% (39)

- EPA07 Maxxforce 11, 13 Diagnostic Manual-1Dokument190 SeitenEPA07 Maxxforce 11, 13 Diagnostic Manual-1Manuel Alejandro Velez NavaNoch keine Bewertungen

- 0000003221Dokument3 Seiten0000003221Ael Ch100% (2)

- DDEC FOR MBE (MBE 900/4000) Vehicle Interface Harness: Power WiringDokument1 SeiteDDEC FOR MBE (MBE 900/4000) Vehicle Interface Harness: Power WiringDagar GR67% (3)

- Maxxforce 11-13 (2010)Dokument2 SeitenMaxxforce 11-13 (2010)Dennito Cumito67% (3)

- Diagnostic Manual Maxx 11&13Dokument1.861 SeitenDiagnostic Manual Maxx 11&13Jose Black100% (6)

- Diagrama VT365-2004 PDFDokument2 SeitenDiagrama VT365-2004 PDFHilario Gayosso Cruz100% (14)

- Engine Wiring Diagram (Side 1)Dokument2 SeitenEngine Wiring Diagram (Side 1)ORLANDO100% (1)

- 2007 Maxx Force 7 ServiceDokument415 Seiten2007 Maxx Force 7 Servicebullfly100% (2)

- N9 and N10 With SCR (2014 - 2016) : Engine Wiring Diagram Engine Control Module (ECM)Dokument4 SeitenN9 and N10 With SCR (2014 - 2016) : Engine Wiring Diagram Engine Control Module (ECM)Phil B.Noch keine Bewertungen

- MaxxForce DT, 9, 10 Diesel Engine Workshop Repair & Service Manual - SAMPLE PDFDokument20 SeitenMaxxForce DT, 9, 10 Diesel Engine Workshop Repair & Service Manual - SAMPLE PDFPedro Aparicio25% (12)

- EPA10 Maxxforce 11, 13 Diagnostic ManualDokument985 SeitenEPA10 Maxxforce 11, 13 Diagnostic ManualAndy Zepeda100% (1)

- EPA07 Maxxforce 7 Diagnostic Manual-2Dokument232 SeitenEPA07 Maxxforce 7 Diagnostic Manual-2Jhon Constantine100% (8)

- Ddec IiDokument1 SeiteDdec IiEduardo PerezNoch keine Bewertungen

- Navistar Diagnostic Trouble Codes EGES395 - DTCDokument8 SeitenNavistar Diagnostic Trouble Codes EGES395 - DTCjpablop1278% (9)

- 2010 Model Year MaxxForce DT, 9 and 10 Engine Diagnostic ManualDokument520 Seiten2010 Model Year MaxxForce DT, 9 and 10 Engine Diagnostic ManualJIMJEO91% (69)

- X15 Cm2350 X116B - Performance Series Wiring DiagramDokument1 SeiteX15 Cm2350 X116B - Performance Series Wiring DiagramVeterano del Camino100% (3)

- EPA10 Maxxforce 11, 13 Diagnostic ManualDokument985 SeitenEPA10 Maxxforce 11, 13 Diagnostic ManualJuan luis100% (7)

- 2010 Maxx Force 7 DiagnosticDokument831 Seiten2010 Maxx Force 7 Diagnosticbullfly96% (23)

- Maxxforce 7 Epa 10Dokument2 SeitenMaxxforce 7 Epa 10Juan Martinez100% (4)

- Diagrama Maxxfoce 11-13 PDFDokument2 SeitenDiagrama Maxxfoce 11-13 PDFRuthAnaya100% (1)

- Diagrama International VT365Dokument2 SeitenDiagrama International VT365Edwin Motta Piamba89% (55)

- 2015 N13 Engine Diagnostic ManualDokument2.009 Seiten2015 N13 Engine Diagnostic ManualHarlinton descalzi97% (32)

- MaxxForce 7 Diesel Engine Repair & Service Manual - 0Dokument14 SeitenMaxxForce 7 Diesel Engine Repair & Service Manual - 0RuthAnaya45% (11)

- EGED430Dokument2 SeitenEGED430manhlinh08cdNoch keine Bewertungen

- CT13 With SCR Engine Wiring HarnessDokument4 SeitenCT13 With SCR Engine Wiring HarnessAnonymous MHfAPigNoch keine Bewertungen

- Section Schematic and Routing Diagrams: ECM Wiring Diagram (1.4l/1.6L DOHC - 1 OF 6)Dokument30 SeitenSection Schematic and Routing Diagrams: ECM Wiring Diagram (1.4l/1.6L DOHC - 1 OF 6)Ivan Leonardo Acevedo Galan94% (16)

- Schematic and Routing Diagrams: Pcm/Ecm Wiring Diagram (1 of 6) (IPCM-6KD/ISFI-6TD)Dokument13 SeitenSchematic and Routing Diagrams: Pcm/Ecm Wiring Diagram (1 of 6) (IPCM-6KD/ISFI-6TD)José BOBADILLANoch keine Bewertungen

- 2uz-Fe Engine Control System - Sfi SystemDokument4 Seiten2uz-Fe Engine Control System - Sfi SystemMortada Alsonni83% (6)

- Fault Code Identification TableDokument1 SeiteFault Code Identification TableBUTERA1Noch keine Bewertungen

- B Emission ApplicationDokument3 SeitenB Emission Applicationdguruge8Noch keine Bewertungen

- Toyota Sensors Basic WaveformsDokument6 SeitenToyota Sensors Basic Waveformscartronix2010100% (5)

- Engine PerformanceDokument965 SeitenEngine Performance5cubero5Noch keine Bewertungen

- Crusader ECM 07Dokument143 SeitenCrusader ECM 07Giapy Phuc Tran100% (2)

- B767 Flightdeck and AvionicsDokument142 SeitenB767 Flightdeck and Avionicsoscar89% (19)

- HAR-1058 LS2 Harness Instructions 10Dokument15 SeitenHAR-1058 LS2 Harness Instructions 10Jacob HernandezNoch keine Bewertungen

- Mack Truck Fault Codes ListDokument2 SeitenMack Truck Fault Codes ListAlexanderRomero100% (3)

- Acronime BMWDokument7 SeitenAcronime BMWmaciu1Noch keine Bewertungen

- Workshop Manual Chassis SUPPLEMENT 3000GT 1996 EuroDokument38 SeitenWorkshop Manual Chassis SUPPLEMENT 3000GT 1996 Euromb7050Noch keine Bewertungen

- Multiport Fuel System (Mfi) : Group 13ADokument64 SeitenMultiport Fuel System (Mfi) : Group 13Ajagjitemir6014Noch keine Bewertungen

- Usp BookletDokument77 SeitenUsp BookletJamie Gwen StewertNoch keine Bewertungen

- UntitledDokument5 SeitenUntitledXimena Justiniano LeytonNoch keine Bewertungen

- LIST OF ABBREVIATIONS USED IN HANATECH SCANNERDokument5 SeitenLIST OF ABBREVIATIONS USED IN HANATECH SCANNERIvan Torres VillalobosNoch keine Bewertungen

- Manual For: LS2 LS3 Drive by Cable EFI Harness InstructionsDokument15 SeitenManual For: LS2 LS3 Drive by Cable EFI Harness InstructionsJacob Hernandez100% (1)

- Electronic Engine ControlDokument19 SeitenElectronic Engine ControlSohail Bashir97% (31)

- Glossary of Sae and Toyota TermsDokument3 SeitenGlossary of Sae and Toyota TermsKevin StrongNoch keine Bewertungen

- Toyota P 2121 PDFDokument3 SeitenToyota P 2121 PDFMaria OwensNoch keine Bewertungen

- Ecd System (Hilux/1Kd - FTV, 2Kd - FTV (Tsam Made For South Africa) )Dokument1 SeiteEcd System (Hilux/1Kd - FTV, 2Kd - FTV (Tsam Made For South Africa) )Katu2010Noch keine Bewertungen

- ECM Connector Pinout Identification GuideDokument3 SeitenECM Connector Pinout Identification GuideSebastian OlayaNoch keine Bewertungen

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BVon EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNoch keine Bewertungen

- Automotive Air Conditioning and Climate Control SystemsVon EverandAutomotive Air Conditioning and Climate Control SystemsBewertung: 4 von 5 Sternen4/5 (6)

- 2 Valves and Injectors Adjustment VEBDokument21 Seiten2 Valves and Injectors Adjustment VEBRuju RujuNoch keine Bewertungen

- 2002f650750wire Power StrokeDokument1 Seite2002f650750wire Power StrokeRuju RujuNoch keine Bewertungen

- Codigos Motor Navistar 466EDokument5 SeitenCodigos Motor Navistar 466EJj Marquez Chacon75% (4)

- Serie 60 Ddec Iv Egr Harnes de Motor PDFDokument1 SeiteSerie 60 Ddec Iv Egr Harnes de Motor PDFLaura Cabarte100% (2)

- INTERNATIONAL MAXXFORCE DiagramaDokument2 SeitenINTERNATIONAL MAXXFORCE Diagramamiguel290890% (177)

- Caterpillar 3126 DiagramaDokument2 SeitenCaterpillar 3126 Diagramagalvez_85875% (12)

- Diagrama C15Dokument2 SeitenDiagrama C15Charly Ramos100% (5)

- Title: Gas Spring Kit Model Number: S650 Serial Number: B4SZ11001 & AboveDokument49 SeitenTitle: Gas Spring Kit Model Number: S650 Serial Number: B4SZ11001 & AboveIbrahim AhmedNoch keine Bewertungen

- Commercial Vehicle Business Unit: Product Spare Parts CatalogueDokument164 SeitenCommercial Vehicle Business Unit: Product Spare Parts CatalogueKamaldeep SinghNoch keine Bewertungen

- Tata Motors PESTLE Analysis: Political, Economic, Social, Tech FactorsDokument2 SeitenTata Motors PESTLE Analysis: Political, Economic, Social, Tech Factorspushpraj rastogi100% (1)

- Performance, Emission Parameters and Challenges of Homogeneous Charge Compression Ignition (HCCI) EngineDokument19 SeitenPerformance, Emission Parameters and Challenges of Homogeneous Charge Compression Ignition (HCCI) EngineAshit RajNoch keine Bewertungen

- Mazda Premacy Training Manual: GI B1 D E F1 G H J1 KDokument50 SeitenMazda Premacy Training Manual: GI B1 D E F1 G H J1 KRafael Olave0% (1)

- 303-01b Engine TD4Dokument166 Seiten303-01b Engine TD4Juraci Diniz100% (1)

- FaultDokument20 SeitenFaultbobaker salahNoch keine Bewertungen

- Kode Error Honda Pre ObdDokument11 SeitenKode Error Honda Pre ObdSabri Bprf HuarrNoch keine Bewertungen

- Doosan D18napDokument397 SeitenDoosan D18napHarlinton descalzi100% (6)

- VolkswagenAudi Standardized Measuring Block Groups For Gasoline EnginesDokument26 SeitenVolkswagenAudi Standardized Measuring Block Groups For Gasoline Enginesh0m3s1ck50% (2)

- WA500 7 KomatsuDokument20 SeitenWA500 7 Komatsuwidyo saptotoNoch keine Bewertungen

- Engine 3 0l Turbo Diesel - Specifications - TorqueDokument3 SeitenEngine 3 0l Turbo Diesel - Specifications - TorqueAlex Sirgiovanni0% (1)

- Faulty CodesDokument89 SeitenFaulty CodesAnca Pinzaru50% (4)

- Trouble Codes OBDIIDokument55 SeitenTrouble Codes OBDIIDanyel MoralesNoch keine Bewertungen

- Test Engine E Specificatio NS: Iveco F1C Ceuro4Dokument3 SeitenTest Engine E Specificatio NS: Iveco F1C Ceuro4Rafael FernandesNoch keine Bewertungen

- SKANDIX Pricelist Volvo XC60 (-2017) PDFDokument922 SeitenSKANDIX Pricelist Volvo XC60 (-2017) PDFMay ReyesNoch keine Bewertungen

- zd30 Engine Use ManualDokument53 Seitenzd30 Engine Use Manuallocario1Noch keine Bewertungen

- Doosan Engine DX Serie NON DPF TrainingDokument136 SeitenDoosan Engine DX Serie NON DPF Trainingmnowaq100% (20)

- CASE IH FARMALL 120U Tier 4B (Final) Tractor Service Repair ManualDokument37 SeitenCASE IH FARMALL 120U Tier 4B (Final) Tractor Service Repair Manualejky93201573Noch keine Bewertungen

- Delmag RH Reihe enDokument20 SeitenDelmag RH Reihe enIvanNoch keine Bewertungen

- 1985 Toyota Truck & 4-Runner Gasoline Repair ManualDokument1.025 Seiten1985 Toyota Truck & 4-Runner Gasoline Repair Manualkamel hatt100% (3)

- 3 - CM D-2.2L EngineDokument52 Seiten3 - CM D-2.2L EngineDardan Husi100% (1)

- MAN EDC MS6.1 With Exhaust Gas Recirculation EGR (EURO 3)Dokument6 SeitenMAN EDC MS6.1 With Exhaust Gas Recirculation EGR (EURO 3)Mircea Gilca50% (2)

- Thesis On Exhaust Gas RecirculationDokument8 SeitenThesis On Exhaust Gas Recirculationsarahmichalakwarren100% (2)

- SK200-8 SK210LC-8 CatalogueDokument8 SeitenSK200-8 SK210LC-8 CatalogueThisara NiroshNoch keine Bewertungen

- EGR Valve Cooler Delete (BKD)Dokument75 SeitenEGR Valve Cooler Delete (BKD)Rafael troyano cardenasNoch keine Bewertungen

- Hyundai Excel X2 1989-1998 Fuel SystemDokument135 SeitenHyundai Excel X2 1989-1998 Fuel SystemRdo Orbo73% (11)

- Installing The Mann Provent CCV Filter in A VW PD TDI EngineDokument11 SeitenInstalling The Mann Provent CCV Filter in A VW PD TDI Enginejeff_daigle387100% (1)

- Schematics (Engine Controlsfuel - 1.0L - 1.19L - or 1.2L)Dokument9 SeitenSchematics (Engine Controlsfuel - 1.0L - 1.19L - or 1.2L)Data TécnicaNoch keine Bewertungen

- 1990 Ford Truck Emmisions ManualDokument1.365 Seiten1990 Ford Truck Emmisions ManualPaul Roth100% (4)