Beruflich Dokumente

Kultur Dokumente

WSA02 2002 Part3 2 3

Hochgeladen von

abhijithavalOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

WSA02 2002 Part3 2 3

Hochgeladen von

abhijithavalCopyright:

Verfügbare Formate

Sewerage Code of Australia

Part 3: Construction

Second Edition

Version 2.3

WSA 022002-2.3

148

CONTENTS

11 GENERAL

153

11.1 SCOPE

11.2 INTERPRETATION

153

153

12 QUALITY

155

12.1 QUALITY ASSURANCE

12.1.1 General

12.1.2 Quality system

12.1.3 Project management plan

12.1.4 Inspection and test plans

12.1.5 Quality tests

12.1.6 Quality audits

12.1.7 Traceability

12.1.8 Quality records

12.1.9 Inspection

12.2 PERSONNEL QUALIFICATIONS

155

155

155

155

155

155

156

156

156

156

156

13 GENERAL CONSTRUCTION

158

13.1 GENERAL

13.2 ORDER OF CONSTRUCTION, TESTING AND COMMISSIONING

13.3 CONTRACT INTERFACES

13.4 CUSTOMER FOCUS

13.4.1 General

13.4.2 Resolution of complaints

13.5 PROTECTION OF PEOPLE, PROPERTY AND ENVIRONMENT

13.5.1 Safety of people

13.5.2 Protection of other services

13.5.3 Disused / Redundant sewers

13.5.4 Road reserves or other thoroughfares

13.5.4.1 Treatment of pavements and other surfaces

13.5.4.2 Traffic management

13.5.4.3 Cleanliness of roads, paths, accesses and drainage paths

13.5.4.4 Storage of products, materials and equipment

13.5.4.5 Obstruction of street drainage

13.5.5 Private and public properties

13.5.6 Protection of the environment and heritage areas

13.5.6.1 General

13.5.6.2 Collection and disposal of wastes

13.5.6.3 Protection of adjacent lands and vegetation

13.5.6.4 Control of water pollution

13.5.6.5 Acid sulphate and contaminated soils

13.5.6.6 Control of noise and atmospheric pollution

13.6 AFFECTED PARTY NOTIFICATIONS

13.7 ALTERATION OF EXISTING SERVICES

13.8 SURVEY MARKS

13.9 CONSTRUCTION TOLERANCES

13.10 LATENT CONDITIONS

14 PRODUCTS AND MATERIALS

158

158

158

158

158

158

159

159

159

160

160

160

160

161

161

161

161

161

161

161

162

162

162

163

163

163

163

163

163

164

14.1 AUTHORISED PRODUCTS AND MATERIALS

164

14.2 REJECTED PRODUCTS AND MATERIALS

164

14.3 TRANSPORTATION, HANDLING AND STORAGE OF PRODUCTS AND MATERIALS164

14.3.1 General

164

14.3.2 Plastics-lined concrete products

164

14.4 DELIVERY INSPECTION OF PRODUCTS AND MATERIALS

165

14.5 CONCRETE WORKS

165

COPYRIGHT

149

14.5.1 Delivery

14.5.2 Transportation of concrete

14.5.3 Formwork

14.5.3.1 General

14.5.3.2 Formwork for plastics-lined concrete

14.5.4 Reinforcement

14.5.5 Placement

14.5.5.1 General

14.5.5.2 Placement in water

14.5.6 Slump

14.5.7 Compaction

14.5.8 Stripping

14.5.9 Curing

14.5.10 Repair of blemishes

14.6 SUPPLY OF WATER TO THE WORKS

14.7 ON-SITE STOCKPILES

15 EXCAVATION

WSA 022002-2.3

165

165

166

166

166

166

166

166

166

167

167

167

167

167

167

168

169

15.1 SAFETY

15.2 LIMITS OF EXCAVATION

15.3 EXCAVATION ACROSS IMPROVED SURFACES

15.4 EXCAVATION IN ROOT ZONES

15.5 BLASTING

15.6 SUPPORT OF EXCAVATIONS

15.7 DRAINAGE AND DEWATERING

15.8 FOUNDATIONS AND FOUNDATION STABILISATION

15.9 SURPLUS EXCAVATED MATERIAL

169

169

169

169

169

170

170

170

170

16 BEDDING FOR PIPES AND MAINTENANCE STRUCTURES

171

16.1 TRENCH FLOOR PREPARATION

16.2 BEDDING MATERIALS

16.3 PLACEMENT OF BEDDING

16.4 SPECIAL PIPE SUPPORT FOR NON-SUPPORTIVE SOILS

16.5 BEDDING FOR MAINTENANCE SHAFTS AND BENDS

16.6 BEDDING FOR MAINTENANCE HOLES

171

171

171

171

171

171

17 PIPE LAYING AND JOINTING

172

17.1 INSTALLATION OF PIPES

17.1.1 General

17.1.2 Cleaning, inspection and joint preparation

17.1.3 Polyethylene

17.1.4 Laying

17.2 HORIZONTAL AND VERTICAL DEFLECTION OF SEWERS

17.2.1 General

17.2.2 Methods of deflection

17.2.3 Horizontal curves

17.2.4 Vertical curves

17.2.5 Compound curves

17.3 HORIZONTAL AND VERTICAL SEPARATION OF CROSSING PIPELINES

17.4 FLOTATION CONTROL

17.5 TRENCH STOPS

17.6 BULKHEADS

17.7 PROPERTY CONNECTION SEWERS

17.8 DEAD ENDS

17.9 MARKING OF PROPERTY CONNECTION SEWERS AND DEAD ENDS

17.10 CORROSION PROTECTION OF CAST IRON

17.11 MARKING TAPES

17.11.1 Non-detectable marking tape

17.11.2 Detectable marking tape

COPYRIGHT

172

172

172

172

172

172

172

173

174

174

174

174

174

175

175

175

175

175

175

176

176

176

WSA 022002-2.3

150

17.12 BORED PIPES UNDER ROADS, DRIVEWAYS AND ELSEWHERE

17.13 AQUEDUCTS

17.14 BRIDGE CROSSINGS

17.15 PLASTICS-LINED RC PIPE JOINTING

17.15.1 General

17.15.2 Plastics lining work protection

17.15.3 Field jointing

17.15.4 Plastics lining ancillary work

17.15.4.1 Alignment of lining keys

17.15.4.2 Provision of seepage channels

17.15.4.3 Use of jointing accessories and adhesives

17.16 WELDING OF STEEL PIPELINES

17.16.1 General

17.16.2 Field welding of flanges

18 MAINTENANCE HOLES (MHS)

176

176

176

176

176

177

177

177

177

177

177

177

177

177

179

18.1 GENERAL

18.2 MH BASE

18.3 TRENCH DRAINAGE AROUND MHS

18.4 PRECAST CONCRETE MH SYSTEMS

18.5 CAST IN-SITU CONCRETE MH

18.6 BENCHING AND CHANNELS

18.7 CONCRETING FOR PLASTICS-LINED WORK

18.7.1 Concrete work planning

18.7.2 Fixing of plastics lining for concrete work

18.7.3 Concrete placement and formwork removal

18.8 INTERNAL COATING OF CONCRETE MHS

18.9 COVERS

18.10 CONNECTIONS TO MHS

18.11 MH DROPS

19 MAINTENANCE SHAFTS (MS AND TMS) AND INSPECTION OPENINGS (IO)

19.1 GENERAL

19.2 SEALING CAPS

19.3 COVERS

19.4 CONNECTIONS TO MSS AND TMSS

179

179

179

179

179

180

180

180

180

180

180

180

181

181

182

182

182

182

182

20 PIPE EMBEDMENT AND SUPPORT

183

20.1 GENERAL

183

20.2 EMBEDMENT MATERIALS

183

20.3 COMPACTION OF EMBEDMENT

183

20.3.1 Methods

183

20.3.2 Compaction trials / Pre-qualification of embedment compaction method

184

20.3.2.1 General

184

20.3.2.2 Test method

184

20.3.2.3 Interpretation and applicability

184

20.3.3 Compaction control

184

20.4 SPECIAL BEDDING AND EMBEDMENTS / GEOTEXTILE SURROUND AND PILLOW184

20.5 REMOVAL OF TRENCH SUPPORTS

184

20.6 CONCRETE EMBEDMENT AND ENCASEMENT

184

21 FILL

186

21.1 TRENCH FILL

21.1.1 General

21.1.2 Material requirements

21.1.3 Compaction of trench fill

21.2 EMBANKMENT FILL

21.3 DRIVES AND TUNNEL FILL

186

186

186

186

187

187

COPYRIGHT

151

22 ACCEPTANCE TESTING

WSA 022002-2.3

188

22.1 GENERAL

188

22.2 VISUAL INSPECTIONABOVE-GROUND

188

22.3 COMPACTION TESTING

188

22.3.1 General

188

22.3.2 Minimum compaction

189

22.3.3 Embedment compaction testing

189

22.3.3.1 Applicable pipe sizes

189

22.3.3.2 Frequency and location of embedment tests

189

22.3.3.3 Retesting

189

22.3.4 Trench fill compaction testing

190

22.3.4.1 Trafficable Test Zone

190

22.3.4.2 Non-trafficable test zone

190

22.3.4.3 Test method

190

22.3.4.4 Frequency and location of tests

190

22.3.4.5 Retesting

190

22.3.5 Other fill compaction testing

191

22.3.5.1 General

191

22.3.5.2 Trafficable test zone

191

22.3.5.3 Non-trafficable test zone

191

22.3.5.4 Frequency and location of tests

191

22.3.5.5 Retesting

192

22.4 AIR PRESSURE AND VACUUM TESTING OF SEWERS

192

22.4.1 General

192

22.4.2 Air testing methods for sewers

192

22.4.2.1 Vacuum testing

192

22.4.2.2 Low pressure air testing

193

22.4.3 Testing of sewers >DN 1500

194

22.4.3.1 General

194

22.4.3.2 Method of test

194

22.4.4 Testing of concrete MHs

194

22.4.4.1 General

194

22.4.4.2 Test method

194

22.5 INFILTRATION TESTING

195

22.6 DEFLECTION (OVALITY) TESTING OF FLEXIBLE SEWERS

196

22.6.1 General

196

22.6.2 Ovality proving tools

196

22.6.3 Flexible sewers DN 300

196

22.6.4 Flexible sewers >DN 300

196

22.6.4.1 General

196

22.6.4.2 Flexible sewers >DN 300 and <DN 750

197

22.6.4.3 Flexible sewers DN 750

197

22.7 CCTV INSPECTION

197

22.8 INSPECTION AND TESTING OF PLASTIC LINED CONCRETE SEWERS AND MHS 198

22.8.1 Visual inspection

198

22.8.2 Spark testing

198

22.8.3 Locking key pull-out tests

199

22.9 PRESSURE TESTING OF INVERTED SYPHONS

199

22.9.1 General

199

22.9.2 System test pressure

199

22.9.3 Maximum allowable loss

199

22.9.4 Test procedure

199

22.9.5 Satisfactory pressure test

200

22.9.6 Failure of test

200

COPYRIGHT

WSA 022002-2.3

152

23 TOLERANCES ON AS-CONSTRUCTED WORK

23.1 HORIZONTAL TOLERANCES

23.1.1 Sewers and on-line structures (e.g. MHs, MSs, TMSs, vents)

23.1.2 Property connection sewers

23.2 VERTICAL TOLERANCES

23.2.1 Sewers and structures

23.2.2 Property connection risers and inspection openings

23.2.3 Grade

23.2.4 Verticality (plumb)

23.3 TOLERANCES ON FINISHED SURFACE STRUCTURES AND FITTINGS

23.4 CAST IN-SITU CONCRETE STRUCTURES AND SLABS

202

202

202

202

202

202

202

202

203

203

203

24 CONNECTION TO EXISTING SEWERS

204

25 RESTORATION

205

25.1 GENERAL

25.2 PAVEMENTS

25.3 LAWNS

25.4 GRASSED AREAS

25.5 BUSHLAND

25.6 PROVISION FOR SETTLEMENT

25.7 MAINTENANCE OF RESTORED SURFACES

26 WORK AS CONSTRUCTED DETAILS

205

205

205

205

206

206

206

207

APPENDIX G OVALITY TESTING OF PVC AND GRP GRAVITY SEWERS DEFAULT

PROVER DIAMETERS

208

G1 GENERAL

G2 DEFAULT PROVER DIAMETERS

208

208

TABLES

TABLE 17.1

TABLE 20.1

TABLE 22.1

TABLE 22.2

TABLE 22.3

TABLE 22.4

TABLE 22.5

TABLE 22.6

TABLE 22.7

TABLE 23.1

TABLE 23.2

TABLE G1

METHODS OF ACHIEVING CURVED SEWERS

MAXIMUM PARTICLE SIZE

EMBEDMENT OF FLEXIBLE PIPES MINIMUM COMPACTION

EMBEDMENT OF RIGID PIPES MINIMUM COMPACTION

TRENCH / EMBANKMENT FILL OF RIGID AND FLEXIBLE PIPES AND

MAINTENANCE STRUCTURES MINIMUM COMPACTION

PRESSURE AND VACUUM AIR TESTING ACCEPTANCE TIMES FOR

7 KPA PRESSURE CHANGE

CONCRETE MH TESTING FREQUENCY

MINIMUM TEST TIMES FOR CONCRETE MHs

MAXIMUM ALLOWABLE SHORT-TERM PIPE DEFLECTIONS

SEWER GRADE TOLERANCES

PROPERTY CONNECTION SEWER GRADE TOLERANCES

PROVER OUTSIDE DIAMETER FOR PVC AND GRP PIPES

COPYRIGHT

173

183

189

190

190

193

194

195

197

203

203

208

153

WSA 022002-2.3

11 GENERAL

11.1 SCOPE

This Part of the Code details default requirements for the construction of gravity sewers

including maintenance and inspection structures.

This document should be read in conjunction with relevant Water Agency supplementary

manuals, development agreements, specific project contract documents, general

conditions of contract e.g. AS 2124 and other documents nominated by the Water Agency.

11.2 INTERPRETATION

Unless specifically stated otherwise, construction of the sewers includes all functions

described in this Part and the provision of any minor materials and services that are not

described but are reasonably necessary to produce a fully functional sewerage system.

For the purposes of this Part, except where otherwise shown:

"Authorised" means acceptable to, authorised by or approved by the Water Agency

or Owner or Regulator.

Constructor means the individual, corporation or legal entity including any

contractors and sub-contractors that is accountable at law for delivery of Works under

a specific contract or development agreement.

Design Drawings means plans, elevations and drawings required for the

construction of the sewerage systems and showing the locality including roads and

sewer details, the site plan including lots, boundaries, roads, proposed and existing

sewers, proposed property connection sewers, pumping stations, pressure mains,

water mains, drains, watercourses, site contours, proposed aqueducts, proposed

boreholes, a longitudinal section, construction details and a connection to existing

sewer schedule. Supplementary information may include proposed buildings, existing

services, and groundwater and watercourse levels.

The Designer may nominate Standard Drawings or parts thereof as Design Drawings

for the purposes of the project.

Improvements are deemed to include but not be limited to pavements, shrubs,

gardens, retaining walls, fences and all other structures.

"Owner means the Agency, Authority, Board, Company, Controlling Authority,

Corporation, Council, Department, Individual, Regulator, Utility or other legal entity

who is the owner of the asset and/or who has responsibility for the asset.

Part means the Sewerage Code of Australia, Part 3: Construction.

Purchase Specification means the WSAA Purchase Specification detailing the

requirements for the supply of a product or material.

Regulator means a Regulator who has the power to enforce Regulations related to

the activities and responsibilities of a Commonwealth, State, Territory or Local

government. It applies to environmental management and protection, occupational

health and safety and the like.

"Specification" means the Specification detailing the work involved in the particular

project in hand.

Specified means as specified in the Specification, Design Drawings, Purchase

Specifications and/or by the Superintendent.

Standard Drawings means the Sewerage Code of Australia, Part 4: Standard

Drawings.

COPYRIGHT

WSA 022002-2.3

154

Superintendent means the individual appointed by the contract principal as an

independent arbiter of contract directions, issues, claims and variations.

Tester means an individual, corporation or legal entity registered by the National

Association of Testing Authorities for the relevant classes of tests and that is

accountable at law for delivery of testing services under a specific contract with the

Constructor.

Water Agency means an authority, board, business, corporation, council or local

government body with the responsibility for planning or defining planning

requirements, for defining and authorising design requirements, for defining and

authorising construction requirements and for operating and maintaining or defining

operation and maintenance requirements for a water supply and/or sewerage system

or systems.

Works means all those Works being sewers, maintenance structures, pumping

stations, pressure mains and accessories and shall include valve chambers and

storage facilities as shown on the Design Drawings and includes any part or parts of

the Works.

Specific requirements, including those in the Specification and Design Drawings, shall take

precedence over general requirements.

Headings are for the convenience of the reader and shall not be used in the interpretation

of this Part. Italicised text is advisory and has been included to assist the reader to better

understand some requirements. It is strongly recommended that the reader consult the

Standard Drawing Commentaries in Part 4 of this Code.

COPYRIGHT

155

WSA 022002-2.3

12 QUALITY

12.1 QUALITY ASSURANCE

The Water Agency is responsible for specifying quality assurance of construction activities

and personnel qualifications. Unless otherwise specified, the requirements of this section

apply.

12.1.1 General

The Constructor shall comply with all requirements of the Civil Contractors Federation

(CCF) Civil Construction Management Code or Water Agency authorised equivalent

system. The quality management system shall address the more pertinent elements of

quality assurance (ISO 9001), health and safety issues (AS/NZS 4801) and environmental

requirements (ISO 14001). These elements are incorporated within the Civil Construction

Management Code and shall be addressed within the management system documentation.

The Constructor shall provide evidence of its certification to the CCF Code (or equivalent)

prior to the commencement of any work.

12.1.2 Quality system

The Constructor shall plan, establish, document and maintain a quality system that

conforms to the requirements of the contract and shall provide the Superintendent with

access to the Constructor's quality systems for monitoring and quality auditing. The quality

system proposed by the Constructor shall be used as an aid to achieve compliance with

the requirements of the contract and to document such compliance.

If the Constructor discovers material or work that is not in accordance with the contract, the

Constructor shall promptly initiate the non-conformance procedure required by the quality

system. If the Constructor proposes a disposition of any non-conforming materials or work

which is at variance with the requirements of the contract, the proposal shall be submitted

in writing to the Superintendent whose decision on the proposal shall be obtained in writing

before the non-conforming material or work is covered up and/or incorporated into the

Works, or is the subject of any other disposition.

12.1.3 Project management plan

The Constructor shall conform to the policies and procedures stated in the project

management plan submitted with the Constructor's tender.

12.1.4 Inspection and test plans

The Constructor shall submit inspection and test plans (ITPs) to the Superintendent for

verification before commencing work on activities covered by the project quality plan. The

ITPs shall include where applicable, observations, measurements or tests at the

Constructor's facilities.

Model ITPs for construction of reticulation sewers will be available at www.wsaa.asn.au.

12.1.5 Quality tests

The Constructor shall be responsible for the quality of all products, processes and services

under the contract, and unless otherwise specified, shall provide all tests required to

demonstrate conformance of all products, processes and services to the technical

requirements of the contract.

Unless otherwise agreed by the Superintendent, all laboratory tests and field tests

undertaken by the Constructor shall be performed by a Tester currently registered with the

National Association of Testing Authorities (NATA) or equivalent authority for the class of

tests being undertaken.

COPYRIGHT

WSA 022002-2.3

156

12.1.6 Quality audits

The Superintendent may nominate selected times and hold points at which quality

compliance audits may be conducted within the contract period.

Upon request, the Superintendent shall be given access in conjunction with or through the

Constructor, to carry out quality audits, reviews or surveillance or to ascertain the

effectiveness of the quality system put in place by the Constructor.

The Superintendent shall be entitled to carry out the second or third party audits of the

Constructor's quality system by:

(a)

reviewing of the Constructor's conformance to the project management plan; and

(b)

reviewing and verifying of the Constructor's quality procedures and work instructions

and documentary evidence of compliance with technical requirements of the contract.

12.1.7 Traceability

The Constructor shall maintain records clearly identifying the source of materials and

equipment, the suppliers declaration of conformity, the design drawings used for the

construction of the works and all test results. These shall be stored and maintained in

accordance with Clause 12.1.8.

12.1.8 Quality records

Quality records shall be stored and maintained such that they are readily retrievable in

facilities that provide a suitable environment to minimise deterioration or damage, and to

prevent loss. Quality records shall be available for evaluation by the Superintendent during

the period of the Contract and shall include all pertinent Constructor and third party

records.

The Constructor shall retain quality records for seven (7) years from the date of practical

completion of the Works.

The Constructor shall maintain records in two categories:

(a)

Test records, which shall comprise all working sheets and summaries associated with

testing in accordance with the Inspection and Test Plans.

(b)

Project quality records, which shall include, but not be limited to site meeting

minutes, technical reviews, minutes of meetings between Superintendent and

Constructor and other relevant documentation.

The Constructor shall submit to the Superintendent quality records as evidence that the

work has complied with the specified quality requirements. If unsatisfactory, the records

shall be submitted within twenty-four (24) hours of creation or receipt, and within seven (7)

days of creation or receipt if satisfactory.

Within three (3) months of the date of practical completion the Constructor shall make

available a register of all quality records required to be held under the contract. The

Constructor shall supply copies of all quality records or parts thereof as required by the

Superintendent.

12.1.9 Inspection

The Superintendent shall be given access in conjunction with or through the Constructor to

all laboratories and other facilities used for quality control tests to verify that specified

requirements are being met.

12.2 PERSONNEL QUALIFICATIONS

The handling, laying, jointing, trench filling and testing of all sewers, construction and

testing of associated structures and installation of appurtenances shall be carried out, and

supervised by, acceptably qualified and/or accredited personnel.

COPYRIGHT

157

WSA 022002-2.3

Personnel shall hold minimum qualifications or specialist accreditation appropriate for the

work undertaken.

Minimum qualifications shall mean Statements of Attainment for all those Units of

Competence, nominated by the Water Agency, from the Water Industry National Training

Package NWP01 or Local Government Training Package LGA00 or the Civil Construction

Training Package BCC98 or other relevant Training or a combination of one or more of the

aforementioned.

Specialist accreditation shall mean a qualification achieved through specialised training

and assessment for a specific product and/or situation that is not covered by relevant

Training Packages.

Qualifications from Training Packages shall be awarded by a registered training

organisation.

Training and assessment for specialist accreditation shall be provided by registered

training organisations or recognised organisations with appropriately qualified and

experienced trainers and assessors.

Registered training organisations shall be those listed by the National Training Information

Service for the provision of training or assessment services as required.

Training packages, together with relevant short training courses and training/assessment

service providers are provided by the National Training Information Service at

www.ntis.gov.au.

COPYRIGHT

WSA 022002-2.3

158

13 GENERAL CONSTRUCTION

13.1 GENERAL

Construct the sewerage works to the lines, levels, grades and in the locations using the

materials and methods as specified.

If insufficient detail or instruction is provided in the Design Drawings or Specification,

obtain instruction from the Superintendent prior to commencement.

Use only the types, materials, sizes, lengths, classes, jointing methods and corrosion

protection systems for the pipes, fittings and maintenance structures as specified. Use only

manufacturers products and product range authorised by the Water Agency.

Keep on site at all times a copy of the Specification, all relevant Design Drawings,

Standard Drawings and the Water Agencys manual or catalogue or listing of authorised

products and materials.

13.2 ORDER OF CONSTRUCTION, TESTING AND COMMISSIONING

Undertake and complete all Works in accordance with the following process:

(a)

Except where connection to a live sewer is required, start construction from the

furthest downstream point. Otherwise, start construction at a point clear of the live

sewer as specified by the Water Agency.

(b)

Install all Works in accordance with the Design Drawings and the Specification,

progressively working upstream.

(c)

Clean sewer(s) by flushing.

(d)

Conduct acceptance testing.

(e)

Connect to the live sewer after all other Works have been constructed as specified.

13.3 CONTRACT INTERFACES

The Contract Interfaces shall be as indicated on the Design Drawings and/or Specification.

If in doubt, obtain clarification from the Superintendent. Where the Constructor is required

to connect or fit to existing infrastructure provided by Water Agency, check all relevant

measurements on site, notwithstanding the dimensions shown on the Design Drawings,

and adjust work to fit as required. The Constructor shall not be entitled to any claim for loss

or damage directly or indirectly due to its failure to take such measurements.

13.4 CUSTOMER FOCUS

13.4.1 General

Ensure that the execution of the Works complies with the Water Agency's "Requirements

for customer service.

Fully brief all affected customers and property owners about the impact of the Works on

buildings, garden features, trees and vegetation, noise levels, out of hours work, traffic

restrictions, etc before commencing work.

Keep documented evidence of contact details with all affected customers.

It is the aim of the Water Agency to achieve a high level of customer understanding and

co-operation in the construction process resulting in high satisfaction levels.

13.4.2 Resolution of complaints

Establish a single point of contact for all customer queries and complaints relating to the

Works being executed.

Resolve enquiries and complaints promptly, sensitively and in accordance with the Water

Agencys Requirements for customer service.

COPYRIGHT

159

WSA 022002-2.3

Keep the Superintendent informed and fully briefed of any contentious issues raised about

the Works.

13.5 PROTECTION OF PEOPLE, PROPERTY AND ENVIRONMENT

13.5.1 Safety of people

Protect the safety of all employees and people on or adjacent to the Works in accordance

with the relevant legislation, statutory requirements, regulations and codes of practice.

All people on the site shall have completed the relevant site induction program and wear

the certified safety apparel including helmets, vests, boots, ear and eye protection.

Conduct a hazard survey to identify potential hazards during construction in accordance

with the requirements designated by the Water Agency.

Comply with the relevant power authority requirements when operating near overhead

power lines. Provide an observer when working below or within 6 m of power lines to

advise on proximity. Maintain a clearance of at least 3 m at all times between plant and

power lines.

Store or leave unattended equipment, tools and materials in a condition that minimises

hazards.

Adhere at all times to the OH&S requirements of the Water Agency.

Ensure all employees are suitably trained in OH&S compliance.

13.5.2 Protection of other services

Prior to excavation, contact Dial Before You Dig by telephone 1100 or facsimile

1300 652 077 to determine or reconfirm the location of underground services.

Implement special precautions where excavations are to be undertaken near any other

services including petroleum pipelines, gas pipelines, overhead and buried electricity and

communication cables, drains, sewers and water mains. For these assets and any other

services:

(a)

Comply with the notification requirements and construction conditions as specified.

(b)

Ensure plans for other services are on site.

(c)

As appropriate for critical services, arrange for a representative from the service

Owner to be present, unless the service Owner directs otherwise.

(d)

Adopt an appropriate method for exposing and protecting the service from damage if

the service is to be exposed.

Industry practice is generally to hand dig and locate underground services prior to

machine digging. Alternatively, location by vacuum potholing may provide a more

efficient and safer means in congested pipe corridors.

(e)

Prove the location of all underground services e.g. by potholing.

(f)

Take special care to ensure that other services are protected in accordance with the

conditions specified by the service Owner.

(g)

Arrange for isolation and subsequent restoration of any service that needs to be

removed from service while the Works are in progress.

(h)

Immediately notify the owner or responsible authority of any damage or interference

to any service, structure or property.

If a service is damaged during construction, arrange or perform repair to the

satisfaction of the Owner. Obtain from the Owner, a certificate stating that the repair

has been carried out to their satisfaction.

COPYRIGHT

WSA 022002-2.3

160

If the Owner cannot be located within a reasonable time, report the damage to the

Superintendent, and arrange or perform repair to an approved standard. Do not

backfill, cover up or make the repair inaccessible prior to obtaining authorisation from

the Superintendent.

(i)

Notify the Superintendent of any interference to the Works caused by an existing

service and the proposed action.

13.5.3 Disused / Redundant sewers

Take action regarding disused sewers e.g. removal or capping at points of disconnection

and removing surface fittings as specified.

13.5.4 Road reserves or other thoroughfares

13.5.4.1 Treatment of pavements and other surfaces

Any pavement or surface of any road, driveway, footway, nature strip, median strip,

kerbing, channelling or any other thoroughfare disturbed as a result of the Works, shall be:

(a)

Continuously maintained as far as practicable, for the duration of the Works.

(b)

Restored to its original surface and material condition and to the satisfaction of the

Owner.

Restore the surface of unpaved streets before they are reopened to traffic.

Restore the surface of any excavation in a sealed road, footway or other pavement or

provide a temporary bituminous seal before being reopening it to the public.

13.5.4.2 Traffic management

Where required by the Water Agency, prepare a traffic management plan detailing the

proposals for traffic diversion and control. The plan shall detail the access requirements for

all developed properties, and outline specific proposals for continued access to these

properties. Traffic management plans shall be designed and supervised by persons

accredited to an approved national course. The plan shall include names and accreditation

details of the Designer and supervisor.

Construction within any public road will generally not be permitted until the traffic

management plan has been authorised by the relevant road Owner.

Ensure all personnel working on or adjacent to roadways wear safety vests and are

suitably trained and certified.

Follow traffic management practices:

(a)

Provide a flagman, temporary traffic lights and/or protection by hurdles, barricades or

safety cones where traffic is restricted or roads closed.

(b)

Place detour and warning signs or devices on the hurdles or barricades, in

accordance with the responsible road authority signage code of practice.

(c)

As appropriate, notify the relevant road Owner, traffic authority, police, fire services,

ambulance services, bus companies, and any other service whose operations may be

affected by the change to the regular traffic flow pattern in the vicinity of the Works.

(d)

Provide an alternative means of access to all rights of way, buildings and property

where the Works disrupt access.

(e)

Ensure that pedestrians are kept clear of the work area and are provided with safe

alternative means of passing the Works.

(f)

Complete any work involving the opening of street pavements without delay.

COPYRIGHT

161

WSA 022002-2.3

13.5.4.3 Cleanliness of roads, paths, accesses and drainage paths

Keep the surface of all roads, footways, drainage paths and any access through public and

private lands clear of any build-up of debris such as clay, sand and the like, resulting from

plant used on the site. Ensure the exterior of all machinery and plant working on or

crossing roadways is free of all construction debris in accordance with relevant regulation.

13.5.4.4 Storage of products, materials and equipment

Store all products, materials, equipment, packaging materials and excavated material in

accordance with the requirements of the relevant storage site Owner.

13.5.4.5 Obstruction of street drainage

Protect all drains, channels or gutters from any obstruction using silt traps, sediment

control and other means as appropriate.

13.5.5 Private and public properties

Where work is carried out in private property or lands owned by Municipalities or other

authorities, whether in an easement, reserve or otherwise:

(a)

As far as practicable confine operations to easements or reserves. If there are no

easements or reserves, or the area of the easement or reserve is inadequate, confine

operations to an area agreed upon with the Owner.

(b)

Comply with the Water Agency requirements for resolution of any dispute associated

with access or entry rights to the Works.

(c)

Minimise damage to existing vegetation and improvements.

(d)

Obtain the Owner's written permission for storage of materials, equipment or

excavated material for Works on any of Owner's land.

(e)

Replace damaged conduits with the same, or agreed equivalent, material and

authorised connectors. Repair and/or replace all property and environmental damage

caused by the Works.

(f)

Remove all facilities for the Works from the site within the time frame specified or

agreed.

(g)

Restore all services, drains, fences, structures, surfaces and improvements affected

by the Works to the original surface and condition to the satisfaction of the Owner,

and within the time frame specified or agreed.

13.5.6 Protection of the environment and heritage areas

13.5.6.1 General

Take all necessary measures to protect the environment and heritage areas.

13.5.6.2 Collection and disposal of wastes

Provide, operate and maintain adequate facilities for the collection, transportation and

disposal of liquid wastes including portable toilet wastes, fuels, lubricants, oils and

greases.

On no account allow any untreated liquid waste to discharge to the ground surface of the

site or into any drain or open area. Ensure that no contamination of the soil occurs and that

all sludge and solid material is removed and disposed of safely and lawfully.

On Works completion, completely remove all the storage and treatment facilities.

If soil pollution occurs, remove all contaminated material from the site and dispose of in

accordance with the requirements of the Water Agency and relevant Regulators.

COPYRIGHT

WSA 022002-2.3

162

13.5.6.3 Protection of adjacent lands and vegetation

Confine all operations associated with the construction Works to the designated Works

area either within roadway reserves or enclosed by temporary and existing fences.

Fence all stockpile areas.

Make every attempt to minimise impact of the Works on adjacent areas and cooperate with

the owners / occupiers of adjacent land to minimise inconvenience.

Protect trees, shrubs and grasses outside the Works area by appropriate site management

and fencing.

Only remove or trim trees and shrubs if essential for the Works. Treat all cut branches and

roots with a suitable fungicide. Collect seeds from existing vegetation for use during

restoration (Refer to Clause 25.5). Where specified, employ a qualified bush regenerator to

weed the Works area prior to commencement to prevent the spread of weeds during

construction.

Stockpile vegetation separately on geotextile filter fabric when the line is initially cleared

for use during restoration (Refer to Clause 25.5). Similarly, if present, stockpile bush rock

separately during the initial clearing of the line.

Do not remove trees and shrubs on or adjacent to the Works without obtaining prior written

permission from the Owner and replace as required / agreed.

Lop trees and prune shrubs in a professional manner using appropriate tools to the extent

authorised by the relevant Owner before Works commencement.

Suitably dispose of all debris from the cutting, pruning, lopping of trees and shrubs,

including removing trunks and roots.

13.5.6.4 Control of water pollution

Prior to work commencing, develop and provide to the Superintendent, or other approving

authority, an erosion and sediment control plan (or soil and water control plan) for the site.

The plan shall outline:

(a)

Measures to be taken to minimise erosion and to trap sediment in any water leaving

the site.

(b)

Defined access locations to the worksite.

(c)

Location of stockpiles of excavated materials, fill and other erodable materials.

(d)

Procedures for construction and rehabilitation activities to minimise erosion and

sediment transport.

(e)

Procedures for monitoring, maintaining and removing erosion and sediment control

measures.

(f)

Procedures to trap and dispose of excess water during testing, disinfection and

swabbing of the completed Works.

Implement the requirements of the approved plan and comply with all applicable

Commonwealth, State, Territory and Local Government laws and regulations.

13.5.6.5 Acid sulphate and contaminated soils

Determine from the Design Drawings and mark out prior to work commencing the sites of

acid sulphate (or potential acid sulphate) soil and other contaminated sites to be

excavated. Where such sites exist, take appropriate measures during excavation, storage,

transport and disposal of soil and filling of the trench, to ensure that excavated material is

treated on-site or at an authorised remote location.

COPYRIGHT

163

WSA 022002-2.3

Refer to the Product and Material Information and Guidance for pipeline suitability in acid

sulphate and contaminated soils

13.5.6.6 Control of noise and atmospheric pollution

Comply with relevant Regulator requirements for mitigating noise and atmospheric

pollution.

Operate all plant and construction equipment such that it does not cause undue noise and

atmospheric pollution.

Fit compressors, air tools, generators and other plant as necessary with appropriate

silencers.

Take all necessary measures to prevent dust generation on the site and in particular its

spread to adjacent areas. Preventative measures shall include, but not be limited to,

regular watering of the Works area and the access tracks and roads.

13.6 AFFECTED PARTY NOTIFICATIONS

Ensure that all owners and residents of property directly and indirectly affected by the

Works are notified in writing of the proposed Works before their commencement.

Notify commencement of Works to the Superintendent. The period of notice shall comply

with the relevant notification requirements specified in the contract or by the Water Agency.

Comply with the notification requirements of all affected municipal, services and other

Owners having care, management or control over streets, services and/or property affected

by the Works.

Retain copies of all notices for audit purposes.

13.7 ALTERATION OF EXISTING SERVICES

Carry out alterations to other services in accordance with the policies, practices and

procedures specified by the responsible service Owner.

13.8 SURVEY MARKS

Maintain all State and Territory survey marks in their correct position.

When such survey marks are disturbed, re-establish or reinstate the marks to the

requirements of the relevant Regulator.

13.9 CONSTRUCTION TOLERANCES

Adhere to tolerances specified in Section 23.

13.10 LATENT CONDITIONS

Obtain instruction from the Superintendent regarding latent site conditions and obstacles

that impact on the project, such as:

(a)

Where sewers cannot be laid to achieve the minimum specified cover over the top of

the pipe barrel.

(b)

Poor ground conditions.

(c)

A building approval that has been given to construct a structure over the sewer.

(d)

Disused pipelines.

(e)

Cultural and/or natural heritage items.

COPYRIGHT

WSA 022002-2.3

164

14 PRODUCTS AND MATERIALS

14.1 AUTHORISED PRODUCTS AND MATERIALS

All product and materials shall be supplied to Purchase Specifications that are referenced

in Section IV of Part 0.

Use only products and materials authorised by the Water Agency.

Instruct suppliers of products to declare that all products and materials supplied comply

with the nominated Purchase Specifications.

Some Water Agencies maintain a list of authorised products and materials and their

suppliers.

14.2 REJECTED PRODUCTS AND MATERIALS

Reject any damaged or defective product or material.

Do not use any rejected product or material in the Works.

Place rejected product or materials in a quarantined area and remove them from the site at

the earliest opportunity.

14.3 TRANSPORTATION, HANDLING AND STORAGE OF PRODUCTS AND

MATERIALS

14.3.1 General

Transport, handle and store all products and materials in accordance with the

manufacturers recommendations and in a manner that prevents damage or deterioration

or excessive distortion.

Pay particular attention to the protection of product and material coatings and linings.

Stack all pipe in a manner that minimises pipe ovalisation.

Do not store plastic pipe and fittings and plastic coated pipe and fittings near generators or

other heat emitting equipment.

Store rubber sealing rings, lip seals and gaskets away from sunlight and in an unstrained

condition.

Do not store PVC, GRP, ABS and non-black PE pipe and fittings uncovered in direct

sunlight for more than twelve (12) months. If storage periods are likely to exceed twelve

(12) months, cover and store pipe in a manner that allows ventilitation and prevents heat

entrapment.

Except for checking against the purchase order, keep pipe, fittings, valves, seals and other

components delivered within protective crating or packaging, until immediately prior to use.

Keep the ends of plastic pipe and fittings or plastic couplings on GRP pipe free of loading.

Use PVC, GRP, ABS and non-black PE pipe and fittings within two (2) years of

manufacture.

14.3.2 Plastics-lined concrete products

Transport, handle and store plastics lined precast concrete products in accordance with the

product manufacturer's printed instructions. Notwithstanding this requirement:

(a)

Use only lifting and transportation equipment that does not contact plastics linings

and plastics accessories, except where appropriate padding or protective systems

are used.

COPYRIGHT

165

WSA 022002-2.3

(b)

Provide special protection for unsecured plastics linings and PVC sheet flaps and

accessories during handling, storage and construction operations until secured in the

completed installation.

(c)

Prevent exposure to sunlight of plastics lining sheets and accessories for the duration

of the project.

(d)

Provide a secure, clean and dry storage area for plastics linings work materials and

tools.

(e)

Do not incorporate in the Works any plastics-lined concrete product or accessory:

(i)

which has not complied with the requirements of this sub-clause; or

(ii)

whose bore, in the case of pipe or MH product, is affected by plastic lining

corrugations and/or non-circularities, which reduce:

(iii)

(A)

pipe waterway area by more than 1.5%; and/or

(B)

pipe diameter by more than 5 mm for pipe <DN 1800; or

(C)

pipe diameter by more than 10 mm for pipe DN 1800 over; or

which is above the dimensional tolerances permitted by the requirements of the

Purchase Specification for unlined concrete product.

14.4 DELIVERY INSPECTION OF PRODUCTS AND MATERIALS

Inspect all products and materials at the time of delivery for damage and excessive

distortion.

Replace products and materials that are damaged, excessively distorted, outside their useby date or storage period and indelibly mark or tag with wording such as Do not use or

other identification.

Do not use:

(a)

PE pipes and fittings scored deeper than 10% of the wall thickness.

(b)

Faded / discoloured PVC, PE, ABS, GRP and plastic coated pipes and fittings.

(c)

PVC and ABS pipes and fittings scored deeper than 0.5 mm.

(d)

GRP pipes and fittings scored deeper than 1 mm or with impact damage.

Remove rejected products and materials and store separately from useable products to

prevent inadvertent use.

14.5 CONCRETE WORKS

14.5.1 Delivery

Concrete shall be delivered to site for placement within 90 minutes of commencement of

mixing at the plant or within the time limitations for the mix and ambient temperature.

14.5.2 Transportation of concrete

Use pneumatic and pumping or other methods for conveying and placing concrete when

nominated in the Specification or when authorised by the Superintendent. Where concrete

is conveyed by wheeled vehicles or barrows, the equipment used and the distance

travelled shall be authorised by the Superintendent.

If concrete is conveyed by chute, the equipment shall be of such size, slope and type as to

ensure the continuous flow of concrete without segregation of materials. The delivery end

of the chute shall be as near as possible to the final position of the concrete and it shall be

provided with an effective baffle. If the chuting operation is not continuous, the chute shall

discharge the concrete into a hopper.

COPYRIGHT

WSA 022002-2.3

166

14.5.3 Formwork

14.5.3.1 General

Formwork, including all temporary supporting structures and precast members, shall

comply with the requirements of AS 3610 and the additional requirements of this Code,

including Standard Drawings.

Forms shall be sufficiently tight to prevent loss of mortar from the concrete. Form surfaces

shall be smooth and free from holes or irregularities detrimental to the finished concrete

surface.

Before placing the concrete, coat the forms with a suitable, non-staining coating, which will

facilitate their release.

Finish surfaces as specified.

14.5.3.2 Formwork for plastics-lined concrete

Set out and install formwork for in-situ concrete structures to be plastic lined so as to

facilitate fixing of plastic lining materials to internal formwork faces and in a manner that

will:

(a)

Ensure intimate continuous contact of lining materials with the formwork.

(b)

Position fixing holes within areas of lining that will be subsequently covered by

jointing or welding strips.

(c)

Avoid the securing of lining materials by means of bands or straps otherwise than as

provided for in the lining material manufacturer's printed instructions.

14.5.4 Reinforcement

Supply, fix and place reinforcement in accordance with AS 3600. Ensure the specified

minimum cover is achievable between ends of members and / or construction joints.

Continuously monitor placement.

14.5.5 Placement

14.5.5.1 General

Place concrete within the time limitations for the mix and ambient temperature. Place in

discrete layers in one continuous operation between ends of members and/or construction

joints.

Continuously monitor placement.

Surfaces upon or against which concrete is to be placed shall be free of standing water,

mud and debris.

Prior to placing concrete on concrete that has set, prepare the surface of the set concrete

by scabbling to expose aggregate, clean off loose material and dampen and apply a

bonding agent recommended by the concrete supplier.

In the placement of vertical elements, do not allow free fall of concrete to exceed 1.6 m.

14.5.5.2 Placement in water

Deposit concrete in water only where specified or authorised by the Superintendent.

Place concrete in water under the direct supervision of the Superintendent.

Take precautions to prevent significant mortar loss where concrete is to be placed in

running water.

Place concrete in water continuously in a compact mass, with the top surface kept as level

as practicable, by:

(a)

Using a properly designed tremie or drop bottom bucket;

COPYRIGHT

167

WSA 022002-2.3

(b)

Pre-packing and grouting; or

(c)

Placing in suitably tied jute bags, each containing not less than 15 litres of concrete.

Where concrete is provided in bags, place the bags in header and stretcher courses so

that the entire mass in interlocked.

14.5.6 Slump

Slump shall be appropriate to the project specified by the Constructor on advice from the

concrete supplier.

There is no default value for slump in the Purchase Specifications because slump is

dependent on the method of placement.

The slump at the point of acceptance shall be in the range 80120 mm. Under no

circumstances is additional water to be added onsite unless approved by the concrete

supplier.

Higher slumps can result in an increase in bleed water requiring additional precautions

when finishing concrete. The constructor should liaise with the concrete supplier in

determining the slump.

The addition of excess water onsite can adversely affect the strength and durability of the

concrete.

14.5.7 Compaction

Immediately compact concrete after placing. Use internal and/or external vibration in a

systematic manner to ensure that all concrete is thoroughly compacted. Vibrate to the full

depth of each layer and extend into the top 100 mm of the underlying layer. Do not vibrate

to the point where segregation of the ingredients occurs.

Use rotary out of balance vibrators.

Where internal vibrators are used, insert them vertically at successive locations and at

spacings not exceeding the manufacturers stated zone of influence. Do not allow vibrators

to contact partially hardened concrete or reinforcement embedded in it.

In regions of closely spaced horizontal reinforcement, ensure full compaction directly

beneath the closely spaced horizontal reinforcement prior to encasing the reinforcement

with concrete.

14.5.8 Stripping

Ensure that concrete has adequate strength before stripping formwork.

Remove forms in a manner that will not injure the concrete. Provide temporary support to

the concrete structure so as to protect freshly stripped concrete from construction loads.

14.5.9 Curing

Cure concrete as specified.

14.5.10 Repair of blemishes

Fill surface holes and damage exceeding specified limits by filling with cementitious mortar

bonded to the concrete.

14.6 SUPPLY OF WATER TO THE WORKS

Obtain an authorisation from the Superintendent for the supply of water for construction

purposes.

Do not take water from any metered or private trunk service without the Owner's

permission.

Maintain all hydrants to protect the quality of water supplied.

COPYRIGHT

WSA 022002-2.3

168

Fit an authorised backflow prevention device in accordance with AS/NZS 3500.1.2 to any

equipment drawing water from the Water Agency supply system.

Introduction of water supply restrictions over the designated Works area may prohibit the

supply of water to the site. The Water Agency should be consulted to confirm the

availability of water supply during the construction period. Alternative sources of supply

may need to be sought in the case of restrictions.

14.7 ON-SITE STOCKPILES

Store only sufficient materials on-site as are necessary to allow timely and efficient

progress of the work. Locate stockpiles of excavated or imported material where they

cause no interference to the public, drainage routes or vehicular or pedestrian traffic.

Do not obstruct clear lines of sight for drivers.

Do not stack materials against structures, fences, trees or other property improvements.

Leave a clear path between the edge of any excavation and the inner toe of any stockpile

or spoil banks such that no loading is imposed on the trench wall.

Do not stack or stockpile materials under overhead electrical conductors.

Obtain written permission of the Owner for storage of materials, equipment and/or

excavated material for the Works on the Owner's land.

COPYRIGHT

169

WSA 022002-2.3

15 EXCAVATION

15.1 SAFETY

Do not commence any excavation until all equipment and materials necessary to make the

excavation safe are on site and available for use. This includes any necessary fencing and

barriers, as well as trench support systems.

Assess site for prior excavations and consider their impact on the new excavation.

Conduct a site hazard and safety assessment prior to commencement of any excavation to

identify all potential hazards.

15.2 LIMITS OF EXCAVATION

Keep the extent of excavation to the minimum possible to allow efficient construction of the

Works while meeting the requirements shown on relevant Design Drawings.

Unless specified otherwise, keep the sides of excavations vertical to at least 150 mm

above the sewer.

Ensure that the minimum cover requirements shown on relevant Design Drawings are

satisfied following any earthworks that may occur in the area of the sewer. This is

particularly relevant in new subdivisions or developments where earthworks are expected

to form roads, driveways, footways and for general shaping of the surfaces. If minimum

cover requirements cannot be achieved, submit a proposal to the Superintendent to

overcome the problem.

15.3 EXCAVATION ACROSS IMPROVED SURFACES

Obtain written permission of the Owner prior to commencing any excavation across

improved surfaces.

If excavation is required across improved surfaces such as pavements, driveways, kerbs

and gutters, where the surfaces cannot be satisfactorily reinstated, use boring in

accordance with Clause 17.12.

For open excavations across improved surfaces, keep the trench width to the minimum

allowed. Saw cut neat straight lines at least 150 mm beyond the outer limits of the

excavation through bitumen, asphalt and concrete. Remove pavers, blocks or brick

pavements by hand, clean them and set them aside for later replacement. Ensure trench

fill is compacted to requirements of Clause 21.1.3.

15.4 EXCAVATION IN ROOT ZONES

Take every precaution to ensure that no undue damage is caused to a tree root system as

a result of excavation for the Works. Excavation for sewer construction by hand or by

boring may be required to protect the root zone.

Cleanly cut all roots 60 mm diameter encountered during excavation.

Do not cut tree roots larger than 60 mm diameter without authorisation of the

Superintendent.

15.5 BLASTING

Use alternative methods of excavation to blasting wherever achievable.

Obtain prior authorisation from the Superintendent, relevant Regulator and affected

Owners of assets within the vicinity before undertaking blasting.

Where authorisation is granted, prepare a blasting plan that includes management of the

blasting and means to be used to satisfy the requirements of AS 2187 and the authorising

parties.

COPYRIGHT

WSA 022002-2.3

170

15.6 SUPPORT OF EXCAVATIONS

Support all trenches of depth 1.5 m or greater.

Support all excavations as the work proceeds to meet OH&S requirements. Ensure that

adjacent structures and services are not subject to disturbance by the trench support

system.

When removing, raising or withdrawing supports, prevent slips or falls and ensure that no

damage, disturbance or displacement occurs to the pipes, fittings, geotextile filter fabric,

pipe embedment and trench fill already installed. Fill the trench simultaneously with the

raising or withdrawal of trench supports. Ensure that compaction of pipe embedment and

trench fill material occurs below such trench support and against native ground.

Where specified, leave the trench support system in place as permanent support. Cut off

the support system at a depth below ground surface that will satisfy the structural and

development requirements of the site.

15.7 DRAINAGE AND DEWATERING

Keep all excavations free of water. Provide, maintain and operate intercepting Works to

prevent surface water from entering the excavations. Provide all equipment necessary for

dewatering the excavations and keeping the Works free from water.

Only lower the water table by well points or other external dewatering methods if no

damage is likely to be caused to adjacent structures and services or the environment.

Ensure that all downstream Works that are under construction, completed or in use are

protected at all times against the effects of any drainage that is discharged or likely to be

discharged from the Works.

Do not discharge dewatering to sewers, storm water drains or watercourses without

appropriate authorisation and without complying with the Owners or Regulators

requirements.

15.8 FOUNDATIONS AND FOUNDATION STABILISATION

The bottom of the excavated trench is required to provide a foundation suitable for the

adopted construction method.

Prior to placing embedment, check the proposed foundation using Standard Drawing

SEW1200 as a guide. Where the bottom of an excavation is unable to provide a firm

foundation with minimum bearing capacity of 50 kPa at the required level (tolerance +0, 50 mm) without abrupt irregularities or undulations, obtain written instruction from the

Superintendent on the means for providing a satisfactory foundation.

The Superintendent will seek the instruction from the Designer in most instances.

Construct special supports in accordance with the Design Drawings.

15.9 SURPLUS EXCAVATED MATERIAL

Surplus material is the property of the Owner of the excavation site.

Where the spoil from trench excavation is to be used for trench fill, isolate the topsoil for

later use in restoration.

Promptly remove and dispose of excavated material that is not required for reuse. Dispose

of lawfully and in accordance with project requirements.

COPYRIGHT

171

WSA 022002-2.3

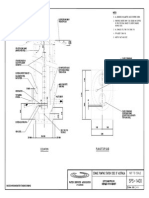

16 BEDDING FOR PIPES AND MAINTENANCE STRUCTURES

16.1 TRENCH FLOOR PREPARATION

Inspect the trench floor on excavation for rock outcrops and soft and loose areas. Take

appropriate action to ensure that the pipe or fitting or other appurtenance or structure will

not be subject to differential settlement in the future.

Where rock outcrops are present, trim the trench floor and fill with granular material to

restore the design trench floor level limits. Treat soft and loose areas as specified in

Clause 15.8.

Compact all fill and all disturbed areas to not less than the density of the natural ground.

Remove all debris and water before bedding sand is placed.

16.2 BEDDING MATERIALS

Use specified bedding materials.

16.3 PLACEMENT OF BEDDING

Provide bedding of the type shown on relevant Design Drawings. Place and rake-in the

bedding to support the pipe uniformly along the whole length of the barrel with chases

provided for sockets, couplings and other appurtenances. Do not compact the bedding.

Do not walk on the centre of the bedding either during or after placement.

Reference: Standard Drawings SEW1201 and SEW1202.

16.4 SPECIAL PIPE SUPPORT FOR NON-SUPPORTIVE SOILS

Construct piered or other special support as specified.

Reference: Standard Drawings SEW1203, SEW1204 and SEW1205.

16.5 BEDDING FOR MAINTENANCE SHAFTS AND BENDS

Prepare bedding in accordance with Clause 16.3 to provide full support of the sewer,

maintenance shafts and bends.

Reference: Standard Drawings SEW1314, SEW1315, SEW1316 and SEW1317.

16.6 BEDDING FOR MAINTENANCE HOLES

Lay the base of a maintenance hole in supportive ground.

Prior to casting a base, check the proposed foundation using SEW1200 as a guide.

Where the allowable bearing pressure appears to be less than 50 kPa, obtain instruction

from the Superintendent on the means for providing satisfactory foundation.

Where a precast base is used, place bedding materials in accordance with Clause 16.3.

Construct special supports as specified.

Reference: Standard Drawings SEW1201 and SEW1205.

COPYRIGHT

WSA 022002-2.3

172

17 PIPE LAYING AND JOINTING

17.1 INSTALLATION OF PIPES

17.1.1 General

After preparing pipe bedding, lay and joint pipes in locations and sizes as specified. Use

methods, materials, tools and equipment in accordance with manufacturer's and/or

suppliers instructions and recommendations, relevant Standards and requirements of this

Part. Adhere to any limitations imposed by the Water Agencys OH&S and/or

environmental requirements.

17.1.2 Cleaning, inspection and joint preparation

Clean and examine all pipeline system items before installation. Inspect each joint seal for

fit and flaws before making the joint in accordance with the manufacturers instructions. Do

not use damaged, dirty or incorrect seals. Ensure that the correct joint lubricant is used for

rubber seals.

Inspect all items just prior to use in accordance with Clause 14.4. Remove damaged items

from the Works site and replace.

Chamfer, if required, and provide witness marks on the unmarked length of any cut pipes.

Do not score pipes when providing the witness mark.

Treat cut pipe ends in accordance with pipe manufacturers recommendations.

The jointing methods will vary depending upon the material used and the jointing systems

available. The Product and Material Information and Guidance, suppliers drawings and

Standard Drawings provide information on jointing systems.

17.1.3 Polyethylene

Weld PE pipe system components in accordance with WSA 01.

17.1.4 Laying

Commence laying at the downstream end. Lay pipes with their sockets at the upstream end

and their barrels firmly and evenly embedded on the bedding material. Form chases in the

bedding to accommodate the pipe sockets and/or couplings to allow even bearing along

the full length of the pipe barrel.

To prevent movement, restrain pipes already laid before the next joint is made. Prevent

flotation of pipes during laying in accordance with Clause 17.4.

At the end of each day's laying, seal the end of the pipe to prevent ingress of trench

material and/or water and other foreign matter.

Reference Standard Drawings: SEW1103 and SEW1201.

17.2 HORIZONTAL AND VERTICAL DEFLECTION OF SEWERS

17.2.1 General

Achieve horizontal and vertical deflections as specified and in accordance with Clause

17.2.2. Where not specified, do not deflect the sewer unless:

(a)

the Superintendents authorisation has been obtained, and

(b)

the Design Drawings have been revised to show the bend or curve details, including

location, angle and methods of achieving deflection.

Ensure that actual details of deflections are accurately recorded on the Work as

Constructed drawings.

COPYRIGHT

WSA 022002-2.3

173

17.2.2 Methods of deflection

Achieve horizontal and vertical deflections as specified using one of the following methods:

(a)

Deflecting consecutive flexible joints in accordance with Table 17.1, provided no

individual joint deflection exceeds 80% of the manufacturers recommended

maximum joint deflection. In some pipe systems the maximum allowable joint

deflection is marked on the pipe socket.

(b)

Manually (not mechanically) cold bending flexible pipes in circular arcs of uniform

radius to exceed the minium prescribed radii specified in Table 17.1. Limit cold

bending to DN 150 and DN 225 pipe sizes only. Do not cold bend SCJ PVC pipe

where branch sewers or property connection branches are to be installed along the

curve. Curves formed by cold bending the pipes should be designed.

(c)

Using a variable bend (Refer to Standard Drawing SEW1315).

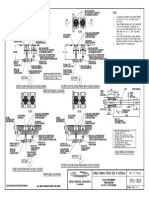

TABLE 17.1

METHODS OF ACHIEVING CURVED SEWERS

Curve type

Cumulative

deflection at

joints

Manual cold

bending

Manufactured

bends

Material and

joint

Pipe size

Pipe length

DN

Deflection

at joint

Minimum horizontal

and vertical curve

radius

m

VC

Socket - Spigot

Yes

100 1400

Up to 2.5

varies with DN

Note 1

VC

polypropylene

coupling

Yes

100 300

Up to 2.5

varies with DN

Note 1

PVC

elastomeric seal

jointed (RRJ)

Yes

100 375

3.0 6.0

Note 1

Profiled wall PE

Socket - Spigot

Yes

375 2100

2.4 6.0

Note 1

PVC

solvent cement

jointed

No

100 300

PE

welded joints

SDR 21

No

160 355

Not dependent

Not dependent

0.3 X DN

o

0.02 X DN at T 20 C

0.05 X DN at 0 o C

Note 2

PVC

Yes

RRJ only

100 375

Not dependent

Note 3

GRP

Yes

300 1200

Not dependent

Note 3

Profiled wall PE

Yes

Up to 1500

Not dependent

Note 3

PVC variable

bend

No

150 225

Not dependent

0.9

NOTES:

1

The minimum radius for solvent cement welded PVC pipes and welded PE pipes is based upon:

(a)

the deflection that may be achieved without overstressing the pipe or pipe joint; and

(b)

ensuring that the necessary restraint of the pipe and joints around the curve is readily

achievable based on manually cold bending the pipe in the field.

Interpolate values for temperatures between 0C and 20C.

Refer to Water Agency for minium acceptable radii for manufactured bends.

COPYRIGHT

WSA 022002-2.3

174

17.2.3 Horizontal curves

Install curves either adjacent to an MH or MS or in a straight run between MHs or MSs or

combinations of both.

Place horizontal variable bends on the upstream side of MHs adjacent to the MH but clear

of the external face of the MH wall. It is important that the bend is clear of benching and

the MH wall to allow easier manipulation of equipment.

Place horizontal variable bends on the upstream side of MSs and immediately adjacent to

the MS.

Install horizontal bends clear of all drop structures.

Ensure that the commencement of any cold bent PVC pipe is clear of the external face of

the MH wall.

After completion of pipelaying and placement of embedment material, remove temporary

pegs or stakes used to restrain curved pipes.

Removal of temporary pegs or stakes is essential to avoid point loading of the pipes. Nonremoval may result in pipe failures.

17.2.4 Vertical curves

Install curves either adjacent to an MH or MS or in a straight run between MHs or MSs or

combinations of both.

Place vertical variable bends on the upstream side of MHs adjacent to the MH but clear of

the external face of the MH wall. It is important that the bend is clear of benching and the

MH wall to allow easier manipulation of equipment.

When installed adjacent to a MS, place vertical variable bends on the side of the MS that

maximises the vertical alignment of the MS riser. Alternatively, install bends either side of

the MS to achieve the total change in grade.

Install vertical bends clear of all drop structures.

Limit vertical variable bends to two locations adjacent to and between MHs or MSs. Place

on the upstream and/or downstream side of the MH/MS immediately adjacent to the

structure i.e. one at the outlet of MH/MS and one at the inlet of the downstream MH/MS.

Limit cumulative joint and cold vertical bends to one additional location between adjacent

MHs or MSs or combinations of both.

After completion of pipelaying and placement of embedment material, remove temporary

pegs or stakes used to restrain curved pipes.

Removal of temporary pegs or stakes is essential to avoid point loading of the pipes. Nonremoval may result in pipe failures.

17.2.5 Compound curves

Where authorised by the Water Agency, compound bends may be used with any of the

bend methods and in any of the allowable horizontal bend locations.

17.3 HORIZONTAL AND VERTICAL SEPARATION OF CROSSING PIPELINES

Maintain minimum horizontal and vertical separation of crossing pipelines as specified. Fill

the separation with embedment material and compact.

17.4 FLOTATION CONTROL

Prevent floatation of pipes and MSs by:

(a)

Using trench stops in accordance with SEW1206; and/or

(b)

Placing and compacting sufficient height of fill material; and/or

COPYRIGHT

175

(c)

Filling the pipeline with water, where authorised; and/or

(d)

Other appropriate methods authorised by the Superintendent.

WSA 022002-2.3

Where trench de-watering is necessary, fully place and compact embedment and fill

material in accordance with Sections 20 and 21 while dewatering systems are operating.

Some materials such as PE have a density less than that of water and sewers can float

even when full of water.

17.5 TRENCH STOPS

Construct trench stops with trench drainage as specified.

Reference: Standard Drawings SEW1206 and SEW1207.

17.6 BULKHEADS

Construct concrete bulkheads with trench drainage as specified. Do not position the

bulkhead directly beneath a kerb.

Reference: Standard Drawings SEW1206 and SEW1207.

17.7 PROPERTY CONNECTION SEWERS

Install property connection sewers as specified.

Ensure tolerances for position, level and plumb are within the limits specified in Section 23.

Fill and compact as specified for the reticulation sewer.

Where concrete surround or encasement of a riser is specified, allow a minimum of 16 h

for the concrete to set before constructing a property connection sewer.

Locate vertical drops or risers to prevent damage to the sewer and provide support to

maintain their position during encasement or backfilling.

Mark locations of property connection points by placing a marking tape from the connection

point to a hardwood surface peg or by using detectable marking tape similarly placed.

Reference: Standard Drawings SEW1105, SEW1106, SEW1107, SEW1108, SEW

1109, SEW1314 and SEW1316.

17.8 DEAD ENDS

Terminate sewer lines as specified.

Reference: Standard Drawings SEW1109 and SEW1316.

17.9 MARKING OF PROPERTY CONNECTION SEWERS AND DEAD ENDS

Mark the position of each dead end and location of each property connection point using

identification tape and hardwood peg or by using a detectable tape.

Reference: Standard Drawings SEW1107 and SEW1109.

17.10 CORROSION PROTECTION OF CAST IRON

Sleeve uncoated buried cast iron items with polyethylene, fixed with PVC tape complying

with AS 3680. Install sleeving to AS 3681. Do not allow sleeved items to be exposed to

sunlight for more than seven (7) days.

Sleeving may be omitted for items that have a thermal-bonded polymeric external coating

complying with specified requirements in Part 2 of the Code.

Cast iron includes grey cast iron and ductile (cast) iron.

COPYRIGHT

WSA 022002-2.3

176

17.11 MARKING TAPES

17.11.1 Non-detectable marking tape

When specified, lay non-detectable marking tape on top of the pipe embedment material

before trench filling.

Reference: Standard Drawing SEW1201.

17.11.2 Detectable marking tape

Lay detectable marking tape on top of the pipe embedment material before trench filling or

1 m below the surface for:

(a)

non-metallic pipelines, as specified;

(b)

all curved pipelines;

(c)

property connection sewers, as specified;

(d)

all sewers without an upstream access point; and

(e)

at other locations as specified.

Lay the tape over the embedment to form a continuous connection between access cover

frames. Strip the ends of the tape to expose its conducting wires. Connect bare wires to a

nut or bolt of the access cover frame to form an electrical connection.

Reference: Standard Drawing SEW1201.

17.12 BORED PIPES UNDER ROADS, DRIVEWAYS AND ELSEWHERE

Construct bored sewers under roads, railways, driveways, footways and elsewhere of the

type, size and locations shown in the Design Drawings.

Construct encasing pipe as detailed in the Design Drawings. Where grouting of the annulus

between the encasing pipe and sewer is specified, commence grouting from the downhill