Beruflich Dokumente

Kultur Dokumente

COBB Tuning 335i BMW FMIC Installation Instructions - 5-14-13

Hochgeladen von

Javi MartinezCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

COBB Tuning 335i BMW FMIC Installation Instructions - 5-14-13

Hochgeladen von

Javi MartinezCopyright:

Verfügbare Formate

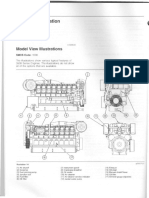

FRONT MOUNT INTERCOOLER

2007-2012, E9X 335i, E8X 135i, 1M

Congratulations on your purchase of the COBB Front Mount Intercooler for your 2007-2012 E9X BMW

335i, 135i, 1M! The following instructions will assist you through the installation process. Please read

through all of the instructions first BEFORE beginning the install and familiarize yourself with the steps

and tools needed. If you feel that you cannot properly perform this installation, we HIGHLY recommend

you take the vehicle to a qualified and experienced automotive technician.

Part List

(1) Front Mount Intercooler

(1) Inlet Coupler

(1) Outlet Coupler

(1) Elbow Pipe

(4) T-bolt Clamps

(2) Phillips 1.5 Screws

(2) M6x20MM Hex Screws

(2) Rubber Bushings

(2) Stainless Steel Washers

Tools Needed

7mm socket

8mm socket

10mm socket

11mm socket

Pliers

T20 TORX

T25 TORX

Phillips and Flathead screw driver

Socket Extensions

Socket swivel

Removal of Stock Front Mount Intercooler:

1. Remove the air intake snorkel. There are two (2) T20 screws that hold the snorkel in. Use a T20

TORX socket.

Use a flat head screwdriver to pull back on the tabs that hold the snorkel to the air intake box. Once

pulled back, the snorkel can be pulled out.

2. Loosen the factory worm clamp on the charge pipe and stock elbow pipe with a 7mm socket.

3. Remove the underbody plastic tray. The underbody tray is secured by 8mm screws. Remove the

screws.

Copyright 2012 COBB Tuning Products LLC. All Rights Reserved | www.cobbtuning.com

4. Remove the two (2) C clips on the stock FMIC using pliers. These clips are located on the outlets of

the intercooler.

Start by using a set of pliers to pull back on the clip.

5. Position a stand or floor jack under the FMIC.

Copyright 2012 COBB Tuning Products LLC. All Rights Reserved | www.cobbtuning.com

6. Loosen the inlet coupler and outlet elbow from the intercooler using a flat head screwdriver.

7. Unclip and remove the plastic piece that is on the bottom of the stock intercooler. To do this there are

two tabs that need to be unlocked.

LOCKED

UNLOCKED

Copyright 2012 COBB Tuning Products LLC. All Rights Reserved | www.cobbtuning.com

8. Unscrew two (2) T25 TORX bolts that secure intercooler to the fan shroud. Once the bolts are

removed, the only thing holding the intercooler up will be the elbow pipe and OEM inlet coupler that

are loosely supporting the intercooler.

9. Lower the intercooler and remove from vehicle.

Copyright 2012 COBB Tuning Products LLC. All Rights Reserved | www.cobbtuning.com

10. Remove the factory turbo outlet coupler. The factory coupler should be held together to the turbo

outlet pipe via a metal band. On the metal band there should be a saw/zipper pattern. Using a

screwdriver gently pry at the saw/zipper pattern until the metal band pops loose. Now the factory inlet

coupler can be removed. Note: Be gentle with the screwdriver because it is connected to the turbo

outlet pipe which is made out of aluminum and can be easily bent. Another alternative is using a

dremel to cut the metal band but once again, caution must be used.

Copyright 2012 COBB Tuning Products LLC. All Rights Reserved | www.cobbtuning.com

11. Remove the factory elbow pipe.

The factory worm clamp that connects the elbow pipe to the charge pipe should already be loosened at

this point. Start from above the car and push back on the charge pipe and pull on the elbow pipe until it

is freed from the charge pipe.

Copyright 2012 COBB Tuning Products LLC. All Rights Reserved | www.cobbtuning.com

Next, the factory elbow pipe will need to be removed from the rubber grommet hold it to vehicle. From

above the car, pull on the elbow pipe upwards to free the elbow pipe from the grommet.

Once freed from the grommet, you will need to wiggle and snake the elbow pipe out from below the car.

It will be a tight fit.

12. Remove the passenger side plastic bracket. This will require some wiggling and the use of a

screwdriver. This piece needs to be removed or the FMIC will not fit properly. Be aware of the tabs

that hold this piece in. Push back on the tabs with the screwdriver and the bracket will easily come

out.

Copyright 2012 COBB Tuning Products LLC. All Rights Reserved | www.cobbtuning.com

Installation of the COBB Front Mount Intercooler:

1. Install the new outlet coupler onto the COBB elbow pipe. Use an 11mm socket to lightly tighten the

T-bolt clamp so the coupler can still move but will not fall off. Try to roughly match the shape of the

OEM charge pipe. Note that there are two (2) different size T-bolt clamps for this FMIC kit. The two

(2) large T-bolt clamps are for the inlet and outlets of the FMIC. The two (2) smaller sized ones are

for the elbow pipe and the turbo outlet pipe.

2. Take the elbow pipe and coupler assembly and snake it up to the charge pipe from below the car.

Make sure the T-bolt can be accessed from below for final tightening.

Copyright 2012 COBB Tuning Products LLC. All Rights Reserved | www.cobbtuning.com

3. Lower the car and slide the elbow pipe into the charge pipe coupler. Lightly tighten the charge pipe

worm clamp from above the car with a 7mm socket. You will tighten this at the end of the installation.

4. Lift the car back up and install the turbo outlet coupler onto the turbo outlet pipe. Tighten the T-bolt

clamp with an 11mm socket but make sure that the clamps are loose enough to allow the silicone

coupler to move. Position the coupler such that the larger outlet is facing downwards towards the

ground.

Copyright 2012 COBB Tuning Products LLC. All Rights Reserved | www.cobbtuning.com

Screw

5. Put one T-bolt clamp over each end tank inlet and outlet on the FMIC.

Rubber Bushing

Fender Washer

6. Supplied are two (2) rubber bushings and two (2) fender washers. Use the supplied fender washers

between the screw head and bracket and the rubber bushing between the bracket and car chassis.

These rubber bushings are meant to reduce vibrations to the FMIC. For the 3 Series, please use the

1.5 Phillips screw in the kit as a replacement for the OEM screw. For the 1 Series, use the

M6x20MM hex screw instead.

Copyright 2012 COBB Tuning Products LLC. All Rights Reserved | www.cobbtuning.com

10

(For the 1 Series) An adapter bracket is required because the intercooler cannot sit as far forward as it

can in the 3 Series so the mounting point must be shifted back. Begin by installing the adapter bracket to

the OEM mounting locations on the fan using the OEM T25 TORX screw.

7. Put the FMIC on a stand or floor jack and raise the intercooler up towards the car. Pull back on the

radiator fan and possibly the bumper. The fitment should be tight but the fan shroud should allow the

FMIC to push back on it.

8. As the FMIC is raised into position, pull back on the elbow pipe coupler and adjust the turbo outlet

coupler to make sure both couplers fit over the intercooler end tank holes. There are also two tabs on

the bottom of the FMIC core that are meant to slide over the fan shroud. Make sure that the tabs are

properly secured when the FMIC is lifted into place.

Copyright 2012 COBB Tuning Products LLC. All Rights Reserved | www.cobbtuning.com

11

9. For the 3 Series, use a Phillips screwdriver now to secure the screws lightly on the FMIC to the fan

shroud. Note: Be gentle because the threads on the fan shroud are plastic. Repeated use and too

much torque may cause the threads to strip.

(For the 1 Series) Use a 10mm socket to drive the M6x20mm hex screw into the adapter bracket.

Copyright 2012 COBB Tuning Products LLC. All Rights Reserved | www.cobbtuning.com

12

Water Pump

Belts

10. Wiggle and adjust the inlet coupler to the turbo outlet piping. Make sure the coupler is over the beadrolled edges on both the end tank and turbo outlet pipe. Then tighten both of the T-bolt clamps. The

use of a swivel socket will make things much easier here. Do not over tighten the clamp on the turbo

outlet as it could crush the aluminum tube.

11. Next adjust the elbow coupler to the elbow pipe. Check for any leaks. Make sure that the coupler is

over the bead-rolled edges on the endtank and the elbow pipe. Also check to make sure the elbow

pipe, couplers and clamps are not interfering with any engine components such as the serpentine

belt, pulleys or hoses. When satisfied, tighten down the T-bolt clamps.

Copyright 2012 COBB Tuning Products LLC. All Rights Reserved | www.cobbtuning.com

13

12. Double check all T-bolt clamps, couplers and tighten the mounting screws. Make sure all clamps are

tightened sufficiently and that the couplers are properly seated over their respective inlets. Failure to

secure couplers and T-bolt clamps properly may result in a boost leak which can give error codes. In

some cases, the clamps on couplers can blow off under higher boost pressures. This is often caused

by loose clamps or clamps that are not positioned properly behind the bead rolls.

13. Reinstall the underbody panel using an 8mm socket.

14. Finally, lower the car and tighten the worm clamp that secures the elbow to charge pipe coupler

using a 7mm socket.

15. Congratulations! You have completed the installation of the COBB FMIC for your E9x BMW. Go out

and enjoy!

Copyright 2012 COBB Tuning Products LLC. All Rights Reserved | www.cobbtuning.com

14

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- HM300 2Dokument1.412 SeitenHM300 2Ivica Šućur100% (1)

- PACCAR - MX (2013 Emissions) .MX-13 (EPA 2013-16)Dokument13 SeitenPACCAR - MX (2013 Emissions) .MX-13 (EPA 2013-16)Miguel Tirado100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Gym Jones Public Content and Workout PDFDokument17 SeitenGym Jones Public Content and Workout PDFPierre Lheureux100% (25)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Case IH MX Tractor SRT ManualDokument81 SeitenCase IH MX Tractor SRT Manualhuskerchamps60% (5)

- Workshop Manual Technical Data TAD530 531 532GE TAD730 731 732 733GE Group 20 26Dokument140 SeitenWorkshop Manual Technical Data TAD530 531 532GE TAD730 731 732 733GE Group 20 26Courtney French91% (23)

- 3512 Engine MaintenanceDokument30 Seiten3512 Engine Maintenancekhir khirNoch keine Bewertungen

- Cat 3406C 380HP D RatingDokument4 SeitenCat 3406C 380HP D RatingDian Aprilia II100% (1)

- GEARS March 2015 - Annual Torque Converter IssueDokument84 SeitenGEARS March 2015 - Annual Torque Converter IssueRodger Bland60% (5)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Man of Steel Pre Phase HORIZONTALDokument6 SeitenMan of Steel Pre Phase HORIZONTALJavi Martinez100% (1)

- New 1000 SeriesDokument0 SeitenNew 1000 SeriesWere WolfNoch keine Bewertungen

- DEUTZ Ellecttrroniic DiispllayDokument37 SeitenDEUTZ Ellecttrroniic DiispllayAkhtar ButtNoch keine Bewertungen

- CATERPILLAR C18- PART CODE (HD 22-CYG1-Up (Engine) ) (đã cắt) PDFDokument32 SeitenCATERPILLAR C18- PART CODE (HD 22-CYG1-Up (Engine) ) (đã cắt) PDFsfsdffdsdfsdfsdfNoch keine Bewertungen

- Gym JonesDokument19 SeitenGym Jonesmgj2100% (1)

- Despiece MaxionDokument84 SeitenDespiece Maxionnelsonreus100% (1)

- 6 - Manual de Partes en Ingles D 2876 Le301Dokument138 Seiten6 - Manual de Partes en Ingles D 2876 Le301wilmerNoch keine Bewertungen

- Everything You Need to Know About SuperchargersDokument22 SeitenEverything You Need to Know About SuperchargersVinod Subramaniam50% (2)

- 300 Workout Routine AbsDokument8 Seiten300 Workout Routine AbsJavi MartinezNoch keine Bewertungen

- 21 Day Fix Extreme 1500 1799Dokument1 Seite21 Day Fix Extreme 1500 1799Javi MartinezNoch keine Bewertungen

- 21 Day Fix Meal PlannerDokument1 Seite21 Day Fix Meal PlannerJavi MartinezNoch keine Bewertungen

- Max30 7 Day JournalDokument7 SeitenMax30 7 Day JournalJavi MartinezNoch keine Bewertungen

- Combox Installation Instruction For Exx Series BMWDokument14 SeitenCombox Installation Instruction For Exx Series BMWJavi MartinezNoch keine Bewertungen

- 21 Day Fix Meal 1Dokument1 Seite21 Day Fix Meal 1Javi MartinezNoch keine Bewertungen

- BodyBeast Calendar LeanDokument1 SeiteBodyBeast Calendar LeanJavi MartinezNoch keine Bewertungen

- Oic Competence Reviewer 2017Dokument647 SeitenOic Competence Reviewer 2017Reinier Callanta100% (1)

- Cabstar PDFDokument8 SeitenCabstar PDFChristopherNoch keine Bewertungen

- Energized Innovation: The Next Generation Color DisplayDokument4 SeitenEnergized Innovation: The Next Generation Color DisplayAdriano lopes da silvaNoch keine Bewertungen

- 10 DPI - Oct 17Dokument77 Seiten10 DPI - Oct 17Ratnin PanityingNoch keine Bewertungen

- Bailey M Deer Conf 2000Dokument19 SeitenBailey M Deer Conf 2000Hannu JaaskelainenNoch keine Bewertungen

- Study of Turbo Super Charger in Diesel Locomotives.: Diesel Loco Shed, KazipetDokument47 SeitenStudy of Turbo Super Charger in Diesel Locomotives.: Diesel Loco Shed, KazipetSravan GundamNoch keine Bewertungen

- Qsx15 BrochureDokument8 SeitenQsx15 BrochureferminNoch keine Bewertungen

- United Tractors Machines & EnginesDokument17 SeitenUnited Tractors Machines & EnginesAkbar WijayaNoch keine Bewertungen

- Tad 720 GeDokument2 SeitenTad 720 GeRudy Okta LNoch keine Bewertungen

- Jgs616 Ds Preliminary DataDokument4 SeitenJgs616 Ds Preliminary DataEdutamNoch keine Bewertungen

- Grupo Presion Del MotorDokument12 SeitenGrupo Presion Del MotorGenaro GutierrezNoch keine Bewertungen

- Engine - Gtdi 2.0L PetrolDokument5 SeitenEngine - Gtdi 2.0L PetrolroryNoch keine Bewertungen

- ProjectDokument35 SeitenProjectlokeshkrkushwahaNoch keine Bewertungen

- Diesel Loco Parameters: Main Parameters Wdm2 Wdm3A Wdm3D Wdg3A Wdg4 Wdp4 Wds6 Demu (DPC)Dokument3 SeitenDiesel Loco Parameters: Main Parameters Wdm2 Wdm3A Wdm3D Wdg3A Wdg4 Wdp4 Wds6 Demu (DPC)mukesh lachhwaniNoch keine Bewertungen

- Type Moteurs CATDokument42 SeitenType Moteurs CATait mimouneNoch keine Bewertungen

- VHP Series Four F3524Gsi: 560 - 840 BHP (418 - 626 KWB)Dokument2 SeitenVHP Series Four F3524Gsi: 560 - 840 BHP (418 - 626 KWB)Sulistiani ArlimNoch keine Bewertungen

- 0042258Dokument6 Seiten0042258GiovaniAricettiNoch keine Bewertungen