Beruflich Dokumente

Kultur Dokumente

Sop

Hochgeladen von

Al Arafat RummanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sop

Hochgeladen von

Al Arafat RummanCopyright:

Verfügbare Formate

Basic Technical SOP for Cutting Section in Apparel Mfg FacilityThis research paper is

relevant to Indian Apparel manufacturing sector.SOP Designed under guidance of Mr.

Jayashantha PereraInputs

Details related to Fabric such as face side /Shade bands etc..Shade swatches along with

the face side swatch approved by the buyer should be received from the Godown and

Merchandising dept respectively.Shade segregation should be complying with the

approved swatches.Verify whether the shade segregation is matching to the

standard.Approval from H/office mandatory if the received lots of fabric are not matching

to standards.The approval must have a checklist form for all the tests & approval

standards w. r. t colour, wash,embroidery, printing, hand feelShade band details (Shade A,

B, C, D) after verification should be received from fabric inspector &spreading team also

should be given a copy for reference.Shade grouping also must be received from the

fabric godown.Fabric details such as to face/back, nap direction; hand feel should be

received from the godown dulyapproved by the merchant.Shade wise/widthwise

segregated rolls only should be received, checked & then should proceed forlaying.Both

ends of every roll should have sticker consisting details of shade no, roll no, width and

otherrelevant detail to enable easy identification of rolls.Cutting Forecast shade

wiseCuttable quantities from each lot and shade should be informed to marketing, QA, &

Buyer QA inadvance for approval.Cutting of rolls/bales should be done shade wise as per

the breakdown of the PO

Garment manufacturing process from

fabric to poduct

Karthika M Dev SOFT ( NIFT, Pune )

MANUFACTURING WORKFLOW Consumption planning to order fabric Fabric

order placement Receipt of fabric Fabric inspection (Check physical appearance

and properties) Marker Planning (For bulk production) Sampling Spreading &

Cutting Presewing operations (Fusing, embroidery, marking- if required in style)

Bundling Feeding in lines (As per production plan) Finishing Packing

Warehousing Packing and dispatch SOFT ( NIFT, Pune )

GARMENT ENGINEERING It starts in design development stage because it

directly affects the costing of the garments . People involved: Designers, sample

room manager, industrial engineering department and production management

should all report from cutting to finishing. Key areas for analysis: Seam types

Various seam types should be analyzed and considered to simplify/reduce the

work. Stitch types- Explore various options in terms of seam types. For

example replace lock stitches by chain stitch in case of Multineedle seams.

Machine types- Optimum use of technology to maximize, look in to machine

type, bed shapes and automation thats possible. Attachments Attachment help

in simplifying and reducing the work content and to increase line balancing

efficiency. Special work aids- Special work aids can be used to simplify/reduce

the work content. Fabric consumption- Fabric being 70% of the garment cost is

vitally important to monitor and if the engineering is done properly we can

certainly expect to save fabric or reduce consumptions. Cutting- how should it be

done- we do not have Tailors now, we have operators instead and they should be

working with clippers in their hands Finishing- Finishing is the last link of the

value chain which is essential for p erformance point of view. SOFT ( NIFT,

Pune )

CAD DEPARTMENT Receiving tech pack: Tech pack is received from Head

office that contains all the information regarding the style illustration, size, trims,

colors, stitch and seam class, fit, sampling details, and packing and finishing

details. Make basic pattern: Basic pattern is made manually by pattern master in

one base size. Digitizing: This base size is then digitized on the Gerber digitizer

board. Grading: After digitizing, its transferred to the computer on Gerber pattern

design studio. Patterns initially are made in only one size. We need to

proportionally increase or decrease the size of a pattern, while maintaining shape,

fit, balance and scale of style details. Getting correct fit and drape of a garment

but also maintain the measurements as graded specs is essential. Using the CAD

system, the pattern is resized according to a predetermined table of sizing

increments (or "grade rules"). The computerized plotter can then print out the

pattern in each size. Incorporating shrinkage in pattern grading - - First fabric has

to be relaxed so that there is no tension or strain during rolling or unrolling while

layering or cutting. This will ensure that there is minimum shrinkage in garments.

So unwashed garments are made with additional shrinkage tolerance included so

that they gain their original measurements after washing. Woven fabric garments

shrink about 2-3%. This shrinkage incorporated in patterns could be lengthwise or

width wise depending on type of fabric. SOFT ( NIFT, Pune )

Shrinkage adjusting Shrinkage adjustments should not distort the original shape

and balance of the patterns. When shrinkage is applied to a panel in garment all

corresponding patterns must also be applied with shrinkage adjustments. The

picture on the left shows how a garment panel looks like after it has been scanned

and graded. Gerber plotter printing: The patterns are then printed on the Gerber

plotter. They are then pasted to thick aortic sheets and converted into full fledged

patterns. Send patterns to cutting department OTHER CONSIDERATIONS

Efficiency: Marker plans indicate efficiency of the cutting process i.e. the

efficiency of fabric consumption. Lay plan: determines the no. of lays required

to cut the specified quantity in the predetermined size ratio. Precision in checks

in stripes SOFT ( NIFT, Pune )

FABRIC STORE This is the most important department of the unit, where in the

quality and quantity of fabric is inspected as soon as it is received in the store,

along with storing and maintaining stock levels and ensuring to stock up in proper

clean way. When the fabric is in-house, it should be capable of being supplied to

the cutting department. Inspection is done prior the cutting room issue so as to

remove the defective fabrics. WORKFLOW OF FABRIC STORE Receive P.O

at head office D/O Document are sent to Fabric received at gate (challan) dept for

checking Documents verified Bales received in fabric dept Bales counting Fabric

unloaded Bales opened Swatches and cuts maintained Checking 4 point system

JC & GRN Made Fabric mounted on greasy perch Fabric sent for inspection

Fabric stored Fabric issued to cutting room as and when required. FCR prepared

SOFT ( NIFT, Pune )

FABRIC VISUAL INSPECTION The 4 point system is generally used for

fabric inspection. In this system, points are assigned for every possible defect in

the fabric as follows. Width wise point criteria Upton 3 3-6 6-9 9 Length wise

point criteria Upton 5 3-6 6-9 9 Area wise point criteria Penalty points 1 point

2 points 3 points 4 points Penalty points 1 point 2 points 3 points 4 points Penalty

points 1X1 cm float Upto 1X1 cm hole/stain Over 1X1 cm to 2X2 hole/stain Over

2X2 cm hole/stain 1 point 2 points 3 points 4 points Yarn variation/Beam

motion/Barre effect Penalty points Minor Major 2 points 4 points 3 points and 4

points are pointed and are called cutable defects. 1 and 2 point are identified by

stickers and panels replaced cutting. The maximum points and flags allowed as

follows:SOFT ( NIFT, Pune )

FABRIC 100% cotton and its blends 100% linear and its blends Max. no. of

allowed points Max. no. of flags per linear mts. 40 40 5 4 Defect points/100m2 =

Total pointsX3600/Fabric widthXFabric length. If defect points/100m3 < 40

then accept the fabric. If defect points/100m3 > 40 then reject the fabric. Major

woven defects : slubs, holes, missing yarns, yarn variation, end out, soiled yarns,

wrong warns. Major dyeing or printing defects: out of register, dye stops, machine

stops, color out, color smear, or shading. These defects are marked wth colored

tape so that they can be easily located. Others Penalty points Patta Count or

composition variation Short end Selvedge loose Wrong drawing Reed marks

Temple marks Damaged selvedge Wrong weave Cutable defect Cutable defect

Reject roll Reject roll Reject roll Reject roll Reject roll Reject roll Reject roll

Other points to remember: 1. No linear meter shall be assigned more than 4 point

or a flag. 2. All holes regardless of size small be assigned be assigned 4 point. 3.

There should not be a major defect within 5 meters from beginning or the end of

the roll or part therein. SOFT ( NIFT, Pune )

4. The shade of the fabric should match with the approved shade of fabric from

H.O. 5. There should not be shade variation from selvedge to selvedge, centre to

selvedge and start and end 6. A repeating defect or running should not extend for

more than 3 yards (2.73 meters), otherwise the roll will be considered second

quality. 7. No piece will be acceptable as first quality if it has noticeable side-toside, side-to-centre or end-to-end shading within a roll or a piece. FABRIC

INSPECTION MACHINE This is used to inspect the fabric defects and measure

the total meters of the fabric. Machinery Brands include Kaigu, Aura, Ramsons

checkmate. FABRIC TESTS o Fabric Shrinkage is a very important factor for

any physical inspection. Mistakes in appropriate checking might prove

disadvantageous for the pilot run followed by production. An optimum

conduction of the width and shrinkage properties has to be made. The fusing of

lining to some parts may also be done in the cloth store. If the shrink

characteristics are consistent, then the patterns may be designed to the correct

oversize and sampling checks for consistent shrinkage carried out. Color changes

can also occur at the time of fusing as the temperatures might have been

controlled or were out of the prescribed limits. E .g Size of the fabric= 100 * 100

Or 50 * 50 According to the above picture, a fabric piece of the above mentioned

specification is cut and marked accordingly. Then a wash with a soft enzyme is

given. The deviation is shrinkage if any is marked between the points. Shrinkage

of 1-1.5 cm is acceptable. If it is more than this then the merchandiser is supposed

to take the desired action. SOFT ( NIFT, Pune )

o Color Fastness or Crocking: In order to check color fastness, 2 fabric swatches

are taken. On 1 of the swatch, a white seam is put on all the four sides of the

fabric. Both of the them are washed and the results are compared. If it is stained

or slotted then its rejected. o C.S or Centre Selvedge test: This test is used to

check the color variation in the fabric. Full width of the fabric is taken (length can

vary according to requirement say 10). The Fabric is divided into 6 pieces and

their grain line is marked. These pieces are then cut and re stitched in a random

series. For e.g. 3, 6, 2, 5, 4, 1. When we arrange these fabric pieces in a series, we

can see the shade variation in the same fabric. Noting of this variation is very

important at the time of cutting. Maximum CS is seen in solid/printed fabrics as

compared to stripes and checks. o Others include dry clean and washability,

abrasion resistance, pilling (especially for mixed fibers), Bow and skew (using a

ruler and set square for checks and stripes), Drape and crease resistance (that

includes permanent press capability), Strength (tensile, tear and bursting (for

seams), Flammability, Surface wetting and penetration. FABRIC DEFECTS o

Abrasion Mark: A place in the fabric where the surface has been damaged due to

friction or abnormally weakened by any operation through which it has been

passed. o Misprint: In printed fabrics, either missed, or partially missed, or

incorrectly positioned relative to each other. o Double Pick: Two yarns running

simultaneously, mostly in the weft yarn. SOFT ( NIFT, Pune )

o o o o o o o o o o o Oil Stain: Oil mark on the fabric. Hole: A breakage of yarns

in the fabric involving more than two yarns. Bow: When the weft/filling yarns lie

in an arc across the width of the fabric. Skew: Distortion in the construction of the

fabric i.e. in the yarn that constitute the fabric. Crease: A fabric defect across the

fabric width usually caused by a sharp fold. Dye Stain: An area of discoloration

due to uneven absorption of colorant. Miss-pick: A pick/weft yarn not properly

interlaced. Slubs: An abruptly thickened place in a yarn. Screen Out: The

appearance of a colored separation line in a printed design. Calendar Line: Sharp

pressmark on fabric due to the calendar during the processing. Contamination:

Colored fibers with the warp or weft fibers. Name of suppliers V.C.M synthetics,

Symbolic fabrics, Arvind mills, Ashok weaving, Vaibhav trading, Siyarams, J

Hampstead. SOFT ( NIFT, Pune )

TRIMS STORES This store is responsible for storing and neatly maintaining the

trims received from the suppliers, approved by H/O. Trims card to be readily

available for each of the PO/style being processed that is duly approved by the

nominated quality assurance person. WORKFLOW OF TRIMS STORE

Receive W/O Purchase dept issues D/O to supplier Challan Make trims card

Checking Trims receiving Issue for stitching according to production plan

Different types of trims:- Buttons Hooks Badges Zippers SOFT ( NIFT, Pune )

- Collar pick bone Tags : brand name, collection name and fit type Labels : wash

care, size and fit, brand Fusible labels Leather patches Twill tape/ Cross grain tape

( cotton/polyester) Needles Threads : sewing and embroidery Laces Packing

materials: hangers, collar stand, brand label, packing box, polybag SPREADING

AND CUTTING DEPARTMENT Net cutting is an essential part of garment

engineering that demands precession in cutting and low shape deformation

afterwards. Accurate control of cloth width produces economies in edge margins.

Precise cutting not only avoids spoilt work at the making up stage but is the key to

modern sewing room practice. As soon as the work order is received, a fabric

enquiry is conducted in fabric store weather the fabric is available or not. The

CAD department is responsible for making the pattern markers available in

various graded sizes for cutting purpose and calculate the consumption per

garment. SPREADING - Spreading is the process of unwinding large rolls of

fabric onto long, wide tables and laying them in superimposed plies of specified

length. - The number of lays depends upon the number of garments desired and

the fabric thickness. - The maximum cutting width is the usable fabric width

minus selvedge or needle marks caused by stencil marks. - Fabric utilization is the

amount of fabric actually utilized in the marker as the percentage of the total

fabric area. - The cutting marker is laid on the topmost layer. SOFT ( NIFT,

Pune )

Type of lay plan used: Since open width fabric is used, full garment lay is used

that has both left and right pieces. Type of lay: Multiple Ply is used in which a

number of fabric layers are stacked on one top of other. Forms of spreading:

Fabric is laid the same way up with grain or print pattern running in the same

direction. Fabric has to be cut at the end of each ply. Fabric weight Ideal lay

height for cutting : Height Heavy Weight 4-5" Med Weight 3-4" Light Weight

2.5-3" Laying parameters Pattern matching. Relaxing the fabric to remove all

the tensions. Allignment of ply edges in correct position over each other. Lay

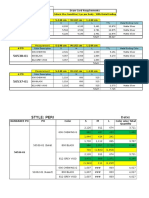

order plan : Example 1 Size ratio = 1:2:2:1 39 31 48 37 43 40 40 62 48 58 42 40

62 48 58 44 20 31 24 29 Total 131 203 157 188 679 Average no of lays 39 31 31

40 20 20 42 20 20 44 20 0 Avg. no. of lays I II SOFT ( NIFT, Pune )

11 0 0 0 III Average no. of lays = 3 Average no. of pieces = Total meters of fabric

Total no. of pieces in each color = 190.50 = 1.45 mts. 131 Lay length = 1.45 mts

X 3 = 4.35 CUTTING Cutting parameters: - Precision in cutting: To ensure the

cutting of fabric - accurately according to the line drown of the marker plan.

Clean edge: By avoiding the fraying out of yarn from the fabric edge. Cutting

edge must be smooth clean. Knife must be sharp for smooth or clean edge.

Consistency in cutting: All the sizing safe of the cutting parts should be same of

knife should be operated of the right angle of the fabric lay. Types of cutting

equipments: - Scissors Round knife Straight knife Band knife cutting m/c Die

cutting ( collars and cuffs ) Methods for marking directly on the cloth:

CHALK: This is the traditional method in which thick lines are drawn on the

cloth. Preparation for sewing: 1) Position marking : Egg- pocket positions,

tucks, pocket positions etc SOFT ( NIFT, Pune )

2) Shade marking: each component is marked with a unique no. printed on a small

ticket stuck on the component. 3) Bundle making: according to size, color,

quantity 4) Bungle tickets: to identify each bundle to size, lot, style and color

wise. 5) Fusing parameters: There are different types of fusings depending upon

the end use and type of fabric. Type Microdot Semi fusing Woven fusing Heat 150

degree 140 degree 175 degree Pressure 2.5 1.5 3 Time 13 sec 15 sec 18 sec

EMBROIDERY DEPARTMENT Embroidery pattern is received that specifies the

no. of stitches, colors, the pattern, size and placement. Design is loaded in floppy

disc and inserted in the machine memory. Embroidery machines: Company

Silver sun Barudan No. of heads 9 4 No. of needles 9 9 No. of machines 3 1

Machine rings sizes: 6, 9, 7, 15, 19, 25, and 230X160 Embroidery defects: loose

uncut threads, skipped stitches, pattern misalignment. Embroidery threads: Silky

and calypso threads. Type of stitches: satin, filling, patchwork etc Types of motifs:

Institutional logos (jindal, essar, cyberoam), kids wear motifs (cartoons), company

logos (oxerberg, J hampstead), jeans back pocket embroidery, shirt cuff and front

panel embroidery are done. SOFT ( NIFT, Pune )

A Strike-off : is a pre production sample of embroidery which is done in order to

check the accuracy of the pattern and the associated stitches in it. This is then sent

to the H.O for feedback and approval. If any changes, theH.O will return their

feedback with necessary changes or comments. The type of stitches depends upon

the fabric. If the fabric is thin, then heavy stitches are avoided. MAJOR

PROBLEM FACED IN EMBROIDERY: The major problem faced during

embroidery is the thread breakages. The reason for this may be that either the

thread is too tight or has less strength. Since the designs are fed into these

machines through computer, if even a single thread breakdown happens, then all

the machines stop at the same time. To help avoid it to some extent, a helper is put

up against each machine that keeps a check on the breakages and accuracy of the

stitches. The bobbin case also plays an integral part. SAMPLING DEPARTMENT

The sampling for each season begins according to the product cycle of style. This

process is also called Product development (P.D). One should also know the

tentative size ratio in each style. This is because the costing of the product

depends highly on the fabric consumption. Kinds of samples prepared: 1)

Photosample: only sketch/illustration of the garment is present in the photosample

sheet. 2) Fit sample: one sample in base size measurement is made and send for

approval at head office. 3) Size set: one garment sample in each size is prepared

and sent for approval. No need to add the trims to the garment. 4) PP sample: This

is the pre-production sample that is the exact replica like original sample. 5)

Shipment sample: A random sample is picked from the production lot and sent for

approval. PRODUCTION DEPARTMENT Sewing Process SOFT ( NIFT, Pune

)

The basic process of sewing involves fastening of fabrics, with the help of needle

and threads. Most of such industrial sewing is done by industrial sewing

machines. The cut pieces of a garment are generally tacked, or temporarily

stitched at the initial stage if required. The complex parts of the machine then

pierces thread through the layers of the cloth and interlocks the thread. Industrial

Sewing Industrial sewing is quite a complex process involving many preparations

and mathematical calculations for the perfect seam quality. Good quality sewing

also depends on the sound technical knowledge that goes into pattern designing

and making. Flat sheets of fabric having holes and slits into it can curve and fold

in three-dimensional shapes in very complex ways that require a high level of

skill and experience to manipulate into a smooth, wrinkle-free design. Aligning

the patterns printed or woven into the fabric also complicates the design process.

Once a clothing designer, with the help of his technical knowledge, makes the

initial specifications and markers, the fabric is then cut using templates and sewn.

These undesirable variations in the cloth tension affect the product quality.

Therefore, there arises the need of strict control over the whole process. The work

of sewing is focused on the handling of fabrics lying on the working table and

guide them towards the sewing machines needle along the seam line. The

attention is equally focused on the control of appropriate tensional force so as to

maintain high quality seam. Pre sewing functions Before the actual task of sewing

begins, there are certain other tasks that have to be taken care of which can be

termed as fabric handling functions - Ply separation; Placing the fabric on

working table; Guiding the fabric towards sewing needle; and tension control of

fabric during the sewing process. When the fabric is placed on the working table,

the tasks that are performed before the sewing process include - recognizing the

fabric's shape, edges that will be sewn, planning of the sewing process and

identification of the seam line. Fabric Edges to be sewn There are two basic types

of stitches - one is that are for joining two parts of cloth together and the second

one is done for decorative purposes. Sometimes, both types of stitching have to be

done on some parts of cloth, for example, a denim pocket has to be joined on

three sides with the apparel as well as it may be given some decorative stitches

too. At what points and which type of stitching has to be done- all such

information is decided by the industrial engineering department and accordingly

sewn. Planning of sewing process SOFT ( NIFT, Pune )

Sequence of seams to be stitched is determined before the sewing starts. Which

part will be joined first, what stitches will follow one another, etc. are decided.

However, some stitches have to be necessarily done before or after another stitch.

In the example above, the decorative stitches must be done first followed by the

joining stitches. Identification of seam lines Sewing process is performed on seam

lines situated inside the fabric edges, some millimeters inside the fabric's outer

line. For the straight lines, the seam line is found by transferring the outer lines

inside the fabrics i.e. the seam line is parallel to the outer edge and the distance

between the two has to be determined as it is different for different parts of the

cloth. Seam allowance is the area between the edge of the fabric and the line of

stitching. Sewing Fabrics The sewing process consists of mainly three functions guiding fabric towards needle; sewing of the fabric edge; and rotation around the

needle. The fabric is guided along the sewing line with a certain speed that is in

harmony with the speed of sewing machine The orientation error is either

manually monitored or if monitored automatically then error is fed to the machine

controller so that the machine corrects the orientation of the fabrics. When one

edge of seam line is sewed, the fabric is rotated around the needle till the next

edge of the seam line coincides with the sewing line. The sewing process is thus

repeated until all the edges of seam line planned for sewing, are sewed.

Significant Aspects of Sewing There are certain aspects that have to be carefully

considered while the sewing process as they are very crucial for high quality

sewing. Thread tension and consumption: Correct balancing of the stitch and the

tension given to the threads is very important for quality stitch formation. Thread

consumption, which is closely associated with correct stitch geometry and thread

tension, is usually measured by digital encoders. Presser- foot displacement and

compressing force: Presser- foot is the part of the sewing machine that holds the

fabric in place as it is being sewn and fed through by the feeder. The feeding

system is one of the most important constituting systems of the sewing machine.

If this system is not efficient then it results into irregular seams and many other

defects, especially when running on high speed. To evaluate feeding efficiency,

the force on the presser foot is measured with the help of electric or other sensors.

Needle penetration force measurement: The interaction of needle with fabric is

very crucial. Fault-free needle penetration depends chiefly on the properties of

fabric and needle choice. Needle penetration force is one of the variables whose

measurement is important for the SOFT ( NIFT, Pune )

analysis of quality problems or "sewability testing" and also quality monitoring. It

takes various factors into consideration, such as the needle geometry (including

the point angle and point length of the needle), the friction between the needle and

the fabric, the friction between the needle eye and the thread along with fabrics'

property, and the sewing conditions. ACCEPTABLE QUALITY LEVEL (AQL)

Quality measurre The AQL (Acceptable Quality Level) is the maximum per cent

defective that for the purpose of sampling inspection can be considered

satisfactory as a process average. In inspection how much percentage of defective

pieces will be accepted, depends on acceptable quality level The AQL level varies

process to process, product to product and even buyer to buyer. Sample size Code

letter: This code is indicative a range of batch size. (Code 'G' means your lot size

range is from 151 pieces to 280 pieces. Sample size: It means that how many

pieces will be picked up for inspection from the total offered pieces (Batch). Ac

(Accepted): The number in this column denotes that if the inspector finds up to

that much defective pieces the shipment will be accepted by buyer. Re (Rejected):

On the other hand number in this column denotes that if the inspector finds that

much defective pieces or more than the listed number, the shipment will be

rejected (or asked to the manufacturer for 100% inspection and re-offer for final

inspection) by buyer. Example: Suppose you have been offered a shipment of

1000 pieces for inspection. Select the range from table, it is 501-1200. Now from

table you have to select number of sample you are going to actually inspect.

According the above table you will select 80 pieces out of 1000 pieces. Now

assume that you are inspecting at 2.5 AQL. So, after inspecting all 80 pieces if

you find 5 or less than 5 defective pieces will accept the shipment. And if you find

6 or more than 6 defective pieces in 80 samples you will reject that shipment. Lot

or Batch size Size Code Sample Size 28 A 9 15 B 2 3 Acceptable Quality level

2.5 4.0 6.5 Ac Re Ac Re Ac Re 0 1 0 1 0 1 0 1 0 1 0 1 SOFT ( NIFT, Pune )

15 25 26 50 51-90 91-150 151-280 251-500 501-1200 1201-3200 C D E F G

H J K 5 8 13 20 32 50 80 125 0 0 1 1 2 3 5 7 1 1 2 2 3 4 6 8 0 1 1 2 3 5 7 10 1 2 2

3 4 6 8 11 0 1 2 3 5 7 10 14 1 2 3 4 6 8 11 15 3201-10000 L 10001- 35000 M 200

315 10 14 11 15 14 21 15 22 21 21 22 22 LIST OF POSSIBLE DEFECTS IN

PRODUCTION Component and materials Materials/fabric Cleanliness Pressing

Seams and Stitching Possible Defects 1. Fabric holes 2. Slubs 3. Shading

variation 4. Misprints, out-of-register prints, undesired color spots 5. Cut, visible

notch mark tears or visible surface repairs 6. Bow or skew exceeding 1.5 percent

7. Double picks 8. Pilling 1. Soil, Spots, stains or Dust 2. Attached thread clusters

1. Burn or scorch marks 2. Glaring shine marks 3. Press marks from camps 4.

Absence of pressing when specified 5. Products packaged moist after steam

pressing 6. Improper pressing 7. Seams not lined up when specified for center leg

crease 8. Loops twisted after pressing 9. Uneven creases after press 1. Twisted,

roped, or puckered seams 2. Open or broken stitches 3. Raw edges where covered

edges are specified SOFT ( NIFT, Pune )

Button holes Button/Button Sewing Waistband Belt Loops Front and back 4.

Seams not back stitched or bar tacked when specified 5. Irregular or uneven top

stitching 6. Seam grin-through, seam slippage 7. Pinching or any part of product

caught in seam or stitches 8. Any exposed drill holes 9. Length of legs off by

more than 3/8 inch 10. Stitch count not conforming to specifications 11. Stitch or

seam type not conforming to specifications 12. Label is not correctly attached,

position and layout 13. Sewn on design attached at incorrect place and sewn not

according to specs 14. Double needle stitch on crotch seam is missing 15. Use of

monofilament thread, other seams than where specified 1. Size is not within specs

2. Ragged edges 3. Uncut button hole 4. Out of alignment or improper button

spacing 5. Stitch depth too narrow or wide 1. Button not securely attached 2.

Butler-missing 3. Broken or damaged button 4. Out of alignment or improper

spacing 5. Button not matches to specs 6. Lack of support materials on fragile

fabric 7. Buttons that crack, chip, discolor, rust, bleed, melt or otherwise cause

consumer dissatisfaction when care label is followed 1. Uneven in width 2.

Excessive fullness, puckering or twisting 3. Closure misaligned 4. Belt loops are

crooked 1. Not fully secure 2. Extend above waistband 3. Missing tacks 4. Color

shade not to specs 5. Thread shade not to specs 6. Raw edges showing 1. Uneven

at bottom hem 2. Under facing showing 3. Pockets conspicuously uneven 4. Darts

uneven in length 5. Darts poorly shaped 6. Spot shirring not even right and left

sides SOFT ( NIFT, Pune )

Hems Pockets Zippers Gripper Fly area Labels 1. Twisted, roped, puckered,

pleated, or excessively visible from exterior 2. Uneven in width 3. Uneven length

of product unless specified 1. Not uniform in size and shape 2. Misaligned

horizontally or vertically 3. Crooked 4. Missing bar tack, back tack or rivet where

specified 5. Bar tack or rivet not as specified 6. Sewn-in pleats or puckers 1. Any

malfunction in operation 2. Tape does not match color specs 3. Wavy zipper 4.

Exposed zipper that distracts from product's appearance 5. Irregular or uneven

stitching on zipper 6. Crooked or uneven zipper 7. Bar tack missing or incorrectly

located at bottom or base of zipper 1. Misaligned 2. Missing or incorrect 3.

Defective in operation 1. Width is not uniform 2. Bottom stopper does not

securely clinched 3. Top of zipper not caught in band 4. Either side of fly extends

past other side by excessive amount. 1. Labels are not correct, text and/or layout

2. Located at incorrect location 3. Insecurely attached to the garment Garment

inspection procedures : During the course of garment production, i.e right from

cutting to final dispatch, Oxemberg QAD team will conduct various inspections

as follows: 1. Inline/mid inspection : This will be carried out during the

production of garment in order to carry out this inspection effectively following

information is a must. A) Updated W/O sheet B) Style approved, saple approved

by the merchandiser C) Fabric, trims and accessories cards rectified by the

merchandiser. D) Approved measurement specification. SOFT ( NIFT, Pune )

2. Random final audit or inspection : this will be carried out when goods are in the

pressing and packing till its completion. Oxemberg QAD team will carry out

random audit at AQL 4 inorder to make this audit a truly effective tool, since it is

the last check point before dispatch, following information is essential. A) All the

line detail information mentioned there in plus. B) Washed approved samples ( in

case of washed order). C) Packing list wherever applicable. PRODUCTION

PLANNING, SCHEDULING AND CONTROLLING i. Planning: This involves a

long term overview around the year, based on market forecast. An agreement is

necessary about whether the production unit can cope up with the expected sales,

in terms of overall volume and in terms of specialized plant and operatives. The

action is required of relevant departments to revise the plan, purchase the

necessary machinery, train staff, obtain new premises or lease off unwanted ones,

buying additional capacity from other manufacturers etc. ii. Scheduling: The work

is allocated to the production capacity according to the agreed plan as soon as the

orders are confirmed. It is at this stage that schedules are prepared as an exercise

and later drafted in detail. iii. Controlling: The production process is very

uncertain and rarely goes according to the schedule, especially when the processes

are complex and dependent on the performance of individuals. Sometimes orders

are cancelled and rush orders come through. Inefficiency can be avoided if the

preliminary work is done thoroughly and the routine terms are accurately

recorded. Balancing is a part of the process. KEY FACTORS IN

CONTROLING AND SCHEDULING i.Time/ unit input: e.g. meters of cloth or

SAM of work per minute. SOFT ( NIFT, Pune )

ii.Work in process delays: Extension in output time is necessary to provide buffer

against fluctuations in output where the no. of processes involved are many.

iii.Technical maintenance: Proper usage and maintenance of the machines and

other electronically equipments should be done to provide smooth operation

processes. iv.Employee Training: The employees should be trained efficiently to

increase production efficiency and reduce wastage. v.Non productive hours: A

provision for non-productive hours should be provided in the total available

minutes as these by default are bound to happen. For e.g. lunch time, talking,

going to washroom, sitting idle etc. These hours can be deceased by making

changes in the production plan wisely. vi.Line balancing: This is necessary to

reduce the wastage of time as some workers might be sitting idle because the

feeding has not been done properly and the pieces are not being delivered to them

on time. The overall operation machine layout is faulty due to improper line

balancing. A machine layout is considered to be optimum if all the machines in

the line are producing their required quantities of pieces and no worker is sitting

idle. Line balancing can be a way to increase the productivity as increasing or

decreasing unwanted operations from the line can be done. vii.Analyzing labour

requirements and deficiencies: A difference in skilled and non-skilled labour can

be assessed and accordingly work can be assigned to them. viii.Optimum

utilization of time and raw materials: Any type of unnecessary wastages should be

avoided as far as possible. This requires a good production plan and the co

ordination of related activities. Production flow This refers to the series in

which the garment moves from one workstation to another, requiring completion

of the desired operation. The garments move from one work station to another in a

straight line. The straight could be work stations set up on either side of a belt

conveyer/runner table. There is little amount or work in process between the

stations. In these SOFT ( NIFT, Pune )

cases, a limited amount of storage occurs after each workstation. This can take the

form of work bins attached to the machines stand in which the work is Straight

line or conveyer chain system Where a work station is is storage indicates the

direction of movement A production process comprises of : Fabric consumption

calculation, Thread consumption calculation, Fabric inspection, pattern making,

fabric cutting, machine layout and SAM calculation completed, pilot run

completed, testing sampling completed, line sewing completed, finishing sewing

completed, final machine inspection completed, end of line quality check

completed, off pressing and finishing done, packing completed and goods

dispatched. Production Quality Control Quality implies value. It is something

that is build into the garment from the stage of market research and design right

up to pack and dispatch and extends beyond a careful analysis of the customer

returns and consultation with the buyers. The quality of the garment is the reason

that is bought by the customer and comprises of a set of quality characteristics

which together make up its fitness for purpose. The key to profitable garment

manufacture is to provide the best combination at lowest cost the economic

quality level. The costs of quality come from: style; fabric and trimmings;

cutting and making and packing (including repairs and rejects); Quality control

function; Learning time of the workers; Work content; Present

productivity; Other overhead costs (like salary, electricity, administrative cost,

maintenance, transport etc) SOFT ( NIFT, Pune )

Fitness for purpose comprises of: Quality of design Quality of

conformance Quality of delivery and service Economic cost Quality Control

Department The main function of the quality control department is not to

control quality but to provide a service which allows people to make good clothes.

Their main concern should be to do this at the minimum cost, balancing the

expense of the department against the savings in terms of reduced repairs and

rejects. One aspect of this is to define the quality level of plant and of the

workplace in it. The raising of quality levels requires a major project involving

investment in machinery and training which cannot be done quickly. The

maintenance of quality at an agreed level implies clear specifications and these

are an important task for this department. The Product information sheet for

individual styles can be kept as brief as possible. They should contain the

maximum information in the form of sketches and all dimensions should me

quoted with tolerances. Tolerances reflect the extent to which less than perfect is

acceptable. However, small tolerances exist for the garments. The function of the

quality control department is to reduce the amount of bad work being made. This

gives savings in cost of the repairs and rejects but also speeds up delivery. Its aim

is to make garments correctly at the first time. When the consistency of quality is

poor, the expected quality level is substantially below standard. Greater

consistency has an even higher priority than raising the standard of the majority of

the garments made. Tolerances These are the limits of acceptability expressed in

figures usually or by examples or photographs to demonstrate the limits of

acceptability. For example, the specification for a seam margin may be 1 cm and

the tolerance is -/+2 mm. SOFT ( NIFT, Pune )

Quality characteristics Quality of design requires higher amount of market

research to establish what is the ultimate customers preference at an acceptable

price amongst a competitive set of characteristics. These can form the basis for

design. Customers demand various combinations of the following, in various

orders of importance: Price and value for

money Individuality of appearance Fashion is appropriate to the period and group

Image enhancement (e. g reliability of an executives suit, smartness for the air

hostess etc) Comfort in wear, both from cut and fabric Durability of function and

appearance Psychological qualities(waterproofing, warmth, sweat absorption etc)

Ease of Care (crease and stain resistance, shape retention, washability etc) Size

and shape Consistency of the product The production incharge must stick to the

specifications and should also consider the needs of the retailers like: Consistency

(means to achieve the required quality level, the will to confirm of Management

and workforce, maintaining the specifications with tolerances). Delivery on time

Lower cost to support competitive price. Quality Specifications o Factory

specifications Cloth and trimmings, button spacing Threads, needle

types and sizes, by fabric and seam type Stitches per inch or per 2 cms Seam

types, seam margins and tolerances Cutting standards o Style or garment

specifications Items of difference Special size ranges and grading Key

features and quality points SOFT ( NIFT, Pune )

Special tolerances Fabric and trimmings, colors and shades ( shade cards

checked regularly for fading) Department wise quality system in factory 1)

FABRIC STORES: o Neatly arrange the fabric rolls received and maintaining the

department cleanliness to avoid spotting and contamination of the fabrics.

Packing the fabrics in plastic sheets can be useful. o Fabric inspection is done on

4 point system. o Shade cards/fabric quality swatches for each style approved by

the PO are maintained. 2) TRIMS STORES: o Trims stores have racking system

to store the trims in a proper order. o Trims card for each PO/style being

processed should be maintained. 3) CUTTING SECTION: o Making CSV

( centre to selvedge variation) sample for each of the roll to analyze the shade

variation. o Maintaining shade samples and providing shade details to

presentation checkers in finishing dept for shade reference. o Proper pattern

checking report. o Proper lay check, marking check, sorting/bundling check

report. o Cutting projection tallies updated. 4) SEWING SECTION o Effective

maintenance for each of the machine. o Proper updated broken needle log (should

have needle issuing record from stores and properly pasted broken needle book).

o Keyhole, bartack, overlock, label attach operation internal approvals and display

of mockups. o Effective mockup system on all operational areas. o All scissors

and trimmers should be secured properly. o Clearance of WIP at all levels. o

Display of trim card at required areas. o Checking garments before wash and after

wash for both quality and measurement. SOFT ( NIFT, Pune )

o Random in-line checking at each chain stitch operation like feed of arm

machine. o Each supervisor is advised to check randomly the operation in their

own working limits. o Each operator is advised to clean their machine and area

before start of work in the morning and after lunch- waste fabric is issued to the

operator for the same. o In-line and end-line checking report. o Before wet

processing in-line audit report is also maintained. o Washing facility is not

available in-house. Its done on jobber basis. 5) FINISHING SECTION o Fabric

defect identification by stickering and alteration piece identified by knotting at

place of alter by the checker. o Dusting is done by dust pads wherever sucking

machine is not used. o Cartoons are properly stacked. o Presentation checker to

have ready reference of shade cards of fabric and trims cards as well. o Daily

checking report is maintained. o Measurement audit report is maintained. o Prefinal auditing is also gone on garments. o Defective cartoons are replaced by good

cartoons. 6) PACKING AND DESPATCH SECTION o Separate departments are

maintained for topwear and bottom wear. o The fully packed garments are racked

in sequential manner and each rack is given a number for identification. o

Garments are stored brand wise, sizewise, and garment wise. o Barcode stickering

is done and checked. o Packing in inners and outer cartoons is done according to

the size ratio or packing specifications as specified. o Goods to be shipped are

packed readily with proper covering and sealing and kept near the main gate to be

loaded in the cargo. o Proper recording of dispatch, packing and stock stored inhouse pending for shipment are maintained along with Chelan entries of cargo

and transportation services. o Good relations with distributors are held. 7)

ENTIRE WORKING AREA o o o o Properly certified fire extinguisher to be free

from all obstacles. Each operator to wear mask to avoid inhalation of dust inside

the factory. Dust collection bags for each work station/machine. Separate area for

storing rejected garments. SOFT ( NIFT, Pune )

o Proper covering of stored pieces. o Properly maintained QC reports and files

maintained by QA. Department wise quality check points Fabric Store - 100%

fabric inspection Trim & accessories- Trims inspection Cutting Room - Marker

checking Cut parts checking or audit Bundle inspection Embroidery - 100%

inspection of embroidery Sewing Department - Inline check point (at critical

operation) Roaming checking (Random checking) End of Line checking (100%)

Audit of checked pieces Initial finishing inspection (after wash) and alterations

Final finishing inspection (After Pressing) Internal shipment audit Finishing

Department - 1. Fabric Store: In the fabric store fabric is being checked before

issuing it to cutting department. In general not all the fabric is checked. 100 %

fabric checking is done. Fabrics are checked in flat table, flat table with light box

or on fabric checking machine. 4 point system for fabric inspection is used to

measure the quality level of the incoming fabric. 2. Trims & Accessory: Trims

quality is also very important for having a quality garment. Trims inspection is

done randomly against the given standards, like color matching. But for trims and

accessories quantity checking is essential. 3. Cutting Room: It is said that cutting

is the heart of production. If cutting is done well then chances of occurring defects

in the following processes comes down. In cutting room, check points are I)

marker checking, ii) cut part audit and iii) bundle checking. SOFT ( NIFT, Pune )

4. Embroidery checking: It is also not a compulsory process. If there is

embroidery work in the garment panels then 100% inspection is done before

issuing to sewing. 5. Sewing Department: Checkpoints in the sewing departments

are as following. - Inline inspection: In assembly line generally check pints are

kept for the critical operations. In these checkpoints, 100% checking is done for

partially stitched garments and defect free pieces are forwarded to the next

process. - Roaming inspection: In this case checkers roam around the line and

randomly check pieces at each operation. - End of line inspection or table

checking: A checker checks completely stitched garment at the end of the line.

100% checking is done here. - Audit of the checked pieces: 100% inspected

garment are sent to finishing from sewing department. And all defective pieces

are repaired before sending to finishing. 6. Finishing Department: Check points in

finishing department consists - Initial finishing inspection: checking done prior to

pressing of the garment at finishing room is known as initial finishing. - Final

finishing Inspection: After pressing garments are again checked and passed for

tagging and packing. - Internal final audit: After garments are packed up to certain

quantity, quality control team, does audit of packed garments. This process is

carried out to ensure that before handing over shipment. If the completed work is

being checked at each process and defective pieces are corrected before handing

to the next process than at the end of production there is very little chance to have

a defective at final inspection stage. SOFT ( NIFT, Pune )

FINISHING DEPARTMENT The finishing process includes all those activities

concerned with making the appearance of the fabric more presentable. It includes

activities like stain removal, thread trimmings, washing, ironing, tagging, and

hanger alignment. Bartack: Putting barracks on loops, pockets etc. Washing:

Sometimes, the buyers demand that garments must be given a wash after

stitching. Button, button hole and rivet attach Extra Thread trimming: The extra

threads which have been left uncut are trimmed. This can be done manually with

thread cutters. Stain removal: Different types of stains might be formed at the

time of garment handling operations. Different kinds of stains include ball point

stains, oil stains, dirt stains etc. Different kinds of chemicals are used for their

removal. For example, Ball point stain is removed with ink remover, stains on

white fabrics are removed with a chemical called Ariel lines, Ltk-45 is used for

removing yellow and black stains from colored fabrics, N-9 is used to remove

stains on light colored fabrics, Emrol-ol and petrol is used to remove other hard

stains. Thread sucking : this is done to remove the threads stuck to the fabric

surface that are too minute to remove. For this, a thread sucking machine is used

to remove threads with air blow and vaccum sucking. Also, adhesive tapes are

wrapped on rolls and then moved over the garments, especially in trouser

finishing this step is essential. SOFT ( NIFT, Pune )

End of line inspection:Garments are compared against measurements and

tollerences, defects, loose and misaligned threads and buttons, open seams etc.

Alteration: Any garment found faulty of defects will be sent for alteration.

Ironing: After all these steps, the garments are ironed in a proper manner, folding

on the right creases. Steam ironing is preferred. The garment measurements are

continuously monitored at the time of ironing also. The garments can be shrunk or

stretched to some extent in case the measurements go beyond the tolerance levels.

Ironing depends upon the type of fabric viz. knitted or woven. Knitted garments

require light pressing where as wovens require deliberate wrinkle removal and

crease setting. A dolly or body form press is also used to trouser pressing.

WORKFLOW OF FINISHING Bartack and buttonholing Washing Button and

rivet attatch Thread sucking Stain removal Thread trimming End of line

inspection Alteration Ironing Warehousing Packing Tagging and stickering

TYPES OF DEFECTS I. PATTERN DEFECTS IN GARMENTS: (CAD) Some

parts of pattern are missing, probably because the marker did not include the

correct number of parts. SOFT ( NIFT, Pune )

Mixed parts, probably because the marker is not correctly labeled, resulting in a

marriage of wrong sized parts. Patterns not facing in correct direction on napped

fabrics. Patterns not aligned with respect to the fabric grain. Poor line

definition (e.g. too thick chalk; indistinctly printed line, perforated lay not

powdered) leading to inaccurate cutting. Skimpy marking, caused by either the

marker did not use the outside edge of the pattern; or the pattern was moved or

swung after partial marking to squeeze the pattern into a smaller space for

economizing the fabric. The pattern may have worn out edges. Generous

marking, especially in combination with skimpy marking results in components

being sewn together with puckering and pleating. When the marker is too wide,

the garment parts at the edges of the lay get cut with bits missing. Not enough

knife clearance freedom. Wrong check matching, i.e. lines across the seam are

not matching. Wrong checks boxing i.e. checks are not showing a full/partial

box across the seam. Notches and drill marks omitted, indistinct or misplaced.

II. SPREADING DEFECTS IN GARMENTS Not enough plies to cover quantity

of garments required. Plies misaligned, resulting in garment parts getting cut

with bits missing in some plies at the edge of the spread. Narrow fabric width,

causes garment parts at the edge of the lay getting cut with bits missing.

Incorrect tension of plies, i.e. fabric spread too tight or too loose. This will result

in parts not fitting in sewing, and finished garments not meeting size tolerances.

Not all plies facing in correct direction (whether 'one way' as with nap, or 'one

way either way' as with some check designs). This happens when fabric is not

spread face down, face up, or face to face as required. Unacceptable damages in

the garment parts. Parts not fully included owing to splicing errors. Spread

distorted by the attraction or repulsion of plies caused by excessive static

electricity e.g. in satin fabric. Plies are not spread accurately one above another

for cutting. This results in mismatching checks. III. CUTTING DEFECTS IN

GARMENTS SOFT ( NIFT, Pune )

Failure to follow the marker lines resulting in distorted garment parts. Top and

bottom plies can be a different size if the straight knife is allowed to lean, or if a

round knife is used on too high a spread. Notches, which are misplaced, too deep,

too shallow, angled, omitted, or wrong type to suit fabric. Frayed edges,

scorched or fused edges, caused by a faulty knife, not sharp enough, or rotating

at too high a speed knife cut. Garment part damaged by careless use of knife,

perhaps overrunning cutting previous piece. Marker incorrectly positioned on

top of spread. Garment parts have bits missing at edge of lay. If too tight or too

loose then garment parts are distorted. Spread distortion due to electricity,

particularly in checks. IV. COLOR DEFECTS IN GARMENTS Color defects

that could occur are difference of the color of final produced garment to the

sample shown, accessories used are of wrong color combination and mismatching

of dye amongst the pieces. V. SEWING

DEFECTS IN GARMENTS Broken buttons Broken snaps Broken stitching

Creasing of garments Defective snaps Different shades within the same garment

Dropped stitches Exposed notches Exposed raw edges Fabric defects Holes

Inoperative zipper Loose / hanging sewing threads and buttons Misaligned

buttons and holes Missing buttons Missing stitches SOFT ( NIFT, Pune )

Needle cuts / chews Open seams Pulled / loose yarn ( thread

tension ) Stain Unfinished buttonhole Wrong stitching technique Zipper too

short Usage of different color threads on the garment, creasing of the garment

Sizing defects - Wrong gradation of sizes, difference in measurement of a garment

part from other, for example- sleeves of XL size but body of L size. Such

defects do not occur has to be seen too. VI. WASHING DEFECT IN

GARMENTS A rotation, usually lateral, between different panels of a garment

resulting from the release of latent stresses during laundering of the woven or

knitted fabric forming the garment. Twist may also be referred to as Torque or

Spiraled. WAYS OF DEFECT ALTERATION OBSERVED Most of the fabric

defects that are not acceptable in garments are removed during cutting and

stitching processes. Still damaged part is found in the sewn garment due to heavy

washing, dyeing or other reasons. Instead of rejecting the defective garment, only

damaged part can be changed and converted it into a quality garment. It should

not increase the fabric consumption or produce further defective garment in the

part changing process 1. End bit usage for part changing: In the cutting room,

during layering cutters store end bits that are not layered in the lay for a cutting.

These end bits are one type of cutting waste. So for the part change we can use

those end bits without increasing fabric consumption. We need to take care about

shade matching or lot matching of the fabrics with the damaged garments. If the

garments were heavily washed, then it will be very difficult to match the garment

fabric shade. After changing the parts garment must be washed again to give

matching finished look and similar hand feel. 2. Fresh fabric usage for Part

changing: SOFT ( NIFT, Pune )

If there are not enough end bits to replace the damaged parts from the garment,

then available fresh fabric is used. Only use fresh fabric if there is no problem

with shade matching otherwise it will increase the fabric consumption. But for

solid colors and yarn dyed fabric there is no issue related to shade matching. 3.

Using good components from other damaged garments: This option is chosen

when garments are dyed and there are no fresh fabric or end bits or fresh fabric

for that order. Also for the high value garment with fine hand embroidery work

and where you have less time to complete the shipment, this option is preferred.

Here we need to keep care of shade matching. SHIRT AND TROUSER

WASHING 1. Drum washing m/c (horizontal loading) Capacity: 98kg (big) 450

and 48kg (small). This machine is used for washing cotton shirts and trousers.

This machine can also be used for dyeing. Shirt 200 germs Trouser 700 germs

Denim 800 germs Garment Shirt Trousers 98kg m/c 350 pHs 200 pHs 48kg m/c

200 pHs 80pcs 2. Sample washing m/c (horizontal loading) Capacity: 8 kegs This

is used for washing the samples that are less in quantity. 3. Hydro extractor

(squeezing m/c) 4. Dryer (S.R.E engineering) Shirts 200 Trouser 60 pcs SOFT

( NIFT, Pune )

5. Steam boiler Gas, coal, thermal oil WASHES a. Softener wash ( enzyme

wash ) Its of 3 types ionic, non-ionic, and cationic. b. Enzyme wash OT, desizer,

lubricant, water washing at 52degrees, Acetic acid (pH), Enzyme (to stabilize),

Water wash, Silicon, softener. Power wash enzyme: Powdered enzyme is used

with ball beating Biofinish c. Detergent wash Ariel and tide d. Leather wash e.

Powder wash pumice in powder form f. Pumice stone wash PRECAUTIONS

FABRIC Pigment padded fabric White garment Worsted fabric Trouser Shirt

fabric Yarn dyed X No heavy wash is given because it can cause color bleeding.

No heavy wash No heavy wash Enzyme wash, leather wash can be given.

Enzyme wash. Beach ball wash, chlorine bleach ( caco2 + thermal balls) Heavy

wash DENIM WASHES o MACHINERY USED Front vertical loader m/c: (98kg,

150kg, 300 kg). SOFT ( NIFT, Pune )

1. Raw/Rinse wash: removal of sizing agent and then garment is rinsed, softener

is added and then dried in hydro. No fading process is done. 2. Raw resin: This is

done to fix the color onto the fabric and to make it wrinkle resistant. Catalyst,

softener and resin are added then ironing is done. 3. Denimix: After desizing,

enzymes (bio-degradable agent) are added (acidic/neutral) to give fading of color

(lighter tone). For fancy denims, scraping and tucking is used along with denimix.

Neutral (pH 6.5-7) Temp 45-55 degrees Neutral (pH 4.5-5.5) Temp 45-55 degrees

+ Acetic acid is added otherwise enzyme wont work 4. Stone washing

(bleaching): In this, chlorine bleach is used yellowness from fabric and to five

faded effect. Time required for bleach depends on the original sample/shade card.

Neutral ALCL3 or (H2o2 i.e. hydrogen peroxide, soda ash, soap, tinopol). After

stone washing, we can do brightening (with tinopol) to remove chlorine. 5. Ice

wash: Its similar to stone washing, but more qty of bleach is used. 6. Dyeing: The

denim is dyed in different color. After desizing, its bleached and then dyed.

Denimix and softening processes follow if required. 7. Pumice stone denimix:

After desizing, denimix wash is given and after that its abraded with pumice

stone. For denimix 40-120 grms/pc pumice stone has to be added and for stone

wash, denimix+bleaching is used. 8. Vintage: After denimix, we tint the denim

with direct dye or reactive dye. VALUE ADDED WASHES:1. Tucking : The

piece is tucked with the help of tucking machine at the place where we want to

have the wash effect. 2. Scraping: Sandpaper is used to scrap the fabric to reveal

the faded effect. 3. Spraying: Dyes are sprayed over the garment in different

angles and strokes to reveal the sprayed effect. 4. Whiskering: 5. Crinkling 6.

Crackle: The piece is tied at the place where we want to avoid color penetration in

pleats and then dyed. SOFT ( NIFT, Pune )

7. Grinding: Upper layer of the fabric is peeled/scrapped off with a grinding

machine. 8. Sandblasting: Pressurized compressed air with sand is blown on the

garment. 9. Ball blast: Its conducted into wooden m/c. bleach+caco3 power is

used. 10.G2: Its an advanced bleaching process done with ozone(O3). Bleaching

pressure is 240. If its done with chlorine bleach, it will become yellow. So, ozone

is used. 11.Pigment spray: Pigment dyes are sprayed over the denim. CASE

STUDY : Common Denim Seam Quality Defects 1. Broken Stitches - Needle

Cutting Where the thread is being broken where one seam crosses another seam

(ex: bar tacks on top of waistband stitching, seat seam on top of riser seam)

resulting in stitch failure. Minimizing broken stitches due to Needle Cutting

SOFT ( NIFT, Pune )

- Use a higher performance core spun thread - Use a larger diameter thread on

operations where the thread is being cut. - Make sure the proper stitch balance is

being used. On a chain stitch seam on denim, we should maintain a 60%/40%

relationship of Needle thread to looper thread in the Seam. - Use needles with the

correct needle point. - Change the needles at regular intervals on operations where

the Needle Cuts are occurring frequently. 2. Broken Stitches- washing procedures

Where thread on the stitch line is broken during stone-washing, sand blasting,

hand sanding, etc. Broken stitches must be repaired by re stitching over the top of

the stitch-line. Minimizing broken Stitches due to abrasion - Use a higher

performance core spun thread. SOFT ( NIFT, Pune )

- Use a larger diameter thread on operations where excessive abrasion is occurring

- Make sure stitches are balance properly, - Monitor the Finishing Cycle for

compliance to specs. 3. Broken Stitches by Chemical Degradation Where thread is

being compromised by the chemicals used during laundering resulting in loss or

change of color and seam failure. Minimizing broken stitches due to Chemical

Degradation: - Use a higher performance core spun thread that has greater

resistance to chemical degradation. - Using larger thread sizes when the Denim

Garments will be subject to Harsh Chemical washes. - Making sure that the water

temperatures and PH Levels are correct and that the proper amounts and sequence

of chemical dispersion are within guidelines. - Make sure the garments are being

rinsed properly to neutralize the chemicals in the SOFT ( NIFT, Pune )

fabric. - Monitor the drying process, cycle times, and temperatures to make sure

they are correct so that the best possible garment quality can be achieved. 4.

Unraveling Seams: Generally occurs on 401 chain stitch seams where either the

stitch has been broken or a skipped stitch has occurred. This will cause seam

failure unless the seam is Re stitched. 4. Minimizing unraveled Stitches: - Use a

high performance Core-spun thread that will minimize broken stitches and

skipped stitches. - Insure proper machine maintenance and sewing machine

adjustments. - Observe sewing operators for correct material handling techniques.

SOFT ( NIFT, Pune )

5. Restitched Seams: Where there is a "splice" on the stitch line. If this occurs on

Topstitching, then the seam does not appear to be 1st quality merchandise. Caused

by: 1. Thread breaks or thread run-out during sewing; or 2. Cut or broken stitches

during a subsequent treatment of the finished product (I.e., stone washing).

Minimizing Restitched Seams - Use a better quality sewing thread. This may

include going to a higher performance thread designed to minimize sewing

interruptions. - Insure proper machine maintenance and sewing machine

adjustments; - Make sure sewing machines are properly maintained and adjusted

for the fabric and sewing operation - Observe sewing operators for correct

material handling techniques. 6. Skipped Stitches: SOFT ( NIFT, Pune )

Where the stitch forming device misses the needle loop or the needle misses the

looper loop. Skips are usually found where one seam crosses another seam and

most of the time occurs right before or right after the heavy thickness. Minimizing

Skipped Stitches: - Use minimum thread tension to get a balanced stitch. - Use the

ideal foot, feed and plate that help to minimize flagging. - Training sewing

operators NOT to stop on the thickness. - Make sure the machine is feeding

properly without stalling. - 7. Use core spun thread. Make sure the machine is not

back feeding. Wavy Seams on Stretch Denim: Where the seam does not lay flay

and is wavy due to the fabric stretching as it was sewn or during subsequent

laundering and handling operations. SOFT ( NIFT, Pune )

Solutions for wavy seams on stretch Garments - Use minimum presser foot

pressure 0- Instruct sewing operators to use proper handling techniques and not

stretch the fabric as they are making the seam. - Where, available, use differential

feed to compensate for the stretch of the fabric. 8. Ropy Hem: - Where hem is not

laying flat and is skewed in appearance. Solutions for Ropy Hems - Usually

caused by poor operator handling. - Instruct the sewing operator to make sure they

get the hem started correctly in the folder before they start sewing. Also, make

sure they don't hold back excessively as the seam is being sewn. SOFT ( NIFT,

Pune )

- Use minimum roller or presser foot pressure 9. Twisted Legs: Is where the side

seam twists around to the front of the pant and distorts the appearance of the

jeans. Solutions for Twisted Legs: - Usually caused by poor operator handling.

Instruct the sewing operator to match the front and back properly so they come

out the same length. Sometimes notches are used to insure proper alignment. They

should NOT trim off the front or back with scissors to make them come out the

same length - Make sure the cut parts are of equal length coming to the assembly

operation. - Check fabric quality and cutting for proper skew - Make sure the

sewing machine is adjusted properly for uniform feeding of the top and bottom

plies. 10. Disappearing Stitches in Stretch Denim: Is where the thread looks much

smaller on seams sewn in the warp direction than in the weft direction of the

fabric. SOFT ( NIFT, Pune )

Solutions to minimizing disappearing stitches on stretch Denim: - Use a heavier

thread size on topstitching. - Go to a longer stitch length (from 8 to 6 spi). - Make

sure the thread tensions are as loose as possible so the thread sits on top of the

fabric rather than burying in the fabric on seams sewn in the warp. 11. Thread

discoloration after Laundry It is the thread picks up the indigo dyes from the

fabric giving the thread a 'dirty' appearance. A common discoloration would be

the pick-up of a greenish or turquoise tint. Solutions to Thread Discoloration Use thread with proper color fastness characteristics. - Correct PH level (too low)

and Water Temperature (too low) during laundry. - Use the proper chemicals &

laundry cycles. - Use Denimcol PCC in wash or similar additive SOFT ( NIFT,

Pune )

- Do not overload washers with too many garments at one time. 12. Poor

Colorfastness after Laundry is where the thread does not wash down consistently

in the garment or changes to a different color altogether. Solutions to poor

Colorfastness after Laundry: - Use thread with proper color fastness

characteristics. - Use threads from the same thread supplier and do not mix

threads in a garment. - Always do preproduction testing on denim garments using

new colors to assure that they will meet your requirements. - Make sure sewing

operators select thread by type and color number and do not just pick a thread off

the shelf because it looks close in color. SOFT ( NIFT, Pune )

PACKING AND FINISHING ORDER PROCESSING, PACKAING AND

DESPATCH Order Processing Order processing is the period between the time

of placement of the order by the buyer to the time of arrival of the goods at his

destination. This cycle is made up of the transmission of the order, document

processing in the department and shipment of goods. The documentation is a

routine activity. The procedure of receiving and handling the orders, granting

credit, invoicing, giving dispatching orders, collecting the bills and post dispatch

adjustments. Correct order processing can be very useful from the point of view

of the customers as it affects order time i.e. time interval between two orders of a

customer and secondly, the uniformity of delivery i.e. regular and dependable

deliveries. Customer Merchandising Department Order Processing SOFT ( NIFT,

Pune )

Credit Check Inventory Check Order for Dispatch Replenishment of stock

Intimation to customers Dispatch of goods Collection of payments Packaging

Packing is traditionally meant to protect goods. However, it is also a promotional

tool and a major image builder contributing to product success. Packing is a

process that speaks of companys ability to contain economically man made or

natural products for shipment, storage, sale or final use. Packaging on the other

hand deals with activities of planning and designing of different means of

packaging the product. However, it should be noted that packing is concerned

with product protection while packaging is concerned product promotion.

Objectives of packing Protection of the product: To keep the garments clean,

fresh and unspoilt by using moisture proof and damage resistant materials. Its

done basically to avoid any type of deterioration or contamination of the garment.

The main aim is to maintain the quality of the garments intact unaffected by dust

and dirt. Product identification: Packing is a convenient way to identify the

products of different buyers as each buyer would have a different type of

packing requirement. The size, color combinations, graphics used in each package

are unique and can be easily remembered. Product convenience: Packing aims at

providing maximum convenience to the purchasers, producers and distributors

alike. A nicely designed product package facilitates product shipping, storage,

stocking, handling and display on part of producers and distributors. Neat packing

can bring reduction in inventory costs, packing cost, space and time costs.

Product package promotion: A good packaging performs effective advertising

function. The general appearance and selling features created by the packaging

techniques decide the product success. As a promotional tool, it does self

advertising, displaying, publishing and acts as an advertising medium. Essentials

of Good Packing It should protect the contents: A good packaging is a means of

preservation of products from possible damage or loss in value. The quality of

the garments is maintained intact. The packing is SOFT ( NIFT, Pune )

designed to protect it against natural and artificial factors of damage

like dirt, dust, theft, shrinkage, contamination etc. It Should be attractive: Apart

from protection, seeking the attention of the consumers is also essential. Package

design, weight, material, color combinations, graphics, texture, illustrations etc

form the essentials of a good package. Some customers buy products because they

are impressed by the packing. Therefore, package attraction generates impulsive

buying. It Should provide convenience: Good packaging increases product

sanitation, ease in handling, transportation, storing and using packages. The

package so designed should grant highest degree of convenience to

manufacturers, distributors and consumers alike. Consumers are seeking packages

that are easy to handle, open and reusable. It Should be economical: Economy is

something that reduces not only packing and its expenses, but also brings down

other allied expenses such as transport, warehousing, tax-levies and handling.

Cost reduction are possible through multi-packaging allows more cost re3duction

than when one pack is sold on its own. It should be pollution free: It is a well

known fact all over the world that packing has environmental problem,

particularly the discarded packing. Hence it is advisable to use recycled or biodegradable packaging materials that minimize pollution. It should be informative:

Provision of information about product illustration, features/specifications,

instruction to handle, prices, the amount of product in the package, the content

brands name, and other relevant information for the consumer as well as

distributor. Detailed labeling is a must. It should assure adjustability: The

packaging should have the ability to adjust or flexibility to be put to different

uses. Paper packaging is known for cheapness and lightness. It should be labeled:

Labeling is the act of attaching or tagging labels. A label may be a piece of paper ,

printed statement which is either a part of a package or attached to it, indicating

value of contents, price, product name, and place and name of producer. Thus, a

label is an informative tag, wrapper or seal attached to a product or products

package. Considerations for new packing development In designing a new

product package or redesigning the existing one, the manufacturers take into

account: Nature of product: The type of container to be used depends upon the

form and ingredients of the product. Transparent containers are most suited for

attractive colors and appearance, vacuum sealed ingredients for volatile

ingredients and glass containers to minimize chemical reactions. Plastic and metal

packages can also be used. Costs: The cost of packing must be absorbed by the

production economies, increased sales volumes or higher price. The packing

material, label, filling and closure costs, handling, distribution and breakage cost

of package are important. Family resemblance: If the product is one of a number

of related items, its advisable to design the package that confirms to the

containers of other products in the same line to assist consumer and dealer

identification Advertising value: Unique shape, attractive design gives a package

greater sales and advertising value. Legal requirements: the packages must

confirm to the laws prohibiting the deception of consumers by the use of false

bottoms, slack fill and other means of giving an impression that a SOFT ( NIFT,

Pune )

package contains a larger quantity than the case. There are legal requirements

prescribing the copy appearing on the labels of the cartoons which should be

confirmed to. Test the design in the market: test-marketing must be conducted in

the market to get indirect replies through dealer feedback. Environmental

checking: the packing development decision may be influenced by legal,

ecological and social forces. Thus issues like consumer packing safety, disposable