Beruflich Dokumente

Kultur Dokumente

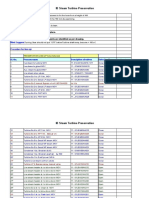

How To Increase Vacuum of ACC Case Study Paper

Hochgeladen von

Udhayakumar VenkataramanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

How To Increase Vacuum of ACC Case Study Paper

Hochgeladen von

Udhayakumar VenkataramanCopyright:

Verfügbare Formate

Technical paper ID 309 for POWER-GEN EUROPE 2012

How to improve air cooler vacuum steam

condensers performance in the field

By Marc Ellmer

ELFLOW BV The Netherlands

www.elflow.nl

Technical paper ID 309 for POWER-GEN EUROPE 2012

Introduction

Air cooled vacuum steam condensers (ACCs) are used to condense exhaust steam from

turbines in a closed cycle. They are mostly used in power plants (Waste Incineration Plants

and Combined Cycle Plants). Axial flow fans located below heat exchanger bundles; sloped

in an A-frame structure; force a stream of ambient cooling air through the system. In so

doing, heat from the condensing steam is rejected to the environment via the finned tubes.

Steam flows down across the bundles. Condensates are recovered inside a manifold connected

to a hot water tank. Non condensable goes up in a counter flow current through a secondary

condenser part (dephlegmators) for final condensation.

The rejection capacity of an ACC is proportional to the air mass flow rate and the temperature

difference between the ambient air and finned tubes. Therefore owing to the dynamic

interaction between the steam turbines and the ACC, ambient conditions (e.g. dry bulb

temperature, wind) and the flow rate delivered by the axial fans have a direct influence on the

efficiency of such a direct air cooled power plant

Due to the fact that there is a clear dynamic interaction between the steam turbine and the

ACC, a change in condensation capacity of the ACC will directly influence the efficiency of

the steam turbines and hence have an important influence on electricity production.

As the design and manufacturing of ACCs has tended to be limited to a relatively select

number of manufacturers mostly focussed on manufacturing and not assessing and optimizing

its current performance, it is not uncommon to find new and old ACCs that do not perform to

their full potential. This is also due to a lack in understanding of the end user and to a lack of

cooperation of the ACC manufacturers in general.

This means there is almost always room for improvement on existing ACCs.

www.elflow.nl

Technical paper ID 309 for POWER-GEN EUROPE 2012

This technical paper aims at detailing a few practical examples of how to improve Your

existing ACC in the field. Examples of ways to improve ACC performance are:

Optimization of airflow system (higher efficiency)

Installation of wind screens to counter negative effects of cross winds on ACCs

Installation of fogging systems (adiabatic cooling)

Elimination of hot air recirculation

Leak detection of vacuum system

Better and more efficient cleaning methods for finned tube bundles

Other problems related to ACC performance loss

Optimization of airflow system (higher efficiency)

Generalofrule

ofscreens

thumb to counter negative effects of cross winds on ACCs

Installation

wind

o

At 24 C; 1% more air corresponds to approximately 1 mbarA in vacuum

improvement

More than 70% of the current installations are not performing optimally in terms of fan

settings. This is caused by the fact that on the one hand there is a lack of practical field

experience of OEMs in terms of fan optimization. Most OEMs are more focused on

manufacturing the ACC than operating it. Furthermore, not a single ACC OEM has

manufactured their own fans in Europe or in the USA over the last couple of years. Clearly,

the latter situation does not help on acquiring expertise concerning fan behavior in the field.

This is why there is often room for improving airflow on an existing ACC by simply

optimizing the fan settings or replacing it by a high efficiency fan. It has been observed that in

most cases, an improvement of 10-20% increase in airflow was achieved with the same motor

power resulting in improvement in electricity production for the power plant at the same

steam load.

www.elflow.nl

Technical paper ID 309 for POWER-GEN EUROPE 2012

Pictures 1 & 2 - Illustration of an on-site fan setting optimization on a large ACC fan and replacement to high efficiency fan

on another ACC

Installation of wind screens to counter negative effects of cross winds on ACCs

General rule of thumb

Experience has indicated that reducing the negative effects of crosswinds can reduce

the turbine backpressure by as much as 15 mbarA with an average wind speed of 10

m/s

Crosswinds can result in a substantial reduction in fan performance of the upwind fans. This

can result in loss in electricity production and reliability of related problems of the mechanical

parts such as gearbox and fan failures. Crosswinds that hit an ACC will be deflected due the

existence of a wind wall creating a jet stream under the fan (illustrated in figure 1). As the

deflected winds are accelerated (due to the deflection), this creates a flow separation at the fan

inlet which causes mal-distribution of airflow into the fan (vacuum under the fan illustrated in

figure 2). Inlet flow distortions caused by structures (wind walls), wind and induced cross

winds have an negative effect on fan performance, due to a combination of increased inlet

flow losses (i.e. flow separation at the inlet section), mal-distribution of air into the fan (i.e.

non uniform inlet profiles). The stronger the wind, the stronger the jet stream and in turn the

more the fan starts to stall resulting in a loss of performance of the ACC and a potential risk

of breaking down fans and gearboxes.

As the fan deck on large ACCs is mostly at 20-25 m in height, the wind at height is always a

lot stronger than on the ground. the latter is also accentuated by the wind deflection caused by

the bundles or wind walls. Therefore, it is not uncommon to see wind speeds of 12-15 m/s at

the level of the fan ring whereas the ground wind speed (where the wind speed is mostly

recorded) is only 3 m/s as illustrated in figure 3. This has also been registered by us during

field surveys using a vane anemometer.

www.elflow.nl

Technical paper ID 309 for POWER-GEN EUROPE 2012

Figure 1 - Illustration of deflected wind resulting in jet stream under fan of ACC

Figure 2 - Illustration of CFD modeling with strong winds (25 m/s) on ACC showing non uniform inlet profiles(source: GBR

Industries)

Figure 3 - Illustration of wind speeds just under fan deck versus ground wind speed

www.elflow.nl

Technical paper ID 309 for POWER-GEN EUROPE 2012

A solution for this problem can be to install wind screens in order to break up the jet stream as

illustrated in pictures 3 &4 below.

Picture 3 - Illustration of a fixed wind screen system on an ACC to counter negative effects of cross winds

Picture 4 - Illustration of Rolling System wind screen on an ACC

www.elflow.nl

Technical paper ID 309 for POWER-GEN EUROPE 2012

Installation of fogging systems (adiabatic cooling)

General rule of thumb

A properly installed fogging system will NOT damage your equipment with a

potential improvement of turbine backpressure of as much as 55 mbarA at 30oC

ambient air temperature

When designing new ACCs, one must always decide what ambient air temperature to use.

Ambient air temperature will greatly affect ACC size.

There is always the trade-off between high capital expenditure (high ambient air temperature)

or limitations in production during the hot summer days if one decides to use lower ambient

air temperatures in the design stage. In most cases, the design ambient air temperature is far

lower in comparison to hot summer days as illustrated in Graph 1 below

35

Required

temp

Ambiant air temperature

30

25

Design temp

20

Ambiant

temp

15

10

Temp with

fouling

5

0

1 4

7 10 13 16 19 22 25 28 31 34 37 40 43 46 49

Temp after

aging

Weeks of the year

Graph 1 Different design points determined by real temperature, design points and after aging and external fouling

Because air is used as cooling medium, the heat rejection capacity is strongly influenced by

ambient conditions such as dry bulb temperature and other meteorological phenomena.

This means that in most cases, ACCs are always coping with serious vacuum problems

during the entire summer period (and sometimes even in the spring and autumn). Moreover,

electricity prices fluctuate on a daily basis and follow the temperature curve as illustrated in

Graph 2 on the following page. This is especially true for peak load power plants!

www.elflow.nl

Technical paper ID 309 for POWER-GEN EUROPE 2012

Graph 2 Illustration of price of electricity versus temperature

An efficient chilling system (also called fogging, misting, peak cooling) is a high pressure

fogging system used to influence ambient climatic conditions. By evaporating billions of

micro fine droplets in the inlet air of an ACC, adiabatic cooling is attained and the evaporative

effect results in a drop in inlet air temperature, resulting in an increase in efficiency of the

ACC. The evaporative cooling system effect on an ACC will have a direct positive effect on

Process production.

A proper chilling system can reduce air temperature by as much as 10*C in dry climates

(Steppes and desert) and up to 8*C in continental, Mediterranean and temperate climates.

36*C

08:00

10:00

12:00

14:00

16:00

18:00

90%

Dry Bulb Temp.

Relative

Humidity

80%

Evaporative cooling

(potential 10.5*C)

30*C

27*C

70%

60%

24*C

50%

Wet Bulb

21*C

Dew Point

18*C

Relative Humidity

Temperature

33*C

40%

30%

Time of the day

Graph 3 Illustration of adiabatic cooling

www.elflow.nl

Technical paper ID 309 for POWER-GEN EUROPE 2012

A proper chilling system is also designed and installed in such a way that all of the water

sprayed in the air is completely evaporated before reaching the mechanicals and/or finned

tube bundle, as illustrated in the pictures 1 and 2 below. This is attained by using special

nozzles and high pressure (80-100 Bar) in order to create microscopic droplet sizes (20-25 ).

By doing so, the evaporation time is reduced to almost nothing (instant evaporation) and will

therefore maximize system efficiency, minimum water waste and no damage to your

mechanicals and/or finned tube bundles.

In the pictures 3 and 4 below, one can see that the mist is completely evaporated before

reaching the fans/finned tube bundles. These systems are also multi stage systems for

improved control.

Pictures 6 & 7 - Illustration of a multi stage fogging system in action with complete evaporation

www.elflow.nl

Technical paper ID 309 for POWER-GEN EUROPE 2012

The effects of installing a fogging system under the ACC can be enormous as illustrated in the

following ACC performance curve (graph 4), of an ACC installed in Northern Europe

45 mbarA backpressure improvement

35 mbarA backpressure improvement

25 mbarA backpressure improvement

Graph 4 Illustration of gains in Turbine Back pressure using Fogging Systems

www.elflow.nl

Technical paper ID 309 for POWER-GEN EUROPE 2012

Elimination of hot air recirculation

General rule of thumb

Hot air recirculation can increase the turbine backpressure by as much as 35 mbarA

at a ambient air temperature of 24oC

It is essential that the ACC is equipped with a wind wall in order to prevent hot air

recirculation. If this is not the case, the hot outlet air can recirculate back into the inlet of the

fan such as illustrated in the picture below putting into evidence the hot recirculation by using

smoke bombs. The tricky thing about hot air recirculation, is that the hotter it gets, the higher

the turbine back pressure. The higher the turbine backpressure, the higher the inlet steam

temperature at the ACC and hence the higher the outlet air temperature, thereby ultimately

resulting in a worsened hot air recirculation. For example, at a vacuum of 100 mbarA the

steam temperature should be around 45.8oC whereas the steam temperature would be 60.1oC

at a vacuum of 200 mbarA resulting of course in a far higher outlet air temperature.

Picture 8 - Illustration of hot recirculation on ACC using smoke bombs

www.elflow.nl

Technical paper ID 309 for POWER-GEN EUROPE 2012

Leak detection of vacuum system

In order to check your ACC performance, it is important to carry out a so called vacuum

drop test which will enable you to check whether the system is leaking and therefore causing

severe loss in performances. The test is very simple and immediately shows if there is a leak,

and where one should check for the leaks. Once it has been determined that there is a leak, a

leak detection study should be carried out using helium combined with a helium detector.

The vacuum drop test consists of 3 tests which are described below. The leaking rate should

in theory not exceed 0.5 mbarA per minute.

Test 1

Isolate the complete vacuum system by closing the isolation valve to the holders. (operational

vacuum ejectors)

Test 2

Isolate the vacuum system as per test 1 but with both double ejector systems operational by

opening the steam valves to the holders.

Test 3

Isolate the vacuum system as per test 2 but with the hogger (start-up ejector) in operation by

opening the steam valve to the hogger.

www.elflow.nl

Technical paper ID 309 for POWER-GEN EUROPE 2012

Better and more efficient cleaning methods for finned tube bundles

General rule of thumb

A good cleaning can generate an average vacuum improvement at the turbine

backpressure of as much as 60 mbarA depending on fouling degree

External fouling of finned tubes can reduce the capacity of the ACC by as much as 40% as it

not only restricts the air of going through the finned tube bundles, but also thermally isolates

the fins making up a large portion of the finned tube surface as illustrated in picture 1 below.

Therefore it is very important to clean the ACC regularly and as well as possible. There are a

few challenges in cleaning an ACC quickly and safely.

As one (1) ACC fan covers a large portion of heat transfer surface, the impact of having to

shut the fan down for cleaning is enormous on the steam turbine backpressure, and therefore

electricity production. This is especially true in the late spring when most ACCs are cleaned

right after the period of the pollens. Therefore it is very important to clean the ACC as quickly

as possible in order to limit the loss in electricity production.

It is also not easy to clean an ACC safely due to the fact that the bundles are built in an Aframe configuration. This means that access to the top of the finned tube bundle is very

difficult and delicate, and therefore potentially dangerous.

Pictures9 & 10 - Illustration of external fouling on lower row of finned tube bundle and thermal isolation of fouling on fins

This is why most ACCs are cleaned by using a permanent cleaning rig on the bundles, which

allow fast and safe cleaning of the finned tube bundles. When using such a system, it is

important to use as large a pump capacity as possible, to be able to clean faster than with a

low capacity pump. We therefore recommend a pump system of at least 220 l/min with a

minimum of 20 nozzles. The pump pressure should also be at least 120 bar in order to have

the maximum impact on the finned tube bundle cleaning.

www.elflow.nl

Technical paper ID 309 for POWER-GEN EUROPE 2012

Picture 11 - Illustration of high capacity cleaning head versus normal capacity head. High capacity increases speed of

cleaning by 2 x

The cleaning system of an A-frame steam condenser consists of a support frame, which can

be a ladder or an aluminum space frame, a cleaning rig and rails via which the support frame

moves along the heat exchanger bundles. The cleaning rig is suspended from the support

frame to allow a traveler with spray-head move in vertical direction. Picture 2 illustrates the

permanent cleaning machine specially designed for ACC application which allows for fast

and safe cleaning of the finned tube bundles.

Pictures 12 &13 - Illustration of high flow & pressure permanent cleaning system in action

www.elflow.nl

Technical paper ID 309 for POWER-GEN EUROPE 2012

Other problems/solutions related to ACC performance loss

a. Distance keepers for Single Row Bundles

During our many site surveys, we noticed that there were certain ACCs with large gaps

between certain tubes being created by different thermal expansions of the different tubes.

These gaps allow for air to pass through as it chooses the path of least resistance reducing

ACC capacity considerably. This is caused by the distance keepers not doing the job

correctly. We would recommend placing stainless steel distance keepers more apt to perform

the job, instead of the originally installed PE distance keeping that get eroded by UV lighting

and break after a while, and thus creating gaps.

Pictures 14 &15 - Illustration of creation of gaps between certain tubes caused by failing distance keepers

Pictures 16 - Illustration of newly installed stainless steel distance keepers

www.elflow.nl

Technical paper ID 309 for POWER-GEN EUROPE 2012

b. Variable frequency drives on electrical motors

Many ACC fans are not equipped with variable frequency drives. Variable frequency drives

have many advantages and should in our view always be installed on ACC fans due to the

following:

Noise

There is a European noise directive 2002/49/EG relating to the assessment and management

of environmental noise where they differentiate noise levels between day time, evening and

night-time. Between noise restrictions during the (hotter) day time and the (cooler) evening

and especially (even cooler) night time, there is a large difference. Indeed evening noise

levels need to be day noise level 5dB and the night-time noise levels need to be day noise

level 10dB which is a huge difference. This means that in order to reduce existing noise

level of a plant according to European legislation, one can install variable frequency drives on

the existing fans. One must first of all realize that fans will turn faster (thus produce more

noise) during the hot part of the day which is day time and to a lesser extent the evening time.

During night time (when the price of electricity is also lower), the fans can easily turn at

lower RPM as the air temperature is lower than during the day. ACC fans are sources of low

frequency noise as a normal ACC 30 ft. fan will turn at about 60-70 RPM. The low frequency

noises go further away (so not good for overall plant noise level) and are impossible to filter.

Optimization of fan performance

Most motor loadings of the ACC fans are about 80% of nominal current. This is to be able to

run at 100% during cold winter periods when the air is denser than during hot summer days.

By installing a variable frequency drive on these units, one can load up the motors to 100%

nominal current at for instance 15oC which would be the theoretical value where the fans

would have to run given the maximum load. By using thermal simulation programs, one can

simulate this set point and set the fan to full load current at that particular air temperature. If

the temperature would get lower, the fans would run slower anyhow (pulling less current as a

result) and thus the motors would not trip anyhow???. The motors can be loaded to full

current by increasing pitch angle until full load current is obtained. A preferred (provided

noise level allows for this!) way to load the motors to full load current, is to increase the

frequency of the variable frequency drives to over 50 Hz. This will increase fan RPM and thus

increase motor loading. We prefer to carry out the latter method as in most cases, this will

increase fan efficiency and also pressure capability of a fan. We have experienced average

increases in airflow of 10-15% by carrying out this trick without breaking the rules of plant

noise level restrictions. Increasing fan RPM will also increase the AGMA rating for the

gearbox which will in turn increase MTBF of your mechanical equipment.

www.elflow.nl

Technical paper ID 309 for POWER-GEN EUROPE 2012

Mechanical reliability

Due to the fact that fans do not have to be shut down and started again to regulate the plant

load, this will off course have a very positive effect on the MTBF of your fans and gearboxes.

A variable frequency drive will regulate the plant load in a much smoother way which will

only have positive effects on the MTBF of your mechanics.

www.elflow.nl

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Battery Room Design AspectsDokument4 SeitenBattery Room Design AspectsUdhayakumar VenkataramanNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Handbook - Energy Management For Motor Driven Systems PDFDokument123 SeitenHandbook - Energy Management For Motor Driven Systems PDFmnt6176Noch keine Bewertungen

- KYPipe Reference Manual GuideDokument76 SeitenKYPipe Reference Manual GuideApril TrevinoNoch keine Bewertungen

- Electrical Testing ProeduresDokument9 SeitenElectrical Testing ProeduresUdhayakumar VenkataramanNoch keine Bewertungen

- Faults On Electrical SystemDokument21 SeitenFaults On Electrical Systemjosh bradley100% (3)

- Sliding Pressure Control BasicsDokument4 SeitenSliding Pressure Control BasicsUdhayakumar VenkataramanNoch keine Bewertungen

- Technical Specification ColtcsDokument60 SeitenTechnical Specification Coltcsproloy12Noch keine Bewertungen

- Everything Maths Grade 11 Trig GraphsDokument3 SeitenEverything Maths Grade 11 Trig GraphsAmyNoch keine Bewertungen

- Manual 3322006Dokument46 SeitenManual 3322006mallikapathakNoch keine Bewertungen

- IB Steam Turbine PreservationDokument6 SeitenIB Steam Turbine PreservationUdhayakumar VenkataramanNoch keine Bewertungen

- Boiler CommissioningDokument29 SeitenBoiler Commissioningbratishkaity100% (8)

- IRC Ammendments 2018Dokument31 SeitenIRC Ammendments 2018ਸੁਖਬੀਰ ਸਿੰਘ ਮਾਂਗਟ100% (1)

- 660 MW IIoT AspectsDokument17 Seiten660 MW IIoT AspectsUdhayakumar VenkataramanNoch keine Bewertungen

- Construction Incident Engineering Reports: Collapses & FatalitiesDokument21 SeitenConstruction Incident Engineering Reports: Collapses & FatalitiesUdhayakumar VenkataramanNoch keine Bewertungen

- Improves Concrete Characteristics FA100 S Type FDokument1 SeiteImproves Concrete Characteristics FA100 S Type FUdhayakumar VenkataramanNoch keine Bewertungen

- Top 5 Troubleshooting Issues For Blower SystemsDokument4 SeitenTop 5 Troubleshooting Issues For Blower SystemsUdhayakumar VenkataramanNoch keine Bewertungen

- Keeping Your Lubrication Program in The CrosshairsDokument4 SeitenKeeping Your Lubrication Program in The CrosshairsUdhayakumar VenkataramanNoch keine Bewertungen

- Ash Utilisation in TATADokument5 SeitenAsh Utilisation in TATAUdhayakumar VenkataramanNoch keine Bewertungen

- Valve MOC and ImportantDokument22 SeitenValve MOC and ImportantUdhayakumar VenkataramanNoch keine Bewertungen

- An Overview of Power Sector of BangladeshDokument36 SeitenAn Overview of Power Sector of BangladeshJahid MasudNoch keine Bewertungen

- Improves Concrete Characteristics FA100 S Type FDokument1 SeiteImproves Concrete Characteristics FA100 S Type FUdhayakumar VenkataramanNoch keine Bewertungen

- BFP Performance Assessment Article HelpfulDokument10 SeitenBFP Performance Assessment Article HelpfulUdhayakumar VenkataramanNoch keine Bewertungen

- Woven Sacks DPR Input - Odissa GoIDokument3 SeitenWoven Sacks DPR Input - Odissa GoIUdhayakumar VenkataramanNoch keine Bewertungen

- Energy Audit of Combined Cycle Power Plant: A Case Study: Umair Ahmed, Prof. Javed Ahmad ChatthaDokument6 SeitenEnergy Audit of Combined Cycle Power Plant: A Case Study: Umair Ahmed, Prof. Javed Ahmad ChatthaUdhayakumar VenkataramanNoch keine Bewertungen

- Extend Gear Coupling Life: of Can Be ofDokument5 SeitenExtend Gear Coupling Life: of Can Be ofUdhayakumar VenkataramanNoch keine Bewertungen

- Sliding Pressure Operation of Large Conventional Steam Power UnitDokument6 SeitenSliding Pressure Operation of Large Conventional Steam Power UnitUdhayakumar VenkataramanNoch keine Bewertungen

- Electrical Quality DeviesDokument12 SeitenElectrical Quality DeviesUdhayakumar VenkataramanNoch keine Bewertungen

- Foundation DetailDokument1 SeiteFoundation DetailUdhayakumar VenkataramanNoch keine Bewertungen

- Four important precautions for installing cables and busbar systemsDokument11 SeitenFour important precautions for installing cables and busbar systemsUdhayakumar VenkataramanNoch keine Bewertungen

- Different Type of Motors For Industrial DrivesDokument5 SeitenDifferent Type of Motors For Industrial DrivesUdhayakumar VenkataramanNoch keine Bewertungen

- Different Type of Motors For Industrial DrivesDokument5 SeitenDifferent Type of Motors For Industrial DrivesUdhayakumar VenkataramanNoch keine Bewertungen

- Energy Efficient Motor AspectsDokument3 SeitenEnergy Efficient Motor AspectsUdhayakumar VenkataramanNoch keine Bewertungen

- Master Wall Catalogue August 2019Dokument152 SeitenMaster Wall Catalogue August 2019Udhayakumar VenkataramanNoch keine Bewertungen

- Lesson Learnt From Biomass PlantsDokument31 SeitenLesson Learnt From Biomass PlantsUdhayakumar VenkataramanNoch keine Bewertungen

- 22 - Muhammad Rifky Hasan - 172112238Dokument4 Seiten22 - Muhammad Rifky Hasan - 172112238Rifky hasanNoch keine Bewertungen

- Golden Ratio in Art and Architecture by Samuel ObaraDokument3 SeitenGolden Ratio in Art and Architecture by Samuel ObaraSabyNoch keine Bewertungen

- Structures: Muhammad Zain, Muhammad Usman, Syed Hassan FarooqDokument11 SeitenStructures: Muhammad Zain, Muhammad Usman, Syed Hassan FarooqDilum VRNoch keine Bewertungen

- Lesson 3-F5 PhysicsDokument14 SeitenLesson 3-F5 PhysicsCheng WLNoch keine Bewertungen

- Mechanical EngineeringDokument19 SeitenMechanical EngineeringhenoksolNoch keine Bewertungen

- Accessible Design LightingDokument8 SeitenAccessible Design LightingArch AmiNoch keine Bewertungen

- CHM 2045 Exam 2 Form Code ADokument2 SeitenCHM 2045 Exam 2 Form Code ABritanny NelsonNoch keine Bewertungen

- Co Pia de Garcia System Dynamics 1 Theory PDFDokument294 SeitenCo Pia de Garcia System Dynamics 1 Theory PDFGuilherme AntunesNoch keine Bewertungen

- 23 Electronic TheodolitesDokument4 Seiten23 Electronic TheodolitesEmaNoch keine Bewertungen

- Fast Fourier Transform (FFT) (Theory and Implementation)Dokument59 SeitenFast Fourier Transform (FFT) (Theory and Implementation)Suman BasakNoch keine Bewertungen

- JR Engg WAPDA (Civil)Dokument16 SeitenJR Engg WAPDA (Civil)Hamza MujahidNoch keine Bewertungen

- Lecture 3Dokument10 SeitenLecture 3Abhishek SinhaNoch keine Bewertungen

- CBSE Class 12 Chemistry Sample Paper-15: Material Downloaded From - 1 / 14Dokument14 SeitenCBSE Class 12 Chemistry Sample Paper-15: Material Downloaded From - 1 / 14Allen Neal JonesNoch keine Bewertungen

- GCSE Mini Test 4: Foundation Maths QuestionsDokument2 SeitenGCSE Mini Test 4: Foundation Maths QuestionsSuiatz (Suiatz)Noch keine Bewertungen

- Turbidites and Foreland Basins An Apenninic PerspectiveDokument6 SeitenTurbidites and Foreland Basins An Apenninic PerspectivekoloshrabeaaNoch keine Bewertungen

- Rabin CryptosystemDokument41 SeitenRabin CryptosystemArkadev GhoshNoch keine Bewertungen

- EOR Screening Part 2 Taber-MartinDokument7 SeitenEOR Screening Part 2 Taber-MartinPerwira HandhikoNoch keine Bewertungen

- Numerical Investigation and Design of Aluminum Alloy Circular HollowDokument13 SeitenNumerical Investigation and Design of Aluminum Alloy Circular HollowDjordjeDjNoch keine Bewertungen

- CFD Application Tutorials 2Dokument35 SeitenCFD Application Tutorials 2Jubril AkinwandeNoch keine Bewertungen

- Nuclei QB XiiDokument23 SeitenNuclei QB XiiToshani GuptaNoch keine Bewertungen

- Uluru-KataTjuta Maps VisitoressentialsDokument4 SeitenUluru-KataTjuta Maps VisitoressentialsbennysgigNoch keine Bewertungen

- SM04 Poster 82Dokument6 SeitenSM04 Poster 82lkamalNoch keine Bewertungen

- TDS PH MacTexMXL May2014Dokument1 SeiteTDS PH MacTexMXL May2014Catherine MagnayeNoch keine Bewertungen

- Proportional-Integral-Derivative Control: ObjectivesDokument5 SeitenProportional-Integral-Derivative Control: ObjectivesQuenneBelocuraNoch keine Bewertungen

- Passive Flow Separation Control Over NACA 63018Dokument1 SeitePassive Flow Separation Control Over NACA 63018miladrakhshaNoch keine Bewertungen