Beruflich Dokumente

Kultur Dokumente

LPG Piping

Hochgeladen von

LelosPinelos123Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

LPG Piping

Hochgeladen von

LelosPinelos123Copyright:

Verfügbare Formate

LPG Gas Carriers

Cargo Piping

Robbie Sillars

Lead Specialist Refrigeration

London Design Support Services

Busan Korea - May 2007

LPG Training Course Korea May 2007

LLOYDS REGISTER EMEA

Piping Functions Cargo operations

Cargo tank inerting

Line inerting

Loading

Venting

Reliquefaction

Heating

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

Piping Functions ancillary systems

Initial loading

Tank drying (low dew point air)

Inerting and gassing up

Changing cargo or gas freeing

Stripping and puddle heating

Inerting and gas freeing

Other systems

Emergency discharge

Hold drainage

Methanol

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

Typical Layout of an LPG Tanker

Cargo Machinery Room

Cargo Pump

Fore

Peak

Engine

room

Gas Safe

Area

Water Ballast Tanks

Ballast Pump Room

Gas Dangerous area

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

Cofferdam

Typical Layout of an Oil Tanker

Cargo Tanks

Fore

Peak

Engine

Room

Gas Safe

Area

Pump Room

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

Water Ballast Tanks

Gas Dangerous area

Cofferdam

Oil Tanker Pumping Arrangements

Manifold

Pump room

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

Cargo tanks

Gas Carrier Pumping Arrangements

Cargo Heater

Cargo

Pumps

Sea

Water

Cargo

Tank

Manifold

Booster Pumps

Dome

Relief Valves

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

Mast

Riser

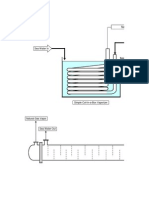

Reliquefaction Plant - Simple System

KO Pot

Sparge Pipe

Vapour

Single stage

connections

Cargo

Condenser

Cargo

Tank

Liquid Gas Return

Expansion

Device

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

Liquid

Sump

Oil-less

Compressors

Intercooler

Sea

water

Deck Tanks

Dependant on proposed cargoes to be carried

Reduced time alongside at terminal

Sufficient liquid to gas up and cool down one system

Size depending on cargoes

Standard arrangement - 1 large and 1 small deck tank

Ammonia main reason Propane butane compatible

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

LPG Cargo Piping System Piping requirements

Material as per Tables 6.1 & 6.4 of the IGC Code

Stainless steel

Thin wall large sizes schedule 10

L Grades (low low-carbon) to allow welding

Design pressure IGC Code 10 bar (Boosters more)

Design Temperature LPG warmer than minus 55 deg C

Class II system

Guidance notes available

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

LPG Cargo Pipe Fittings

Type testing not required due to design temperature

Isolation arrangements

Removable spool pieces

Block and bleed

Seut valves

Bellows pieces (EJMA)

Ball and Butterfly valves

Remote control valves closing time critical

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

Hold Drainage Arrangements

Hold void space

Dome

Ballast tanks

Cargo

to tank

Water

overboard

Cargo tank

(Type A tank)

Ballast water

overboard

Machinery

space

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

Duct keel / Pipe tunnel

Why Use Inert Gas?

Gas Free

Inert

Cargo

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

Inert Gas Non-return Devices

Oil tanker

Deck water seal

+

N.R. Valve

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

Gas Carrier

Two N.R. valves

bleed valve between valves

(no liquid, no ice)

(Back flow from hold

spaces only)

Filling Limits Requirements

IGC Code filling limit states a limit of 98% at the reference

temperature

Type C tanks may be loaded to a level higher than their

relief valve set pressure, but never greater than 98%

SIGTTO document covers how to calculate highest voyage

temperature

Dispensation of 98.5% now common on Type A LPG carriers

Dispensation to be acceptable to the administration

SIGTTO overfill protection guidelines to be followed

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

Filling Limits - Type C

The difference for Type C tanks is that the relative density

can now be taken at the highest temperature the cargo will

reach at design conditions, IGC Code paragraph 15.1.5

This can only be applied where the venting system has been

approved and shown to be suitable for two phase flow.

Savings are not so great for low pressure tanks where the

loading and reference temperatures are close.

High level alarms are still to be fitted for 98%

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

Pressure Relief Arrangements

The setting of the second pressure relief valve can be at 5%

above MARVS.

Reduces the amount of cargo vented during short periods

of pressure rise (not fire condition)

Relief valve vent exit is to be 6 m above the deck storage

tanks and the cargo liquid lines.

Low melting point materials (< 925C) such as aluminium and

neoprene could be accepted for use as internal parts of relief

valves.

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

Pressure Relief Arrangements

The setting of the second pressure relief valve can be at 5%

above MARVS.

Reduces the amount of cargo vented during short periods

of pressure rise (not fire condition)

Low melting point materials, less than 925OC such as

aluminium and neoprene can be accepted for use as internal

parts of relief valves. Neoprene diaphragms being common.

Relief valve vent exit is to be 6 m above the deck storage

tanks and the cargo liquid lines.

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

Relief Valve Pressure Drop Calculations

Pressure drop calculation s need to be undertaken and

submitted for approval

Inlet pressure drop, from tank to relief valve, to be < 3%

Outlet pressure drop is dependant on type of relief valve

fitted.

For Type A tanks with pilot operated relief valve <

50%

For Type C tanks with coiled spring < 10%

Vent mast to be fitted with grill but not flame arrester

LPG Training Course Korea 2007

LLOYDS REGISTER EMEA

For more information

please contact:

Robbie Sillars

Lead Specialist - Refrigeration

Engineering Systems

London Design Support Services

Lloyds Register EMEA

Direct Tel No. +44 (0) 20 7423 1921

Direct Fax No. +44 (0) 20 7423 1824

Email

refrigeration@lr.org

Services are provided by members of the Lloyds Register Group

Lloyds Register, Lloyds Register EMEA and Lloyds Register Asia are

exempt charities under the UK Charities Act 1993.

CHANGE TITLE IN SLIDE MASTER

LLOYDS REGISTER (amend as req.)

The Lloyds Register Group

works to enhance safety and

approve assets and systems at

sea, on land and in the air

because life matters.

Das könnte Ihnen auch gefallen

- Liguefied Gas Tanker Operation NotesDokument30 SeitenLiguefied Gas Tanker Operation NotesDon100% (2)

- LPG Tank SizingDokument1 SeiteLPG Tank Sizinganas shehabiNoch keine Bewertungen

- Loading LPG CalculationsDokument12 SeitenLoading LPG CalculationsJohn Green67% (3)

- 1.1.1 LPG 1.1.2viscosity 1.1.3 Vapor Pressure 1.1.4 Specific Gravity 1.1.5 Flame Temperature 1.1.6 Flash Point 1.1.7 Odorization of LPG 1.1.8 Colour 1.1.9 ToxicityDokument6 Seiten1.1.1 LPG 1.1.2viscosity 1.1.3 Vapor Pressure 1.1.4 Specific Gravity 1.1.5 Flame Temperature 1.1.6 Flash Point 1.1.7 Odorization of LPG 1.1.8 Colour 1.1.9 ToxicityzeyadNoch keine Bewertungen

- LNG Bunker SlidesDokument38 SeitenLNG Bunker SlidesChristopher Hoo100% (5)

- LPG Cargo CalculationDokument1 SeiteLPG Cargo CalculationGauravRai50% (2)

- Design of LPG Terminal PDFDokument1 SeiteDesign of LPG Terminal PDFLPG TERMINAL0% (1)

- LPG SpecificationDokument4 SeitenLPG SpecificationAdeniyi Alese50% (2)

- To Calculate The Weight of LPG VapoursDokument8 SeitenTo Calculate The Weight of LPG VapoursAshraf Farooq100% (2)

- P & ID For Complete LPG Terminal ProjectDokument1 SeiteP & ID For Complete LPG Terminal ProjectLPG TERMINALNoch keine Bewertungen

- The Transportation of Liquefied Gas - An Overview of Some Methods Used For Mitigating The RisksDokument60 SeitenThe Transportation of Liquefied Gas - An Overview of Some Methods Used For Mitigating The RisksAriantoNoch keine Bewertungen

- LNG Marine TerminalDokument100 SeitenLNG Marine TerminalBang Niel100% (2)

- LNG FamiliarisationDokument80 SeitenLNG FamiliarisationGee Villadarez100% (1)

- Loading and Unloading of LPG Tanker ShipDokument13 SeitenLoading and Unloading of LPG Tanker ShipMohammad FarhanNoch keine Bewertungen

- 5000m3 LPG Tank FarmDokument2 Seiten5000m3 LPG Tank FarmLpgTankFarmNoch keine Bewertungen

- LNG Vessel Safety ZonesDokument26 SeitenLNG Vessel Safety Zonesnguyenhung_pv88% (8)

- SNG and LPG Systems Overview - ELY EnergyDokument57 SeitenSNG and LPG Systems Overview - ELY EnergyPref181186% (7)

- Gas Cargo Calculation ExerciseDokument20 SeitenGas Cargo Calculation Exerciseswapneel_kulkarni100% (5)

- SIGTTO SGMF - Standards Guidelines Natural Gas FuelledDokument19 SeitenSIGTTO SGMF - Standards Guidelines Natural Gas Fuelledjomafeba100% (1)

- Safety Practices in The LPG Gas IndustryDokument64 SeitenSafety Practices in The LPG Gas IndustryChristian Vargas100% (1)

- Layout Plans For Installation of LPG Autogas StationsDokument15 SeitenLayout Plans For Installation of LPG Autogas StationsEjaz Ahmed RanaNoch keine Bewertungen

- LNG Fuelling SystemsDokument13 SeitenLNG Fuelling SystemsBlue Corridor Natural Gas Vehicle Rally 2014Noch keine Bewertungen

- LPG Tanker Practice Hyproc SCDokument128 SeitenLPG Tanker Practice Hyproc SCIlyes ArNoch keine Bewertungen

- LPG - Calculation Guide: Liquid PhaseDokument1 SeiteLPG - Calculation Guide: Liquid PhaseChhom100% (1)

- LNG SamplingSystemDokument2 SeitenLNG SamplingSystemGuillermo Lopez-FloresNoch keine Bewertungen

- Cargo Handling Systems WartsillaDokument12 SeitenCargo Handling Systems Wartsillajbloggs2007Noch keine Bewertungen

- Standard Codes Followed in LPG IndustriesDokument41 SeitenStandard Codes Followed in LPG Industriesaarunsnair100% (2)

- Economic Design Concept For Small LNG Carriers Rev 3Dokument26 SeitenEconomic Design Concept For Small LNG Carriers Rev 3hardik5818Noch keine Bewertungen

- Cargo Handling System For Gas CarrierDokument12 SeitenCargo Handling System For Gas CarrierpadangiringNoch keine Bewertungen

- Handling LPG and Ammonia CargoDokument4 SeitenHandling LPG and Ammonia CargoDayo IdowuNoch keine Bewertungen

- Physics of Liq GasesDokument21 SeitenPhysics of Liq GasesOctavianNoch keine Bewertungen

- LNG Custody Transfer Handbook PDFDokument68 SeitenLNG Custody Transfer Handbook PDFJeffry100% (1)

- Oil Tankers: A.A. B. Dinariyana Jurusan Teknik Sistem Perkapalan Fakultas Teknologi Kelautan - ITS Surabaya 2013Dokument28 SeitenOil Tankers: A.A. B. Dinariyana Jurusan Teknik Sistem Perkapalan Fakultas Teknologi Kelautan - ITS Surabaya 2013Annisa Maya Shabrina100% (2)

- Standards Guidelines For Natural Gas Fuelled Ship Projects V5k1Dokument19 SeitenStandards Guidelines For Natural Gas Fuelled Ship Projects V5k1Phuluang Ninrut Na AyuttayaNoch keine Bewertungen

- Liquefied Gas Tanker Operations - Advanced Training ProgramDokument302 SeitenLiquefied Gas Tanker Operations - Advanced Training ProgramFateh SinghNoch keine Bewertungen

- Proposed LPG Terminal and Storage Tank in SeaportDokument1 SeiteProposed LPG Terminal and Storage Tank in SeaportLPG TERMINALNoch keine Bewertungen

- LNG Study by IMODokument290 SeitenLNG Study by IMOnawkong100% (1)

- SGLPG Technical Standard One Storage of LPG in Bulk (HSE-03-10)Dokument39 SeitenSGLPG Technical Standard One Storage of LPG in Bulk (HSE-03-10)anwar01Noch keine Bewertungen

- 1200m Self-Propelled LNG (Type C) Barge: Main Particulars MachineryDokument2 Seiten1200m Self-Propelled LNG (Type C) Barge: Main Particulars MachinerysirvoltusNoch keine Bewertungen

- LPG&LNG FamilizatonDokument40 SeitenLPG&LNG FamilizatonRoken Zgoul100% (1)

- LPG Storage TankDokument5 SeitenLPG Storage TankDimas PratamaNoch keine Bewertungen

- SIGTTO BookletDokument6 SeitenSIGTTO BookletbernardinodinoNoch keine Bewertungen

- Type Dan Jenis Kapal Tanker Gas Utk TarunaDokument25 SeitenType Dan Jenis Kapal Tanker Gas Utk TarunaBebincaNoch keine Bewertungen

- LNG VaporizerDokument4 SeitenLNG VaporizerSharon Lambert0% (1)

- LNG Tech 2Dokument28 SeitenLNG Tech 2genergia50% (2)

- LPG Cargo Measurement and Calculation Procedure PDFDokument3 SeitenLPG Cargo Measurement and Calculation Procedure PDFJohn Green100% (3)

- Chemical Tankers 2Dokument59 SeitenChemical Tankers 2Paolo Ferjančić100% (10)

- LPG CalculatorDokument5 SeitenLPG Calculatormyo kyawNoch keine Bewertungen

- LNG Fuel SystemsDokument33 SeitenLNG Fuel Systemssmithwork100% (1)

- Basic Training For Liquefied Gas Tanker Operations EXACT PDFDokument137 SeitenBasic Training For Liquefied Gas Tanker Operations EXACT PDFhaitacvietnam100% (1)

- Floating Storage and Regasification Unit FSRUDokument4 SeitenFloating Storage and Regasification Unit FSRUshax001100% (5)

- Fire Safety Requirements For Liquefied Petroleum Gas (LPG) Cylinder InstallationsDokument26 SeitenFire Safety Requirements For Liquefied Petroleum Gas (LPG) Cylinder Installationspitong_manning100% (2)

- LNG AgeingDokument13 SeitenLNG AgeingBenoit PuyoNoch keine Bewertungen

- LNG TransportDokument135 SeitenLNG TransportChahbi Ramzi100% (2)

- LNG Jetty OperationDokument3 SeitenLNG Jetty OperationGhanshyam ShuklaNoch keine Bewertungen

- LPGDokument7 SeitenLPGPriyanathan Thayalan100% (1)

- Project Standards and Specifications Liquid and Gas Storage Rev01Dokument19 SeitenProject Standards and Specifications Liquid and Gas Storage Rev01hawk1821Noch keine Bewertungen

- CNG h2 Workshop 8 WongDokument34 SeitenCNG h2 Workshop 8 WongSaravana Rajan KNoch keine Bewertungen

- Ron MansonDokument33 SeitenRon MansonPradeep MotaparthyNoch keine Bewertungen

- LPG Storage VesselsDokument14 SeitenLPG Storage Vesselsthanhphucbr87Noch keine Bewertungen

- Renewable-LNG-Europe Report FINALDokument47 SeitenRenewable-LNG-Europe Report FINALLelosPinelos123Noch keine Bewertungen

- Accelerating Decarbonization in The United States: Technology, Policy, and Societal Dimensions (2023)Dokument653 SeitenAccelerating Decarbonization in The United States: Technology, Policy, and Societal Dimensions (2023)LelosPinelos123Noch keine Bewertungen

- CE - Delft - 200247 - UCO - As - Biofuel - Feedstock - in - EU - FINAL - v5 - 0Dokument65 SeitenCE - Delft - 200247 - UCO - As - Biofuel - Feedstock - in - EU - FINAL - v5 - 0LelosPinelos123Noch keine Bewertungen

- Vivadinar 2021 IOP Conf. Ser. Mater. Sci. Eng. 1143 012045 RemovedDokument10 SeitenVivadinar 2021 IOP Conf. Ser. Mater. Sci. Eng. 1143 012045 RemovedLelosPinelos123Noch keine Bewertungen

- Dolf Gielen Keynote 231113Dokument36 SeitenDolf Gielen Keynote 231113LelosPinelos123Noch keine Bewertungen

- Technical InformationDokument13 SeitenTechnical InformationLelosPinelos123Noch keine Bewertungen

- Appendix C - CCUS SurveyDokument38 SeitenAppendix C - CCUS SurveyLelosPinelos123Noch keine Bewertungen

- Princeton NZA FINAL REPORT (29oct2021)Dokument348 SeitenPrinceton NZA FINAL REPORT (29oct2021)LelosPinelos123Noch keine Bewertungen

- EMERGE Environmental Impacts of EGCSDokument181 SeitenEMERGE Environmental Impacts of EGCSLelosPinelos123Noch keine Bewertungen

- The Role of DAC in EU Decarbonization & Associated Carbon Intensity For The Synthetic Fuel Production (2023)Dokument40 SeitenThe Role of DAC in EU Decarbonization & Associated Carbon Intensity For The Synthetic Fuel Production (2023)LelosPinelos123Noch keine Bewertungen

- Scrubbers Policy Update FinalDokument10 SeitenScrubbers Policy Update FinalLelosPinelos123Noch keine Bewertungen

- Operational Experience With Biofuels & Analysis of NOx, SOx Emissions (2023 by Delft)Dokument40 SeitenOperational Experience With Biofuels & Analysis of NOx, SOx Emissions (2023 by Delft)LelosPinelos123Noch keine Bewertungen

- D2 S3 P4 Klaus MeyersieckDokument14 SeitenD2 S3 P4 Klaus MeyersieckLelosPinelos123Noch keine Bewertungen

- Renewable Natural Gas - State of Market in North America (2023 by Wood Mckenzie)Dokument17 SeitenRenewable Natural Gas - State of Market in North America (2023 by Wood Mckenzie)LelosPinelos123Noch keine Bewertungen

- RES Renewable Energies Positioning Paper 1Dokument20 SeitenRES Renewable Energies Positioning Paper 1LelosPinelos123Noch keine Bewertungen

- 04 MHB en WebDokument82 Seiten04 MHB en WebLelosPinelos123Noch keine Bewertungen

- RNG For Utah - A Sustainable Approach To The Energy Transition (2022 by University of Utah)Dokument16 SeitenRNG For Utah - A Sustainable Approach To The Energy Transition (2022 by University of Utah)LelosPinelos123Noch keine Bewertungen

- Biomethane - Technical Principles & Methodology For Calculating GHG Balances (2016 by DBFZ)Dokument52 SeitenBiomethane - Technical Principles & Methodology For Calculating GHG Balances (2016 by DBFZ)LelosPinelos123Noch keine Bewertungen

- RNG Outlook in California - Resource Assessment, Market Opportunities & Environmental Performance (2023 by ICCT)Dokument35 SeitenRNG Outlook in California - Resource Assessment, Market Opportunities & Environmental Performance (2023 by ICCT)LelosPinelos123Noch keine Bewertungen

- 130 dt6 sheGBPGBPDokument6 Seiten130 dt6 sheGBPGBPLelosPinelos123Noch keine Bewertungen

- RNG For Transportation FAQsDokument4 SeitenRNG For Transportation FAQsLelosPinelos123Noch keine Bewertungen

- Clean Hydrogen Production Standard (CHPS) Guidance (2023 by US DOE)Dokument6 SeitenClean Hydrogen Production Standard (CHPS) Guidance (2023 by US DOE)LelosPinelos123Noch keine Bewertungen

- D1 S2 P2 Luke BriantDokument27 SeitenD1 S2 P2 Luke BriantLelosPinelos123Noch keine Bewertungen

- Vertical Prismatic - The Forgotten CoefficientDokument2 SeitenVertical Prismatic - The Forgotten CoefficientLelosPinelos123Noch keine Bewertungen

- D2 S4 P1 Erik EklundDokument38 SeitenD2 S4 P1 Erik EklundLelosPinelos123Noch keine Bewertungen

- AER - Annual Efficiency Ratio (2014 by JAPAN)Dokument12 SeitenAER - Annual Efficiency Ratio (2014 by JAPAN)LelosPinelos123Noch keine Bewertungen

- D1 S2 P3 Joel ThigpenDokument17 SeitenD1 S2 P3 Joel ThigpenLelosPinelos123Noch keine Bewertungen

- 2019 Virginia Schedule of Income Form 760PY: You (Include Spouse If Filing Status 2) Column A1 Column A2 Column A3Dokument2 Seiten2019 Virginia Schedule of Income Form 760PY: You (Include Spouse If Filing Status 2) Column A1 Column A2 Column A3LelosPinelos123Noch keine Bewertungen

- Ship DesignDokument55 SeitenShip DesignLelosPinelos123Noch keine Bewertungen

- Outlines of EEXI Regulation (12-2021 by ClassNK)Dokument36 SeitenOutlines of EEXI Regulation (12-2021 by ClassNK)LelosPinelos123Noch keine Bewertungen

- Agri MonoblocDokument2 SeitenAgri Monoblockeeprocking9777Noch keine Bewertungen

- 149 - Ic-P&id-07 (Contact Tanks) - Ic-P&id-07Dokument1 Seite149 - Ic-P&id-07 (Contact Tanks) - Ic-P&id-07Fun TonNoch keine Bewertungen

- AP - SPEC - Metro - ViaductDokument103 SeitenAP - SPEC - Metro - Viaductvishal18mNoch keine Bewertungen

- Space in Urban Design, Urban AestheticsDokument16 SeitenSpace in Urban Design, Urban AestheticsFritz Dela Vega100% (1)

- Engineering Materials PDFDokument24 SeitenEngineering Materials PDFPradeepkumarKatgiNoch keine Bewertungen

- #Lec 7 BS101 CodePracticeDokument13 Seiten#Lec 7 BS101 CodePracticeanasNoch keine Bewertungen

- Searay 330 Sundancer-ReportDokument11 SeitenSearay 330 Sundancer-ReportAshok KamathNoch keine Bewertungen

- ExamDokument18 SeitenExamMark MamaradloNoch keine Bewertungen

- Squatting WC Pan: Special FeaturesDokument2 SeitenSquatting WC Pan: Special FeaturesRushan LakdimuthuNoch keine Bewertungen

- Operation and Maint Manual Swill Hydraulic PlateformDokument16 SeitenOperation and Maint Manual Swill Hydraulic Plateformmicell dieselNoch keine Bewertungen

- Architecture Santo Tomas SyllabusDokument3 SeitenArchitecture Santo Tomas SyllabusrichellerojNoch keine Bewertungen

- Monitoring Backlog New 2021 InfrastrukturDokument2 SeitenMonitoring Backlog New 2021 InfrastrukturKhairullahNoch keine Bewertungen

- 102 Strength of MaterialsDokument48 Seiten102 Strength of MaterialsPia Eleanor SantosNoch keine Bewertungen

- The Paombong Public MarketDokument2 SeitenThe Paombong Public MarketJeonAsistin100% (1)

- Automatic Transmission Overhaul: Group 23BDokument57 SeitenAutomatic Transmission Overhaul: Group 23Bahmed meselhyNoch keine Bewertungen

- 2.4 Ccontract ManagmentDokument27 Seiten2.4 Ccontract Managmentbereket gNoch keine Bewertungen

- Irjet V3i12208 PDFDokument4 SeitenIrjet V3i12208 PDFVinay RajNoch keine Bewertungen

- CIP Section 02Dokument14 SeitenCIP Section 02viksofNoch keine Bewertungen

- Ke01 00 000 KD P TD 0015 000 - D03Dokument501 SeitenKe01 00 000 KD P TD 0015 000 - D03Maffone NumerounoNoch keine Bewertungen

- GH Sinopec Ms SC Pkg17 r0Dokument75 SeitenGH Sinopec Ms SC Pkg17 r0AmeerHamzaWarraichNoch keine Bewertungen

- Muhammad Awais: ContactDokument1 SeiteMuhammad Awais: ContactMian AwaisNoch keine Bewertungen

- Design and Analysis of Composite Drive Shaft For Automotive Application IJERTV3IS110410Dokument8 SeitenDesign and Analysis of Composite Drive Shaft For Automotive Application IJERTV3IS110410frindgeNoch keine Bewertungen

- Circular On Listing of Engineered FacadeDokument7 SeitenCircular On Listing of Engineered FacadeS2turtleNoch keine Bewertungen

- Space FrameDokument10 SeitenSpace FramePratyush DajuNoch keine Bewertungen

- Stirling BoilerDokument14 SeitenStirling BoilerDr. BIBIN CHIDAMBARANATHANNoch keine Bewertungen

- Casement WindowsDokument45 SeitenCasement WindowsТијана Радиновић100% (1)

- Sae 1080Dokument1 SeiteSae 1080bharathi_pmNoch keine Bewertungen

- C50X100Dokument3 SeitenC50X100Gabriel RojasNoch keine Bewertungen

- Drilling ProblemsDokument82 SeitenDrilling ProblemsMohamed KamalNoch keine Bewertungen

- Different Types of FoundationDokument16 SeitenDifferent Types of FoundationRedwan RanaNoch keine Bewertungen