Beruflich Dokumente

Kultur Dokumente

2015 Cogging Torque Computation and Meshing For Radial Electric Motor SP CN67

Hochgeladen von

pcg_live0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

30 Ansichten2 Seiten2015 Cogging Torque Computation and Meshing for Radial Electric Motor SP CN67

Originaltitel

2015 Cogging Torque Computation and Meshing for Radial Electric Motor SP CN67

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument melden2015 Cogging Torque Computation and Meshing for Radial Electric Motor SP CN67

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

30 Ansichten2 Seiten2015 Cogging Torque Computation and Meshing For Radial Electric Motor SP CN67

Hochgeladen von

pcg_live2015 Cogging Torque Computation and Meshing for Radial Electric Motor SP CN67

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

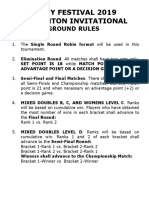

CEDRAT News - N 67 - February 2015

Cogging Torque Computation and Meshing for Radial

Electrical Motors in Flux

Sylvain Perez - CEDRAT.

ll electrical motor designers know that the computation

of cogging torque is a tricky task in 3D. Indeed, the

amplitude of this quantity is almost the same as the

numerical noise. In most cases a classical meshing methodology

is not sufficient and specific methodology must be used. At

CEDRAT, the application team, thanks to its experience has

developed methodologies to successfully compute cogging

torque in most of cases.

This article presents a specific meshing methodology to

compute cogging torque for 2D and 3D radial electrical

machine. It begins with some general recommendation

concerning the definition of the geometry in order to facilitate

the meshing operation. Then, it presents the specific meshing

methodology applied to a 2D SPM motor and to a 3D IPM

motor.

Some general recommendations

As already said, cogging torque computation is a difficult task.

To make sure our chances are as good as possible, it is necessary

to correctly build the motor geometry. In fact, meshing quality

is strongly linked to a correct geometry balance (example:

stator construction based on duplications of the half of a tooth)

and of course to the absence of unnecessary points or lines.

Another point, in 3D it is important to correctly define the sliding

cylinder, that is, to define it at the middle of the air gap and to

surround completely the rotor part. The good way to compute

cogging torque is to make sure these different points are correctly

considered.

a) Classical meshing method.

b) Efficient meshing method with

additional points and lines.

Figure 1: Geometry of the air gap according to the classical and to

the efficient meshing method.

If we apply a classical meshing method without considering a

smart discretisation, the mesh of these parts is done as illustrated

by Fig. 2a. According to the periodicity of this motor (0.45

mechanical degree), the classical mesh is not sufficient to compute

cogging torque.

Finally, the computation step must be adapted to get an elementary

move equal to the length of the edge of a quadrangular element

(Ideal case, 40 steps per cogging torque period Simplify case, 13

steps per cogging torque period).

With the classical mesh method, cogging torque obtained can be

inaccurate, not centered in 0 N.m and not periodic as shown in

the curve above (Fig. 3 Blue curve).

An efficient meshing methodology

In this part, we present a meshing methodology that can be

applied on 2D and 3D (extruded from 2D) radial electrical motor

with main goal to get an accurate cogging torque.

2D model and meshing methodology

To get an accurate cogging torque, it can be necessary to use

a specific meshing method. The main principle of this efficient

method is to have a very regular meshing in the air gap. For this

purpose, we propose to modify the mesh of the exterior air gap

layer (fixed part), that is, to impose mapped mesh elements instead

of triangular mesh elements (classical mesh). Along the air gap,

we advice to impose 40 elements per cogging torque period

to increase accuracy (Fig. 2c) - 40 elements per cogging torque

period) but according to the periodicity of the motor consider,

you have to adapt the number of element in order to obtain the

best compromise between computation time and accuracy (Fig.

2b) - 13 elements per cogging torque period). Period of cogging

torque in mechanical degree is obtained by the formula:

To make mesh elements the most regular as possible according to

the geometry, additional points must be added on the line at the

middle of the air gap. In particular, points in front of slot openings

are created (Fig. 1).

Then, it is necessary to create arithmetic mesh lines to adjust

discretisation of each part of the line at the middle in the air gap

according to slot and to open slot in order to have the most regular

mesh of the whole surface. The face must be structured in order

to mesh them with mapped element (Fig. 2b).

a) Classical method

b) Efficient method

(simplified case)

b) Efficient method

(ideal case)

Figure 2: Mesh according to the classical and to the efficient meshing

method (simplified and ideal case).

With the efficient meshing method, the cogging torque is more

accurate and periodic (Fig. 3, Pink and green curve). According

to Table I and to Fig. 3, the efficient mesh methodology is very

effective. Moreover, if you correctly adjust the number of elements

in the air gap and size of computation step, we obtain a good

compromise between computation time and accuracy.

Figure 3: Cogging torque computation according to the classical

and to the efficient meshing method.

(continued on page 15)

- 14 -

CEDRAT News - N 67 - February 2015

Method

Mesh element

order

Number of

nodes

Computation

time

Classical meshing method

2nd

16605

30

Efficient meshing method Ideal case

2nd

273412

630

Efficient meshing method Simplify case

2nd

49768

Table I: Meshing characteristics and computation time.

3D model and meshing methodology

This part present the meshing methodology used to get an

accurate cogging torque for 3D motor extruded from 2D. We

also compare the mesh and the results obtained with a classical

meshing method and with the efficient meshing method.

In Flux, the most efficient way to build a 3D radial motor with a

constant axial shape is to generate a 2D model and extrude to

3D. In the 2D project, we recommend building the additional

points on the line at the middle of the air gap (same method

as used for 2D motor). Then, it is necessary to delete the infinite

box and to import the Flux 2D model as Flux object in a Flux 3D

project. Once import is done, it is very helpful to use the macro

ExtrudeFaceRegion. In fact, that is the fast way to build the 3D

geometry, the macro automatically defines the regions according

to the 2D model besides extrude volume and associate extrude

meshing. Finally, it is just necessary to add the sliding cylinder and

the infinite box. At this step, if the geometry is meshed we obtain

the results presented by Fig. 4(b).

Figure 4: Meshing

according to the

classical and to the

efficient meshing

method.

b) Efficient meshing

method.

Figure 5: Comparison of the results.

Of course, the computation step is also adapted to get

an elementary move equal to the length of the edge of a

quadrangular element.

According to the period of the cogging torque (7.5 mechanical

degree), this case is less demonstrative but we note that with

mapped element we obtain a better accuracy concerning the

evaluation of amplitude. Once again, the meshing methodology

is very effective.

Conclusion

Cogging torque computation has always been a complex work

specifically in 3D. Nowadays, Flux tools combined with CEDRAT

experience in this domain lead to make this work easier. In

this article we have demonstrated the ability of a meshing

methodology in order to obtain an efficient meshing to compute

cogging torque for radial motor (2D and 3D applications).

To get an accurate cogging torque, it can be

necessary to use a specific meshing method.

The main principle of this efficient method is to

have a very regular meshing in the air gap.

a) Classical

meshing method.

- 15 -

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- 02 Technical 2D BrushlessSPM-MotorTutorialDokument97 Seiten02 Technical 2D BrushlessSPM-MotorTutorialpcg_liveNoch keine Bewertungen

- A1000 Catalogue (Overview)Dokument17 SeitenA1000 Catalogue (Overview)pcg_liveNoch keine Bewertungen

- Magnet - PMSM AnalysisDokument26 SeitenMagnet - PMSM Analysispcg_liveNoch keine Bewertungen

- Yoke Problem SetDokument3 SeitenYoke Problem Setpcg_liveNoch keine Bewertungen

- Loudspeaker Analysis - 2D/3D Magnetostatic: ResultsDokument3 SeitenLoudspeaker Analysis - 2D/3D Magnetostatic: Resultspcg_liveNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Storage Emulated 0 Android Data Com - Cv.docscanner Cache How-China-Engages-South-Asia-Themes-Partners-and-ToolsDokument140 SeitenStorage Emulated 0 Android Data Com - Cv.docscanner Cache How-China-Engages-South-Asia-Themes-Partners-and-Toolsrahul kumarNoch keine Bewertungen

- Cognitive ApprenticeshipDokument5 SeitenCognitive ApprenticeshipRandall RobertsNoch keine Bewertungen

- Simple Past TenselDokument3 SeitenSimple Past TenselPutra ViskellaNoch keine Bewertungen

- Ottley Sandra 2009Dokument285 SeitenOttley Sandra 2009Lucas Fariña AlheirosNoch keine Bewertungen

- Acfrogb0i3jalza4d2cm33ab0kjvfqevdmmcia - Kifkmf7zqew8tpk3ef Iav8r9j0ys0ekwrl4a8k7yqd0pqdr9qk1cpmjq Xx5x6kxzc8uq9it Zno Fwdrmyo98jelpvjb-9ahfdekf3cqptDokument1 SeiteAcfrogb0i3jalza4d2cm33ab0kjvfqevdmmcia - Kifkmf7zqew8tpk3ef Iav8r9j0ys0ekwrl4a8k7yqd0pqdr9qk1cpmjq Xx5x6kxzc8uq9it Zno Fwdrmyo98jelpvjb-9ahfdekf3cqptbbNoch keine Bewertungen

- 1 - HandBook CBBR4106Dokument29 Seiten1 - HandBook CBBR4106mkkhusairiNoch keine Bewertungen

- 4 Major Advantages of Japanese Education SystemDokument3 Seiten4 Major Advantages of Japanese Education SystemIsa HafizaNoch keine Bewertungen

- Cambridge English Key Sample Paper 1 Reading and Writing v2Dokument9 SeitenCambridge English Key Sample Paper 1 Reading and Writing v2kalinguer100% (1)

- D8.1M 2007PV PDFDokument5 SeitenD8.1M 2007PV PDFkhadtarpNoch keine Bewertungen

- Contracts 2 Special ContractsDokument11 SeitenContracts 2 Special ContractsAbhikaamNoch keine Bewertungen

- CH Folk Media and HeatlhDokument6 SeitenCH Folk Media and HeatlhRaghavendr KoreNoch keine Bewertungen

- Ad1 MCQDokument11 SeitenAd1 MCQYashwanth Srinivasa100% (1)

- Bagon-Taas Adventist Youth ConstitutionDokument11 SeitenBagon-Taas Adventist Youth ConstitutionJoseph Joshua A. PaLaparNoch keine Bewertungen

- Bab 3 - Soal-Soal No. 4 SD 10Dokument4 SeitenBab 3 - Soal-Soal No. 4 SD 10Vanni LimNoch keine Bewertungen

- 201606300437271127888362list of Prescribed Textbooks ISC 2017 PDFDokument10 Seiten201606300437271127888362list of Prescribed Textbooks ISC 2017 PDFShrimanta SatpatiNoch keine Bewertungen

- Spisak Gledanih Filmova Za 2012Dokument21 SeitenSpisak Gledanih Filmova Za 2012Mirza AhmetovićNoch keine Bewertungen

- Master Books ListDokument32 SeitenMaster Books ListfhaskellNoch keine Bewertungen

- Indus Valley Sites in IndiaDokument52 SeitenIndus Valley Sites in IndiaDurai IlasunNoch keine Bewertungen

- Ground Rules 2019Dokument3 SeitenGround Rules 2019Jeremiah Miko LepasanaNoch keine Bewertungen

- Chapter 019Dokument28 SeitenChapter 019Esteban Tabares GonzalezNoch keine Bewertungen

- Leisure TimeDokument242 SeitenLeisure TimeArdelean AndradaNoch keine Bewertungen

- S - BlockDokument21 SeitenS - BlockRakshit Gupta100% (2)

- Invitation 2023Dokument10 SeitenInvitation 2023Joanna Marie Cruz FelipeNoch keine Bewertungen

- (Music of The African Diaspora) Robin D. Moore-Music and Revolution - Cultural Change in Socialist Cuba (Music of The African Diaspora) - University of California Press (2006) PDFDokument367 Seiten(Music of The African Diaspora) Robin D. Moore-Music and Revolution - Cultural Change in Socialist Cuba (Music of The African Diaspora) - University of California Press (2006) PDFGabrielNoch keine Bewertungen

- Economic Value Added in ComDokument7 SeitenEconomic Value Added in Comhareshsoni21Noch keine Bewertungen

- Los Documentos de La Dictadura Que Entregó Estados Unidos (Parte 2)Dokument375 SeitenLos Documentos de La Dictadura Que Entregó Estados Unidos (Parte 2)Todo NoticiasNoch keine Bewertungen

- Site Master S113C, S114C, S331C, S332C, Antenna, Cable and Spectrum AnalyzerDokument95 SeitenSite Master S113C, S114C, S331C, S332C, Antenna, Cable and Spectrum AnalyzerKodhamagulla SudheerNoch keine Bewertungen

- RWE Algebra 12 ProbStat Discrete Math Trigo Geom 2017 DVO PDFDokument4 SeitenRWE Algebra 12 ProbStat Discrete Math Trigo Geom 2017 DVO PDFハンター ジェイソンNoch keine Bewertungen

- ImpetigoDokument16 SeitenImpetigokikimasyhurNoch keine Bewertungen

- HRM and The Business EnvironmentDokument18 SeitenHRM and The Business Environmentsuzzette91Noch keine Bewertungen