Beruflich Dokumente

Kultur Dokumente

Risk Assessment Rope Works.e

Hochgeladen von

Rod CavicchioniCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Risk Assessment Rope Works.e

Hochgeladen von

Rod CavicchioniCopyright:

Verfügbare Formate

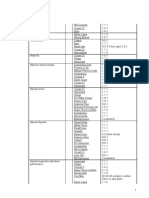

Risk Assessment for Rope change at MGD Sentosa Iland Mt.

Faber ( Singapore)

Step

1

Description of the step

Set-up of the equipment as shown in

attachment

Possible hazards

General public accessing rigging areas

Oil leaking from the winches

Manual pushing of heavy equipment

components

Cuts and grazes

Punches and blows to the head

Falling, slipping, stumbling

Installation of anchors, bottom roll, deflection Failure of the anchor or rigging points

roll

respectively

Working with ropes and slings

Endangerment third parties

Controls / precautions

Fence around the winch and the

area to be equipped on the west

side

Warning signs to prevent persons

from trespassing the area

Entombment package nearby the

winches

Observe entombment plan

specific to the location

Employees qualified by training in

handling of heavy components

Use shoes with steel toe cap

Always wear shirts with short

sleeves and trousers

Compulsory wearing of a helmet

Working area must be kept clean

Works on the ground acc. to

Doppelmayr instructions

Install double anchor or rigging

points for high forces. Anchor

calculated with a safety factor of 3

to max. Acting load.

Helmet / stepping aside

As few people as possible

Keep working area clean / secure

with guy ropes

Visual check the anchor

During pulling work no persons

Tear of ropes/ slings

Fall down from assembly material and

slings/ropes

Incorrect serving of winches, and

machines

Slip of clamping plate and ropes

Uncontrolled unreeling from ropes

are allowed to stay under the

ropes. Walk ways and traffic road

have to be secured. The lateral

safety margin between people

and the rope is to be adapted to

the local conditions and should at

least 10 meter.

The maximum rope and

anchorage forces must be

admit . Slings and ropes must be

selected with a security from at

least 2,5 to the minimum

breaking load. The condition of

ropes and Slings are to be

visually examined before use.

Defective material has to to be

removed.

Rope, assembly aids and tools for

the work are to be secured

against falling down.

Only trained personal to allowed

to operate winches and

machines.

For the rope attachments use

only anchorage material which is

appropriate for the selected kind

of anchorage and the arising

forces . Clamping plate diameter

must correspond with the rope

diameter. Screws (e.g. of

clamping plates) are to be

tightened with torque wrench.

Rope drums are to be secured

against uncontrolled unreeling.

Nobody is allowed to stay inside

Hang up at construction works and

structures

Fixing 29 mm hauling rope at Mount Faber

by installation of attachments slings on one

side and 5 To Winch and 16 To tackle block

on the other side.

Pull with 5 To Winch until 29 mm Rope at Mt.

Faber is loose.

Cut 29 mm rope at Mt. Faber.

Release 29 mm Rope until the tension

weight at Sentosa is placed on the ground.

Fixing 29 mm Hauling Rope at Sentosa

Station by installation of Attachment slings.

Falling of parts from certain height

Slipping of clamping plate

Tear of attachment slings

Tear of anchors

Falling of parts from certain height

Slipping of clamping plate

Tear of attachment slings

Tear of anchors

See point 3

Sparks and fire

Protect surrounding area against

sparks. Place fire extinguisher.

Only trained operators on

winches and machines

Clean area below counterweight

at Sentosa

Ensure that the tension of the

rope has been released before

cutting it.

Use tension holder against twist

of tackle block and rope

See point 3

Injuries caused by the falling or releasing

rope and by falling parts

Loss of the rope

Sparks and fire

Twisted ropes

Fixing 29 mm Hauling Rope at Sentosa

Station by installation of Attachment slings

loosely rope rings. Likewise

critical rope angles from guide

rollers are to be avoided.

During the pulling work the rope is

to be controlled on the critical

places and/or accompanied

during pulling. It has to be

considered that changing the rope

tension means changing also the

rope position.

See point 3

Falling of parts from certain height

Slipping of clamping plate

with 16 to tackle block an Tirfor. Same side

as winch.

Cut 29 mm rope at Sentosa

Tear of attachment slings

Tear of anchors

Sparks and fire

Pull 29 mm Hauling Rope trough 25 to winch Twisted ropes

at Sentosa and roll up on Hasp winch.

Incorrect serving of winches, and

At Mt. Faber, connect the 29 mm hauling

machines

rope to 14 mm winch rope by means of

Falling of parts from certain height

splice connection.

Slipping of clamping plate

Tear of rope splice connection

Pulling out 29 mm Hauling Rope with 25 to

winch over the spilling ring and roll on to

hasp winch.

Continue release with 5 to winch until 14 mm

winch rope has reached Sentosa

Endangerment third parties

Loss of the rope

Loss of communication

Loss of winch control

Protect surrounding area against

sparks. Place fire extinguisher.

See point 3

10

Fix 14 mm winch rope at Sentosa and Mt.

Falling of parts from certain height

Faber.

Slipping of clamping plate

Cut 14 mm rope between winch an fixation at Tear of attachment slings

Mt. Faber

Tear of anchors

Sparks and fire

Splice connection to be done

only by special trained

Garaventa people.

See point 3

Limit winches to breaking load of

rope

Ensure adequate communication

Check radio equipment before

using it

Back-up radio for the operator of

the winches

Headset for operator of winches

One person to regulate the winch

speed

Limiting to the tensioning values

indicated by the Engineering

Dept.

See point 3

Protect surrounding area against

sparks. Place fire extinguisher.

11

12

13

14

15

16

Change Winches in both Stations to the

opposite Side and pull out 29 mm hauling

rope as described in point 8 and 9.

The 14 mm winch rope remain placed.

Install 40 to tackle block to Track rope at Mt.

Faber and release Track rope until counter

weight is placed on the ground.

Install chain hasp in the parking area at

Faber.

Endangerment third parties

Fall down from assembly material and

slings/ropes

Loss control of mobile crane

See point 3

Use only trained machinist on

mobile crane

Twisted ropes

Incorrect serving of winches, and

machines

Clamping fingers and feet

Personal falling over slings and tools

Twisted ropes

Incorrect serving of winches, and

machines

Clamping fingers and feet

Personal falling over slings and tools

Sparks and fire

Wear hand cloves and safety

shoes

Clean up working tools and

equipment

Install Liner hoist at Mt. Faber and feed the

42mm track rope through the liner hoist to

the chain hasp

Fix the 29 mm rope at Sentosa coming

through the spilling ring of the 25 to winch to

the track rope by means of casting head

While pulling with the liner hoist, releasing

with the 25 to winch the 29 mm rope. Pull

42mm track rope on to the chain hasp until

29 mm rope has reached Mt. Faber.

Clamping fingers and feet

Personal falling over slings and tools

Falling of parts from certain height

Slipping of clamping plate

Tear of attachment slings

Tear of anchors

Endangerment third parties

Loss of the rope

Loss of communication

Wear hand cloves and safety

shoes

Clean up working tools and

equipment

See point 3

Wear hand cloves and safety

shoes

Clean up working tools and

equipment

Casting head to be installed only

by special traind Garaventa

people

See point 3

Limit winches to breaking load of

rope

Loss of winch control

17

Fix 29 mm rope at Sentosa and Mt. Faber.

Cut of casting head.

The 29 mm rope remain in place.

Sparks and fire

Injuries caused by the falling or releasing

rope and by falling parts

Loss of the rope

Sparks and fire

Twisted ropes

18

Move linear hoist an winches to the opposite

side.

19

Repeat point 12 to 16.

Clamping fingers and feet

Personal falling over slings and tools

Ensure adequate communication

Check radio equipment before

using it

Back-up radio for the operator of

the winches

Headset for operator of winches

One person to regulate the winch

speed

Limiting to the tensioning values

indicated by the Engineering Dept.

Protect surrounding area against

sparks. Place fire extinguisher.

Only trained operators on

winches and machines

Clean area below counterweight

at Sentosa

Ensure that the tension of the

rope has been released before

cutting it.

Use tension holder against twist of

tackle block and rope

Wear hand cloves and safety

shoes

Clean up working tools and

equipment

Das könnte Ihnen auch gefallen

- How To Manage A Crane Accident: Guest Speaker: Joe Collins, Heavy Lift Manager, Becht EngineeringDokument45 SeitenHow To Manage A Crane Accident: Guest Speaker: Joe Collins, Heavy Lift Manager, Becht EngineeringTrainer 1 TVSNoch keine Bewertungen

- Basic WSH Rules For Safe Forklift OperationDokument1 SeiteBasic WSH Rules For Safe Forklift OperationPrecious OladipoNoch keine Bewertungen

- HSE Induction Visitors R-67 CROSCO ShortDokument15 SeitenHSE Induction Visitors R-67 CROSCO ShortTaras IvanchukNoch keine Bewertungen

- Working On HeightsDokument13 SeitenWorking On HeightsRutuja ShikhareNoch keine Bewertungen

- Hand Operated Chain Lever Hoists SI 12.3Dokument2 SeitenHand Operated Chain Lever Hoists SI 12.3reda mesbahNoch keine Bewertungen

- WSHGuidelines Safe Use of Lorry CraneDokument38 SeitenWSHGuidelines Safe Use of Lorry CraneSaravanaah VJNoch keine Bewertungen

- Fixed Ladder and Step-Ladder Inspection ChecklistDokument6 SeitenFixed Ladder and Step-Ladder Inspection Checklistjoesuhre100% (1)

- Part VI (M) - Hand & Power Tool SafetyDokument24 SeitenPart VI (M) - Hand & Power Tool Safetykwong siongNoch keine Bewertungen

- Jha Clarke Engine PumpDokument4 SeitenJha Clarke Engine Pumpperquino oasanNoch keine Bewertungen

- Lifting Operations Risk Assessment Crane Risk AssessmentDokument13 SeitenLifting Operations Risk Assessment Crane Risk Assessment9853318441Noch keine Bewertungen

- Work Zone Traffic Control ManualDokument31 SeitenWork Zone Traffic Control ManualTrainer 1 TVSNoch keine Bewertungen

- 99 Hand Power Tool Use - Job ProcedureDokument5 Seiten99 Hand Power Tool Use - Job ProcedureAbdullah KamilNoch keine Bewertungen

- Lifting SafetyDokument1 SeiteLifting SafetyAaquil RaziNoch keine Bewertungen

- Safety Risk Assessment: THFC Stadium, Paxton House J. Murphy & Sons 07/07/2017 Piling POH0001/MST/001 Rev 00Dokument14 SeitenSafety Risk Assessment: THFC Stadium, Paxton House J. Murphy & Sons 07/07/2017 Piling POH0001/MST/001 Rev 00nico AlpaNoch keine Bewertungen

- Plastering & RenderingDokument7 SeitenPlastering & Renderingmohd firdausNoch keine Bewertungen

- 2.5 Fall ProtectionDokument52 Seiten2.5 Fall ProtectionjantskieNoch keine Bewertungen

- I. Categories of Fall Protection Fall Arrest SystemDokument5 SeitenI. Categories of Fall Protection Fall Arrest SystemMikaella ManzanoNoch keine Bewertungen

- Safety Flash - FlagmanDokument1 SeiteSafety Flash - FlagmanarslanahmedkhawajaNoch keine Bewertungen

- Workingatheights 110623224858 Phpapp02Dokument21 SeitenWorkingatheights 110623224858 Phpapp02naveeduddin2001Noch keine Bewertungen

- Fall Protection PlanDokument11 SeitenFall Protection PlangrantNoch keine Bewertungen

- Eis 28Dokument4 SeitenEis 28Ab AUNoch keine Bewertungen

- Stack Safety Training ModuleDokument7 SeitenStack Safety Training ModuleBhaskar ShuklaNoch keine Bewertungen

- Chain Pulley Block or Chain Hoist Safety Dos and Don'tsDokument5 SeitenChain Pulley Block or Chain Hoist Safety Dos and Don'tsAkram BadranNoch keine Bewertungen

- Solutions For Tree Care HazardsDokument2 SeitenSolutions For Tree Care HazardsTerex14253Noch keine Bewertungen

- Guide: A To & Personal FallDokument12 SeitenGuide: A To & Personal FallHaran Prabha100% (1)

- Job Environmental Safety AnalysisDokument24 SeitenJob Environmental Safety AnalysisLeo PascualNoch keine Bewertungen

- TBT 30 HousekeepingDokument2 SeitenTBT 30 HousekeepingfrancisNoch keine Bewertungen

- RiggingDokument2 SeitenRiggingpruncu.alianmNoch keine Bewertungen

- Safety Management: Scaffolds and BarricadesDokument25 SeitenSafety Management: Scaffolds and BarricadesIrene Pudiquet SilvaniaNoch keine Bewertungen

- CP For Safe Lifting OperationDokument26 SeitenCP For Safe Lifting OperationLaughlikesiao HeheNoch keine Bewertungen

- Confined Spaces TrainingDokument3 SeitenConfined Spaces Traininghello3232Noch keine Bewertungen

- Tower Crane Erection and UseDokument5 SeitenTower Crane Erection and UseSufiyan KhedekarNoch keine Bewertungen

- Driving On Site YansabDokument20 SeitenDriving On Site YansabjhoniNoch keine Bewertungen

- Construction SafetyDokument30 SeitenConstruction SafetyBharath CjNoch keine Bewertungen

- Concrete Work Formingand PouringDokument3 SeitenConcrete Work Formingand PouringKimberly Juarez100% (1)

- CPCCLSF2001 Basic ScaffoldDokument66 SeitenCPCCLSF2001 Basic ScaffoldArdamitNoch keine Bewertungen

- Safe Lifting Operations in The WorkplaceDokument14 SeitenSafe Lifting Operations in The WorkplacetlalovićNoch keine Bewertungen

- PZ TBT - Height Safety v2Dokument2 SeitenPZ TBT - Height Safety v2AshishNoch keine Bewertungen

- Lift Plan - Method Statement - Risk Assessment - SafetyCultureDokument21 SeitenLift Plan - Method Statement - Risk Assessment - SafetyCulturebalachander100% (1)

- Risk Assessment Man Cage and Telehandler Pklands July 2022Dokument4 SeitenRisk Assessment Man Cage and Telehandler Pklands July 2022Dáithí O'LaoghaireNoch keine Bewertungen

- SWP Welder Manual Metal Arc AS562Dokument2 SeitenSWP Welder Manual Metal Arc AS562Jonathan BajelaNoch keine Bewertungen

- A Complete Guide To Working at Height Regulations by At-HeightDokument6 SeitenA Complete Guide To Working at Height Regulations by At-Heightat-height0% (1)

- Safe Use of Cranes, Hoists & SlingsDokument79 SeitenSafe Use of Cranes, Hoists & SlingsAhmed GaballaNoch keine Bewertungen

- Hand and Power Tools SafetyDokument3 SeitenHand and Power Tools SafetyFairus Muhamad DarusNoch keine Bewertungen

- Qualitas Golden Rules of SafetyDokument1 SeiteQualitas Golden Rules of SafetyQualitas RemosNoch keine Bewertungen

- Site Safety Supervisor - Lifting OperationDokument10 SeitenSite Safety Supervisor - Lifting Operationflex xibleNoch keine Bewertungen

- Alimak Hek 65 - 32Dokument5 SeitenAlimak Hek 65 - 32Zhoro Boyssan LestaluhuNoch keine Bewertungen

- Method StatementDokument7 SeitenMethod StatementGerson FernandesNoch keine Bewertungen

- Working at Heights, Fire Protection and Prevention & Confined SpaceDokument22 SeitenWorking at Heights, Fire Protection and Prevention & Confined Spaceadrian100% (1)

- Review Safety Rigging and LiftingDokument4 SeitenReview Safety Rigging and Liftingferry ferdiansyah pradanaNoch keine Bewertungen

- Conveyor SafetyDokument18 SeitenConveyor Safetyshaik sakeemNoch keine Bewertungen

- Gin WheelDokument10 SeitenGin WheelBarkat Ullah100% (2)

- 3 Safe Use of Crawler CranesDokument2 Seiten3 Safe Use of Crawler CranesSiewkuan LeeNoch keine Bewertungen

- Chain Slings SI 1.3Dokument2 SeitenChain Slings SI 1.3reda mesbahNoch keine Bewertungen

- The 12 Golden Rules: Safety at WorkDokument11 SeitenThe 12 Golden Rules: Safety at WorkStacey FejerNoch keine Bewertungen

- Safe Use of Work PlatformsDokument5 SeitenSafe Use of Work PlatformsFrancis Enriquez TanNoch keine Bewertungen

- Do's & Don't - Belt ConveyorDokument3 SeitenDo's & Don't - Belt ConveyorHimanshu AgarwalNoch keine Bewertungen

- Method StatementDokument9 SeitenMethod StatementMr MrrNoch keine Bewertungen

- Mechanical Material HandlingDokument64 SeitenMechanical Material HandlingsivaguruaksNoch keine Bewertungen

- Operation Manual For Lifting Magnets: EN DE FR RU NL S NO DK FIN ESP P ITDokument52 SeitenOperation Manual For Lifting Magnets: EN DE FR RU NL S NO DK FIN ESP P ITosvaldo lopezNoch keine Bewertungen

- 10 1 1 460 989Dokument6 Seiten10 1 1 460 989Rod CavicchioniNoch keine Bewertungen

- Shelbourne Reynolds (C)Dokument3 SeitenShelbourne Reynolds (C)Rod CavicchioniNoch keine Bewertungen

- BL 12 20'boxDokument2 SeitenBL 12 20'boxRod Cavicchioni0% (1)

- Status Shipments in Transit COMMENTS PBI 20140527Dokument1 SeiteStatus Shipments in Transit COMMENTS PBI 20140527Rod CavicchioniNoch keine Bewertungen

- Automotive Parts: Essential Sourcing IntelligenceDokument6 SeitenAutomotive Parts: Essential Sourcing IntelligenceRod CavicchioniNoch keine Bewertungen

- 5 Years High and Low PointsDokument7 Seiten5 Years High and Low PointsNaresh Kumar VishwakarmaNoch keine Bewertungen

- Resource Access ControlDokument19 SeitenResource Access Controlusamadar707Noch keine Bewertungen

- Faujifood Pakistan PortfolioDokument21 SeitenFaujifood Pakistan PortfolioPradeep AbeynayakeNoch keine Bewertungen

- Aerodrome Advisory Circular: AD AC 04 of 2017Dokument6 SeitenAerodrome Advisory Circular: AD AC 04 of 2017confirm@Noch keine Bewertungen

- EXP1POSTLABDokument13 SeitenEXP1POSTLABGiane MagimotNoch keine Bewertungen

- Coca ColaDokument50 SeitenCoca Colamariyha PalangganaNoch keine Bewertungen

- Acer AIO Z1-752 System DisassemblyDokument10 SeitenAcer AIO Z1-752 System DisassemblySERGIORABRNoch keine Bewertungen

- AC350 Specs UsDokument18 SeitenAC350 Specs Uskloic1980100% (1)

- HBT vs. PHEMT vs. MESFET: What's Best and Why: Dimitris PavlidisDokument4 SeitenHBT vs. PHEMT vs. MESFET: What's Best and Why: Dimitris Pavlidissagacious.ali2219Noch keine Bewertungen

- Airbus A319-A320-A321 - Quick Reference HandbookDokument113 SeitenAirbus A319-A320-A321 - Quick Reference Handbookrafaelldalpra100% (9)

- DHT, VGOHT - Catloading Diagram - Oct2005Dokument3 SeitenDHT, VGOHT - Catloading Diagram - Oct2005Bikas SahaNoch keine Bewertungen

- Macleod - 1974 - Lucian's Knowledge of TheophrastusDokument2 SeitenMacleod - 1974 - Lucian's Knowledge of TheophrastusSIMONE BLAIRNoch keine Bewertungen

- Timer Relay ERV-09Dokument1 SeiteTimer Relay ERV-09wal idNoch keine Bewertungen

- Ays 082914 3331 PDFDokument18 SeitenAys 082914 3331 PDFFabian R. GoldmanNoch keine Bewertungen

- Lec 8-10Dokument5 SeitenLec 8-10osamamahmood333Noch keine Bewertungen

- Afectiuni Si SimptomeDokument22 SeitenAfectiuni Si SimptomeIOANA_ROX_DRNoch keine Bewertungen

- Draft STATCOM Maintenance Schedule (FINAL)Dokument36 SeitenDraft STATCOM Maintenance Schedule (FINAL)Sukanta Parida100% (2)

- 2.4 Assembly ManualDokument139 Seiten2.4 Assembly Manualgustavo dlsNoch keine Bewertungen

- Hygiene PassportDokument133 SeitenHygiene PassportAsanga MalNoch keine Bewertungen

- Augocom Micro 768 Battery Tester User ManualDokument29 SeitenAugocom Micro 768 Battery Tester User ManualJorge PontonNoch keine Bewertungen

- Ge Druck PTX 7535Dokument2 SeitenGe Druck PTX 7535ICSSNoch keine Bewertungen

- XC24M MG DatasheetDokument3 SeitenXC24M MG DatasheetAbdulJawad Ibrahim ElmezoghiNoch keine Bewertungen

- Syntorial NotesDokument13 SeitenSyntorial NotesdanNoch keine Bewertungen

- VlsiDokument79 SeitenVlsimdhuq1Noch keine Bewertungen

- Glacial Lakes of Himachal PradeshDokument4 SeitenGlacial Lakes of Himachal PradeshMonidipa DeyNoch keine Bewertungen

- AdPoe The Hunting of The HareDokument2 SeitenAdPoe The Hunting of The HarePI CubingNoch keine Bewertungen

- Civil Engineering Topics V4Dokument409 SeitenCivil Engineering Topics V4Ioannis MitsisNoch keine Bewertungen

- Mwangi, Thyne, Rao - 2013 - Extensive Experimental Wettability Study in Sandstone and Carbonate-Oil-Brine Systems Part 1 - Screening ToDokument7 SeitenMwangi, Thyne, Rao - 2013 - Extensive Experimental Wettability Study in Sandstone and Carbonate-Oil-Brine Systems Part 1 - Screening ToMateo AponteNoch keine Bewertungen

- Streamline SWR (S) - Rev - 00-04-2019 PDFDokument2 SeitenStreamline SWR (S) - Rev - 00-04-2019 PDFarjun 11Noch keine Bewertungen

- Sindarin-English Dictionary - 2nd EditionDokument192 SeitenSindarin-English Dictionary - 2nd EditionNea Tan100% (1)