Beruflich Dokumente

Kultur Dokumente

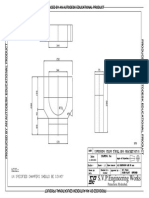

GD&T

Hochgeladen von

gopojiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

GD&T

Hochgeladen von

gopojiCopyright:

Verfügbare Formate

Department of Mechanical Engineering and Mechanics

Geometrical Dimensioning &

Tolerancing (GD&T)

Fundamentals of Computer Aided Design

MEM 201

Department of Mechanical Engineering and Mechanics

Tolerances and why do we need them.

Different types of tolerances.

To learn how to effectively tolerance parts

in engineering drawings.

Allowance/Clearance

Expressing tolerances in AutoCAD.

Todays Objectives..

Department of Mechanical Engineering and Mechanics

Hence, engineers have come up with a way to make things

close to perfect by specifying Tolerances !

Since variation from the drawing is inevitable the

acceptable degree of variation must be specified.

Large variation may affect the functionality of the part

Small variation will effect the cost of the part

requires precise manufacturing.

requires inspection and the rejection of parts.

Why is it needed: No one or thing is perfect !

Definition: Allowance for a specific variation in the size and

geometry of part.

Tolerancing

Tolerances do not affect its function

Department of Mechanical Engineering and Mechanics

Tolerances are important here !

Assemblies: Parts will often not fit together if their

dimensions do not fall with in a certain range of values.

Interchangeability: If a replacement part is used it must be

a duplicate of the original part within certain limits of

deviation.

The relationship between functionality and size or shape

of an object varies from part to part.

When does Tolerances become important

Department of Mechanical Engineering and Mechanics

Food for thought: Tolerance levels in this mechanism?

Department of Mechanical Engineering and Mechanics

Do not specify a smaller tolerance than is necessary!

Parts with small tolerances often require greater inspection

and call for the rejection of parts

Greater Quality

Inspection

Greater cost.

Parts with small tolerances often require special methods of

manufacturing.

Therefore your duty as an engineer have to consider : Do

you need 1.0001in or is 1.01in good enough?

Small tolerances cause an exponential increase in cost

Cost generally increases with smaller tolerance

Tolerance in relation to $$$$

Department of Mechanical Engineering and Mechanics

features of a part

Allows for specification of tolerance for the

geometry of a part separate from its size

GDT (Geometric Dimensioning and Tolerancing)

uses special symbols to control different geometric

Geometric Tolerancing

Geometry

Limits specifying the allowed variation in each

dimension (length, width, height, diameter,

etc.) are given on the drawing

Size

How are Tolerances Specified

Department of Mechanical Engineering and Mechanics

The tolerance is total variation between the upper and lower

limits.

The tolerance for a single dimension may be specified

with the dimension and then the tolerance.

Value of Tolerance

Department of Mechanical Engineering and Mechanics

These are specified when all dimension in the drawings

have the same tolerance.

These notes are used to reduce the number of

dimensions required on a drawing and to promote

drawing clarity.

General Tolerances

Department of Mechanical Engineering and Mechanics

LMC: Least Material Condition

MMC: Maximum Material Condition

These tolerance values indicate the:

Unilateral Tolerances - (12.00 + or - xxx)

Bilateral Tolerances - (12.00 +xxx/- xxx)

Limit Tolerances (12.75/12.25 )

Plus/Minus Tolerances

Tolerances specified for size

Department of Mechanical Engineering and Mechanics

LMC: Least Material Condition

MMC: Maximum Material Condition

Limit Tolerances

Department of Mechanical Engineering and Mechanics

Limit Tolerances

Department of Mechanical Engineering and Mechanics

Plus/Minus Tolerances

CLEARANCE = LMC HOLE LMC SHAFT

CLEARANCE

Clearance is defined as the loosest fit or maximum intended difference

between mating parts.

The calculation formula for clearance is:

ALLOWANCE = MMC HOLE MMC SHAFT

ALLOWANCE

Allowance is defined as an intentional difference between the maximum

material limits of mating parts. Allowance is the minimum clearance (positive

allowance), or maximum interference (negative allowance) between mating

parts. The calculation formula for allowance is:

Department of Mechanical Engineering and Mechanics

Allowance and Clearance

Department of Mechanical Engineering and Mechanics

Types of Fit

Clearance fit

The parts are toleranced such that the largest shaft is

smaller than the smallest hole

The allowance is positive and greater than zero

Interference fit

The max. clearance is always negative

The parts must always be forced together

Transition fit

The parts are toleranced such that the allowance is

negative and the max. clearance is positive

The parts may be loose or forced together

Types of Fit

Department of Mechanical Engineering and Mechanics

Locational fits are intended to determine only the location of the mating

parts.

MAX INTERFERENCE = MMC SHAFT - MMC HOLE

The greatest amount of interference is:

MIN INTERFERENCE = LMC SHAFT - LMC HOLE

A force fit is referred to as interference fit or a shrink fit. The smallest

amount of interference is:

Force fits (FN) or Shrink fits constitute a special type of interference fit

characterized by maintenance of constant pressure. The range is from FN1

to FN5.

Running and Sliding fits (RC) are intended to provide a running

performance with suitable lubrication allowance. The range is from RC1 to

RC9.

Standard ANSI Fits:

BASIC FITS OF MATING PARTS

Department of Mechanical Engineering and Mechanics

= 1.51 1.46 = 0.05mm

Clearance: LMC-Hole LMC-Shaft

= 1.43 1.53 = - 0.1mm

Allowance: MMC-Hole - MMC-Shaft

Type of Fit: Transition Fit

Clearance: 0.05mm

Allowance: -0.1mm

Answer

Lower Limit Tolerance : 0.05mm

Upper Limit Tolerance : 0.03mm

Given: Diameter of Hole: 1.48mm

Lower Limit Tolerance : 0.04mm

Upper Limit Tolerance: 0.03mm

Given: Diameter of shaft: 1.5mm

Sample Calculation

Department of Mechanical Engineering and Mechanics

Geometric Dimensioning & Tolerancing

(GD&T)

Department of Mechanical Engineering and Mechanics

Straightness Tolerance Zone

Straightness

Straightness Tolerance

Tolerance of Form

Department of Mechanical Engineering and Mechanics

FLATNESS

Note: 0.16 < 0.5 (size tolerance)

Tolerance of Form

Department of Mechanical Engineering and Mechanics

Circularity Tolerance Zone

Circularity

Circularity Tolerance

Tolerance of Form

Cylindricity Tolerance

Cylindricity Tolerance Zone

Department of Mechanical Engineering and Mechanics

Cylindricity

Tolerance of Form

Perpendicularity Tolerance Zone

Perpendicularity Tolerance

Department of Mechanical Engineering and Mechanics

Perpendicularity

Tolerance of Orientation

Parallelism Tolerance

Parallelism Tolerance Zone

Department of Mechanical Engineering and Mechanics

T: Tangent Plane

Parallelism

Tolerance of Orientation

Department of Mechanical Engineering and Mechanics

Tolerances in AutoCAD

Department of Mechanical Engineering and Mechanics

Tolerances in AutoCAD

Department of Mechanical Engineering and Mechanics

Tolerances in AutoCAD

Geometry tolerancing is necessary to control specific geometric form and location.

Major features of the part should be used to establish the basic coordinate system, but are not

necessary defined as datum.

Subcoordinated systems that are related to the major coordinates are used to locate and orient

features on a part.

Define part features in relation to three mutually perpendicular reference plans, and along features

that are parallel to the motion of CAM equipment.

Establish datum related to the function of the part, and relate datum features in order of precedence

as a basis for CAM usage.

Completely and accurately dimension geometric shapes. Regular geometric shapes may be defined

by mathematical formulas. A profile feature that is defined with mathematical formulas should not

have coordinate dimensions unless required for inspection or reference.

Coordinate or tabular dimensions should be used to identify approximate dimensions on an arbitrary

profile.

Use the same type of coordinate dimensioning system on the entire drawing.

Continuity of profile is necessary for CADD. Clearly define contour changes at the change or point of

tangency. Define at least four points along an irregular profile.

Circular hole patterns may be defined with polar coordinate dimensioning.

When possible, dimension angles in degrees and decimal parts of degrees.

Base dimensions at the mean of a tolerance because the computer numerical control (CNC)

programmer normally splits a tolerance and works to the mean. While this is theoretically desirable,

one can not predict where the part will be made. Dimensions should always be based on design

requirements. If it is known that a part will be produced always by CNC methods, then establish

dimensions without limits that conform to CNC machine capabilities. Bilateral profile tolerances are

also recommended for the same reason.

Department of Mechanical Engineering and Mechanics

Some dimensioning and tolerance guidelines for use in conjunction with CADD/CAM:

GEOMETRY DIMESIONING AND TOLERANCE

FOR CADD/CAM

Department of Mechanical Engineering and Mechanics

Tolerance Stack-Up Analysis by James D. Meadows

Geometric Dimensioning and Tolerancing by Cecil H. Jensen

Inspection and Gaging by Clifford W. Kennedy

Dimensioning and Tolerancing Handbook by Paul J. Drake

Tolerance design : a handbook for developing optimal specifications

by C.M. Creveling.

Geo-Metrics III : The Application of Geometric Dimensioning and

Tolerancing Techniques (Using the Customary Inch Systems) by

Lowell W. Foster

Geometric Dimensioning and Tolerancing by Alex Krulikowski

Interpretation of Geometric Dimensioning & Tolerancing by Daniel E.

Puncochar

Further Reading

Department of Mechanical Engineering and Mechanics

4. Please draw circularity and perpendicularity symbol blocks

with geometric tolerance of 0.005 for each, and sketch their

tolerance zones for a cylinder and a upside down T shape block

respectively.

3. If a shaft is 10 0.05 inch what is its maximum and least material

conditions.

1. Find TH, Ts, Allowance, Cmax, Cmin, and what kind of fit it is ?

Hole F 66 upper deviation +0.051, lower deviation 0.0

Shaft F 66 upper deviation -0.024, lower deviation -0.050

2. Find TH, Ts, Allowance , Cmax, Imax, and what kind of fit it is ?

Hole F 32 upper deviation +0.021, lower deviation 0.0

Shaft F 32 upper deviation +0.029, lower deviation +0.016

Home Work #2

Department of Mechanical Engineering and Mechanics

Will be due during the next Lecture Class.

Home works should include your names and the section you belong to.

Refer Notes and AutoCAD text book for help in solving problems.

F66 and F32 indicates the nominal dimensions of the hole or shaft

Th= tolerance of hole

Ts= Tolerance of shaft

Cmax= Maximum clearance

Cmin= Minimum clearance

Imax= Maxiumum interference

Home Work #2 contd..

Das könnte Ihnen auch gefallen

- GDT TutorialDokument76 SeitenGDT TutorialSivananthaa MurtheeNoch keine Bewertungen

- GD&T Fundamentals in 40 CharactersDokument76 SeitenGD&T Fundamentals in 40 CharactersAnish PaiNoch keine Bewertungen

- GD&T 1Dokument41 SeitenGD&T 1Sai CharanNoch keine Bewertungen

- Latest Report 2Dokument13 SeitenLatest Report 2Piyush BariNoch keine Bewertungen

- GDT UserDokument51 SeitenGDT UserRajesh MuthuramalingamNoch keine Bewertungen

- GD&T Seminar Agenda and ConceptsDokument69 SeitenGD&T Seminar Agenda and ConceptsJayanthiANoch keine Bewertungen

- True Position - GD&T BasicsDokument55 SeitenTrue Position - GD&T BasicsManoj SinghNoch keine Bewertungen

- DATUMSDokument84 SeitenDATUMSmaddy_scribd100% (2)

- Plastic Product Design With NXDokument8 SeitenPlastic Product Design With NXTungdinh NguyenNoch keine Bewertungen

- GD&T Position TolDokument204 SeitenGD&T Position Toldramilt100% (2)

- GD T Q BankDokument9 SeitenGD T Q Banknewchap chapNoch keine Bewertungen

- GD&T GlossaryDokument4 SeitenGD&T GlossarythindmanmohanNoch keine Bewertungen

- Tolerance Analysis TechniquesDokument8 SeitenTolerance Analysis TechniquesDrew KammerzellNoch keine Bewertungen

- Tolerance Variance Analysis WP PDFDokument22 SeitenTolerance Variance Analysis WP PDFNirmalan GanapathyNoch keine Bewertungen

- Geometric Dimensioning & Tolerancing (GD&T)Dokument89 SeitenGeometric Dimensioning & Tolerancing (GD&T)Vijay PawarNoch keine Bewertungen

- TolAnalyst TutorialDokument15 SeitenTolAnalyst TutorialAnton Nanchev100% (1)

- GD&T Symbols Reference GuideDokument2 SeitenGD&T Symbols Reference Guidecreating_24Noch keine Bewertungen

- Composite Positional TolerancingDokument5 SeitenComposite Positional TolerancingCarlos García Hernández100% (1)

- (A) "Basics of GD&T + Advanced GD&T" SyllabusDokument4 Seiten(A) "Basics of GD&T + Advanced GD&T" SyllabusSwapnil GujarathiNoch keine Bewertungen

- Advanced GD & TDokument95 SeitenAdvanced GD & Tpavan_0380% (5)

- Why car lines are used in BIW designDokument2 SeitenWhy car lines are used in BIW designasddsffdsfNoch keine Bewertungen

- GDandT Seminar ChennaiDokument89 SeitenGDandT Seminar Chennais ReddyNoch keine Bewertungen

- GD&T StandardDokument100 SeitenGD&T StandardsudhirNoch keine Bewertungen

- Tolerance AnalysisDokument10 SeitenTolerance Analysisdineshnexus100% (1)

- GD&T Training BrochureDokument5 SeitenGD&T Training BrochurePritam PolekarNoch keine Bewertungen

- Microsoft PowerPoint - G D & T 17.11Dokument96 SeitenMicrosoft PowerPoint - G D & T 17.11vijaykkhal100% (1)

- Free Ebook Library: GD&T: Application and InterpretationDokument5 SeitenFree Ebook Library: GD&T: Application and InterpretationIsa been MaryemNoch keine Bewertungen

- Introduction To Geometric Dimensioning and TolerancingDokument3 SeitenIntroduction To Geometric Dimensioning and TolerancinganandparasuNoch keine Bewertungen

- G4 - Advance GD&T and Tolerance Stack-UpDokument9 SeitenG4 - Advance GD&T and Tolerance Stack-UpAnkit NaphadeNoch keine Bewertungen

- GDTDokument38 SeitenGDTAntonio CervantesNoch keine Bewertungen

- GOVT. POLYTECHNIC CHAPTER ON LIMITS, FITS AND TOLERANCESDokument68 SeitenGOVT. POLYTECHNIC CHAPTER ON LIMITS, FITS AND TOLERANCESVinod KumarNoch keine Bewertungen

- Tolerance Analysis ManualDokument262 SeitenTolerance Analysis ManualelfrascosNoch keine Bewertungen

- Basic GD&T - Datums PDFDokument35 SeitenBasic GD&T - Datums PDFtnchsgNoch keine Bewertungen

- GD&T Fundamentals: Geometric Dimensioning and Tolerancing ExplainedDokument43 SeitenGD&T Fundamentals: Geometric Dimensioning and Tolerancing ExplainedVictor Manuel Estrada0% (1)

- GD&T Fundamentals: Your Source For GD&T Training and MaterialsDokument33 SeitenGD&T Fundamentals: Your Source For GD&T Training and Materialskameron074Noch keine Bewertungen

- Composte TolDokument5 SeitenComposte TolJuan Posada G100% (1)

- GD&T Symbols, Definitions ASME Y14Dokument8 SeitenGD&T Symbols, Definitions ASME Y14deepak0% (1)

- GDT Use CasesDokument52 SeitenGDT Use CasesAnkur JainNoch keine Bewertungen

- CF Standards-5 11 2012Dokument83 SeitenCF Standards-5 11 2012Sushant Bhartiya100% (1)

- Comparison Between GD&T and Coordinate TolerancingDokument5 SeitenComparison Between GD&T and Coordinate TolerancingHarish Neware50% (2)

- On NX Cad and NC ProgrammingDokument29 SeitenOn NX Cad and NC ProgrammingJames Prajwal PrajuNoch keine Bewertungen

- Introduction To Geometric Dimensioning and TolerancingDokument14 SeitenIntroduction To Geometric Dimensioning and Tolerancingtushk20Noch keine Bewertungen

- 05 StraightnessMeasurement90Dokument90 Seiten05 StraightnessMeasurement90maddy_scribdNoch keine Bewertungen

- GD&T QuestionsDokument3 SeitenGD&T Questionsbkattimani0% (1)

- Dimensional Engineering Seminar: Geometric Dimensioning and Tolerancing Variation Simulation ModelingDokument71 SeitenDimensional Engineering Seminar: Geometric Dimensioning and Tolerancing Variation Simulation Modelingprasungovindan100% (1)

- Geometric dimensioning and tolerancing Second EditionVon EverandGeometric dimensioning and tolerancing Second EditionNoch keine Bewertungen

- Design For Assembly A Complete Guide - 2020 EditionVon EverandDesign For Assembly A Complete Guide - 2020 EditionNoch keine Bewertungen

- Design For Manufacture And Assembly A Complete Guide - 2020 EditionVon EverandDesign For Manufacture And Assembly A Complete Guide - 2020 EditionNoch keine Bewertungen

- MEM201 L6-Tolerance RCDokument82 SeitenMEM201 L6-Tolerance RCNizar Pratama PutraNoch keine Bewertungen

- MEM201 L6-Tolerance RCDokument31 SeitenMEM201 L6-Tolerance RCKaliya PerumalNoch keine Bewertungen

- Experiment No 10 - Exercises in Preparation of Detailed Production DrawingsDokument29 SeitenExperiment No 10 - Exercises in Preparation of Detailed Production DrawingsS S PatilNoch keine Bewertungen

- Uses of Geometrical Dimensional and Tolerance: IntroductionDokument11 SeitenUses of Geometrical Dimensional and Tolerance: IntroductionJuicYm mNoch keine Bewertungen

- Geometrical Dimensioning and TolerenceDokument61 SeitenGeometrical Dimensioning and TolerenceAd Man GeTigNoch keine Bewertungen

- Design of Machine Elements ProjectDokument43 SeitenDesign of Machine Elements ProjectGirish ChandankarNoch keine Bewertungen

- Die CastingDokument7 SeitenDie CastingSumeet SainiNoch keine Bewertungen

- Exercise 1 - Pipework Design PdmsDokument25 SeitenExercise 1 - Pipework Design PdmsLorenzo SantanaNoch keine Bewertungen

- ChartsDokument1 SeiteChartsravikumarmgowdaNoch keine Bewertungen

- This Article Is About A BirdDokument10 SeitenThis Article Is About A BirdgopojiNoch keine Bewertungen

- Sheetmetal Design Interview Questions and AnswersDokument4 SeitenSheetmetal Design Interview Questions and Answersgopoji100% (1)

- WeldingDokument11 SeitenWeldinggopojiNoch keine Bewertungen

- Equipment Modeling Structure Modeling Draft Isodraft Cable ModelingDokument3 SeitenEquipment Modeling Structure Modeling Draft Isodraft Cable ModelinggopojiNoch keine Bewertungen

- Welding Symbol Guide (ISO 2553Dokument32 SeitenWelding Symbol Guide (ISO 2553Marcelo CunhaNoch keine Bewertungen

- HG Series Catalog OptDokument22 SeitenHG Series Catalog OptPanchoMiyamotoNoch keine Bewertungen

- Is 808-1989 Steel TableDokument24 SeitenIs 808-1989 Steel TableAtul Kumar Engineer86% (28)

- Nuts Bolts Screws and WashersDokument4 SeitenNuts Bolts Screws and WashersneevarpsufurNoch keine Bewertungen

- Taper HSG For AgitatorDokument2 SeitenTaper HSG For AgitatorgopojiNoch keine Bewertungen

- Unwinding Stand T-Roll HSG Bracket-Model PDFDokument1 SeiteUnwinding Stand T-Roll HSG Bracket-Model PDFgopojiNoch keine Bewertungen

- Nuts Bolts Screws and WashersDokument4 SeitenNuts Bolts Screws and WashersneevarpsufurNoch keine Bewertungen

- V. Induction GeneratorsDokument4 SeitenV. Induction GeneratorsAli OmaniNoch keine Bewertungen

- Piping Lube OilOilconsole - enDokument8 SeitenPiping Lube OilOilconsole - engopojiNoch keine Bewertungen

- Unwinding Stand T-Roll HSG Bracket-Model PDFDokument1 SeiteUnwinding Stand T-Roll HSG Bracket-Model PDFgopojiNoch keine Bewertungen

- CNC Report1Dokument55 SeitenCNC Report1coolguy02088775% (4)

- DNCDokument4 SeitenDNCgopojiNoch keine Bewertungen

- CNC Report1Dokument55 SeitenCNC Report1coolguy02088775% (4)

- 2 Contents p1Dokument1 Seite2 Contents p1gopojiNoch keine Bewertungen

- Page 1Dokument1 SeitePage 1gopojiNoch keine Bewertungen

- 1 Sample Letter Head p1Dokument2 Seiten1 Sample Letter Head p1gopojiNoch keine Bewertungen

- Hyper-Threading Technology Architecture and Microarchitecture - SummaryDokument4 SeitenHyper-Threading Technology Architecture and Microarchitecture - SummaryMuhammad UsmanNoch keine Bewertungen

- Why Genentech Is 1Dokument7 SeitenWhy Genentech Is 1panmongolsNoch keine Bewertungen

- Evaluating MYP Rubrics in WORDDokument11 SeitenEvaluating MYP Rubrics in WORDJoseph VEGANoch keine Bewertungen

- Water Jet CuttingDokument15 SeitenWater Jet CuttingDevendar YadavNoch keine Bewertungen

- Accomplishment Report 2021-2022Dokument45 SeitenAccomplishment Report 2021-2022Emmanuel Ivan GarganeraNoch keine Bewertungen

- Personalised MedicineDokument25 SeitenPersonalised MedicineRevanti MukherjeeNoch keine Bewertungen

- Last Clean ExceptionDokument24 SeitenLast Clean Exceptionbeom choiNoch keine Bewertungen

- International Certificate in WealthDokument388 SeitenInternational Certificate in Wealthabhishek210585100% (2)

- 10 1 1 124 9636 PDFDokument11 Seiten10 1 1 124 9636 PDFBrian FreemanNoch keine Bewertungen

- India Today 11-02-2019 PDFDokument85 SeitenIndia Today 11-02-2019 PDFGNoch keine Bewertungen

- NLL - Elementary - Coursebook 2019 PDFDokument24 SeitenNLL - Elementary - Coursebook 2019 PDFgilmolto100% (1)

- Liebert PSP: Quick-Start Guide - 500VA/650VA, 230VDokument2 SeitenLiebert PSP: Quick-Start Guide - 500VA/650VA, 230VsinoNoch keine Bewertungen

- MBO, Management by Objectives, Pooja Godiyal, Assistant ProfessorDokument20 SeitenMBO, Management by Objectives, Pooja Godiyal, Assistant ProfessorPooja GodiyalNoch keine Bewertungen

- 8.1 Interaction Diagrams: Interaction Diagrams Are Used To Model The Dynamic Aspects of A Software SystemDokument13 Seiten8.1 Interaction Diagrams: Interaction Diagrams Are Used To Model The Dynamic Aspects of A Software SystemSatish JadhaoNoch keine Bewertungen

- Jfif 1.02Dokument9 SeitenJfif 1.02Berry Hoekstra100% (1)

- Nursing Care Management of a Client with Multiple Medical ConditionsDokument25 SeitenNursing Care Management of a Client with Multiple Medical ConditionsDeannNoch keine Bewertungen

- Chapter 3 of David CrystalDokument3 SeitenChapter 3 of David CrystalKritika RamchurnNoch keine Bewertungen

- 1.each of The Solids Shown in The Diagram Has The Same MassDokument12 Seiten1.each of The Solids Shown in The Diagram Has The Same MassrehanNoch keine Bewertungen

- Os PPT-1Dokument12 SeitenOs PPT-1Dhanush MudigereNoch keine Bewertungen

- Analytical Approach To Estimate Feeder AccommodatiDokument16 SeitenAnalytical Approach To Estimate Feeder AccommodatiCleberton ReizNoch keine Bewertungen

- #### # ## E232 0010 Qba - 0Dokument9 Seiten#### # ## E232 0010 Qba - 0MARCONoch keine Bewertungen

- Marshal HMA Mixture Design ExampleDokument2 SeitenMarshal HMA Mixture Design ExampleTewodros TadesseNoch keine Bewertungen

- IGCSE Chemistry Section 5 Lesson 3Dokument43 SeitenIGCSE Chemistry Section 5 Lesson 3Bhawana SinghNoch keine Bewertungen

- Ensayo Bim - Jaime Alejandro Martinez Uribe PDFDokument3 SeitenEnsayo Bim - Jaime Alejandro Martinez Uribe PDFAlejandro MartinezNoch keine Bewertungen

- 2014 mlc703 AssignmentDokument6 Seiten2014 mlc703 AssignmentToral ShahNoch keine Bewertungen

- Quality Management in Digital ImagingDokument71 SeitenQuality Management in Digital ImagingKampus Atro Bali0% (1)

- Final Thesis Report YacobDokument114 SeitenFinal Thesis Report YacobAddis GetahunNoch keine Bewertungen

- Postgraduate Notes in OrthodonticsDokument257 SeitenPostgraduate Notes in OrthodonticsSabrina Nitulescu100% (4)

- Tigo Pesa Account StatementDokument7 SeitenTigo Pesa Account StatementPeter Ngicur Carthemi100% (1)

- En dx300lc 5 Brochure PDFDokument24 SeitenEn dx300lc 5 Brochure PDFsaroniNoch keine Bewertungen