Beruflich Dokumente

Kultur Dokumente

EXEL - Insulating Rail Joints For Web PDF

Hochgeladen von

hariridkOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EXEL - Insulating Rail Joints For Web PDF

Hochgeladen von

hariridkCopyright:

Verfügbare Formate

E X E L INSULATE D RAIL JO INTS

Fail safe function in combination with

cost saving is your goal

You and Exel have the similar target. Signal failures are

too often the reason for delays in traffic, causing problems not only for the maintenance but more important,

for the passengers. The Exel joints have the highest

possible electrical insulation properties, and due to the

design and material they are practically fail safe with

respect to insulation. The mechanical strength in the

fishplates is very similar to the rail. Fatigue resistance

is far above the fatigue resistance for metals. All this

in combination with a simple design using a minimum

number of parts, easy and fast installation without the

need for handling chemicals, welding, or detergents

gives you a total cost saving.

Quality

Being one of the leaders in the use and design of high

quality composite materials, we know the demanding

requirements of the manufacturing of products for

the railway industry. In fact you can see the difference

in quality and structure already by looking at an Exel

joint.

Exel is using materials to highest quality standards, and

the structure of the material is optimised for insulated

rail joints. The in-house developed manufacturing

method and materials are constantly monitored.

Exel insulated rail joints are manufactured to highest

quality standards according to ISO 9001.

Design and available specifications

The design is based on extensive research and testing

and the know-how obtained has been proven over

years of successful installations of thousands of joints

in climate from tropical to arctic. The range available

is covering joints for UIC 60 welded track used in the

main lines to special joints in small series for jointed

track. Due to the special design and strength a four

hole configuration is normally recommended, but six

hole joints are also supplied.

Special joints, as sample Emergency repair joints, distintively

coloured for attention. Weight

per joint appr. 20 kg.

Standard joint

This joint type is used in jointed track and positions

were longitudinal loads are limited. It is frequently

used to replace plastic coated steel fishplates or

fishplates with a plastic insulation liner or even wooden

joints. Exel gives you a trouble free solution that will

last.

CWR joint

The design and testing is made in order to meet the

requirements for use in continuously welded track. It

meets the operational strength requirements for heavy

traffic and high climatic and temperature loading in

welded track. The CWR joint is used instead of glued

joints as an easier and more cost effective solution.

More than ten years and thousands of joints in use

has proven the design and strength. The time needed

for installation is approx. 20 minutes including drilling

operations.

Special installations, underground

and tunnel installations

The simple installation of the Exel joints is an obvious

advantage in tunnel and underground installations.

No smoke, no chemical fumes, no fire risk, makes it an

ideal solution. The fast installation limits the track time

needed to a minimum.

Exel joints in turn outs will prove a valuable solution.

Maintenance of the turn outs is easy because the joints

can be opened and reinstalled, no need to damage an

existing joint because of maintenance of other track

components.

Send your present specification or the design of your

rail - sleeper configuration together with information of

axle loads and allowed speed, and get the best solution based on our wide know-how of joint design

Exel Oyj/Mntyharju Factory

P.O. Box 29

FI-52701 Mntyharju

Finland

www.exel.net

Das könnte Ihnen auch gefallen

- CVBHW FlexsteelDokument10 SeitenCVBHW FlexsteelSrini KumarNoch keine Bewertungen

- CVBHW FlexsteelDokument10 SeitenCVBHW FlexsteelfranciscocvNoch keine Bewertungen

- Bollhoff HeliCoil Plus ImperialDokument48 SeitenBollhoff HeliCoil Plus ImperialAce Industrial SuppliesNoch keine Bewertungen

- Cathodic Protection of Reinf. Concrete OverviewDokument8 SeitenCathodic Protection of Reinf. Concrete OverviewvolkanNoch keine Bewertungen

- Shotcrete UKDokument8 SeitenShotcrete UKAhirul YahyaNoch keine Bewertungen

- Bollhoff Helicoil Plus Kits and Inserts CatalogueDokument49 SeitenBollhoff Helicoil Plus Kits and Inserts CatalogueThor InternationalNoch keine Bewertungen

- Stronger Together en WebDokument8 SeitenStronger Together en WebMandar ChikateNoch keine Bewertungen

- CompositeDokument24 SeitenCompositeKartik SharmaNoch keine Bewertungen

- Roofing Tech - EngDokument36 SeitenRoofing Tech - EngwindyNoch keine Bewertungen

- Steel As A Structural MaterialDokument10 SeitenSteel As A Structural MaterialFaisal ShahzadNoch keine Bewertungen

- Green Building LibraryDokument21 SeitenGreen Building LibraryYadnesh DeorukhkarNoch keine Bewertungen

- Flexible Steel Pipe Applications: Dana FraserDokument15 SeitenFlexible Steel Pipe Applications: Dana FraseraishahNoch keine Bewertungen

- Sheet Pile Design HandbookDokument368 SeitenSheet Pile Design HandbookLandon Mitchell92% (12)

- Dobro PDFDokument8 SeitenDobro PDFbaneNoch keine Bewertungen

- Bollhoff HeliCoil Plus MetricDokument48 SeitenBollhoff HeliCoil Plus MetricAce Industrial SuppliesNoch keine Bewertungen

- The Dirt On Ground RodsDokument3 SeitenThe Dirt On Ground Rodsalexis oliveraNoch keine Bewertungen

- Avdel LockboltSystems enDokument16 SeitenAvdel LockboltSystems enkamaleshaiahNoch keine Bewertungen

- BellowsTech Ebook 11-15 Vs4Dokument9 SeitenBellowsTech Ebook 11-15 Vs4abs0001Noch keine Bewertungen

- RPA112 Structural Cable Catalogue 72dpi 0Dokument60 SeitenRPA112 Structural Cable Catalogue 72dpi 0CallumWoodwardNoch keine Bewertungen

- EEI Utility BrochureDokument6 SeitenEEI Utility BrochurepdeloneyNoch keine Bewertungen

- ABB - Composite Hollow Core InsulatorDokument8 SeitenABB - Composite Hollow Core InsulatorAnu SunNoch keine Bewertungen

- Ar Bricks-21Dokument34 SeitenAr Bricks-21ManishaChary100% (1)

- ConstructionSpecifier Studcast 07Dokument7 SeitenConstructionSpecifier Studcast 07Roberto FernandesNoch keine Bewertungen

- Aac ComparisonsDokument6 SeitenAac ComparisonsSrinivas GoudNoch keine Bewertungen

- Linton Coupler LT0381Dokument20 SeitenLinton Coupler LT0381Sayed Diab AlsayedNoch keine Bewertungen

- A Comparison of Concrete Steel and Timber Construction EssayDokument4 SeitenA Comparison of Concrete Steel and Timber Construction EssayJordan Kurt S. Gu100% (3)

- 3.design and Weight Optimization of Lift Base PlateDokument40 Seiten3.design and Weight Optimization of Lift Base Plateumesh KudalkarNoch keine Bewertungen

- Characteristics:: Identify An AESA U-Bolt: Check The Printing On Its Side Containing The Name, ResistanceDokument2 SeitenCharacteristics:: Identify An AESA U-Bolt: Check The Printing On Its Side Containing The Name, ResistancemfurrierNoch keine Bewertungen

- Fiberglass Structural Shapes and PlateDokument12 SeitenFiberglass Structural Shapes and Plateaurora borealissNoch keine Bewertungen

- English Lectrobar 26may2021Dokument3 SeitenEnglish Lectrobar 26may2021SCHAEFFER CAPITAL ADVISORSNoch keine Bewertungen

- Bridges: The New Standard For Bridges and Bridge ReinstatementDokument9 SeitenBridges: The New Standard For Bridges and Bridge Reinstatementdanielsu87Noch keine Bewertungen

- Aluminium Domes of The Enel Plant in Civitavecchia, ItalyDokument16 SeitenAluminium Domes of The Enel Plant in Civitavecchia, ItalyLaura Elena ThijovNoch keine Bewertungen

- The Case For SteelDokument2 SeitenThe Case For Steelimcoolmailme2Noch keine Bewertungen

- Hebel Supercrete AWS Design GuideDokument36 SeitenHebel Supercrete AWS Design GuideEddy Ng Chi ChungNoch keine Bewertungen

- Piling Handbook (2008)Dokument368 SeitenPiling Handbook (2008)RUXUS100% (1)

- The Next Generation of Metal Roofing: EverlocDokument4 SeitenThe Next Generation of Metal Roofing: EverlocThangaraj SelviNoch keine Bewertungen

- ABB Composites. ABB Composite Insulators Design For Reliable PerformanceDokument24 SeitenABB Composites. ABB Composite Insulators Design For Reliable Performancenamsaigon316Noch keine Bewertungen

- Duplex Stainless BrochureDokument13 SeitenDuplex Stainless BrochurepramodtryNoch keine Bewertungen

- Automotive PDFDokument24 SeitenAutomotive PDFbathinsreenivasNoch keine Bewertungen

- Axis Electrical InterviewDokument8 SeitenAxis Electrical InterviewRAJ SAROJNoch keine Bewertungen

- Tensile Fabric StructuresDokument15 SeitenTensile Fabric StructuresMary FelisminoNoch keine Bewertungen

- Avdel RevetDokument104 SeitenAvdel RevetvinodmysoreNoch keine Bewertungen

- Diagnostic Methods For Outdoor Polymeric InsulatorsDokument16 SeitenDiagnostic Methods For Outdoor Polymeric InsulatorsluqmansulymanNoch keine Bewertungen

- Non-Metallic Applications in Oil - Gas IndustryDokument6 SeitenNon-Metallic Applications in Oil - Gas IndustryzaheerNoch keine Bewertungen

- Marcel Poser - Cable Stayed Structures and Stay Cable TechnologyDokument7 SeitenMarcel Poser - Cable Stayed Structures and Stay Cable Technologylarisa_bucatariuNoch keine Bewertungen

- Innovative Structural Steel SystemsDokument12 SeitenInnovative Structural Steel SystemsCIVILNoch keine Bewertungen

- 2007 Koegel Presents Its Own Axle SystemDokument4 Seiten2007 Koegel Presents Its Own Axle SystemKhawar HayatNoch keine Bewertungen

- SteelPipe Versus DIPDokument10 SeitenSteelPipe Versus DIPHichem BenniaNoch keine Bewertungen

- Mcrma Decking Doc15Dokument16 SeitenMcrma Decking Doc15ibnmessaoud10Noch keine Bewertungen

- Exotic Alloys For Spring ApplicationsDokument8 SeitenExotic Alloys For Spring ApplicationsVishaka ThekkedathNoch keine Bewertungen

- Busway GeDokument8 SeitenBusway GeJuan E Torres MNoch keine Bewertungen

- Quick-Connect Moment Connection For Portal Frame Buildings - An Introduction and Case StudiesDokument10 SeitenQuick-Connect Moment Connection For Portal Frame Buildings - An Introduction and Case StudiesTuroyNoch keine Bewertungen

- Steel Structures Design Based on Eurocode 3Von EverandSteel Structures Design Based on Eurocode 3Bewertung: 3 von 5 Sternen3/5 (1)

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsVon EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNoch keine Bewertungen

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesVon EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesBewertung: 4.5 von 5 Sternen4.5/5 (16)

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesVon EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNoch keine Bewertungen

- Triangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsVon EverandTriangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsBewertung: 5 von 5 Sternen5/5 (1)

- demag-crawler-cranes-spec-CC1400 (250T)Dokument68 Seitendemag-crawler-cranes-spec-CC1400 (250T)hariridkNoch keine Bewertungen

- Demag Crawler Cranes Spec CC1800 (300T)Dokument58 SeitenDemag Crawler Cranes Spec CC1800 (300T)hariridkNoch keine Bewertungen

- Rekapitulasi Hasil Pemeliharaan PlasmaDokument1 SeiteRekapitulasi Hasil Pemeliharaan PlasmahariridkNoch keine Bewertungen

- HTTP M.tatamotors - Co.id Wp-Content Uploads 2017 03 SUPER-ACE-DLEDokument127 SeitenHTTP M.tatamotors - Co.id Wp-Content Uploads 2017 03 SUPER-ACE-DLEhariridkNoch keine Bewertungen

- Expertadvisor Indicator TutorialDokument1 SeiteExpertadvisor Indicator TutorialhariridkNoch keine Bewertungen

- GO Train Emergency Evacuation PlanDokument4 SeitenGO Train Emergency Evacuation PlanhariridkNoch keine Bewertungen

- Disinfection Water Treatment Plants: Awwa StandardDokument16 SeitenDisinfection Water Treatment Plants: Awwa StandardhariridkNoch keine Bewertungen

- Introduction of Pneumatic Brake System - July 31, 2015Dokument6 SeitenIntroduction of Pneumatic Brake System - July 31, 2015hariridkNoch keine Bewertungen

- Disinfection Water Treatment Plants: Awwa StandardDokument16 SeitenDisinfection Water Treatment Plants: Awwa StandardhariridkNoch keine Bewertungen

- Chapter 9 - Railway Electrification PDFDokument51 SeitenChapter 9 - Railway Electrification PDFhariridk100% (4)

- Medium Velocity Water Spray NozzleDokument6 SeitenMedium Velocity Water Spray NozzlehariridkNoch keine Bewertungen

- 04 P&ID CVC SeparatorDokument4 Seiten04 P&ID CVC Separatorhariridk100% (1)

- 02 P&ID Guide PDFDokument9 Seiten02 P&ID Guide PDFcharleselitb92Noch keine Bewertungen

- Solid Works Video Tutorial by MagnitudeDokument3 SeitenSolid Works Video Tutorial by MagnitudehariridkNoch keine Bewertungen

- The Possible Possible Automotive Applications Automotive Applications of Glass Microspheres of Glass MicrospheresDokument30 SeitenThe Possible Possible Automotive Applications Automotive Applications of Glass Microspheres of Glass MicrospheresFJNovaes454Noch keine Bewertungen

- GCBV2e V1Dokument11 SeitenGCBV2e V1Kemal GokovicNoch keine Bewertungen

- Me (2) AdssDokument2 SeitenMe (2) AdssPiyush BhandariNoch keine Bewertungen

- Construction Cost Estimator For Subdivision WorkDokument6 SeitenConstruction Cost Estimator For Subdivision WorkRonaldRayLachica100% (8)

- Braced FrameDokument2 SeitenBraced FrameRicha ShahNoch keine Bewertungen

- FAS Data-Sheet Vantage-Seal PDFDokument10 SeitenFAS Data-Sheet Vantage-Seal PDFVictor Flores ResendizNoch keine Bewertungen

- Selected Welding Application in Offshore IndustryDokument38 SeitenSelected Welding Application in Offshore IndustryzuudeeNoch keine Bewertungen

- Dams and Reservoirs: Prof. Dr. Ali El-Naqa Hashemite University June 2013Dokument141 SeitenDams and Reservoirs: Prof. Dr. Ali El-Naqa Hashemite University June 2013mimahmoudNoch keine Bewertungen

- Screw Jack DesignDokument13 SeitenScrew Jack DesignIbrahimovic Elsaied78% (9)

- Johnson Lee JWELL PresentationDokument30 SeitenJohnson Lee JWELL PresentationRajiv SanghaviNoch keine Bewertungen

- CATALOG 4660-Thermoplastic HoseDokument339 SeitenCATALOG 4660-Thermoplastic HoseJose Antonio GomezNoch keine Bewertungen

- Alfacrimp - Part Numbering SystemDokument1 SeiteAlfacrimp - Part Numbering Systemphankhoa83-1Noch keine Bewertungen

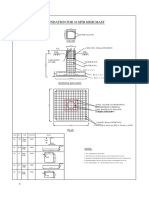

- High Mast Foundation Layout - DiagramDokument8 SeitenHigh Mast Foundation Layout - DiagramTanveer Ahmad89% (9)

- Implementation of Eurocodes in SingaporeDokument18 SeitenImplementation of Eurocodes in Singaporelimegreens100% (1)

- Cebex Cable Grout - FosrocDokument4 SeitenCebex Cable Grout - FosrocIrshadYasinNoch keine Bewertungen

- ThermAFrame 50mm Commerical Door May2021Dokument90 SeitenThermAFrame 50mm Commerical Door May2021LEONARDONoch keine Bewertungen

- Dimensions of Steel Beams Type IPE and INP European StandardDokument4 SeitenDimensions of Steel Beams Type IPE and INP European StandardfarithNoch keine Bewertungen

- Midori Plains Subdivision Tungkop Minglanilla CebuDokument34 SeitenMidori Plains Subdivision Tungkop Minglanilla CebucebudotcomNoch keine Bewertungen

- PO1541 - Ojas Infra GSF - MV Cable Marking and Drum Label v1.0Dokument6 SeitenPO1541 - Ojas Infra GSF - MV Cable Marking and Drum Label v1.0Sanjay GadhaveNoch keine Bewertungen

- Boq Package 4-Mep Rumus1Dokument413 SeitenBoq Package 4-Mep Rumus1Muhammad Iqbal ArdhiansyahNoch keine Bewertungen

- Water Ace R33SU Submersible PumpDokument16 SeitenWater Ace R33SU Submersible PumpatereñoneNoch keine Bewertungen

- HT200AF, 227AF HT300AF, 327AF HT400AF, 427AF HT500AF, 527AF: Owner 'S ManualDokument24 SeitenHT200AF, 227AF HT300AF, 327AF HT400AF, 427AF HT500AF, 527AF: Owner 'S ManualFidelNoch keine Bewertungen

- 2.4 Ccontract ManagmentDokument27 Seiten2.4 Ccontract Managmentbereket gNoch keine Bewertungen

- Static and Cyclic Properties of Clay Subgrade Stabilised With Rice Husk Ash and Portland Slag CementDokument12 SeitenStatic and Cyclic Properties of Clay Subgrade Stabilised With Rice Husk Ash and Portland Slag CementAndrea RinconNoch keine Bewertungen

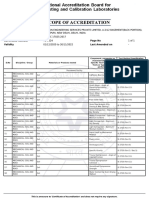

- Scope TC 9124Dokument1 SeiteScope TC 9124Esscon Engineering Services Pvt. Ltd.Noch keine Bewertungen

- Ceg461 - Tutorial 4b - ConsolidationDokument5 SeitenCeg461 - Tutorial 4b - ConsolidationdzikrydsNoch keine Bewertungen

- Angelo DelZotto School of Construction ManagementDokument47 SeitenAngelo DelZotto School of Construction ManagementGonzalo OviedoNoch keine Bewertungen

- 17-01-SEP-New Integral End Bent Pile Design ProcedureDokument17 Seiten17-01-SEP-New Integral End Bent Pile Design ProcedureMainulNoch keine Bewertungen

- Specification For Sewer Bricks (: Indian StandardDokument5 SeitenSpecification For Sewer Bricks (: Indian StandardAnonymous i6zgzUvNoch keine Bewertungen

- InfraCo Review 2007Dokument63 SeitenInfraCo Review 2007m_edas4262Noch keine Bewertungen