Beruflich Dokumente

Kultur Dokumente

Process Mapping in SMD Assembly

Hochgeladen von

smtdrkdCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Process Mapping in SMD Assembly

Hochgeladen von

smtdrkdCopyright:

Verfügbare Formate

PROCESS MAP

SMD ASSEMBLY

INPUTS PROCESS STEP OUPUTS

Board Handling (Loading)

JOT Magazine Loader Bare PCB Panel

Unload one panel at a time to the Screen

Bare PCB Panel

Printer

Operator

Solder Paste Printing

MPM AP25 HiE Stencil Printer

Solder Paste Printing Parameters

Screen Printer Operator PCB with Printed Solder Paste

Bare PCB Panel Stencil contaminated with Solder Paste

Print Solder Paste on PCB

Electroformed Stencil Squeegee Blades contaminated with Solder Paste

Stainless Steel Squeegee Blades Reject Solder Paste

MP100 Solder Paste

Inspector

MPM Paste Inspection

MPM AP25 Camera System PCB Panel with correct amount of solder paste

PCB with Solder Paste Inspect the PCB and accept or reject the

print process based on 70% coverage

Operator area

SPPC Paste Inspection

SPPC Paste Inspection System PCB Panel with correct amount of solder paste

Inspect the PCB Panel and accetp/reject

PCB with Solder Paste

the print process

Operator

Barcode Labeling

PMJ Barcode Labeling System PCB Panel with solder paste and bar code label

PCB with Solder Paste Apply barcode label at a predetermined

Operator location on the PCB Panel

Component Placement

Siemens HS50 Placement System

PCB with printed Solder Paste

Component Feeders

Components on Tape and Reels Automatically Place Components on the

PCB with Printed Solder Paste and Components

Components on Trays (optional) PCBs

Hand Placeable Components

Operator (Hand Placement)

Operator (Reel Changing)

Reflow Soldering

ERSA or BTU Reflow Soldering System (or equivalent)

Inspector PCB with Soldered Components

PCB with Printed Solder Paste and Components PCBs with paste flux residues

Components are soldered to the PCB in

Optimum Reflow Soldering Profile specific to a product a Reflow Oven

Conveyor System to transport the PCB

Center Board Support

PROCESS MAP

SMD ASSEMBLY

INPUTS PROCESS STEP OUPUTS

JOT Magazine Loader Bare PCB Panel

OSP or Ni/Au PCB Panel

Unload one panel at a time to PCB with Printed Solder Paste

the Screen Printer

Operator PCB Panel with solder paste and bar code label

MPM AP25 Camera System Stencil contaminated with Solder Paste

SPPC Paste Inspection System

Inspect the PCB and accept or Squeegee Blades contaminated with Solder Paste

reject the print process based

PMJ Barcode Labeling System Reject Solder Paste

on 70% coverage area

MPM AP25 HiE Stencil Printer PCB with Printed Solder Paste and Components

Solder Paste Printing Parameters PCB with Soldered Components

Screen Printer Operator

Inspect the PCB Panel and PCBs with paste flux residues

accetp/reject the print process

Electroformed Stencil

Stainless Steel Squeegee Blades Apply barcode label at a

MP100 Solder Paste predetermined location on the

Inspector PCB Panel

Siemens HS50 Placement System Print Solder Paste on PCB

PCB with printed Solder Paste Automatically Place

Component Feeders Components on the PCBs

Components on Tape and Reels Components are soldered to

Components on Trays (optional) the PCB in a Reflow Oven

Hand Placeable Components

Operator (Hand Placement)

Operator (Reel Changing)

ERSA or BTU Reflow Soldering System

Inspector

PCB with Printed Solder Paste and Components

Optimum Reflow Soldering Profile

Conveyor System to transport the PCB

Center Board Support

Das könnte Ihnen auch gefallen

- Reflow and Wave Soldering Process Documentation SheetDokument8 SeitenReflow and Wave Soldering Process Documentation Sheetsmtdrkd100% (3)

- Area Ratio and Stencil Thickness CalculatorDokument6 SeitenArea Ratio and Stencil Thickness Calculatorsmtdrkd100% (1)

- PCB DFM V1.1 PDFDokument43 SeitenPCB DFM V1.1 PDFAbster1Noch keine Bewertungen

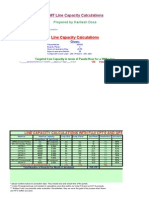

- SMT Line Capacity CalculationsDokument4 SeitenSMT Line Capacity Calculationssmtdrkd100% (3)

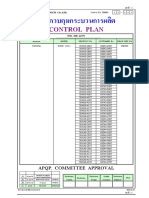

- SMT Generic Control PlanDokument2 SeitenSMT Generic Control Plansmtdrkd81% (21)

- Pin-in-Paste Stencil Design SpreadsheetDokument4 SeitenPin-in-Paste Stencil Design Spreadsheetsmtdrkd100% (1)

- Wave Solder SPC Chart CalculatorDokument6 SeitenWave Solder SPC Chart CalculatorsmtdrkdNoch keine Bewertungen

- Reflow Solder SPC ChartDokument6 SeitenReflow Solder SPC Chartsmtdrkd100% (1)

- SMT Generic Control PlanDokument3 SeitenSMT Generic Control PlanPedro Lopez Rodriguez100% (1)

- NPI Flow ChatrsDokument9 SeitenNPI Flow Chatrsapi-3760998Noch keine Bewertungen

- X-Ray Inspection BGA Glenbrook TechnologiesDokument25 SeitenX-Ray Inspection BGA Glenbrook TechnologiessakthiNoch keine Bewertungen

- Assembly Line BalancingDokument11 SeitenAssembly Line BalancingAyush SinghNoch keine Bewertungen

- PFMEA Solder Paste Printing 03 Sept 2016 (Zul)Dokument129 SeitenPFMEA Solder Paste Printing 03 Sept 2016 (Zul)Sisma Pratama Arum PutriNoch keine Bewertungen

- Wave Solder Profile Documentation SheetDokument4 SeitenWave Solder Profile Documentation SheetsmtdrkdNoch keine Bewertungen

- SMT Process EngineeringDokument4 SeitenSMT Process Engineeringshaktiss24_147930359Noch keine Bewertungen

- 03 Module 4 SOLDERING 610EDokument37 Seiten03 Module 4 SOLDERING 610EMuneendra SharmaNoch keine Bewertungen

- APQP ProjectDokument326 SeitenAPQP ProjectAbdel Nasser AdamNoch keine Bewertungen

- SPC SMT Defects Chart TemplateDokument2 SeitenSPC SMT Defects Chart Templatesmtdrkd100% (2)

- Solder Paste Printing Process - Surface Mount ProcessDokument5 SeitenSolder Paste Printing Process - Surface Mount ProcessMike HHNoch keine Bewertungen

- Lead Free DFM Guidelines From SMTCDokument18 SeitenLead Free DFM Guidelines From SMTCsmtdrkd100% (4)

- NPIDokument1 SeiteNPIsuree_leo0% (1)

- PFMEA-CP-SMT 578W Re.Dokument42 SeitenPFMEA-CP-SMT 578W Re.wgerbecNoch keine Bewertungen

- Animation For SMT ProcessDokument4 SeitenAnimation For SMT Processapi-3760998100% (3)

- SMT Line Improvements For High Mix, Low Volume Electronics ManufacturingDokument98 SeitenSMT Line Improvements For High Mix, Low Volume Electronics ManufacturingNassim DoukhiNoch keine Bewertungen

- DFM Assembly Guidelines1 PDFDokument25 SeitenDFM Assembly Guidelines1 PDFselvakumarNoch keine Bewertungen

- ControlTek - New Product Introduction Flow ChartDokument1 SeiteControlTek - New Product Introduction Flow ChartControl_TekNoch keine Bewertungen

- Solder Paste Stencil Design R. 00Dokument17 SeitenSolder Paste Stencil Design R. 00edwin100% (1)

- Capability Worksheet For CP, CR and CPKDokument4 SeitenCapability Worksheet For CP, CR and CPKsmtdrkd100% (9)

- Chapter 5 - Control Chart For AttributesDokument28 SeitenChapter 5 - Control Chart For AttributesAtirah AsnaNoch keine Bewertungen

- AIAG - Production Part Approval Process (PPAP) 4th EditionDokument74 SeitenAIAG - Production Part Approval Process (PPAP) 4th EditionIvan Bolivar BarrazaNoch keine Bewertungen

- Control Plan FormatDokument1 SeiteControl Plan FormatMagesh WaranNoch keine Bewertungen

- SMT Process Engineer: Engineering, ManufacturingDokument1 SeiteSMT Process Engineer: Engineering, ManufacturingjorgequijanoNoch keine Bewertungen

- Library Expert Through-Hole FamiliesDokument8 SeitenLibrary Expert Through-Hole Familiesjagadees21Noch keine Bewertungen

- PCB ChecklistDokument5 SeitenPCB Checklistizzati_2607100% (1)

- PS - APQP Check ListDokument17 SeitenPS - APQP Check ListalexrferreiraNoch keine Bewertungen

- Stencil Aperture and Area Ratio Table For Optimum PrintingDokument4 SeitenStencil Aperture and Area Ratio Table For Optimum PrintingsmtdrkdNoch keine Bewertungen

- Design Fmea ExampleDokument2 SeitenDesign Fmea ExampleSenthil_KNoch keine Bewertungen

- Surface Mount Technology (SMT)Dokument68 SeitenSurface Mount Technology (SMT)Lishan JayanathNoch keine Bewertungen

- Pcba Process Manual: Manual WHQ-SQD - Man003 Rev.7 Effective From: ReleasedDokument40 SeitenPcba Process Manual: Manual WHQ-SQD - Man003 Rev.7 Effective From: ReleasedTuan Hung NguyenNoch keine Bewertungen

- SMT Manufacturability Design GuidelinesDokument25 SeitenSMT Manufacturability Design GuidelinespcbppcNoch keine Bewertungen

- Solder Filet and StencilDokument150 SeitenSolder Filet and StencilKojOT88Noch keine Bewertungen

- Design Rules Selective SolderingDokument20 SeitenDesign Rules Selective SolderingemirNoch keine Bewertungen

- DFX GuidelinesDokument95 SeitenDFX GuidelinesAkash VermaNoch keine Bewertungen

- A Method To Evaluate PCBA Suppliers PB Free and Leaded Processes For Telecom ApplicationsDokument12 SeitenA Method To Evaluate PCBA Suppliers PB Free and Leaded Processes For Telecom Applicationsrgoulartc100% (1)

- DFM GuidelinesDokument58 SeitenDFM Guidelinesjav_ra993986Noch keine Bewertungen

- Solder Criteris IPC-610GDokument17 SeitenSolder Criteris IPC-610GUbaldo JuarezNoch keine Bewertungen

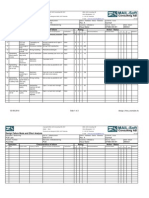

- Process Potential Failure Mode & Effects AnalysisDokument12 SeitenProcess Potential Failure Mode & Effects Analysisankit kumar100% (1)

- Avoiding The Solder VoidDokument7 SeitenAvoiding The Solder VoidReza AnvariNoch keine Bewertungen

- PFMEA at Wave Soldering-21 Dec 2016Dokument50 SeitenPFMEA at Wave Soldering-21 Dec 2016arum100% (1)

- FMEA PDokument6 SeitenFMEA Pparu1982Noch keine Bewertungen

- Ipc 6013aDokument10 SeitenIpc 6013abenmen73Noch keine Bewertungen

- What Is SMT Soldering Process Step by StepDokument12 SeitenWhat Is SMT Soldering Process Step by StepjackNoch keine Bewertungen

- Electronic MFG Overall - ShrunkDokument48 SeitenElectronic MFG Overall - ShrunkShubham SharmaNoch keine Bewertungen

- Unit 2Dokument24 SeitenUnit 2as5857Noch keine Bewertungen

- Diagrama de Flujo PropuestaDokument12 SeitenDiagrama de Flujo PropuestaSofia GonzálezNoch keine Bewertungen

- Everything You Need To Know About SMT LinesDokument6 SeitenEverything You Need To Know About SMT LinesjackNoch keine Bewertungen

- Modeling and Optimization of Stencil Printingoperations - A Comparison StudyDokument16 SeitenModeling and Optimization of Stencil Printingoperations - A Comparison StudycocozhouNoch keine Bewertungen

- 0609 User ManualDokument45 Seiten0609 User Manualmihaiparjolea100% (1)

- STARTDokument7 SeitenSTARTEngr. Christopher Lennon Dela CruzNoch keine Bewertungen

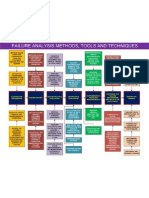

- Failure Analysis Tools, Techniques and Process FlowDokument1 SeiteFailure Analysis Tools, Techniques and Process Flowsmtdrkd100% (1)

- Generic Project Plan Template On ExcelDokument3 SeitenGeneric Project Plan Template On Excelsmtdrkd100% (36)

- Estrogen Dominance-The Silent Epidemic by DR Michael LamDokument39 SeitenEstrogen Dominance-The Silent Epidemic by DR Michael Lamsmtdrkd75% (4)

- The Story of Spanish MossDokument10 SeitenThe Story of Spanish MosssmtdrkdNoch keine Bewertungen

- PCB Surface Finishes Presentation by MultekDokument54 SeitenPCB Surface Finishes Presentation by Multeksmtdrkd100% (1)

- Why Creation of Universe Is Not An AccidentDokument48 SeitenWhy Creation of Universe Is Not An AccidentsmtdrkdNoch keine Bewertungen

- Stencil Aperture and Area Ratio Table For Optimum PrintingDokument4 SeitenStencil Aperture and Area Ratio Table For Optimum PrintingsmtdrkdNoch keine Bewertungen

- Stencil Aperture and Area Ratio Table For Optimum PrintingDokument4 SeitenStencil Aperture and Area Ratio Table For Optimum PrintingsmtdrkdNoch keine Bewertungen

- SMCWP 001Dokument37 SeitenSMCWP 001Wandyy GonçalvesNoch keine Bewertungen

- What You Always Wanted To Know About Wave Soldering But Were Afraid To AskDokument43 SeitenWhat You Always Wanted To Know About Wave Soldering But Were Afraid To Asksmtdrkd100% (4)

- Myths and Beliefs in Modern Electronic Assembly and Soldering TechniquesDokument8 SeitenMyths and Beliefs in Modern Electronic Assembly and Soldering TechniquessmtdrkdNoch keine Bewertungen

- Carnatic Music Composition DatabaseDokument142 SeitenCarnatic Music Composition Databasesmtdrkd86% (14)

- E-Book Proof of Design DFM and Concurrent EngineeringDokument425 SeitenE-Book Proof of Design DFM and Concurrent Engineeringsmtdrkd100% (7)

- Lead Free Reliability Study by BoeingDokument23 SeitenLead Free Reliability Study by Boeingsmtdrkd100% (1)

- Impact of PB Free On Test and Inspection by TeradyneDokument3 SeitenImpact of PB Free On Test and Inspection by TeradynesmtdrkdNoch keine Bewertungen

- Fantastic TripDokument68 SeitenFantastic Tripabiramikdevi100% (17)

- Simple Project Management Template On ExcelDokument2 SeitenSimple Project Management Template On Excelsmtdrkd100% (1)

- Best Practices FactoryDokument207 SeitenBest Practices FactorysmtdrkdNoch keine Bewertungen

- Manufacturable Lead Free SMT ProcessDokument4 SeitenManufacturable Lead Free SMT Processsmtdrkd100% (1)

- Dasa SahityaDokument23 SeitenDasa Sahityasmtdrkd100% (3)

- Andhragaaru RecipesDokument38 SeitenAndhragaaru Recipessmtdrkd100% (5)

- Carnatic Music Composition DatabaseDokument142 SeitenCarnatic Music Composition Databasesmtdrkd86% (14)

- Funniest QuestionsDokument34 SeitenFunniest QuestionssmtdrkdNoch keine Bewertungen

- Lead Free Hand Soldering - Process and Material IssuesDokument3 SeitenLead Free Hand Soldering - Process and Material Issuessmtdrkd50% (2)

- Kadi Jokes1Dokument14 SeitenKadi Jokes1smtdrkd67% (3)

- Idli Recipes FromDokument42 SeitenIdli Recipes Fromsmtdrkd100% (6)

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Glycemic Index and Glycemic LoadDokument36 SeitenGlycemic Index and Glycemic LoadsmtdrkdNoch keine Bewertungen

- Tiny Ph-MeterDokument7 SeitenTiny Ph-MeterrhddevNoch keine Bewertungen

- Pyronix Pyronix: Colt Quad Colt QuadDokument2 SeitenPyronix Pyronix: Colt Quad Colt QuadedosviracNoch keine Bewertungen

- CRT TV Common TroublesDokument89 SeitenCRT TV Common Troublesargie dayotNoch keine Bewertungen

- Patel Sunil R Patel Sandip A: An ISO 9001:2000 CompanyDokument44 SeitenPatel Sunil R Patel Sandip A: An ISO 9001:2000 CompanySunil PatelNoch keine Bewertungen

- Casio CDP200R ServiceManual&PartsList Jul2008Dokument28 SeitenCasio CDP200R ServiceManual&PartsList Jul2008Engkiong GoNoch keine Bewertungen

- ES3640e MFP: Maintenance ManualDokument220 SeitenES3640e MFP: Maintenance ManualkacperorNoch keine Bewertungen

- L350 L300 L355 L210 L110 Series B FixedDokument76 SeitenL350 L300 L355 L210 L110 Series B FixedFabiano LeiteNoch keine Bewertungen

- SM MFC J280W J425W J430w J435W J625DW J825DW J835DW EN 5063 PDFDokument378 SeitenSM MFC J280W J425W J430w J435W J625DW J825DW J835DW EN 5063 PDFokeinfoNoch keine Bewertungen

- EL600 Single Rudder Redundancy Setup v1.11Dokument30 SeitenEL600 Single Rudder Redundancy Setup v1.11RomanNoch keine Bewertungen

- Bitx20A Bidirectional SSB Transceiver by Ashhar FarhanDokument9 SeitenBitx20A Bidirectional SSB Transceiver by Ashhar FarhanDARU WIRANTONoch keine Bewertungen

- Lachoo Memorial College of Science and Technology (Autonomous) JodhpurDokument16 SeitenLachoo Memorial College of Science and Technology (Autonomous) JodhpurGuruji rj19Noch keine Bewertungen

- Imageprograf Ipf780 SM Rev3 022717Dokument320 SeitenImageprograf Ipf780 SM Rev3 022717Rick_IngersollNoch keine Bewertungen

- Autowatch 276 Alarm InstallationDokument2 SeitenAutowatch 276 Alarm InstallationTawanda Nyakupinda52% (31)

- Webasto Heater Remote Control: Here Is The Climate Control Unit J255 That Is Going To Be ModifiedDokument8 SeitenWebasto Heater Remote Control: Here Is The Climate Control Unit J255 That Is Going To Be ModifiedAlexanderNoch keine Bewertungen

- Woodward - Protech GiiDokument172 SeitenWoodward - Protech GiiMarioEnriqueAlcocerÁvilaNoch keine Bewertungen

- Manual 320Dokument12 SeitenManual 320Ricardo PascuaNoch keine Bewertungen

- Desulfator Silicon Chip 07 2009Dokument11 SeitenDesulfator Silicon Chip 07 2009adyhansoloNoch keine Bewertungen

- MNRE Series Guidelines For InverterDokument6 SeitenMNRE Series Guidelines For InverterJEY KEYNoch keine Bewertungen

- Marantz SR4400 Service BulletinDokument5 SeitenMarantz SR4400 Service Bulletinryosaeba666Noch keine Bewertungen

- Konica-Minolta Bizhub 423 363 283 223-101-200-1-30Dokument30 SeitenKonica-Minolta Bizhub 423 363 283 223-101-200-1-30RUBENNoch keine Bewertungen

- Alcohol Vapor Detector D.I.Y Kit: For Detecting Alcohol Vapor in Household or Workplace Environment Using The MQ3 SensorDokument9 SeitenAlcohol Vapor Detector D.I.Y Kit: For Detecting Alcohol Vapor in Household or Workplace Environment Using The MQ3 Sensorahmed chaouki ChamiNoch keine Bewertungen

- Samsung LN55C650L1FXZA Fast Track Guide (SM)Dokument4 SeitenSamsung LN55C650L1FXZA Fast Track Guide (SM)Carlos OdilonNoch keine Bewertungen

- SSP20N60S5Dokument9 SeitenSSP20N60S5Milton AlvesNoch keine Bewertungen

- Heat Transfer Analysis in Electronic Circuit Board: Amol Kharat, Sunil Ingole, Vishal MeshramDokument6 SeitenHeat Transfer Analysis in Electronic Circuit Board: Amol Kharat, Sunil Ingole, Vishal MeshramHữu HưngNoch keine Bewertungen

- Crouzet-Aerospace Brochure AircraftDokument11 SeitenCrouzet-Aerospace Brochure AircraftRavishankarNoch keine Bewertungen

- PADS2007: Alphanumeric Pins Transition GuideDokument22 SeitenPADS2007: Alphanumeric Pins Transition GuideThịnh Trịnh ĐứcNoch keine Bewertungen

- Infineon Board - Assembly - Recommendations General Package v05 - 00 EN PDFDokument43 SeitenInfineon Board - Assembly - Recommendations General Package v05 - 00 EN PDFTin NguyenNoch keine Bewertungen

- Chem m3 2Dokument10 SeitenChem m3 2NeerNoch keine Bewertungen

- Electronics Sector in India: Investment & Technology Promotion Division Ministry of External Affairs New DelhiDokument31 SeitenElectronics Sector in India: Investment & Technology Promotion Division Ministry of External Affairs New Delhiayshwarya sudheerNoch keine Bewertungen

- HCD-EC69 EC79 EC99 Manual de ServicioDokument64 SeitenHCD-EC69 EC79 EC99 Manual de ServicioJuan SerprecoNoch keine Bewertungen