Beruflich Dokumente

Kultur Dokumente

Distibutor Tubes: Important Safety Information

Hochgeladen von

Esteban Vanegas AlvarezOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Distibutor Tubes: Important Safety Information

Hochgeladen von

Esteban Vanegas AlvarezCopyright:

Verfügbare Formate

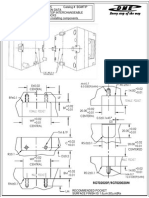

ME-0725-PS-215-B

09-08

FDP/ID

INSTALLATION DATA FOR MICRO SERIES DISTRIBUTOR TUBES,

END CAP, HEATERS AND AUTO-FIXED R "INTEGRAL HEATER"

DISTRIBUTOR PROBES, END CAPS.

Please read carefully before installing components.

REFER TO MINI-PRINT NO. 1700

IMPORTANT SAFETY INFORMATION

DISTIBUTOR TUBES

A hot-runner system includes electrical elements and may contain molten

plastic at elevated temperature and pressure. To avoid injury, exercise

caution by reading these instructions before servicing or operating the

system.

These instructions must be passed on to the end user where they should

be read before using this product. Failure to do so can result in serious

injury or death.

MATERIAL: AISI 4140 STEEL OR EQUIVALENT

HARDNESS:28-35 HRc

LENGTH

0.03 x 45

DANGER

Failure to comply will result in serious injury or death:

ELECTRICAL HAZARDS

Improper voltages or grounding can result in electrical shock. Use only

with proper voltage and a proper earth ground.

To avoid electrical shock, do not operate product when wet.

Do not operate this equipment with covers or panels removed.

To avoid electrical shock, turn off main power disconnect and lockout /

tag out before servicing this device. Do not connect temperature sensors to

electrical power. It will damage the product and it can cause fire, severe

injuries or even death.

If green ground wire present wire must be connected to the ground.

Do not rebend rigid leads. Rebending leads might result in damage to circuit.

Product might absorb moisture when cool. Use low Voltage or power to drive

out residual moisture before applying full power. Failure to do so may cause

damage to this product.

0.628

DIA.

0.375

DIA.

CATALOG NUMBER

LENGTH

HT-05-03-12

HT-05-03-16

11.82

15.76

END CAP FOR DISTRIBUTOR TUBE

MATERIAL: AISI 4140 STEEL OR EQUIVALENT

WARNING

Failure to comply can result in serious injury or death:

STORED ENERGY AND HIGH TEMPERATURE HAZARDS

This product maintains molten plastic at high pressure. Use caution when

operating and servicing the system.

Physical contact with molten plastic may result in severe burns. Proper

protective equipment, including eye protection, must be worn. This product

has heated surfaces. Use caution when operating and servicing the system

to avoid severe burns. Proper protective equipment should be worn.

THERMOCOUPLE (T/C) DISTRIBUTOR TUBE HEATERS

(240 VAC, T/C TYPE J, 34" LEADS)

O.A.L.

1"

HEATED AREA

NO HEAT AREA

1.000

0.562

0.629

+0.002

0.000

1/2-13

THREAD

DIA.

CATALOG NUMBER

1.125

0.000

-0.002

DIA.

EC-11-05

0.375 DIA.

0.750

0.14 RAD.

Note: Dimensions shown in Inches.

WIRING INFORMATION

CATALOG NUMBER

HCTC-03-4

HCTC-03-45

HCTC-03-5

HCTC-03-55

HCTC-03-6

HCTC-03-65

HCTC-03-7

HCTC-03-75

HCTC-03-8

HCTC-03-9

HCTC-03-10

HCTC-03-11

HCTC-03-12

HCTC-03-13

HEATED AREA

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

8.0

9.0

10.0

11.0

12.0

13.0

O.A.L.

5.0

5.5

6.0

6.5

7.0

7.5

8.0

8.5

9.0

10.0

11.0

12.0

13.0

14.0

WATTS

320

340

400

430

450

470

480

515

550

650

710

720

760

810

CAUTION: HANDLE LEADS WITH CARE.

POWER LEADS - MULTICOLOR

T/C LEADS - BLACK & WHITE

WHITE IS NEGATIVE (-) AND CONSTANTAN (NON-MAGNTIC)

BLACK IS POSITIVE (+) AND IRON (MAGNETIC)

D-M-E SHALL NOT BE LIABLE FOR MISUSE OR FAILURE TO FOLLOW THE ENCLOSED

INSTRUCTIONS AND SPECIFICATIONS. D-M-E HERBY TO DISCLAIMS ALL IMPLIED

WARRANTIES, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. IN NO EVENT SHALL D-M-E BE RESPONSIBLE FOR LOSS OF USE, REVENUE

OR PROFIT, OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGED.

ME-0725-PS-215-B

09-08

FDP/ID

INSTALLATION DATA FOR MICRO SERIES DISTRIBUTOR TUBES,

END CAP, HEATERS AND AUTO-FIXED R "INTEGRAL HEATER"

DISTRIBUTOR PROBES, END CAPS.

Please read carefully before installing components.

REFER TO MINI-PRINT NO. 1700

0.080 PLUS DISTRIBUTOR PROBE EXPANSION

ON ALL DISTRIBUTOR PROBE INTERSECTIONS

2.187 MIN.

2.750 MAX.

SEE NOTE #1

0.25 MAX

0.093

0.093

0.562

SEE

NOTE #3

0.750

1.000

MIN.

0.250 RAD.

TYP.

0.39

0.75

MIN.

0.080 0.010

0.250

1.00

MIN.

SEE

NOTE #2

MATERIAL, S-7 STEEL OR EQUIVALENT WITH 32-34 Rc HARDNESS.

B DIA. 0.002

RECOMMENDED RELATIONSHIP BETWEEN HEATERS,

PROBES, INTERSCTIONS AND END CAPS

1.187 MIN.

1.750 MAX.

SEE NOTE #1

0.750

MIN.

AUTO-FIXED "INTEGRAL HEATER" DISTRIBUTOR PROBES

(240 VAC, T/C TYPE J, LEADS ARE 34" LONG AND 90 )

Y

Z

CAT.

NO.

FDP0001

FDP0002

FDP0003

FDP0004

FDP0005

FDP0006

FDP0007

FDP0008

FDP0009

FDP0010

FDP0011

FDP0012

FDP0013

FDP0014

FDP0015

FDP0016

FDP0017

FDP0018

FDP0019

FDP0020

L

3.500

4.000

4.500

5.000

5.500

6.000

6.500

4.000

4.500

5.000

5.500

6.000

6.500

7.000

7.500

8.000

8.500

9.000

9.500

10.000

EXPANB

C

D

E

SION WATTS A

0.004

175

0.004

200

0.005

225

0.005

250 0.394 0.384 0.740 0.394 0.750

0.006

275

0.006

295

0.007

320

0.004

315

0.005

355

0.005

395

0.006

430

0.006

470

0.007

510

0.007

550 0.625 0.615 1.240 0.625 1.125

0.008

590

0.008

630

0.009

670

0.009

705

0.010

745

0.010

785

0.000

D DIA. -0.005

FULL RAD.

E 0.010

0.500 0.002

0.50 0.005

L

NOTE: PROBE DISCOLORATION

Each Integral Heater probe sold by

D-M-E is pre-tested. This procedure

discolors the outer surface of the

probe, but in no way alters its

performance or dimensions.

REPLACEMENT THERMOCOUPLE

(ALL PROBES)

CATALOG NUMBER

LEAD LENGTH

TC-9900

48"

END CAPS FOR DISTRIBUTOR PROBES

NOTES:

1. Due to the longer no heat section atthe Lead end, heater

will not be centered in distributor tube.

X

Y

Z

DISTRIBUTOR

2. The use of (4) 3/8-16 hardened socket head cap screws

MIN. MIN. MIN.

PROBE

with 1.00 minimum thread engagement into mold is recom

0.394 DIA.

0.788 0.500 1.375 -mended to secure end caps to mold. (Solid Block and

Split Plate Distributor System) Screws must be tightened

0.625 DIA.

1.250 0.875 1.375 evenly and torqued to 25-30 foot pounds.

3. The use of (2) 0.250 dia. dowel pins with 0.562 distance

between dowel pin and end cap centerlines is recommended

to secure end cap into mold

(Solid Block Distributor System only).

MATERIAL, AISI 4140 STEEL OR EQUIVALENT WITH 28-35 Rc HARDNESS

DRILLED AND

C'BORED FOR

# 3/8-16 S.H.C.S

1.125

A

0.25

F

D

D

E

B

RECOMMENDED RELATIONSHIP BETWEEN

DISTRIBUTOR PROBE AND SUPPORT PINS

Note: Dimensions shown in Inches.

0.25 x 45 (4)

0.005 TYP.

2 PIECE CONSTRUCTION

# THREAD ENGAGEMENT INTO MOLD MUST BE 1.00 MINIMUM AND TORQUED TO

25-30 FOOT POUNDS.

0.005 TYP.

45

CAT. NO.

SL

DIM

A

NOTE: - SL SPLIT LINE OF MOLD

0.000

C DIA. -0.002

DISTRIBUTOR

PROBE

0.394 DIA.

0.625 DIA.

ECP0003

ECP0006

0.394 DIA.

0.625 DIA.

0.394 DIA. DISTRIBUTOR 0.625 DIA.

DISTRIBUTOR MACHINING

MACHINING

PROBE

PROBE

+0.010

+0.010

1.98

2.49

2.000 -0.000

2.500 -0.000

+0.010

-0.000

+0.010

-0.000

1.98

2.000

+0.001

1.124

1.125 -0.000

0.875

0.375

-

1.98

2.000

0.874

0.139

0.221

D

E

F

0.656

0.437

0.500

0.875 -0.000

0.656

0.437

-

0.875

0.375

0.875

+0.001

D-M-E COMPANY

29111 STEPHENSON HIGHWAY

MADISON HEIGHTS

MICHIGAN 48071 USA

1-800-626-6653

www.dme.net

Das könnte Ihnen auch gefallen

- ADWEA I&C InstallationDokument32 SeitenADWEA I&C InstallationAyman Termanini100% (2)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialVon EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Service Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsDokument30 SeitenService Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsHenry Javier RíosNoch keine Bewertungen

- Allenwest Relay R Type InstructionsDokument4 SeitenAllenwest Relay R Type InstructionsTerry Russell100% (1)

- Yorkville AM100 Service ManualDokument10 SeitenYorkville AM100 Service Manualcaimanater100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Chemistry Matters Ch07 Textbk ANSDokument4 SeitenChemistry Matters Ch07 Textbk ANSZeneon67% (12)

- Out of Plane Design of Masonry Walls Strength Design ExampleDokument37 SeitenOut of Plane Design of Masonry Walls Strength Design Examplegullipalli100% (4)

- Micro Probes Auto-Fixed Integral Heater: ME-0725-PS-216-B AFIP/IDDokument2 SeitenMicro Probes Auto-Fixed Integral Heater: ME-0725-PS-216-B AFIP/IDEsteban Vanegas AlvarezNoch keine Bewertungen

- ACB ManualDokument24 SeitenACB Manual4usangeet100% (1)

- 0859 Solid State Relays Data SheetDokument23 Seiten0859 Solid State Relays Data SheetJaime MorenoNoch keine Bewertungen

- 0859 Solid State Relays Data SheetDokument23 Seiten0859 Solid State Relays Data SheetglennandlynneNoch keine Bewertungen

- Gaumer Process Heaters, Systems, and ControlsDokument43 SeitenGaumer Process Heaters, Systems, and ControlskmpoulosNoch keine Bewertungen

- Multi Wave ManualDokument68 SeitenMulti Wave ManualСања БанковићNoch keine Bewertungen

- Me 0708 PS 014Dokument2 SeitenMe 0708 PS 014Esteban Vanegas AlvarezNoch keine Bewertungen

- He A IgnitorDokument36 SeitenHe A IgnitorE.C.MADHUDUDHANA REDDYNoch keine Bewertungen

- C-Power 02052013Dokument31 SeitenC-Power 02052013Nikhil SinghNoch keine Bewertungen

- P6 Limit SwitchDokument3 SeitenP6 Limit SwitchABCdude1Noch keine Bewertungen

- Manual de Mantenimiento BS2640.180Dokument28 SeitenManual de Mantenimiento BS2640.180Roberto Daniel Sanchez MelgarejoNoch keine Bewertungen

- Refrigerant Detection and Pump Down Systems - Installation and Application ManualDokument56 SeitenRefrigerant Detection and Pump Down Systems - Installation and Application Manualafelipef27Noch keine Bewertungen

- LNT CN CsDokument31 SeitenLNT CN Csgirish19100% (1)

- Eaton CoilDokument28 SeitenEaton Coilramana3339Noch keine Bewertungen

- c-power-ACB (L&T)Dokument31 Seitenc-power-ACB (L&T)Navneet Singh67% (3)

- Catalogo IndoAsian Switch DisconnectorsDokument8 SeitenCatalogo IndoAsian Switch DisconnectorsjackiwongzNoch keine Bewertungen

- Explosion Proof LED Floodlight - CatalogDokument9 SeitenExplosion Proof LED Floodlight - CatalogJames YoungNoch keine Bewertungen

- SCOH-K Tech Guide 0705Dokument48 SeitenSCOH-K Tech Guide 0705Emir OmerdicNoch keine Bewertungen

- 250 Series Extended Sprue Gate Nozzle Installation Data: Machining DetailsDokument2 Seiten250 Series Extended Sprue Gate Nozzle Installation Data: Machining DetailsEsteban Vanegas AlvarezNoch keine Bewertungen

- Catalog: General Purpose Plug-In RelaysDokument12 SeitenCatalog: General Purpose Plug-In Relaysmicaziv4786Noch keine Bewertungen

- Robertshaw - Electrical ThermostatsDokument3 SeitenRobertshaw - Electrical ThermostatsKhairul MuzafarNoch keine Bewertungen

- DS Catalogue Fuses Redspot English UkDokument48 SeitenDS Catalogue Fuses Redspot English UkSamraj MahalingamNoch keine Bewertungen

- Air Circuit BreakerDokument13 SeitenAir Circuit BreakercjtagayloNoch keine Bewertungen

- Series: Inductors For Standard CircuitsDokument13 SeitenSeries: Inductors For Standard CircuitsAriana Ribeiro LameirinhasNoch keine Bewertungen

- Data KapasitorDokument7 SeitenData KapasitorMuhammad Ardi AnggaraNoch keine Bewertungen

- PTC B571Dokument10 SeitenPTC B571DJ KENTNoch keine Bewertungen

- Rin HeaterDokument2 SeitenRin Heaterbalbianj100% (1)

- Horizontal Steam and Hot Water Unit Heaters: 260 North Elm St. Westfield, Ma 01085Dokument24 SeitenHorizontal Steam and Hot Water Unit Heaters: 260 North Elm St. Westfield, Ma 01085Aqeel BismaNoch keine Bewertungen

- F Disconnect SwitchesDokument17 SeitenF Disconnect SwitchesgarysNoch keine Bewertungen

- SibaDokument82 SeitenSibaJuanita EspinozaNoch keine Bewertungen

- Schrack Miniature Relay PT: General Purpose RelaysDokument4 SeitenSchrack Miniature Relay PT: General Purpose RelaysMelih GuneriNoch keine Bewertungen

- Fuse Switch & Switch FuseDokument6 SeitenFuse Switch & Switch FusePriyamwada PawarNoch keine Bewertungen

- FR390Dokument18 SeitenFR390Rayen RamzaanNoch keine Bewertungen

- Anixter TECK Control CablesDokument2 SeitenAnixter TECK Control CablesAnonymous KsH6a0JNoch keine Bewertungen

- FR630 662 700NT PDFDokument44 SeitenFR630 662 700NT PDFwilmerk_159990Noch keine Bewertungen

- DC REGULATED POWER SUPPLY NP-9912 - Service - Manual PDFDokument12 SeitenDC REGULATED POWER SUPPLY NP-9912 - Service - Manual PDFDa ElNoch keine Bewertungen

- Esab Lua 400Dokument164 SeitenEsab Lua 400Pedro Gandia BonetNoch keine Bewertungen

- Water Cooled Package Service NewDokument23 SeitenWater Cooled Package Service NewDiêm Công ViệtNoch keine Bewertungen

- VEVOR Water ChiilerDokument20 SeitenVEVOR Water ChiilerKenny HebertNoch keine Bewertungen

- Pinnacle - Welder - Super160manualDokument13 SeitenPinnacle - Welder - Super160manualhdquanNoch keine Bewertungen

- 1016Dokument46 Seiten1016Jorge DovaleNoch keine Bewertungen

- 160.75-RP1 (210) - Yk (G)Dokument92 Seiten160.75-RP1 (210) - Yk (G)JayashtonNoch keine Bewertungen

- GR Yg55daa (GB) PDFDokument38 SeitenGR Yg55daa (GB) PDFplumber1900Noch keine Bewertungen

- WTCPT Oi PLDokument4 SeitenWTCPT Oi PLomglol2kNoch keine Bewertungen

- 1NT - Fixed Temperature ThermostatsDokument6 Seiten1NT - Fixed Temperature ThermostatsjpntjpntNoch keine Bewertungen

- Sddje: 10A 250V AC Qualified TypeDokument6 SeitenSddje: 10A 250V AC Qualified TypeshyhuNoch keine Bewertungen

- Com-Power NW h1t-h1th, NT h2t With Tesys F - Tds25 (Web)Dokument6 SeitenCom-Power NW h1t-h1th, NT h2t With Tesys F - Tds25 (Web)Anderson TpsNoch keine Bewertungen

- Rele Tyco Rt424024sDokument3 SeitenRele Tyco Rt424024sJose G. Cantillo L.Noch keine Bewertungen

- Uh Svx01a en - 09032008 (Trane Unit Heaters)Dokument60 SeitenUh Svx01a en - 09032008 (Trane Unit Heaters)kayeleNoch keine Bewertungen

- Diodo Mur460Dokument7 SeitenDiodo Mur460marnoonpvNoch keine Bewertungen

- Inverter FR-A800 Installation GuidelineDokument82 SeitenInverter FR-A800 Installation Guidelineprsking187Noch keine Bewertungen

- Strato 35 Series and 70 Series :: ROAL Living EnergyDokument5 SeitenStrato 35 Series and 70 Series :: ROAL Living EnergyroalscribdNoch keine Bewertungen

- SDS271 Diamond CompoundDokument7 SeitenSDS271 Diamond CompoundEsteban Vanegas AlvarezNoch keine Bewertungen

- Abrasive Stones - General Purpose Type A and BDMEabstonesab-msdsDokument6 SeitenAbrasive Stones - General Purpose Type A and BDMEabstonesab-msdsEsteban Vanegas AlvarezNoch keine Bewertungen

- Mold SaverDMEsav-msds 1Dokument7 SeitenMold SaverDMEsav-msds 1Esteban Vanegas Alvarez100% (1)

- D-M-E In2 Innovative Interlocks: Mold Base MachiningDokument2 SeitenD-M-E In2 Innovative Interlocks: Mold Base MachiningEsteban Vanegas AlvarezNoch keine Bewertungen

- Jumbo Gate-Mate Nozzle Assemblies Installation Data: ME-0739-PS-051-C Gmn-PsDokument2 SeitenJumbo Gate-Mate Nozzle Assemblies Installation Data: ME-0739-PS-051-C Gmn-PsEsteban Vanegas AlvarezNoch keine Bewertungen

- Heater Replacement Instructions For Point Gate and Thru Hole TipsDokument2 SeitenHeater Replacement Instructions For Point Gate and Thru Hole TipsEsteban Vanegas AlvarezNoch keine Bewertungen

- D-M-E Mold Straps: Important Safety InformationDokument1 SeiteD-M-E Mold Straps: Important Safety InformationEsteban Vanegas AlvarezNoch keine Bewertungen

- Me 06 0005 0011Dokument2 SeitenMe 06 0005 0011Esteban Vanegas AlvarezNoch keine Bewertungen

- S-Series Straight-Shot T-Series Straight-ShotDokument2 SeitenS-Series Straight-Shot T-Series Straight-ShotEsteban Vanegas AlvarezNoch keine Bewertungen

- DMEInternalLatchLock DKL CAMFingerRemoval InstallationDokument5 SeitenDMEInternalLatchLock DKL CAMFingerRemoval InstallationEsteban Vanegas AlvarezNoch keine Bewertungen

- Me 100005 0227Dokument2 SeitenMe 100005 0227Esteban Vanegas AlvarezNoch keine Bewertungen

- Maintenance Guide: Things To Look ForDokument1 SeiteMaintenance Guide: Things To Look ForEsteban Vanegas AlvarezNoch keine Bewertungen

- Me 06 0005 0012Dokument2 SeitenMe 06 0005 0012Esteban Vanegas AlvarezNoch keine Bewertungen

- "N" "N" "N" "N" R0.125: Me-X741-Ps-421 (B)Dokument2 Seiten"N" "N" "N" "N" R0.125: Me-X741-Ps-421 (B)Esteban Vanegas AlvarezNoch keine Bewertungen

- 250 Series Extended Sprue Gate Nozzle Installation Data: Machining DetailsDokument2 Seiten250 Series Extended Sprue Gate Nozzle Installation Data: Machining DetailsEsteban Vanegas AlvarezNoch keine Bewertungen

- Installation Data For: 250 & 375 Series Point Gate NeedleDokument2 SeitenInstallation Data For: 250 & 375 Series Point Gate NeedleEsteban Vanegas AlvarezNoch keine Bewertungen

- Poisson's RatioDokument20 SeitenPoisson's RatioFaiz HaikalNoch keine Bewertungen

- Indraero Siren 120 050 00Dokument40 SeitenIndraero Siren 120 050 00bobbyflorezNoch keine Bewertungen

- 2 TFB 4Dokument16 Seiten2 TFB 4blasspascalNoch keine Bewertungen

- Auma - Gear OperatorsDokument30 SeitenAuma - Gear Operatorsnabil160874100% (1)

- 11 Equip+water+toiletDokument14 Seiten11 Equip+water+toiletTharrmaselan manimaranNoch keine Bewertungen

- Forced Convection OvenDokument4 SeitenForced Convection Ovensaurabh_acmasNoch keine Bewertungen

- Air Cooled Water Cooled Scroll Chiller SDokument93 SeitenAir Cooled Water Cooled Scroll Chiller SSaleem BashaNoch keine Bewertungen

- Barekar2014P Overview of Twin Roll Casting of Al AlloysDokument12 SeitenBarekar2014P Overview of Twin Roll Casting of Al AlloyskishoreNoch keine Bewertungen

- Envelop Protective Covers Material SpecificationsDokument2 SeitenEnvelop Protective Covers Material SpecificationsronhuttonNoch keine Bewertungen

- Factory Visit ReportDokument14 SeitenFactory Visit ReportSarvesh Kant ThakurNoch keine Bewertungen

- Theog Lift TD 080615Dokument52 SeitenTheog Lift TD 080615HemantSharmaNoch keine Bewertungen

- Activated Sludge Wastewater Treatment Processes and Control of Foam FormationDokument10 SeitenActivated Sludge Wastewater Treatment Processes and Control of Foam FormationGeorge MarkasNoch keine Bewertungen

- Lesson 14 WelderQuals - New2Dokument80 SeitenLesson 14 WelderQuals - New2Mohd Syafiq100% (1)

- Triaxial TestDokument3 SeitenTriaxial TestkanyisileNoch keine Bewertungen

- Barry Bcdi All Elastomer IsolatorsDokument10 SeitenBarry Bcdi All Elastomer IsolatorsdouglascoombsNoch keine Bewertungen

- Final Salt AnalysisDokument8 SeitenFinal Salt AnalysisAnonymous SomeoneNoch keine Bewertungen

- Solid Liquid Seperation PDFDokument30 SeitenSolid Liquid Seperation PDFduvanp92Noch keine Bewertungen

- Generic PID DefinitionsDokument4 SeitenGeneric PID DefinitionsNicoara Stoica Paul FlorinNoch keine Bewertungen

- Flare System PDFDokument41 SeitenFlare System PDFAzar Deen100% (1)

- Q150 R Plus Brochure V1Dokument4 SeitenQ150 R Plus Brochure V1toansNoch keine Bewertungen

- Kaizen WorkshopDokument24 SeitenKaizen WorkshopShiraz S. Syed100% (1)

- Characteristics, Applications, and Processing of Stress - Strain Behavior (I)Dokument7 SeitenCharacteristics, Applications, and Processing of Stress - Strain Behavior (I)nelson bessoneNoch keine Bewertungen

- Polymer Nanoparticles Preparation Techniques and Size-ControlDokument27 SeitenPolymer Nanoparticles Preparation Techniques and Size-ControlsahtehesabmNoch keine Bewertungen

- Food Technology and Biotechnology - StrawberryDokument8 SeitenFood Technology and Biotechnology - StrawberryIfenza HernandaNoch keine Bewertungen

- Metal Cutting Processes 1 - TurningDokument14 SeitenMetal Cutting Processes 1 - TurningmostafaNoch keine Bewertungen

- STD - Form of Separation (IEC 60439-1)Dokument7 SeitenSTD - Form of Separation (IEC 60439-1)Kiliardt ScmidtNoch keine Bewertungen

- Qualitest Canada BrochureDokument7 SeitenQualitest Canada BrochureBala SingamNoch keine Bewertungen