Beruflich Dokumente

Kultur Dokumente

Us 4676137

Hochgeladen von

wererCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Us 4676137

Hochgeladen von

wererCopyright:

Verfügbare Formate

Q

Umted States Patent [191

[11] Patent Number:

Stockton et al.

[45]

[54]

2,522,337

, , 7 6/1980

6/1982 Tay

Gyfzrik

or, Jr.

.................................. ..

WEAPON FIREARM WITH MAGAZINE

[75] Inventora galrlrenbD- ?totflgogl; 1\i/{ill1i=1e(l:1;f

ier,

0t

aersie

Jun. 30, 1987

/

4,487,103 12/1984 Atchisson ......................... .. 219/3102

a1.

[73] Assigneez

Date of Patent:

4,676,137

Primary Examiner-John F. Terapane

Kern Instrument & Tooling, Inc.,

Assistant Examiner__john S Maples

Bakers?eld cahf'

Attorney, Agent, or FirmRoylance, Abrams, Berdo &

[21] Appl. No.: 736,071

[22] Filed:

May 20,1985

Goodman

[57]

[51]

[52]

Int. cu ............................................ .. F41C 25/10

us. 01. ................................................. .. 219/3102

The disdosure relates to ?rearms, especially recoil or

gas operated ?rearms, having a receiver for cartridges,

[58]

Field of Search .................... .. 89/33.02; 42/19, 17

.

and having a magazine for containing a plurality of

cartridges. The magazine can be disposed above and

[56]

References Clted

US PATENT DOCUMENTS

substantially parallel with respect to the barrel. The

magazine includes a housing with a helically disposed

84,685 12/1868 Evans ............................... .. 42/49 01

1,285,263 11/1918 Lohne

1,293,396 2/1919 Fox

23319376

12/1952

015 - ~ - ~ -

89/33.02 X

89/33.02 X

' ' - ' - ~ ' '- 89/33

532C231:

3,747,249

member Providing a helical passageway for the Car

tridges. The cartridges are supported on a cartridge

carrier located in the housing, which can be rotated by

a torque spring. The cartridges are unloaded from the

magazine by a feed lip insert providing communication

7/1973

Ouellette . . . . . . . .

. . . . .. 42/50

3,766,823 10/1973

Folsom et a], .

89/33 D

4,166,408

ABSTRACT

9/1979 Wetzel et al. .................... .. 89/33 D

"th the recelver f the ?rearm

7 Claims, 4 Drawing Figures

4,676,137

2

SUMMARY OF THE INVENTION

WEAPON FIREARM WITH MAGAZINE

A primary aspect of our invention is that the maga

zine is positioned atop the ?rearm so that the longitudi

nal central axis of the magazine extends parallel with

(1) Field of the Invention

respect to the longitudinal central axis of the receiver

This invention may be classi?ed in Class 49 and ap

and/or the barrel of the ?rearm. Accordingly, use can

propriate sub-classes.

be made of gravity in the transfer of cartridges from the

The present invention is concerned with an improved

magazine to the ?ring mechanism of the ?rearm.

?rearm and, more particularly, relates to a ?rearm or 10

The magazine of our invention consists of a longitudi

similar weapon with a magazine which is adapted to

nal cylindrical outer shell, or similar housing, which is

contain or house a large number of rounds or cartridges.

equipped with an interior helically disposed rib mem

Still more particularly, the invention relates to a ?re

ber. Accordingly, a substantially continuous, helical

arm, e. g. a recoil or gas operated ?rearm, constructed in

passageway is formed in and over substantially the full

BACKGROUND OF THE INVENTION

such a manner that it can receive and accept cartridges

length of the housing by the ?ights of the rib member.

It is preferred that the helical rib member is disposed

stored in and delivered from the magazine according to

our invention.

in such a way that its lead is equal to its width plus the

(2) Prior Art

Warren Evans patented a repeating ri?e in 1868,

length of the cartridge, and that its height is approxi

wherein the butt-stock houses an ammunition carrier in 20

the form of an Archimedian screw, which ammunition

carrier has a capacity of 26 cartridges. The breech

mechanism would be operated by an under-leverwhich

also rotates the carrier, with the pitch of the screw

mately one-half of the diameter of a respective car

tridge.

To complement the helical passageway, the magazine

also includes a generally cylindrical cartridge carrier or

similar driver having longitudinal ridges and grooves in

its outer surface for aligned retention of the cartridges.

being such so as to deliver one cartridge for each stroke 25 The ridges and grooves give a ?ute-like appearance to

of the lever. The primary disadvantage of the weapon

the carrier or driver, and such ?utes can be either

of Evans is the slow and cumbersome process of loading

the ammunition carrier. Only upon being fully loaded

and rotated by 26 strokes of the operating lever is the

?rst round delivered to the breech.

The prior art also includes US Pat. No. 1,285,263

issued Nov. 19, 1918, to Lohne. The patent of Lohne is

concerned with a magazine including a cylindrical con

tainer into the wall of which is formed a continuous

straight, i.e. parallel with respect to the longitudinal

central axis of the driver, or alternatively they can also

be helically disposed on the outer circumferential wall

of the driver. The respective cartridges are disposed in

aligned manner in the grooves of the driver.

The cartridge carrier has a longitudinal central pas

sage for arranging therein a spring for the provision of

motive power to the cartridge carrier and consequently

groove which serves to guide a helical screw-type 35 the cartridges arranged thereon in the grooves. It is

feeder, and a slide or driver is adapted to progress along

preferred that the drive spring be a torque spring.

the path of the respective screw for moving the car

Thus, the cartridge carrier or driver can be rotated

tridges forward.

US Pat. No. 1,353,092 issued Sept. 14, 1920, to

Thompson et a1 relates to a cartridge magazine of the

within the housing and the cartridges positioned in the

grooves are then advanced or pushed forward along the

helical passageway by way of the ?ights of the helical

rotary type combining with its functions as a magazine

rib member.

.

that of lubricating the ammunition which it contains.

A feed ramp, or feed lip insert or similar element, is

U.S. Pat. No. 2,619,876 issued Dec. 2, 1952, to Olson

arranged at the exit terminus of the housing. Accord

discloses a magazine ri?e in which a magazine is ?xed 45 ingly, when the ?rst cartridge encounters this terminus,

beneath and disposed longitudinally of the barrel. The

it is taken out of the helical passageway and is passed

cartridges are located in groups in the magazine and are

through an opening in the housing or outer magazine

presented in groups and by way of spring pressure, into

the receiver. The cartridges are then individually

shell to lodge it in the feed lip insert and in proper posi

tion for the ?rearm bolt which will push it forward into

moved into the path of the breech bolt so that the latter

the ?ring chamber. As one cartridge is removed to the

may force successive cartridges into the ?ring chamber.

chamber of the ?rearm, the cartridge carrier is allowed

The more recent US. Pat. No. 4,166,408, issued Sept.

to rotate again, due to the spring being temporarily

4, 1979, of Wetzel et a1, is concerned with an ammuni

slightly released when a cartridge is transferred to the

tion handling system for storing and for feeding ammu

?rearm, and the next cartridge is advanced.

nition at high velocity which is embodied in a system 55

The helical torque spring arranged within the car

for storing and feeding linkless rounds of ammunition to

tridge carrier is ?xed at one end thereof to the cartridge

a high rate of ?re machine gun, as in a pod externally

mounted to an aircraft.

carrier and the other end is attached to an end cap of the

housing. The end cap can be manually rotated to load or

In conventional ?rearms it is also a detriment with

tension the spring, and is prevented from slipping back

respect to magazines that protrude perpendicularly

60 by a ratchet formation at the end of the housing. The

downward from the ?rearm because this mounting

end cap can be manually disengaged to allow cartridges

to be loaded into the magazine prior to tensioning the

attitude tends to cause undesirable interference and

imbalances.

torque spring.

There has continued to remain, accordingly, the need

It is also preferred that the magazine is placed above

to provide an improved ?rearm, for example a recoil or 65 the ?rearm receiver. This is bene?cial because the mass

of the magazine and the contained cartridges will help

gas operated or similar weapon, and a magazine there

to counteract the tendency of the ?rearms muzzle to

fore which are adapted to preclude disadvantages of the

rise after each slot.

prior art ?rearms and magazines.

4,676,137

The ?rearm includes means to accept the magazine,

to orient the magazine, to secure the magazine, and to

release the magazine, for example when it is empty.

Thus, the forearm has an opening at the top of the

receiver to allow insertion of the feed lip arrangement

of the magazine. The ?rearm also includes detents and

mechanisms to correctly orient and grasp the magazine.

The ?rearm otherwise allows customary ?ring of the

cartridges or rounds emanating from the magazine.

zine 20 is in the operative position, the longitudinal

central axis 22 thereof is located above and generally

parallel to the respective axis 16 of the ?rearm receiver

13, and/or parallel to the longitudinal central axis 19 of

barrel 3. Of course, the magazine 20 is then generally

positioned above and parallel to the forearm of a user.

The magazine 20 is secured to the ?rearm 1 by means

of a front socket and pin detent, shown schematically at

the front of magazine 20, but not shown in detail, for

10 holding the magazine 20 on the ?rearm 1, and there is

Included in the objects of our invention are:

also provided a spring pin detent 23 at the bottom rear

To provide a ?rearm and a magazine therefor which

of the magazine for this purpose.

can be easily and quickly utilized by a user.

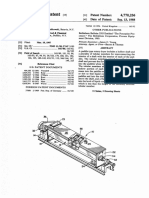

A helical member 24 is arranged on the interior wall

To provide a ?rearm and magazine therefor which

of housing 21, and it terminates near a feed lip insert, or

are balanced for more accurate ?ring of the ?rearm.

To provide a ?rearm which is of minimum frontal

area and overall size for use in a con?ned space.

To provide a magazine which is widely applicable to

various ?rearms and calibers, including semi-automatic

handguns, ri?es, carbines, and shotguns.

BRIEF DESCRIPTION OF THE DRAWINGS

feed ramp arrangement, designated by reference nu

meral 25, see FIG. 4, at the forward terminus. The

rearward end of the housing 21 is closed by an end cap

or winder 26.

A ratchet wheel formation 27 is provided near the

rearward end of the housing 21. The respective ratchet

teeth of this formation are adapted to meshingly coop

erate with corresponding teeth in the winder 26. The

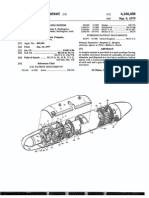

FIG. 1 is a side elevation showing a pistol with the

ratchet wheel formation 27 can be integrally molded

cartridge magazine in accordance with one embodiment

with the housing 21.

of the invention.

The helical member 24 forms a continuous helical

FIG. 2 is a perspective exploded view showing in 25

groove or a similar passageway between its helical

greater detail the various elements of the magazine in

flights. It is preferred that the helical rib member or rib

accordance with one embodiment of the invention.

24 be disposed in the magazine housing 21 in such a way

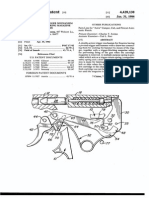

FIG. 3 is a perspective exploded view showing in

so that its lead or pitch is equal to its width plus the

greater detail the ratchet arrangement for the magazine.

length of a cartridge 14, and its height is approximately

FIG. 4 is a perspective view showing the feed lip

half

the diameter of a respective cartridge 14.

insert at the forward terminus of the magazine.

The inclined feed lip insert 25 is arranged at the for

SPECIFIC DESCRIPTION

ward terminus of the helical passage or contained heli

cal path in the outer shell or housing 21, and this feed lip

In the drawing like reference characters designate

35 insert 25 will direct cartridges 14 away from a core or

like elements in the various views of the drawings.

similar cartridge carrier 30 out of the housing 21, for

In this speci?cation and the following claims the

presenting them in succession from above to the open

directional indications are with respect to the ?rearm,

ing 15 of the ?rearm 1.

thus forwardly and the like terminology means in the

Thus, the rib member 24 leaves room for the inner

direction of the discharge of the ?rearm and rear

wardly and the like expressions indicate the opposite

direction.

As suggested in FIG. 1, the ?rearm 1, is exempli?ed

by a hand-held pistol, say a recoil or gas operated unit.

The ?rearm 1 has a handle or grip 2 and a barrel 3

and generally cylindrical cartridge carrier 30. Longitu

dinal upstanding ribs or ridges 31 and rounded grooves

or channel formations 32 are provided on the outer

surface of the cartridge carrier 30. The ridges 31 and

rounded channel or groove formations 32 also extend in

secured forwardly of the handle 2. A ?ash suppressor 4 45 the longitudinal direction of axis 22. The cartridge car

rier 30 has a longitudinal bore or similar central passage,

is mounted on the forward end of the barrel 3. A bolt

i. e. a hole 33 when viewed in cross section.

guide cover 5 surrounds the barrel 3 and a bolt pin 6

The central longitudinal bore 33 serves to receive

with its respective bolt pin spring 7. The ?rearm 1 in

therethrough

a drive spring 35 having a forward end

cludes a trigger 8 protected by a trigger guard 9, and the

35.1 and a rearward end 35.2. It is preferred that the

trigger 8 is adapted to actuate a hammer 10 by way of

drive spring 35 be a torque spring adapted to provide

turning power to the cartridge carrier 30.

Thus, the magazine 20 for the ?rearm 1 is comprised

the associated hammer pin 11, with a hammer pin spring

12 providing the attendant biasing force.

A receiver 13 is provided atop the barrel 3 for intro

ducing cartridges 14 into the ?rearm 1. The receiver 13

has a receiver opening 15 (see FIG. 4) adapted in its size

of an outer cylindrical shell or housing 21 having a

helical member 24 af?xed therein to form a helical pas

to that of the cartridges 14, as well as having a respec

tive axis 16. As is customary in ?rearms of this type, the

cartridges 14 can be serially introduced into a breech 17

sageway for the cartridges 14, and having a separate

hollow core or cartridge carrier 30 which can be ro

tated inside the helical member 24 by way of torque ,

for an understanding of our invention.

be propelled radially and longitudinally along the heli

spring 35. The cartridge carrier 30 has in its circumfer

which is connected to the ?ring chamber 18 for ?ring

through the action of the bolt, i.e. bolt pin 6, and associ 60 ence longitudinally disposed grooves 32 in which the

cartridges 14 are positioned and these, accordingly, can

ated known parts which need not be further described

cal passageway formed by the helical member 24.

Mounted atop the ?rearm 1 is a magazine assembly

20, referred to as magazine hereinafter, which contains

OPERATION

and moves the cartridges 14 for ?ring from the ?rearm 65

The

helical

torque

spring 35 can be wound-up by

1. The magazine 20 includes a hollow cylindrical maga

turning the winder 26 appropriately. The spring 35 can

zine housing 21 which is releasably mounted atop the

then operate as a spring drive or motor when the stored

?rearm 1. This mounting is such that, when the maga

4,676,137

Reference in this disclosure to details of the speci?c

tension is released. The spring 35 applies a radial torque

embodiments is not intended to restrict the scope of the

to the cartridge carrier 30 and propels the cartridges 14

appended claims, which themselves recite those fea

along the helical passageway in the housing 21 towards

tures regarded as essential to the invention.

the feed lip insert 25 that retains the cartridges in posi

We claim:

tion ready for the ?rearms bolt, i.e. bolt pin 6, to propel

1. In combination, a ?rearm and cartridge magazine,

it into the ?ring chamber 18, upon selection of this

said ?rearm comprising a receiver opening for receiv

action.

ing cartridges from said magazine seriatim, said maga

The feed lip insert 25 extends radially away from the

zine having an elongated generally cylindrical con?gu

housing 21 thereby providing a guide which enters or

ration and a longitudinal axis, means to store a relatively

merges into the receiver opening 15 in the upper por

large number of cartridges in said magazine, said maga

tion of the receiver 13. Accordingly, the cartridges 14

zine comprising means forming a helical cartridge feed

are aligned and oriented in the magazine well to the rear

path therein, said cartridges being stored in said maga

of the ?rearm 1. The cartridges are also appropriately

zine with their axes generally parallel to said longitudi

held in a position directly above and parallel to the

nal axis of said magazine, said magazine comprising

?rearms receiver 13 with the housings feed lip insert

cartridge exit means positioned on said magazine at the

25 being nested within the opening 15 of the receiver 13.

front end thereof, said cartridge exit means being coop

The magazine 21 is readily lifted from the ?rearm due

erable with said ?rearm receiver opening to feed said

to the socket and pin detent in the front, and the associ

cartridges into said opening seriatim, power driving

ated spring pin detent 23 at the bottom rear of the maga

zine. Together these two means locate and hold the 20 means for feeding said relatively large number of car

tridges in said helical feed path through said magazine

magazine 20 in the proper relationship with respect to

and out said exit means, said power driving means com

the ?rearm 1 during transfer of cartridges 14 from the

prising a helical torque spring having suf?cient strength

housing 21 to the receiver opening 15 of the ?rearm 1.

to drive all of said relatively large number of cartridges

The helical drive or torque spring 35 is attached with 25

out of said magazine, means for selectively and manu

its end 35.2 joined to the winder 26, but allowing turn

ally energizing said power driving means including

ing or rotation of the winder to wind-up or tension the

means to permit winding of said helical spring indepen

spring 35.

When the cartridge carrier 30 rotates within the

housing 21, the cartridges 14 lying in the longitudinal

grooves 32 are pushed forward or advanced by the

helical member 24. At the terminus of the helical pas

sageway, the cartridges 14 are passed through the feed

dently of the loading and unloading of cartridges into

and out of said magazine; whereby said cartridges may

be loaded into said magazine with said power driving

means relaxed and whereby said power driving means

may be manually energized immediately prior to use of

said ?rearm and magazine; and means to mount said

lip insert 25 into the receiver opening, in proper position

magazine above said ?rearm with its longitudinal axis

for the ?rearm bolt pin 6 to push then forward into the 35 parallel to the line of ?re of said ?rearm and with said

?ring chamber 18. As one cartridge 14 is removed to

exit means in operative cooperation with said receiver

the chamber 18, the cartridge carrier 30 is allowed to

opening and with the weight of said magazine and of

rotate, thus presenting the contained cartridges in suc

said relatively large number of cartridges located rear

cession to the ?rearm receiver 13. This rotation occurs

wardly of said receiver opening means in said ?rearm

because of the helical torque spring 35 arranged within 40 and above and in line with the line of ?re of said ?rearm.

the cartridge carrier

2. The combination of claim 1, said exit means com

The winder 26 is rotated manually to load the spring

35 and is prevented from slipping back by the ratchet

formation 27 and the matching teeth of the winder 26.

In summary, an easier loading of the cartridges 14 is 45

attained than hitherto experienced in similar ?rearms,

with the feed lip insert 25 in the housing 21 supplying

them to the opening 15.

A ?rearm can readily be equipped with the magazine

by having an opening 15 at the top of the receiver 13 50

that permits insertion of the feed lip insert 25 of the

magazine housing 21.

prising

a feed lip insert, said feed lip insert

being located at the forward terminus of said maga

zine for directing cartridges away from said maga

zine and including

means for retaining the next cartridge to exit said

magazine in a position ready for acceptance and

?ring by the ?rearm, and

said feed lip insert extending away from said maga

zine to form a guide that enters said ?rearm re

ceiver opening for orienting said magazine on said

As mentioned, the preferred application of the maga

?rearm.

zine would be to place it above the ?rearm receiver,

3. The combination of claim 1, said means to remov

where the mass of the contained cartridges helps coun 55 ably mount said magazine on said ?rearm comprising

teract the tendency of the ?rearm muzzle or barrel to

socket and pin detent means at the front of said maga

rise after each shot. The ?rearm is readily equipped to

zine and on said ?rearm at the location where said mag

accept the magazine, with respective mechanisms to

azine mounts on said ?rearm and spring pin detent

orient and latch it, and to release it when it is empty.

means at the bottom rear of the magazine, and said

The principles of operation are applicable to most 60 socket and pin detent means and said spring pin detent

calibers and types of existing ?rearms, including semi

means acting together to locate and hold the magazine

automatic handguns, ri?es, carbines, and shotguns. The

in a predetermined relationship to the ?rearm.

magazine provides improvements in capacity, compact

4. The combination of claim 1, said power driving

ness, streamlining and balance over conventional verti

cal stack magazines.

65

The weapon uniquely combines high cartridge capac

ity within a minimum frontal area and overall size for

operating within a con?ned space.

means comprising a

winder;

a cartridge carrier in said magazine; and

means to mount said torque spring in said cartridge

carrier, and said torque spring being adapted to be

4,676,137

wound-up and released'and when released to apply

radial torque to said cartridge carrier for propelling

cartridges in said grooves along said helical path.

5. The combination of claim 4, and further compris

cal path for said relatively large number of car

tridges; and

a cartridge carrier mounted in said housing for rota

tion inside said helical member, said cartridge car

VI

rier having cartridge receiving grooves de?ned by

ridges along its length in which the cartridges lie

mg

for propelling the cartridges radially and longitudi

nally along said helical path.

ratchet means between said winder and said housing

adapted to allow said winder to be rotated freely

only in the direction for winding up said torque

7. The combination of claim 6, wherein the pitch of

the helical path formed by said helical member in the

spring.

magazine is equal to the length of said member mea

6. The combination of claim 1, said magazine com

sured parallel to said axis of said magazine plus the

prising:

length of a cartridge, and wherein the radial height of

said helical member is equal to approximately one half

a longitudinal hollow housing;

a helical member arranged interiorly in said housing 15 the diameter of a cartridge.

*

*

*

*

t

and af?xed thereto, said member forming said heli

25'

30

35

50

55

65

Das könnte Ihnen auch gefallen

- Rudder and PropellerDokument5 SeitenRudder and PropellerSumit SinhaNoch keine Bewertungen

- Us4522106 PDFDokument13 SeitenUs4522106 PDFJin Song100% (1)

- Viii/Ii/Ii": United States Patent (191 (11) Patent Number: 4,708,208Dokument9 SeitenViii/Ii/Ii": United States Patent (191 (11) Patent Number: 4,708,208mohammadreza91Noch keine Bewertungen

- ?é4%.276 /4.7 Easter: RT - A2 (Alw'celeteDokument8 Seiten?é4%.276 /4.7 Easter: RT - A2 (Alw'celeteСлэйтер Строительная компанияNoch keine Bewertungen

- United States Patent (19) : 11) Patent Number: 5,181,477 45 Date of Patent: Jan. 26, 1993Dokument10 SeitenUnited States Patent (19) : 11) Patent Number: 5,181,477 45 Date of Patent: Jan. 26, 199312348Noch keine Bewertungen

- Us 6131519Dokument4 SeitenUs 6131519dgfhjsdg hfsdhyjNoch keine Bewertungen

- United States Patent (19) : VicardDokument4 SeitenUnited States Patent (19) : Vicard155100% (1)

- United States Patent (191: Sullivan Et A1Dokument21 SeitenUnited States Patent (191: Sullivan Et A1fghdfjerNoch keine Bewertungen

- Unlted States Patent (10) Patent N0.2 US 8,291,806 B2Dokument12 SeitenUnlted States Patent (10) Patent N0.2 US 8,291,806 B2dgfhjsdg hfsdhyjNoch keine Bewertungen

- Unlted States Patent (19) (11) Patent Number: 5,335,579Dokument8 SeitenUnlted States Patent (19) (11) Patent Number: 5,335,579fghdfjerNoch keine Bewertungen

- Us 5117735Dokument14 SeitenUs 5117735sdfsdf333Noch keine Bewertungen

- Patented Oct. 27, 1896.: Gas Operated Magazine GunDokument14 SeitenPatented Oct. 27, 1896.: Gas Operated Magazine GunСлэйтер Строительная компанияNoch keine Bewertungen

- United States Patent: Farley US 7,257,919 B1Dokument7 SeitenUnited States Patent: Farley US 7,257,919 B1djsfNoch keine Bewertungen

- 螺栓枪口装步枪 PDFDokument7 Seiten螺栓枪口装步枪 PDFJin SongNoch keine Bewertungen

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Dokument13 Seiten(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNoch keine Bewertungen

- United States PatentDokument13 SeitenUnited States Patent63Noch keine Bewertungen

- US Patent 7090236 Land SailingDokument8 SeitenUS Patent 7090236 Land SailingDimas MaulanaNoch keine Bewertungen

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Dokument7 SeitenSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaNoch keine Bewertungen

- Us1517483 PDFDokument10 SeitenUs1517483 PDFJin SongNoch keine Bewertungen

- United States Patent (19) : WalkerDokument8 SeitenUnited States Patent (19) : Walker155Noch keine Bewertungen

- United States Patent (19) 11 4,274,432: 75 Inventors: Karl N. Tunstall, Farmers Branch E636 / ... 137/315Dokument5 SeitenUnited States Patent (19) 11 4,274,432: 75 Inventors: Karl N. Tunstall, Farmers Branch E636 / ... 137/315Taufik Budi WibowoNoch keine Bewertungen

- References Cited Robiatiorlial Movergents. Pat Least One ElaitigallybexaatrlidDokument7 SeitenReferences Cited Robiatiorlial Movergents. Pat Least One Elaitigallybexaatrlidmohammadreza91Noch keine Bewertungen

- United States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985Dokument5 SeitenUnited States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985mohammadreza91Noch keine Bewertungen

- United States Patent (19) : GrainDokument5 SeitenUnited States Patent (19) : Grainاحمد عبدالكريمNoch keine Bewertungen

- United States Patent (19) : PreticDokument5 SeitenUnited States Patent (19) : Pretic63Noch keine Bewertungen

- 8%, ZGZFMWMD @144': June 4, 1968 R. E. Roy 3,386,336Dokument9 Seiten8%, ZGZFMWMD @144': June 4, 1968 R. E. Roy 3,386,336tyrer567899Noch keine Bewertungen

- Us6772548 PDFDokument8 SeitenUs6772548 PDFJin SongNoch keine Bewertungen

- Jain. 1U, 1939. T.'4 Harris ': MW Gßz/:ÁwDokument4 SeitenJain. 1U, 1939. T.'4 Harris ': MW Gßz/:Áwmoch rizki darmawanNoch keine Bewertungen

- United States Patent (191: SeecampDokument4 SeitenUnited States Patent (191: Seecamp9aszerfNoch keine Bewertungen

- United States Patent (16) Patent N6. US 6,564,491 B2Dokument5 SeitenUnited States Patent (16) Patent N6. US 6,564,491 B2edef345Noch keine Bewertungen

- Us 4207797Dokument7 SeitenUs 4207797fghdfjerNoch keine Bewertungen

- Ashcroft v. Railroad Co., 97 U.S. 189 (1878)Dokument12 SeitenAshcroft v. Railroad Co., 97 U.S. 189 (1878)Scribd Government DocsNoch keine Bewertungen

- Post 6 36083 SA Repeating DerringerDokument18 SeitenPost 6 36083 SA Repeating Derringerbadlabmouse0% (1)

- 枪炮声抑制器 PDFDokument11 Seiten枪炮声抑制器 PDFJin SongNoch keine Bewertungen

- Nun M.: BC BM 0000Dokument12 SeitenNun M.: BC BM 0000shdhsjkNoch keine Bewertungen

- US36505Dokument5 SeitenUS36505ReggieNoch keine Bewertungen

- Err-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695Dokument3 SeitenErr-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695RakeshNoch keine Bewertungen

- United States Patent 19: TaylorDokument6 SeitenUnited States Patent 19: Taylor63Noch keine Bewertungen

- Handbook of The Benet-Mercié Machine Rifle Model of 1909Dokument55 SeitenHandbook of The Benet-Mercié Machine Rifle Model of 1909VoltaireZeroNoch keine Bewertungen

- US1507881Dokument3 SeitenUS1507881Lawrence RyperNoch keine Bewertungen

- Unlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973Dokument4 SeitenUnlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973fgrt45Noch keine Bewertungen

- United States PatentDokument7 SeitenUnited States PatentDouglas TondelloNoch keine Bewertungen

- J. M. Browning.: No. 580,924, Patented Apr. 20, 1897Dokument9 SeitenJ. M. Browning.: No. 580,924, Patented Apr. 20, 1897Слэйтер Строительная компанияNoch keine Bewertungen

- Us 4023499Dokument4 SeitenUs 4023499ererNoch keine Bewertungen

- United States "Patents PDFDokument17 SeitenUnited States "Patents PDFTien Nguyen VanNoch keine Bewertungen

- Us 5988287Dokument14 SeitenUs 5988287mohammadreza91Noch keine Bewertungen

- Us5361479 PDFDokument5 SeitenUs5361479 PDFmohammadreza91Noch keine Bewertungen

- US3200917Dokument5 SeitenUS3200917张淼Noch keine Bewertungen

- Us 6019217Dokument5 SeitenUs 6019217dgfhjsdg hfsdhyjNoch keine Bewertungen

- Rat Hole DiggerDokument4 SeitenRat Hole DiggerDarshan MakwanaNoch keine Bewertungen

- United States Patent (19) : Felix-DalichowDokument5 SeitenUnited States Patent (19) : Felix-DalichowBarmak CheraghiNoch keine Bewertungen

- United States Patent (19) : (54) Roll-Reefing JibsailDokument8 SeitenUnited States Patent (19) : (54) Roll-Reefing Jibsail63Noch keine Bewertungen

- Rudder and PropellersDokument7 SeitenRudder and Propellersantariksa pramudidanNoch keine Bewertungen

- NAA .32 ACP专利 PDFDokument8 SeitenNAA .32 ACP专利 PDFJin SongNoch keine Bewertungen

- Hotchkiss Revolving Cannon ManualDokument48 SeitenHotchkiss Revolving Cannon ManualfogdartNoch keine Bewertungen

- Siley ERS) .: No. 385,875, Patented July 10, 1888Dokument6 SeitenSiley ERS) .: No. 385,875, Patented July 10, 1888Слэйтер Строительная компанияNoch keine Bewertungen

- United States Patent (19) : Gazalel, 72 8Dokument7 SeitenUnited States Patent (19) : Gazalel, 72 8Mihai RobertNoch keine Bewertungen

- Us4358986 PDFDokument9 SeitenUs4358986 PDFJin SongNoch keine Bewertungen

- United States Patent (19) : (75) Inventor: Nahemia Sirkis, King County, WashDokument7 SeitenUnited States Patent (19) : (75) Inventor: Nahemia Sirkis, King County, WashSandeep SNoch keine Bewertungen

- United States Patent (191: Sullivan Et A1Dokument21 SeitenUnited States Patent (191: Sullivan Et A1fghdfjerNoch keine Bewertungen

- Us 4207797Dokument7 SeitenUs 4207797fghdfjerNoch keine Bewertungen

- Unlted States Patent (19) (11) Patent Number: 5,335,579Dokument8 SeitenUnlted States Patent (19) (11) Patent Number: 5,335,579fghdfjerNoch keine Bewertungen

- United States Patent (191 (11) Patent Number: 5,259,288: Vatsvog (45) Date of Patent: Nov. 9, 1993Dokument13 SeitenUnited States Patent (191 (11) Patent Number: 5,259,288: Vatsvog (45) Date of Patent: Nov. 9, 1993fghdfjerNoch keine Bewertungen

- United States Patent: (12) (10) Patent N0.: US 7,213,519 B2 Wiley Et Al. (45) Date of Patent: May 8, 2007Dokument26 SeitenUnited States Patent: (12) (10) Patent N0.: US 7,213,519 B2 Wiley Et Al. (45) Date of Patent: May 8, 2007fghdfjerNoch keine Bewertungen