Beruflich Dokumente

Kultur Dokumente

3.0 Metrology: 3.3 Lab Test

Hochgeladen von

Wasana LakmaliOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

3.0 Metrology: 3.3 Lab Test

Hochgeladen von

Wasana LakmaliCopyright:

Verfügbare Formate

Chapter 3

Literature Review

3.0 Metrology

3.3 Lab Test

3.3.1 Atterberg Limit

The Atterberg limits are a basic measure of the critical water contents of a fine-grained

soil, such as its shrinkage limit, plastic limit, and liquid limit. As a dry, clayey soil takes

on increasing amounts of water, it undergoes dramatic and distinct changes in behavior

and consistency. Depending on the water content of the soil, it may appear in four states:

solid, semi-solid, plastic and liquid. In each state, the consistency and behavior of a soil

is different and consequently so are its engineering properties. Thus, the boundary

between each state can be defined based on a change in the soil's behavior. The Atterberg

limits can be used to distinguish between silt and clay, and it can distinguish between

different types of silts and clays

3.3.2 Hydrometer Test

Used for determining the particle size distribution of very fine materials such

as silt and clay.

Chapter 3

Literature Review

3.3.3 Bulk Density

Bulk density is a property of powders, granules, and other "divided"

solids, especially used in reference to mineral components (soil,

gravel), chemical substances, (pharmaceutical) ingredients, foodstuff,

or any other masses of corpuscular or particulate matter. It is defined

as the mass of many particles of the material divided by the total

volume they occupy. The total volume includes particle volume, interparticle void volume, and internal pore volume

3.3.4 Direct shear Test

A direct shear test is a laboratory or field test used by geotechnical engineers to measure

the shear strength properties of soil[1][2] or rock[2] material, or of discontinuities in soil

or rock masses. The U.S. and U.K. standards defining how the test should be performed

are ASTM D 3080, AASHTO T236 and BS 1377-7:1990, respectively. For rock the test

is generally restricted to rock with (very) low shear strength. The test is, however,

standard practice to establish the shear strength properties of discontinuities in rock.

Chapter 3

Literature Review

The test is performed on three or four specimens from a relatively undisturbed soil

sample. A specimen is placed in a shear box which has two stacked rings to hold the

sample; the contact between the two rings is at approximately the mid-height of the

sample. A confining stress is applied vertically to the specimen, and the upper ring is

pulled laterally until the sample fails, or through a specified strain. The load applied and

the strain induced is recorded at frequent intervals to determine a stressstrain curve for

each confining stress. Several specimens are tested at varying confining stresses to

determine the shear strength parameters, the soil cohesion (c) and the angle of internal

friction, commonly known as friction angle ( ). The results of the tests on each

specimen are plotted on a graph with the peak (or residual) stress on the y-axis and the

confining stress on the x-axis. The y-intercept of the curve which fits the test results is

the cohesion, and the slope of the line or curve is the friction angle.

3.3.4 Triaxial Test

A triaxial shear test is a common method to measure the mechanical properties of many

deformable solids, especially soil (e.g., sand, clay) and rock, and other granular materials

or powders. There are several variations on the test.

In a triaxial shear test, stress is applied to a sample of the material being tested in a way

which results in stresses along one axis being different from the stresses in perpendicular

directions. This is typically achieved by placing the sample between two parallel platens

which apply stress in one (usually vertical) direction, and applying fluid pressure to the

specimen to apply stress in the perpendicular directions.

Chapter 3

Literature Review

The application of different compressive stresses in the test apparatus causes shear stress

to develop in the sample; the loads can be increased and deflections monitored until

failure of the sample. During the test, the surrounding fluid is pressurized, and the stress

on the platens is increased until the material in the cylinder fails and forms sliding

regions within itself, known as shear bands. The geometry of the shearing in a triaxial

test typically causes the sample to become shorter while bulging out along the sides. The

stress on the platen is then reduced and the water pressure pushes the sides back in,

causing the sample to grow taller again. This cycle is usually repeated several times

while collecting stress and strain data about the sample. During the test the pore

pressures of fluids (e.g., water, oil) or gasses in the sample may be measured using

Bishop's pore pressure apparatus.

From the triaxial test data, it is possible to extract fundamental material parameters about

the sample, including its angle of shearing resistance, apparent cohesion, and dilatancy

angle. These parameters are then used in computer models to predict how the material

will behave in a larger-scale engineering application. An example would be to predict the

stability of the soil on a slope, whether the slope will collapse or whether the soil will

support the shear stresses of the slope and remain in place. Triaxial tests are used along

with other tests to make such engineering predictions.

During the shearing, a granular material will typically have a net gain or loss of volume.

If it had originally been in a dense state, then it typically gains volume, a characteristic

known as Reynolds' dilatancy. If it had originally been in a very loose state, then

contraction may occur before the shearing begins or in conjunction with the shearing.

Sometimes, testing of cohesive samples is done with no confining pressure, in an

unconfined compression test. This requires much simpler and less expensive apparatus

and sample preparation, though the applicability is limited to samples that the sides won't

crumble when exposed, and the confining stress being lower than the in-situ stress gives

results which may be overly conservative. The compression test performed for concrete

strength testing is essentially the same test, on apparatus designed for the larger samples

and higher loads typical of concrete testing

Chapter 3

Literature Review

Chapter 3

Literature Review

Das könnte Ihnen auch gefallen

- Standard Oedometer TestDokument8 SeitenStandard Oedometer TestHiro Cerce Wilhelm ALDEN Abareta TonioNoch keine Bewertungen

- Assignment 2 Soil and GeoDokument2 SeitenAssignment 2 Soil and GeoAung KaungNoch keine Bewertungen

- Triaxial Shear TestDokument5 SeitenTriaxial Shear TestBellaNoch keine Bewertungen

- Triaxial Testing of Granular Soil (Colliat-Dangus, 1988)Dokument21 SeitenTriaxial Testing of Granular Soil (Colliat-Dangus, 1988)Abraham FIgueroa ARevaloNoch keine Bewertungen

- Shrinkage of Clays UNSAT 06Dokument13 SeitenShrinkage of Clays UNSAT 06Lea ChahalaneNoch keine Bewertungen

- Shear StrenghtDokument4 SeitenShear Strenghtkc olidanNoch keine Bewertungen

- Modelling and Simulation of Explosions in Soil Interacting With Deformable StructuresDokument2 SeitenModelling and Simulation of Explosions in Soil Interacting With Deformable StructuresradhakrishnanNoch keine Bewertungen

- Oedometer Test: ConceptDokument3 SeitenOedometer Test: ConceptMiguel BenítezNoch keine Bewertungen

- Triaxial Test Report - Group 2Dokument20 SeitenTriaxial Test Report - Group 2Khalidah RosmanNoch keine Bewertungen

- Shear Strength of SoilsDokument21 SeitenShear Strength of SoilsAslam KhanNoch keine Bewertungen

- Direct Shear Test (Complete Report)Dokument7 SeitenDirect Shear Test (Complete Report)Bshfirnaudz74% (23)

- MohrDokument12 SeitenMohrJoseph JboyNoch keine Bewertungen

- Assignment 9Dokument5 SeitenAssignment 9Engr MahwishNoch keine Bewertungen

- SOIL TESTING OF BUILDI MinorDokument50 SeitenSOIL TESTING OF BUILDI MinorlazamNoch keine Bewertungen

- Site Investigation FinalDokument5 SeitenSite Investigation FinalAbdel Yazidi0% (1)

- Thesis ProposalDokument9 SeitenThesis ProposalAbdul Rahman HilmiNoch keine Bewertungen

- Part 1: Key Terminology and Engineering Parameters For Geotechnical EngineeringDokument3 SeitenPart 1: Key Terminology and Engineering Parameters For Geotechnical EngineeringcolawariNoch keine Bewertungen

- SLOPE STABILITY NotesDokument24 SeitenSLOPE STABILITY NotesOmar IsaackNoch keine Bewertungen

- A Common Collapse Test For Granular MaterialsDokument5 SeitenA Common Collapse Test For Granular MaterialsA TrivediNoch keine Bewertungen

- BUADLARTDokument2 SeitenBUADLARTShamRock CasasNoch keine Bewertungen

- Mayne 2006 OverView InSitu Singapore ColourDokument57 SeitenMayne 2006 OverView InSitu Singapore ColoursenhuNoch keine Bewertungen

- Lecture (4)Dokument9 SeitenLecture (4)DDelGGulNoch keine Bewertungen

- Puncture Protection of GeomembranesDokument25 SeitenPuncture Protection of GeomembranesBudhi KurniantoNoch keine Bewertungen

- Direct Shear Lab TestingDokument9 SeitenDirect Shear Lab TestingMelissa SammyNoch keine Bewertungen

- Chapter 4Dokument2 SeitenChapter 4Jokas RiveraNoch keine Bewertungen

- Mu-Cidc Pgri Program: Mewar UniversityDokument9 SeitenMu-Cidc Pgri Program: Mewar UniversityDeepanshu GargNoch keine Bewertungen

- Shrinkage of Clays Unsat 06Dokument12 SeitenShrinkage of Clays Unsat 06jcazNoch keine Bewertungen

- Undrained Shear Strength With A Triaxial Compression Test: Emmanuel Odera IgwebuikeDokument28 SeitenUndrained Shear Strength With A Triaxial Compression Test: Emmanuel Odera IgwebuikeSalehuddin RamliNoch keine Bewertungen

- Shear Box TestDokument13 SeitenShear Box TestNoor100% (1)

- Influence of Swell On Stress-Strain Behaviour of Expansive Soils Under Various Confining PressureDokument7 SeitenInfluence of Swell On Stress-Strain Behaviour of Expansive Soils Under Various Confining PressureIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNoch keine Bewertungen

- Jardine Et Al 1984Dokument18 SeitenJardine Et Al 1984Anonymous D5s00DdUNoch keine Bewertungen

- Laboratory Determination of Creep Properties of Frozen Soil Samples by Uniaxial CompressionDokument7 SeitenLaboratory Determination of Creep Properties of Frozen Soil Samples by Uniaxial CompressionKhin Sandi KoNoch keine Bewertungen

- Ijaret: International Journal of Advanced Research in Engineering and Technology (Ijaret)Dokument12 SeitenIjaret: International Journal of Advanced Research in Engineering and Technology (Ijaret)IAEME PublicationNoch keine Bewertungen

- Part 1 Introduction To Triaxial TestingDokument4 SeitenPart 1 Introduction To Triaxial TestingFernando CachúNoch keine Bewertungen

- Geoteknik PentingDokument8 SeitenGeoteknik PentingAzriil LaaNoch keine Bewertungen

- Experiment No. 6 Consolidated Undrained Triaxial Test For Cohesive SoilDokument5 SeitenExperiment No. 6 Consolidated Undrained Triaxial Test For Cohesive SoilDane LyNoch keine Bewertungen

- Modelling and Simulation of Explosions in Soil IntDokument20 SeitenModelling and Simulation of Explosions in Soil IntrakoNoch keine Bewertungen

- Shear Strength (Soil) - Wikipedia, The Free EncyclopediaDokument6 SeitenShear Strength (Soil) - Wikipedia, The Free Encyclopediaicemage1991Noch keine Bewertungen

- Shear Strength TestsDokument13 SeitenShear Strength TestsPrakash MahandraNoch keine Bewertungen

- The Direct Shear Strength and Dilatancyof Sand-Gravel MixturesDokument27 SeitenThe Direct Shear Strength and Dilatancyof Sand-Gravel MixturesPipatpong NookhaoNoch keine Bewertungen

- Bearing CapacityDokument20 SeitenBearing CapacityClyke RafaNoch keine Bewertungen

- Geotechnical Investigation: EM 1110-2-2504 31 Mar 94Dokument11 SeitenGeotechnical Investigation: EM 1110-2-2504 31 Mar 94Dean SamuelNoch keine Bewertungen

- ResilienceDokument16 SeitenResiliencem abdullah m akmalNoch keine Bewertungen

- 2.06 Soil Mechanical TestsDokument12 Seiten2.06 Soil Mechanical TestsSamuel TREKU-ABRAHAMSNoch keine Bewertungen

- Slope Stability and Soil/rock StrengthDokument11 SeitenSlope Stability and Soil/rock StrengthEmran Banat95Noch keine Bewertungen

- Lab Manual Foundation EnggDokument39 SeitenLab Manual Foundation EnggsahilkaushikNoch keine Bewertungen

- C5Dokument4 SeitenC5Vilma Puma InostrozaNoch keine Bewertungen

- Geo TechnicalDokument16 SeitenGeo TechnicalAyush GorasiyaNoch keine Bewertungen

- Geotechnical ReportsDokument25 SeitenGeotechnical Reportsnicris796100% (1)

- Shear Strength of SoilsDokument13 SeitenShear Strength of Soilspankaj100% (1)

- Shear Tests On PhyllitesDokument8 SeitenShear Tests On PhyllitesDelvin JacobsNoch keine Bewertungen

- 10 52114-Apjhad 948154-1807859Dokument8 Seiten10 52114-Apjhad 948154-1807859cameliawenny.97Noch keine Bewertungen

- Effect of Strain Rate On Shear Strength Parameter of Sand: December 2015Dokument9 SeitenEffect of Strain Rate On Shear Strength Parameter of Sand: December 2015Susmita PandaNoch keine Bewertungen

- Load Controlled Cyclic Triaxial Strength of Soil: Standard Test Method ForDokument10 SeitenLoad Controlled Cyclic Triaxial Strength of Soil: Standard Test Method ForROHITNoch keine Bewertungen

- Shear Strength of SoilsDokument10 SeitenShear Strength of Soilstitukutty6032Noch keine Bewertungen

- Consolidation Test - (Oedometer Test)Dokument8 SeitenConsolidation Test - (Oedometer Test)saleem razaNoch keine Bewertungen

- The Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingVon EverandThe Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingNoch keine Bewertungen

- Lecture Notes on Reinforced Concrete DesignVon EverandLecture Notes on Reinforced Concrete DesignNoch keine Bewertungen

- Constitutive Modeling of Soils and RocksVon EverandConstitutive Modeling of Soils and RocksPierre-Yves HicherBewertung: 5 von 5 Sternen5/5 (1)

- Study of Pullout Resistance of Soil Nails in Tropical Residual SoilDokument1 SeiteStudy of Pullout Resistance of Soil Nails in Tropical Residual SoilWasana LakmaliNoch keine Bewertungen

- Everything About CocreteDokument59 SeitenEverything About CocreteWasana LakmaliNoch keine Bewertungen

- Conclusion & RecommendationsDokument1 SeiteConclusion & RecommendationsWasana LakmaliNoch keine Bewertungen

- Engineer in Society 2015Dokument108 SeitenEngineer in Society 2015Wasana Lakmali50% (2)

- The Institution of Engineers Srilanka: Eng. U.D.I. Prasad Bsceng (Hons), Amie (SL) Civil Engineer CecbDokument1 SeiteThe Institution of Engineers Srilanka: Eng. U.D.I. Prasad Bsceng (Hons), Amie (SL) Civil Engineer CecbWasana LakmaliNoch keine Bewertungen

- Experience Report 3Dokument29 SeitenExperience Report 3Wasana LakmaliNoch keine Bewertungen

- Reinforcement Bar Schedule: Central Engineering Consultancy BureauDokument9 SeitenReinforcement Bar Schedule: Central Engineering Consultancy BureauWasana LakmaliNoch keine Bewertungen

- Elevators 2Dokument1 SeiteElevators 2Wasana LakmaliNoch keine Bewertungen

- MatrixDokument19 SeitenMatrixWasana LakmaliNoch keine Bewertungen

- University Collage-Batangala (BD-025)Dokument2 SeitenUniversity Collage-Batangala (BD-025)Wasana LakmaliNoch keine Bewertungen

- Initial SizingDokument12 SeitenInitial SizingWasana LakmaliNoch keine Bewertungen

- AstmDokument2.848 SeitenAstmNomar garciaparra67% (6)

- Bogey CurvesDokument9 SeitenBogey CurvesGaneshmohite123Noch keine Bewertungen

- Big JoeDokument12 SeitenBig JoeFuentes RodoNoch keine Bewertungen

- Valvula Asiento Inclinado Serie E290 AscoDokument3 SeitenValvula Asiento Inclinado Serie E290 AscoBase SistemasNoch keine Bewertungen

- Blank QuotationDokument4 SeitenBlank QuotationAmarjeet Das100% (1)

- 5 - Body Filler - Polyester Putty - 2019 EditionDokument2 Seiten5 - Body Filler - Polyester Putty - 2019 Editiondamax rec100% (1)

- GreenhouseDokument5 SeitenGreenhousemehta_kpNoch keine Bewertungen

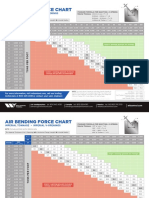

- Air Bend Force ChartDokument2 SeitenAir Bend Force ChartLorenz Joseph PalmaNoch keine Bewertungen

- VCCT For Abaqus PDFDokument14 SeitenVCCT For Abaqus PDFFelipe Dornellas SilvaNoch keine Bewertungen

- 4-Method Statement For Door Frame Fixing, Inspection, Storage and Test 1 - Copy1Dokument7 Seiten4-Method Statement For Door Frame Fixing, Inspection, Storage and Test 1 - Copy1ABHISHEKNoch keine Bewertungen

- FibersDokument238 SeitenFibersdejayzNoch keine Bewertungen

- ERI-3728-5 - Data Sheet - ECCDokument3 SeitenERI-3728-5 - Data Sheet - ECCigor brocaNoch keine Bewertungen

- Bringing Power To Light: Company ProfileDokument32 SeitenBringing Power To Light: Company ProfileYu hongNoch keine Bewertungen

- Section Capacity Section Capacity: AbutmentDokument4 SeitenSection Capacity Section Capacity: AbutmentGajendra SNoch keine Bewertungen

- Fiber Beam-Column Model For Diagonally Reinforced Concrete Coupling Beams Incorporating Shear and Reinforcement Slip EffectsDokument35 SeitenFiber Beam-Column Model For Diagonally Reinforced Concrete Coupling Beams Incorporating Shear and Reinforcement Slip EffectsSinem Kocabaş ŞirikçiNoch keine Bewertungen

- SOM One Linear PDFDokument88 SeitenSOM One Linear PDFDinuSkyNoch keine Bewertungen

- Basic Technology Jss1Dokument23 SeitenBasic Technology Jss1Abdullateef AdedoyinNoch keine Bewertungen

- FitOut GuideDokument108 SeitenFitOut GuideHaris Altaf Bhatti100% (1)

- Catia Analysis of A Roller PinDokument15 SeitenCatia Analysis of A Roller Pinanteneh tesfayeNoch keine Bewertungen

- Building StonesDokument75 SeitenBuilding StonesXhorxhIsm100% (1)

- MODEL5 Final 1Dokument2 SeitenMODEL5 Final 1Vishnu SrivastavaNoch keine Bewertungen

- Joints For Concrete Pipe, Manholes, and Precast Box Sections Using Preformed Flexible Joint SealantsDokument4 SeitenJoints For Concrete Pipe, Manholes, and Precast Box Sections Using Preformed Flexible Joint SealantsRenish Regi100% (1)

- Manual 162 PDFDokument47 SeitenManual 162 PDFDeimer Jose Figueroa ManriqueNoch keine Bewertungen

- 1300-121 Systems One Seed Jet II Closed Center Hydraulic System ManualDokument12 Seiten1300-121 Systems One Seed Jet II Closed Center Hydraulic System Manualwasihun wodajeNoch keine Bewertungen

- GE Basic Appliance Training 31 91611Dokument68 SeitenGE Basic Appliance Training 31 91611dreamyson1983Noch keine Bewertungen

- Series Flat Socket Weld Bolt FlangesDokument1 SeiteSeries Flat Socket Weld Bolt FlangesDerick MendozaNoch keine Bewertungen

- Plumb ExDokument21 SeitenPlumb ExJugno ShahNoch keine Bewertungen

- Aggregate Impact ValueDokument4 SeitenAggregate Impact ValuevinoNoch keine Bewertungen

- 56 Series Fittings - USADokument28 Seiten56 Series Fittings - USAmarcoNoch keine Bewertungen

- CABLE SIZING CALCULATION REv1Dokument4 SeitenCABLE SIZING CALCULATION REv1jack jala0% (1)