Beruflich Dokumente

Kultur Dokumente

Balcan Junior Exercieses A Version 2

Hochgeladen von

Goran MićovićOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Balcan Junior Exercieses A Version 2

Hochgeladen von

Goran MićovićCopyright:

Verfügbare Formate

Exercise 1a: Stamping device

Workpieces are inserted into the gravity feed magazine by hand. The workpiece is pushed out of the

gravity feed magazine by cylinder 1A. Workpieces are clamped by cylinder 1A. Only then can cylinder 2A

stamped the workpiece.

The magazine is monitored by means of a optical proximity switch B5. If there are no more

workpieces in the magazine lamp H turns on and it is not possible to start the cycle.

In one cycle is possible stamped only one workpiece.

Cycle description:

Piston rod of cylinder 1A is in retracted end position. Piston rod of cylinder 2A is in retracted end

position.

By pressing a pushbutton switch START workpiece is pushed out of the gravity feed magazine by

piston rod of cylinder 1A. Piston rod of cylinder 1A reaches the forward end position and clamps the

workpiece. After that, the piston rod of cylinder 2A is pulled out, reaches the forward end position and

stamped workpiece. After that he returns to his initial position. When the piston rod of cylinder 2A has

reached the retracted end position the piston rod of cylinder 1A returned to his initial position.

The piston rod positions are monitored by means of the inductive proximity switches B1 to B4

(options 1) or magnetic proximity switches B1 to B4 ( options 2 ).

Veba 1a: Ureaj za igosanje

Radni komadi se u magacin ubacuju rukom. Cilindar 1A izbacuje komade iz magacina i stee ga. Samo se

tad moe izvui cilindar 2A i udariti ig.

Magacin se nadgleda optikim senzorom B5. Ukoliko nema komada u magacinu nije mogue startovati

ciklus i sija lampica H.

U jednom ciklusu moe se samo obraditi jedan komad.

Opis ciklusa:

Svi cilindri su u uvuenom poloaju.

Pritiskom na taster START cilindar 1A izbacuje komad iz magacina, izvlai se u prednji krajnji poloaj i

stee predmet.. Nakon toga izlazi cilindar 2A u svoj krajnji izvueni poloaj i udara ig. Nakon toga se

automatski vraa u svoj poetni poloaj. Kad se cilindar 2A vratio u svoj poetni poloaj vraa se i cilindar

1A.

Poloaji cilindra se kontroliu induktivnim ili magnetnim senzorima B1 do B4 ( po izboru ).

Exercise 2a: Stamping device

Workpieces are inserted into the gravity feed magazine by hand. The workpiece is pushed out of the

gravity feed magazine by cylinder 1A. Cylinder 1A also clamp him. Only then can cylinder 2A stamp the

workpiece.

The magazine is monitored by means of a optical proximity switch B5. If there are no more

workpieces in the magazine lamp H turns on and it is not possible to start the cycle.

In one cycle is possible stamped only one workpiece.

Cycle description:

Piston rod of cylinder 1A is in retracted end position. Piston rod of cylinder 2A is in retracted end

position.

By pressing a pushbutton switch START workpiece is pushed out of the gravity feed magazine by

piston rod of cylinder 1A. Piston rod of cylinder 1A reaches the forward end position and clamps the

workpiece. After that, the piston rod of cylinder 2A is pulled out, reaches the forward end position and

stamped workpiece. In that position piston rod of cylinder 2A staies 4 seconds. After that he returns to his

initial position. After the piston rod of cylinder 2A has reached the retracted end position the piston rod of

cylinder 1A returned to his initial position.

The piston rod positions are monitored by means of the inductive proximity switches B1 to B4

(options 1) or magnetic proximity switches B1 to B4 ( options 2 ).

Veba 2a: Ureaj za igosanje

Radni komadi se u magacin ubacuju rukom. Cilindar 1A izbacuje komade iz magacina i stee ga. Samo se

tad moe izvui cilindar 2A i udariti ig.

Magacin se nadgleda optikim senzorom B5. Ukoliko nema komada u magacinu nije mogue startovati

ciklus i sija lampica H.

U jednom ciklusu moe se samo obraditi jedan komad.

Opis ciklusa:

Svi cilindri su u uvuenom poloaju.

Pritiskom na taster START cilindar 1A izbacuje komad iz magacina, izvlai se u prednji krajnji poloaj i

stee predmet.. Nakon toga izlazi cilindar 2A u svoj krajnji izvueni poloaj i udara ig. U izvuenom

poloaju cilindar 2A ostaje 4 sekunde. Nakon toga se vraa u svoj poetni poloaj. Kad se cilindar 2A vratio

u svoj poetni poloaj vraa se i cilindar 1A.

Poloaji cilindra se kontroliu induktivnim ili magnetnim senzorima B1 do B4 ( po izboru ).

Exercise 3a: Stamping device

Workpieces are inserted into the gravity feed magazine by hand. The workpiece is pushed out of the

gravity feed magazine by cylinder 1A. Cylinder 1A also clamp him. Only then can cylinder 2A stamp the

workpiece.

The magazine is monitored by means of a optical proximity switch B5. If there are no more

workpieces in the magazine lamp H turns on and it is not possible to start the cycle.

In one cycle is possible stamped only one workpiece.

Cycle description:

Piston rod of cylinder 1A is in retracted end position. Piston rod of cylinder 2A is in retracted end

position.

By pressing a pushbutton switch START workpiece is pushed out of the gravity feed magazine by

piston rod of cylinder 1A. Piston rod of cylinder 1A reaches the forward end position and clamps the

workpiece. After that, the piston rod of cylinder 2A is pulled out, reaches the forward end position, stamped

workpiece and retract once again. When the piston rod of cylinder 2A has reached the retracted end position

the piston rod of cylinder 1A returned to his initial position.

The piston rod positions are monitored by means of the inductive proximity switches B1 to B4

(options 1) or magnetic proximity switches B1 to B4 ( options 2 ).

Veba 3a: Ureaj za igosanje

Radni komadi se u magacin ubacuju rukom. Cilindar 1A izbacuje komade iz magacina i stee ga. Samo se

tad moe izvui cilindar 2A i udariti ig.

Magacin se nadgleda optikim senzorom B5. Ukoliko nema komada u magacinu nije mogue startovati

ciklus i sija lampica H.

U jednom ciklusu moe se samo obraditi jedan komad.

Opis ciklusa:

Svi cilindri su u uvuenom poloaju.

Pritiskom na taster START cilindar 1A izbacuje komad iz magacina, izvlai se u prednji krajnji poloaj i

stee predmet.. Nakon toga izlazi cilindar 2A u svoj krajnji izvueni poloaj i udara ig, vraa se u poetni

poloaj, ponovo izlazi i udara ig jo jednom. Nakon toga se vraa u svoj poetni poloaj. Kad se cilindar

2A vratio u svoj poetni poloaj vraa se i cilindar 1A.

Poloaji cilindra se kontroliu induktivnim ili magnetnim senzorima B1 do B4 ( po izboru ).

Das könnte Ihnen auch gefallen

- Balcan Junior Exercieses A Version 3Dokument2 SeitenBalcan Junior Exercieses A Version 3Goran MićovićNoch keine Bewertungen

- Balcan Junior Exercises A Version 1Dokument10 SeitenBalcan Junior Exercises A Version 1Goran MićovićNoch keine Bewertungen

- EQUIPMENT For Version 3Dokument1 SeiteEQUIPMENT For Version 3Goran MićovićNoch keine Bewertungen

- EQUIPMENT For Version 1 and 2Dokument2 SeitenEQUIPMENT For Version 1 and 2Goran MićovićNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- RAM 5.7 2020 EcmDokument7 SeitenRAM 5.7 2020 Ecmjesus mtzNoch keine Bewertungen

- BMW m54 EngineDokument48 SeitenBMW m54 Enginexgate94% (16)

- Mtu MT 881Dokument2 SeitenMtu MT 881AndrewScotson100% (1)

- Opel Corsa DiagnosticoDokument4 SeitenOpel Corsa DiagnosticoVitor Roberto MoreiraNoch keine Bewertungen

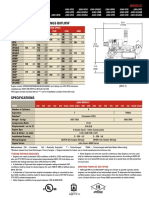

- Proposal - JU6H-UF68 - 200 HP at 1750 RPMDokument10 SeitenProposal - JU6H-UF68 - 200 HP at 1750 RPMMaurilio Batista de LimaNoch keine Bewertungen

- A DaimlerChrysler CompanyDokument19 SeitenA DaimlerChrysler Companycmarqcs100% (1)

- D2842-LE402-sn7007455067A301-1993year-en-1148pages - PartsDokument148 SeitenD2842-LE402-sn7007455067A301-1993year-en-1148pages - PartsBrianNoch keine Bewertungen

- 2006 MFS25B 30B 003-21054-1Dokument310 Seiten2006 MFS25B 30B 003-21054-1Bob SmithscribdNoch keine Bewertungen

- Lombardini 5ld Cylinder Head Valves TimingDokument5 SeitenLombardini 5ld Cylinder Head Valves Timingguata1013Noch keine Bewertungen

- Intake Design v1 8Dokument4 SeitenIntake Design v1 8salahvacNoch keine Bewertungen

- WaukeshaDokument2 SeitenWaukeshaarifin rizalNoch keine Bewertungen

- Z1300 Kawasaki Service Manual NewDokument372 SeitenZ1300 Kawasaki Service Manual NewdNoch keine Bewertungen

- Mitsubishi 6M70 Engine Workshop Manual Copy 364 Pages PDFDokument364 SeitenMitsubishi 6M70 Engine Workshop Manual Copy 364 Pages PDFJATC91% (35)

- So31470Dokument152 SeitenSo31470Gopal Dixit100% (2)

- Running Gear of Diesel Engine ZZDokument26 SeitenRunning Gear of Diesel Engine ZZAlaine Jan de Tablan100% (2)

- Honda TigerDokument22 SeitenHonda Tigeriwan100% (1)

- JWS-400 Triplex Well Service Pump: SpecificationsDokument2 SeitenJWS-400 Triplex Well Service Pump: SpecificationsgfwtNoch keine Bewertungen

- Wartime: National AdvisoryDokument22 SeitenWartime: National AdvisorytejassidhpuraNoch keine Bewertungen

- Aaz 1z Ahu Turbocharger SystDokument39 SeitenAaz 1z Ahu Turbocharger Systboschit100% (1)

- Sxchema 2Dokument10 SeitenSxchema 2Haiducul DelteiNoch keine Bewertungen

- Screemin EagleDokument97 SeitenScreemin EagleSerban DraganNoch keine Bewertungen

- The Path To Misfire DetectionDokument9 SeitenThe Path To Misfire DetectionDaniel Dario Greig SalazarNoch keine Bewertungen

- Piston Cooling Jets - Remove and InstallDokument4 SeitenPiston Cooling Jets - Remove and Installeshopmanual limaNoch keine Bewertungen

- Ee6790 1Dokument3 SeitenEe6790 1Miguel RojasNoch keine Bewertungen

- Series 60 Off Highway Service Manual 6SE660-February 2006Dokument1.648 SeitenSeries 60 Off Highway Service Manual 6SE660-February 2006DmitryNoch keine Bewertungen

- Term Paper of Fluid MechanicsDokument2 SeitenTerm Paper of Fluid MechanicsMahi KaurNoch keine Bewertungen

- CTL85 Compact Track Loader Kubota V3800DI T Engine Parts Manual 917328Dokument62 SeitenCTL85 Compact Track Loader Kubota V3800DI T Engine Parts Manual 917328Edgar Martinez CarmonaNoch keine Bewertungen

- WB93S-5 S/N F00003-Up: Section DescriptionDokument952 SeitenWB93S-5 S/N F00003-Up: Section Descriptionwoodchuck100% (1)

- 2007 Ford Ranger 2.3 PCMDokument4 Seiten2007 Ford Ranger 2.3 PCMpjmh.37Noch keine Bewertungen